Thin SAPH 440 strip steel and production method thereof

A production method and thin-gauge technology, applied in the field of metallurgy, can solve problems such as failure to meet standard requirements, high steelmaking control level requirements, and fluctuations in mechanical properties, achieving good plasticity, low heat storage capacity, and avoiding thermal stress concentration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-13

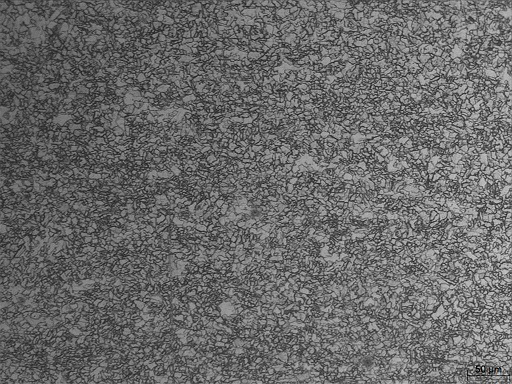

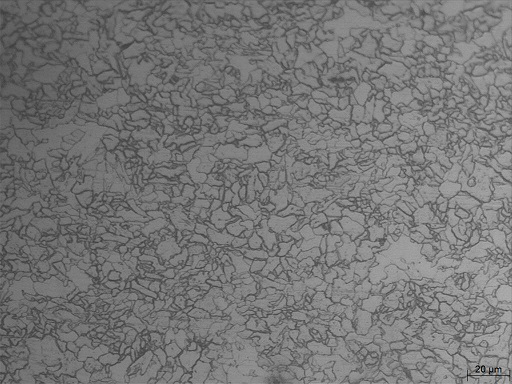

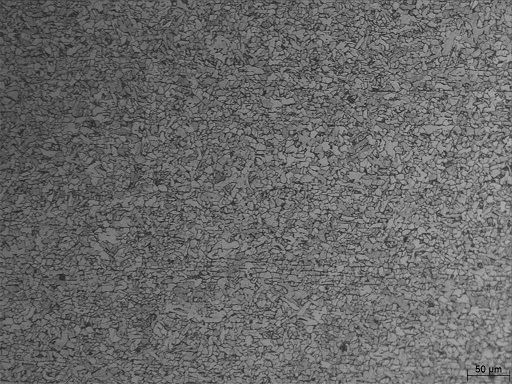

[0029] A method for producing thin-gauge SAPH440 strip steel, the technological process of which mainly includes molten iron pretreatment, converter steelmaking, LF refining, slab continuous casting, heating, rough rolling, finishing rolling, laminar cooling, coiling, slow cooling, Smoothing, pickling and other processes.

[0030] During the tapping process of the converter steelmaking process, aluminum alloy is added for pre-deoxidation, and manganese alloy is added at the same time to form high-temperature stable manganese sulfide. In the LF refining process, aluminum alloy is added for deep deoxidation, and the acid-soluble aluminum in the molten steel is controlled at 0.02-0.05%. At this time, the acid-soluble aluminum in the molten steel mainly exists in the form of aluminum nitride and aluminum sulfide. Then, titanium alloy is added to adjust the Ti content in the molten steel to 0.005-0.01%, and the nitrogen in the aluminum nitride and the elemental nitrogen in the molt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com