Quenching anti-deformation device and method

A technology of anti-deformation and quenching pool, which is applied in the field of quenching, can solve the problems of large changes in the liquid level of the quenching tank, difficulty in applying, and many bubbles, etc., and achieve the effects of improving quenching quality, uniform quenching hardness, and reducing internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

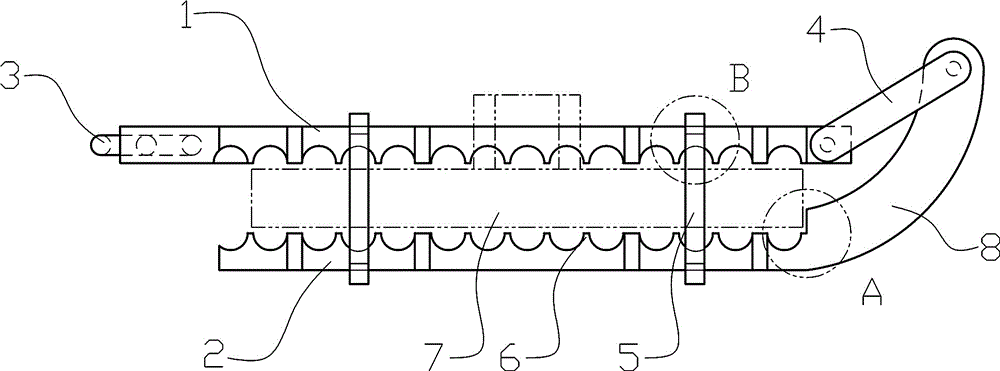

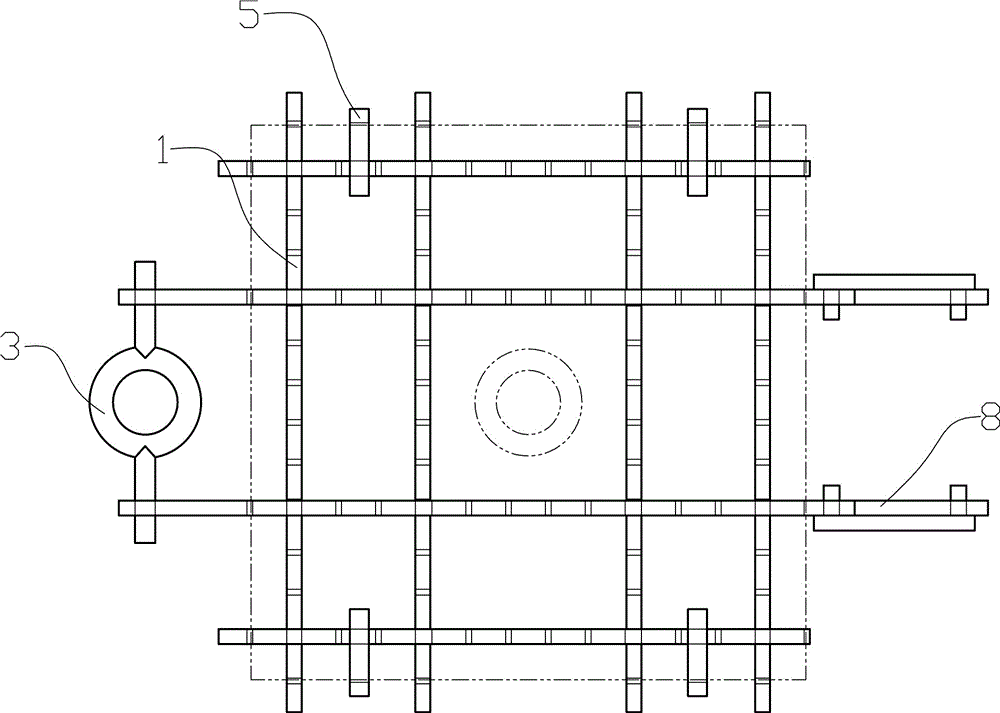

[0041] A quenching anti-deformation device, the lower pressing frame 2 and the upper pressing frame 1 are hinged through the connecting rod 4, so as to facilitate the opening and closing between the lower pressing frame 2 and the upper pressing frame 1, and the lower pressing frame 2 and the upper pressing frame 1 to form a space for pressing the workpiece 7, between the lower pressing frame 2 and the upper pressing frame 1 through a plurality of pressing jaws 5; the pressing jaws 5 are formed into a "C" shape;

[0042] An extension is provided on one side of the lower pressing frame 2 or the upper pressing frame 1, and the turning ring 3 is connected to the extension in a rotatable manner.

[0043] The preferred solution is as figure 2 Among them, the structure of the flip ring 3 is as follows: pin shafts are provided on both sides of the ring body, the extension part is in a fork-shaped structure, and a hole is provided at the end, and the pin shaft is rotatably installed i...

Embodiment 2

[0051] Such as Figure 8 Shown in, a kind of quenching method that adopts above-mentioned quenching anti-deformation device, comprises the following steps:

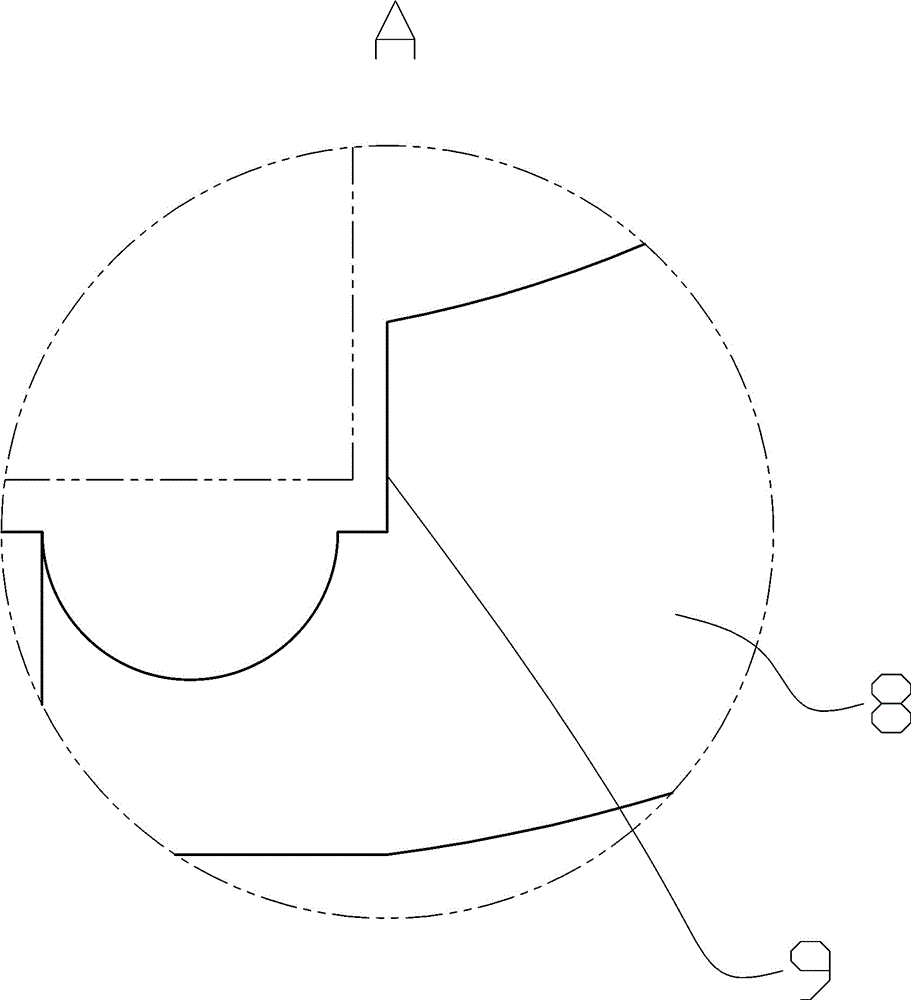

[0052] 1. Install the workpiece 7 between the lower pressing frame 2 and the upper pressing frame 1, the edge of the workpiece 7 is in contact with the workpiece positioning step 9 for positioning, insert the pressing jaw 5 into the jaw positioning gap 10, and press the lower pressing frame 2 is locked with the upper pressing frame 1;

[0053] 2. Put the clamped workpiece 7 flat into the heat treatment furnace; the heat treatment furnace uses a periodic trolley resistance furnace, the position of the turning ring 3 should be convenient for the lifting hook operation of the lifting device 12, and the furnace door should be closed after the furnace is installed.

[0054] Heat insulation. The heat treatment furnace is heated to 840°C and kept for a certain period of time.

[0055] 3. Quenching out of the furnace, hook the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com