A preparation method of ultra-high temperature lightweight zirconia setter plate

A zirconia and ultra-high temperature technology, which is used in the preparation of ultra-high temperature lightweight zirconia setter plates, can solve problems such as poor chemical stability, chemical reaction, cracking, etc., and achieve the effect of low thermal storage and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

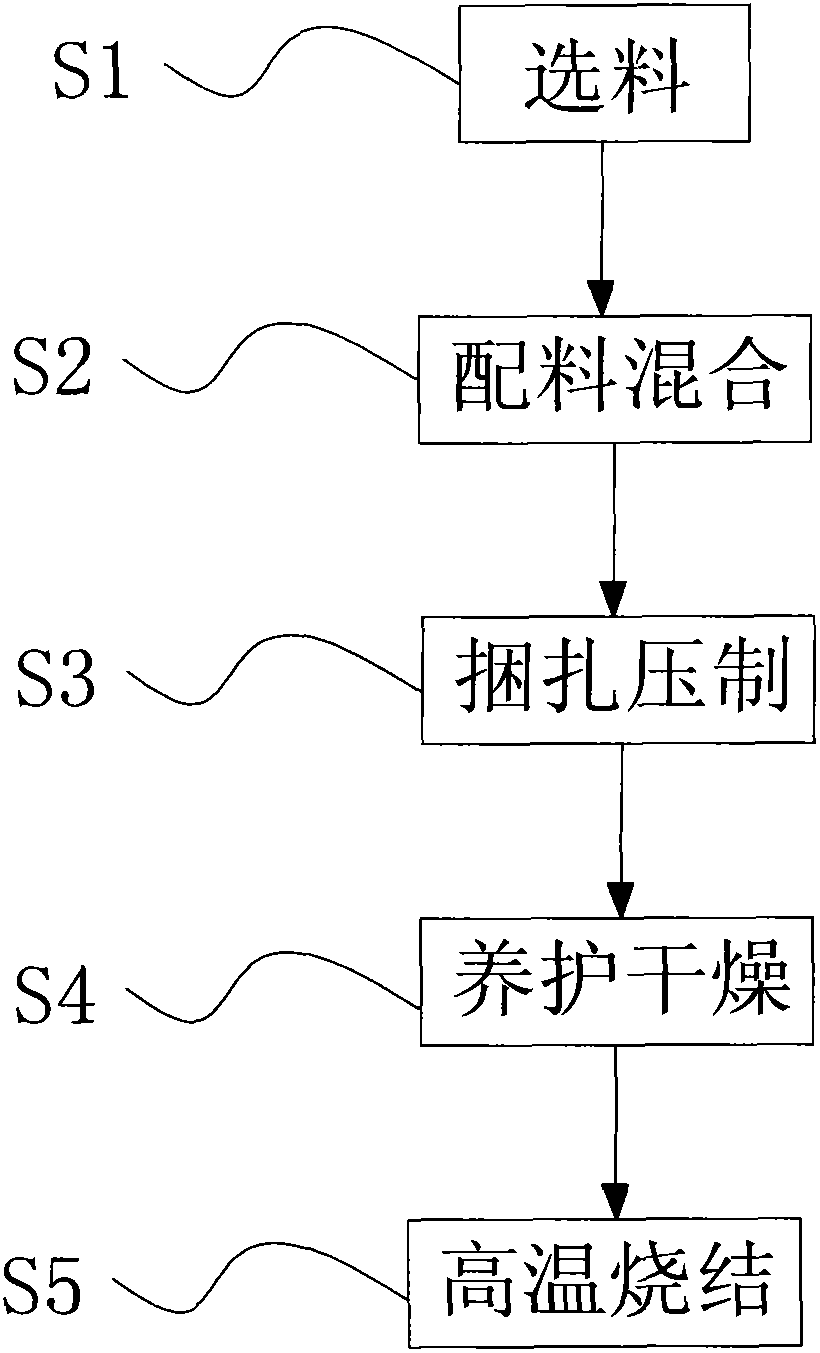

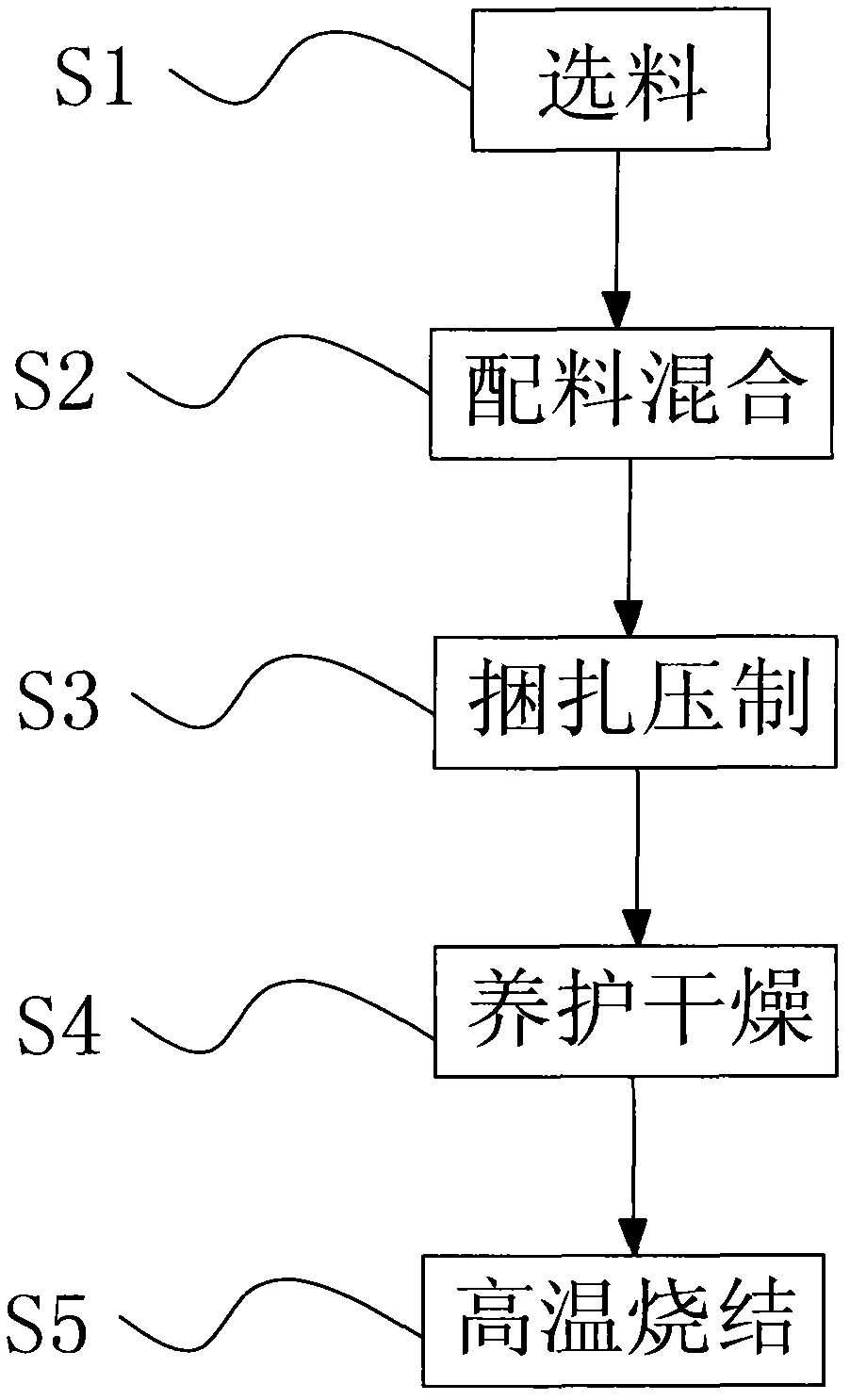

Method used

Image

Examples

Embodiment 1

[0025] (1) Select high-purity zirconia fiber as the main raw material, select zirconia fine powder of ≤0.088mm as the sintering material, and select high-purity zirconia sol as the forming binder;

[0026] (2) Weigh 30% of zirconia fibers with a diameter of 2-15 microns and 70% of zirconia fine powder with a particle size of ≤0.088mm by mass percentage, add a zirconia sol binder and stir and mix;

[0027] (3) The above-mentioned mixed and prepared raw materials are sieved through a sieve and packed into a plastic bag for bundling and storage, then taken out and sieved twice and then pressed into shape;

[0028] (4) Carry out maintenance and drying to the above-mentioned pressed-formed zirconia green body;

[0029] (5) After high-temperature sintering, the desired ultra-high-temperature light-weight zirconia setter is obtained.

Embodiment 2

[0031] (1) Select high-purity zirconia fiber as the main raw material, select ≤0.088mm zirconia fine powder as the sintering material, and select high-purity zirconia sol as the forming binder;

[0032] (2) Weigh 45% of zirconia fibers with a diameter of 2-15 microns and 55% of zirconia fine powder with a particle size of ≤45 microns by mass percentage, add a zirconium sol binder and stir and mix;

[0033] (3) The above-mentioned mixed and prepared raw materials are sieved through a sieve and packed into a plastic bag and stored for 48 hours, then taken out and sieved twice and then pressed into shape;

[0034] (4) curing and drying the solid zirconia after the above-mentioned compression molding;

[0035] (5) After high-temperature sintering, the required high-temperature-resistant zirconia setter plate is obtained.

Embodiment 3

[0037] (1) Select high-purity zirconia fiber as the main raw material, select ≤0.088mm zirconia fine powder as the sintering material, and select high-purity zirconia sol as the forming binder;

[0038] (2) Weigh 60% of zirconia fibers with a diameter of 2-15 microns and 40% of zirconia fine powder with a particle size of ≤0.088mm by mass percentage, add a zirconia sol binder and stir and mix;

[0039] (3) The above-mentioned mixed and prepared raw materials are sieved through a sieve and packed into a plastic bag and stored for 48 hours, then taken out and sieved twice and then pressed into shape;

[0040] (4) curing and drying the solid zirconia after the above-mentioned compression molding;

[0041] (5) After high-temperature sintering, the desired ultra-high-temperature light-weight zirconia setter is obtained.

[0042] The setter plate prepared by the above method has high porosity, light weight, high temperature resistance, good chemical stability and low heat storage, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com