Grading fuel gas low-nitrogen burner

A low-nitrogen burner and gas technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve problems such as incomplete combustion, unstable combustion, unreasonable distribution of fuel and air, etc., to meet environmental protection requirements, Effect of reducing NOx emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

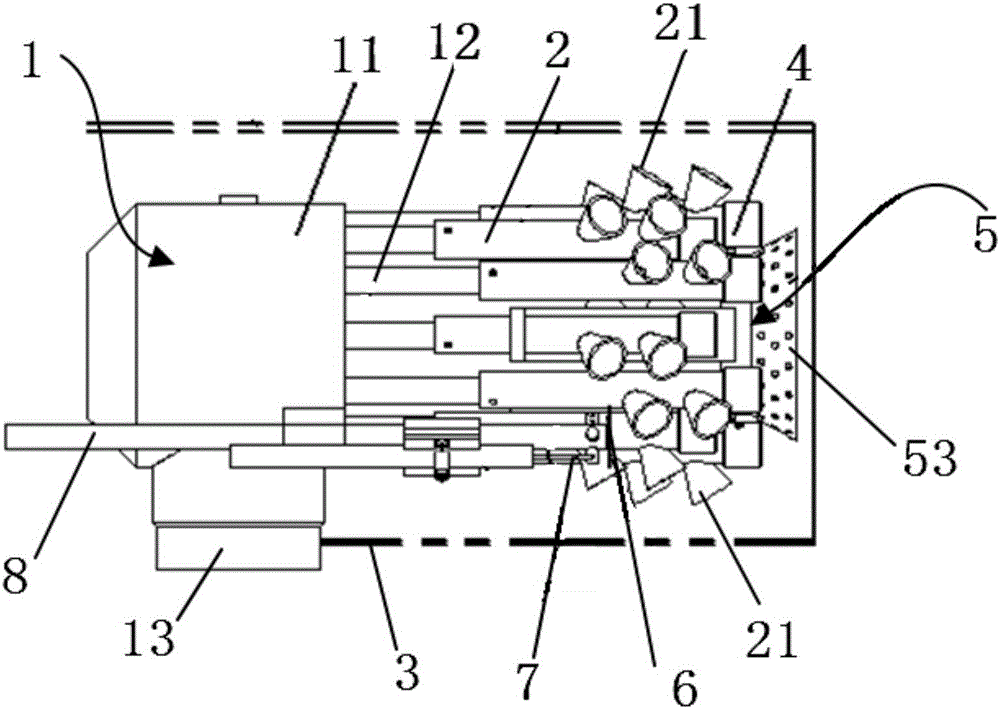

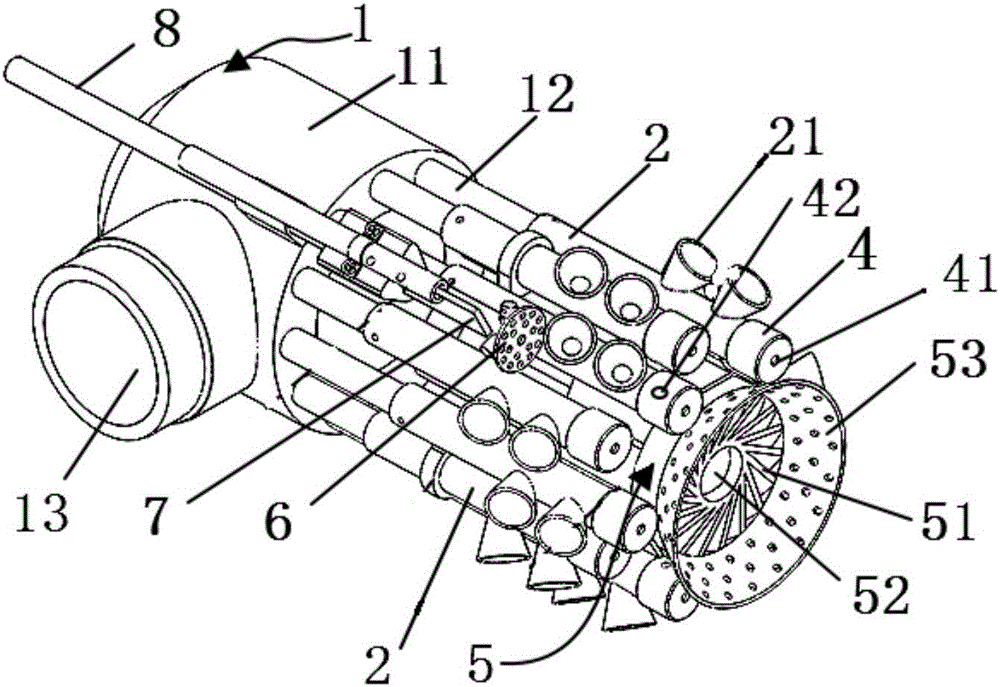

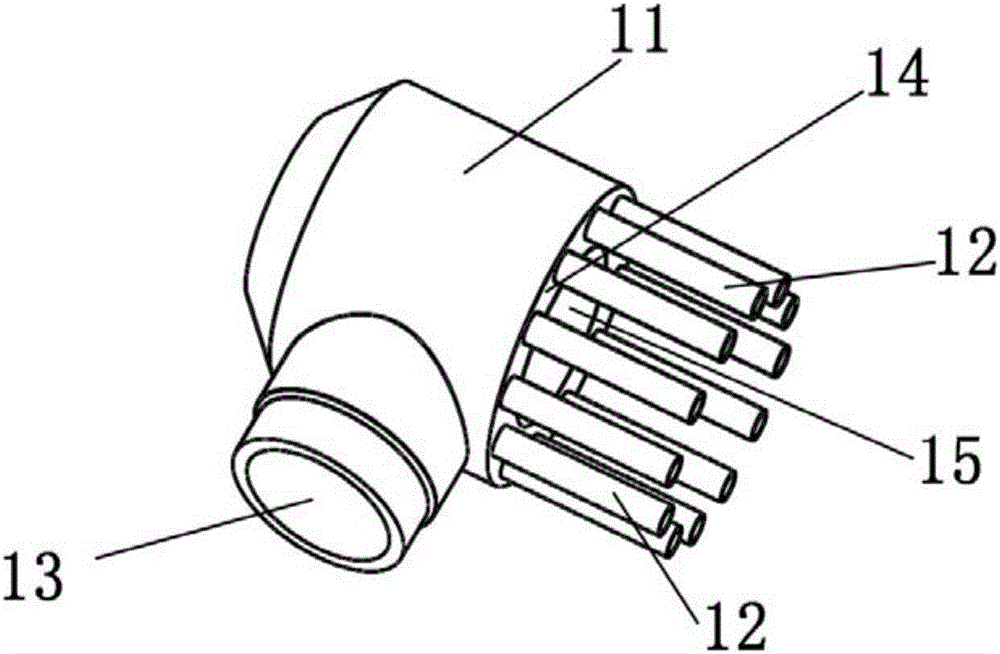

[0035] figure 1 It is a front view of a staged gas low-nitrogen burner according to an embodiment of the present invention. figure 2 It is a three-dimensional structural schematic diagram of a staged gas low-nitrogen burner according to an embodiment of the present invention. image 3 It is a structural schematic diagram of a distributor body in a staged gas low-nitrogen burner according to an embodiment of the present invention.

[0036] Such as figure 1 shown, see also figure 2 with image 3 , this embodiment takes figure 1 To illustrate mainly, the present invention provides a staged gas low-nitrogen burner, including: a staged gas distributor for providing flow paths for the gas and air. The graded gas distributor includes a distributor body 1 , multiple graded fuel nozzles 2 and a burner barrel 3 . The body of the distributor is a cylinder 11 with a sandwich, the outside of which is a sandwich 14, and the inside is a hollow 15, the sandwich 14 is used for gas accu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com