Novel pulverized coal nozzle and pulverized coal feeding mode

A new type of pulverized coal technology, which is applied in the direction of granular/powdered fuel gasification, etc., can solve the problem of not ensuring that the pulverized coal and oxidant are fully mixed and burned, and achieve stable and reliable use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

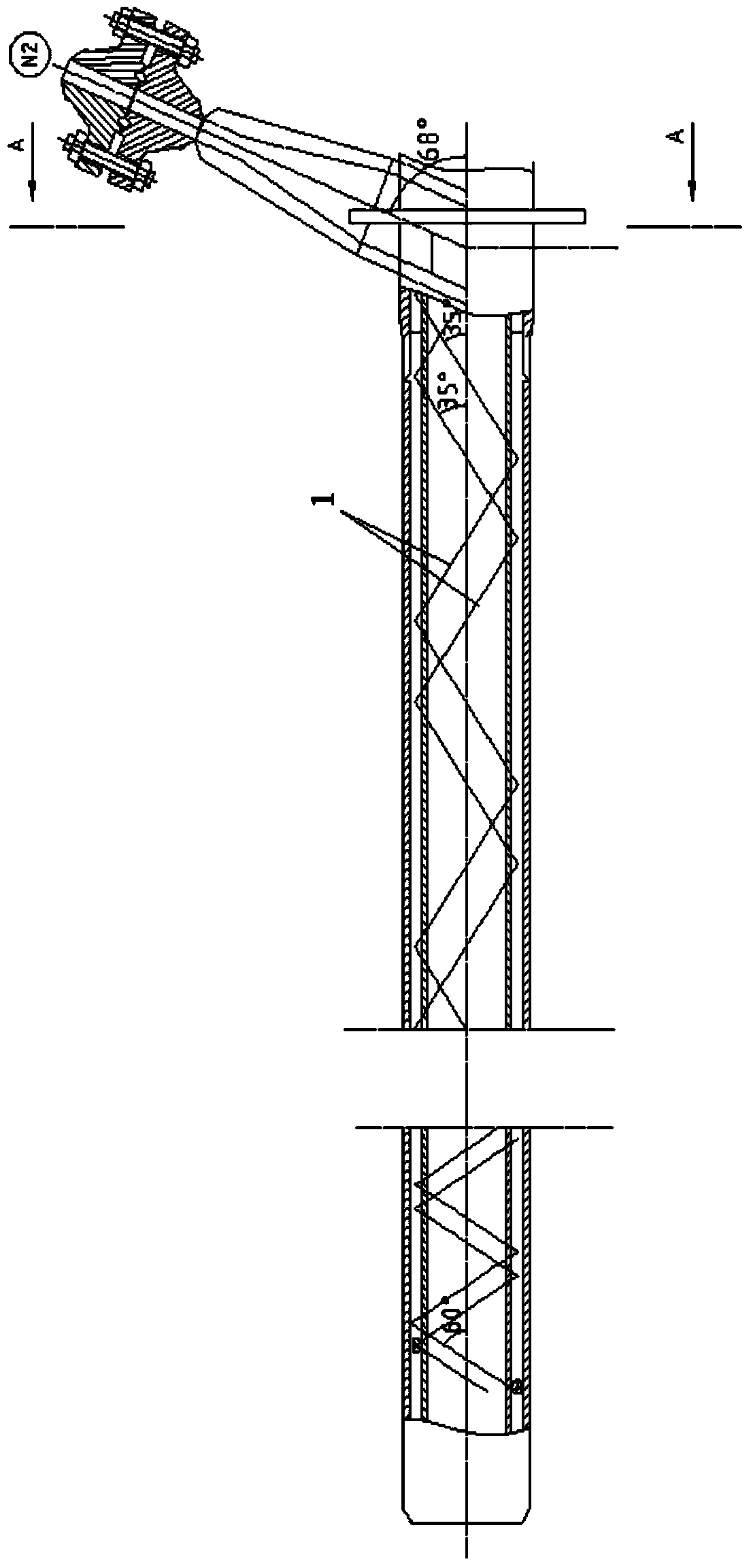

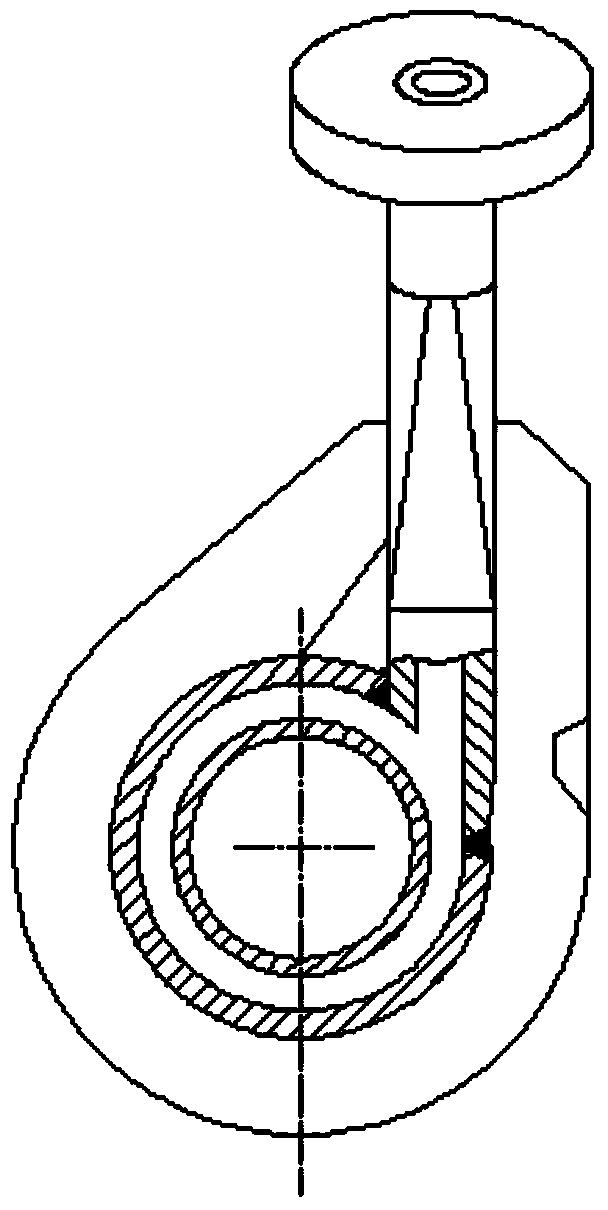

[0010] Such as figure 1 with figure 2 As shown, the pulverized coal burner of the present invention is provided with a pulverized coal inlet N2, and the pulverized coal is carried by nitrogen into the burner from the N2 inlet, and the N2 inlet passage is tangent to the outer wall of the pulverized coal passage, and the angle between the pulverized coal passage centerline 68°; two steel bars 1 with a diameter of 20mm are arranged in parallel in the pulverized coal channel, and are spirally wound on the inner wall of the pulverized coal channel, so that a swirl pulverized coal channel is formed in the pulverized coal channel, and the winding angle at the entrance of the pulverized coal channel is 35°, and the winding angle at the outlet of the pulverized coal channel is 60°.

[0011] The pulverized coal and nitrogen rotate forward along the swirling pulverized coal channel formed between the two steel bars 1, and rotate and spray the pulverized coal channel at a certain angle....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com