Lower feeding biomass smokeless multi-purpose furnace capable of directly combusting crushed straw

A biomass and multi-purpose furnace technology, which is applied in the direction of combustion method, combustion equipment, fuel supply, etc., can solve the problems of insufficient fuel combustion and high cost of biomass fuel, and achieve sufficient combustion, long continuous burning time, and convenient flameout and ash removal Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

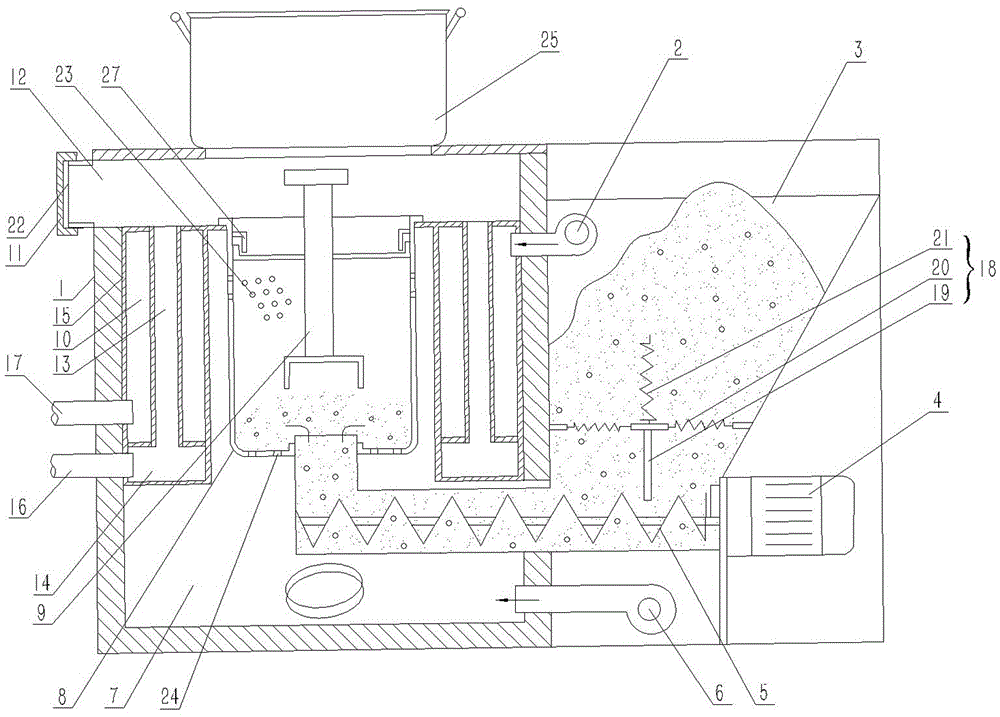

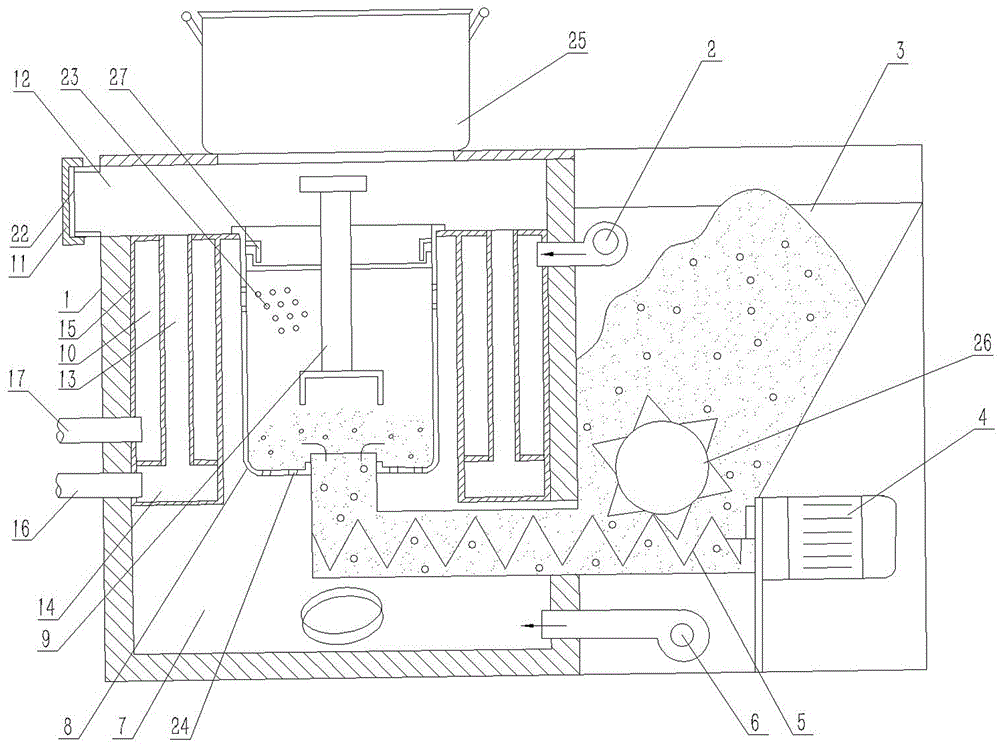

[0021] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0022] as attached figure 1 with 2 As shown, a bottom-feeding biomass smokeless multi-purpose furnace that can directly burn broken straws includes a furnace body 1, a movable combustion barrel 8 arranged in the furnace body 1, and a fuel supply to the combustion barrel 8 through the bottom of the combustion barrel 8. The lower feeding mechanism of the material. The lower feeding mechanism includes a storage hopper 3 , a lower feeding screw feeder 5 arranged in the storage hopper 3 to screw fuel into the combustion barrel 8 , and a driving motor 4 for the lower feeding screw feeder to provide power. The storage hopper 3 is provided with an arch breaking device 18 for preventing and eliminating arching of materials. The arch breaking device 18 includes a T-shaped support 19 whose lower end is in contact with the lower feeding screw feeder 5, a transverse ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com