Double-layer mechanical grate type garbage gasification incinerator and its treatment method

A mechanical grate and gasification furnace technology, applied in the direction of combustion method, incinerator, combustion type, etc., can solve the problem that the heat recovery system and the flue gas treatment system are greatly affected, the continuous gasification and incineration of garbage cannot be realized, and the heat reduction can be reduced. Conversion efficiency and other issues, to achieve the effect of guaranteeing the thermal ignition loss rate of ash and slag, improving heat exchange efficiency, and reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

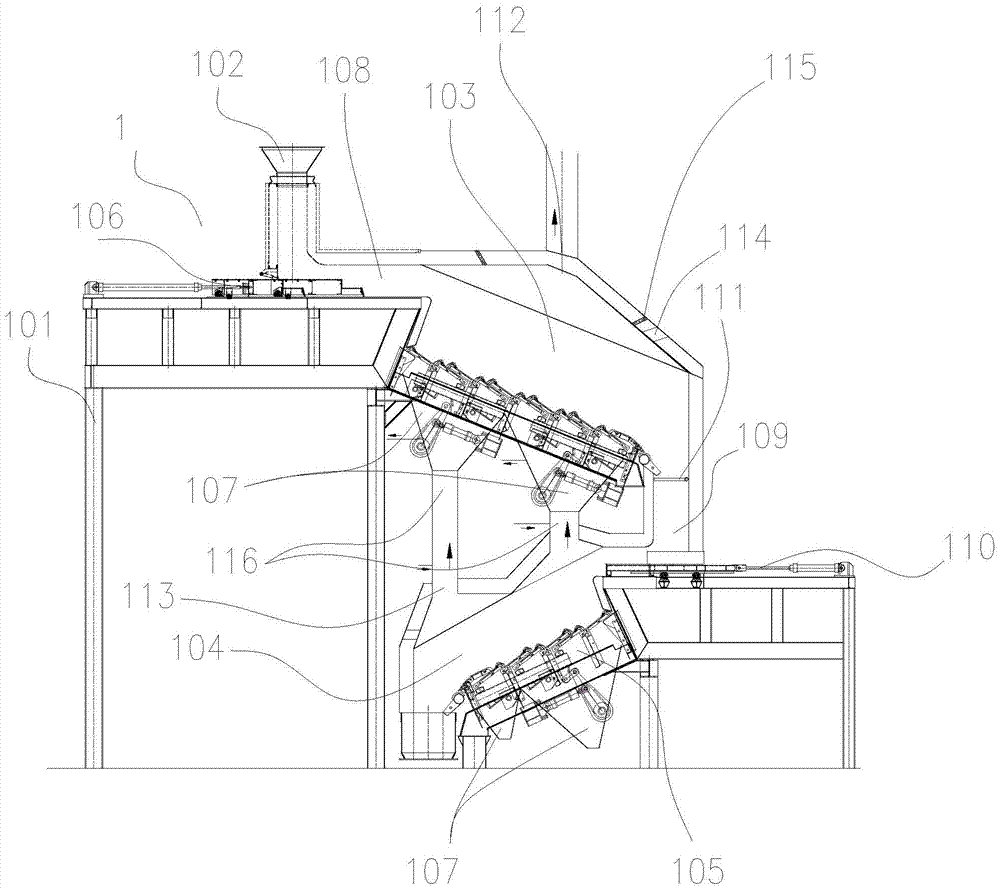

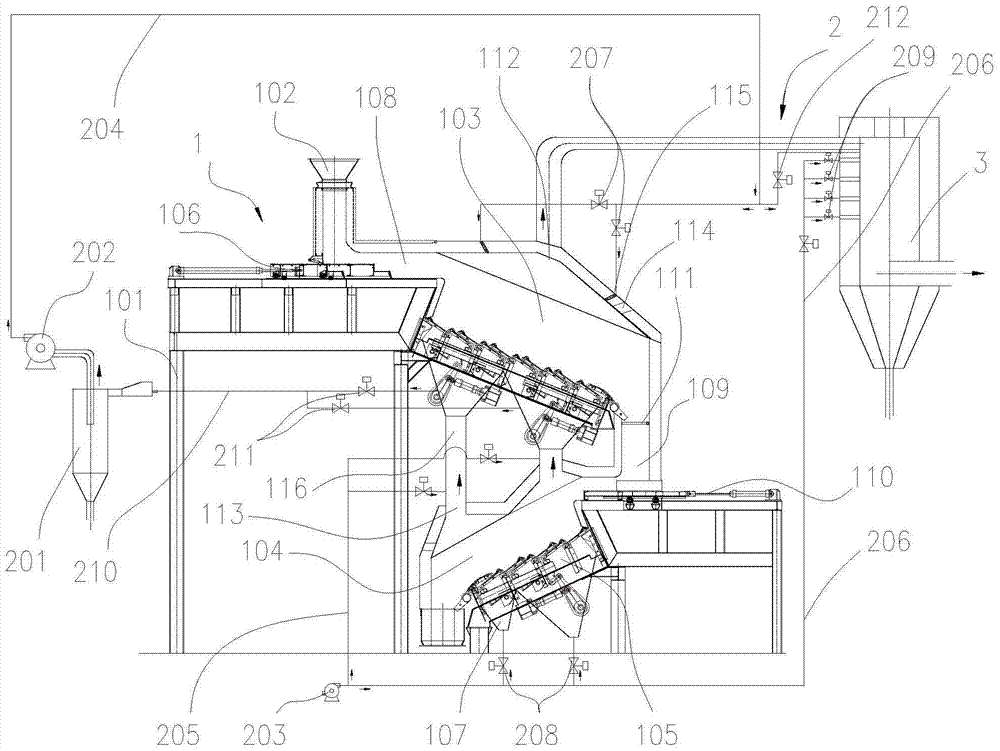

[0040] see figure 1 , is a preferred embodiment of a double-layer mechanical grate type garbage gasification incinerator, including a furnace frame 101, on which a feed bin 102 and a gasifier 103 are sequentially arranged along the feeding direction, The furnace frame 101 is also provided with an ember furnace 104, the ember furnace 104 is located directly below the gasification furnace 103, and the feeding direction of the ember furnace 104 is opposite to that of the gasification furnace 103, and the gasification The furnace 103 mainly gasifies the charcoal part of the garbage, and discharges combustible gasification flue gas and garbage residues, and the ember furnace 104 mainly performs combustion treatment of residual charcoal, and discharges harmless ash. The part of the furnace frame 101 between the outlet of the feed bin 102 and the inlet of the gasifier 103 is provided with a stacking seal section 108, and the outlet of the gasifier 103 and the feed of the ember furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com