Hazardous waste rotary kiln incineration air supply method

A rotary kiln and air supply technology, applied in the combustion method, incinerator, combustion type, etc., can solve the problems of heat loss, increase in the rate of reduction on hot ignition of the moving speed, and high excess air coefficient of the rotary kiln, and achieve low The effect of increasing the burning rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

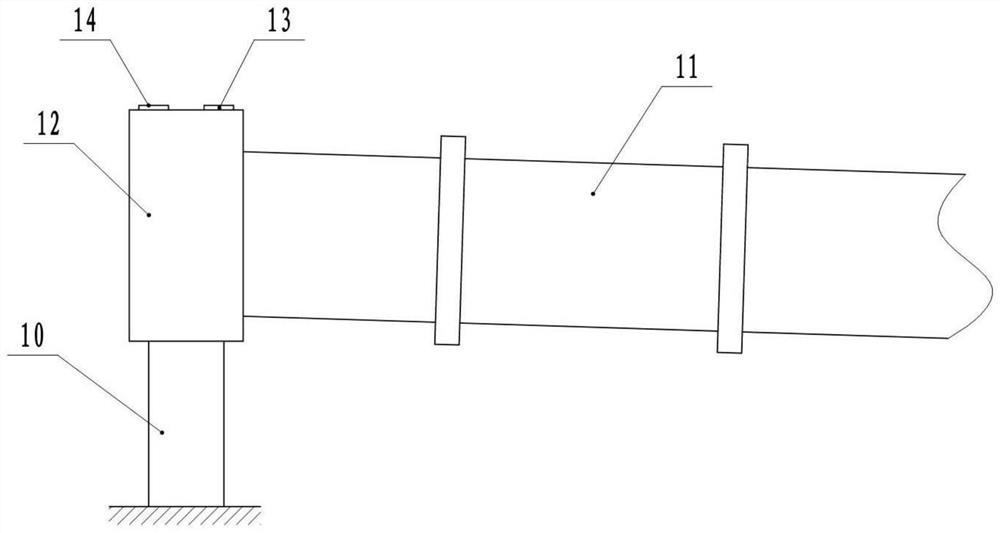

[0031] The air supply method for hazardous waste rotary kiln incineration is realized by using an improved air supply structure, in which the improved air supply structure is combined with figure 1 As shown, it includes a support frame 10, a drum 11 and a kiln head cover 12, wherein the drum 11 is rotatably connected to the support frame 10, and the kiln head cover 12 is fixed on the support frame 10. Between the drum 11 and the kiln head cover 12 In order to rotate and seal the connection, the drum 11 is arranged obliquely, and the end of the drum 11 near the kiln head cover 12 is higher than the other end.

[0032] The kiln head cover 12 includes a cylindrical outer wall and end covers connected to the two ends of the outer wall. The outer wall of the kiln head cover 12 is provided with a main air hole 13 and a secondary air hole 14, wherein the main air hole 13 is located at the top of the outer wall, and the main air hole 13 is located at the top of the outer wall. Both th...

Embodiment 2

[0036] The difference from Example 1 is that in this example, D=1.5d; through model simulation calculation, a conclusion similar to that of Example 1 is obtained, that is, the air excess coefficient of hazardous waste incineration is controlled between 0.8 and 1.0 to control the air The feed rate of hazardous waste incineration in the rotary kiln is less than 3%.

Embodiment 3

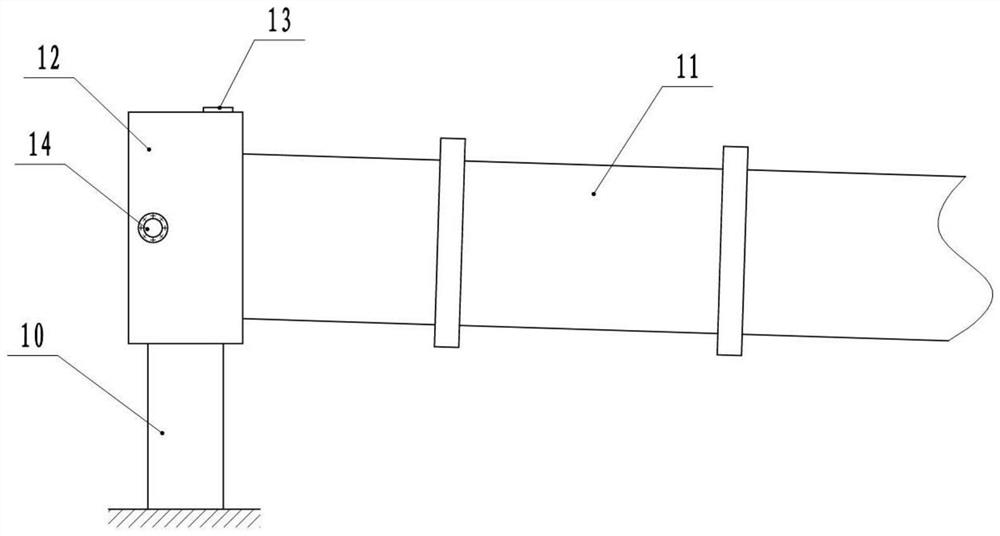

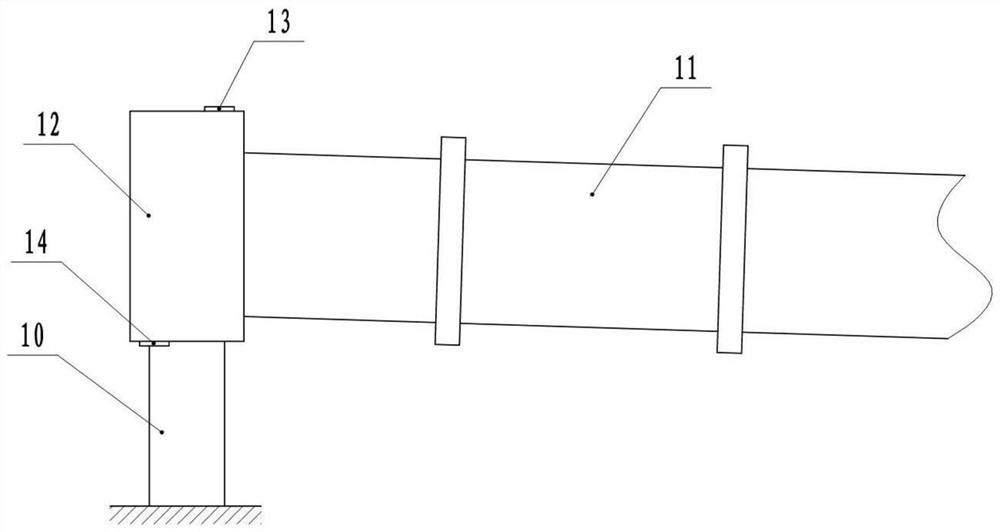

[0038] combine figure 2 As shown, the difference from Embodiment 1 is that in this embodiment, the auxiliary air hole 14 is located in the middle of the outer wall; through model simulation calculations, a conclusion similar to that of Embodiment 1 is obtained, that is, the air excess coefficient of hazardous waste incineration is controlled at 0.8 ~1.0 to control the air supply, and the thermal loss rate of hazardous waste incineration of the rotary kiln is less than 3%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com