Air distribution system for small household garbage pyrolysis and gasification incinerator and incinerator thereof

A domestic waste, pyrolysis and gasification technology, applied in the direction of incinerators, combustion types, combustion equipment, etc., can solve problems such as the inability to achieve an ideal and stable flow field in the furnace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Such as Figure 1-6 As shown, the air distribution system for the small domestic waste pyrolysis gasification incinerator proposed by the embodiment of the present invention includes:

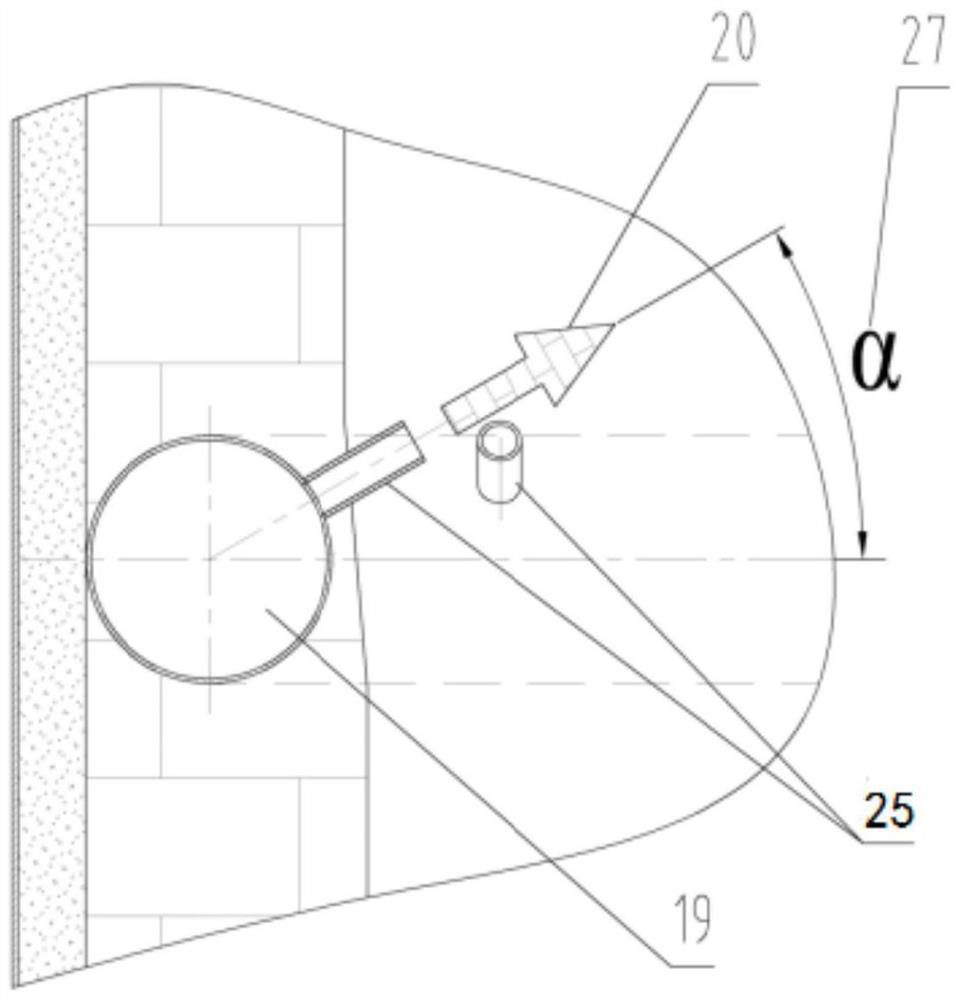

[0067] Annular air duct 19, said annular air duct 19 is arranged on the inside of the side wall of the body of heater 1, and is circumferentially provided with an inward blowing port 25 communicating with the furnace 2; the gas outlet of said inward blowing port 25 points to said Centerline of furnace 2;

[0068] Air supply main pipe 11, described air supply main pipe 11 is arranged on the outside of described furnace body 1, and is provided with first road air duct 6, second road air duct 8, third road air duct 10;

[0069] The first air duct 6 passes through the side wall of the furnace body 1 and communicates with the annular air duct 19;

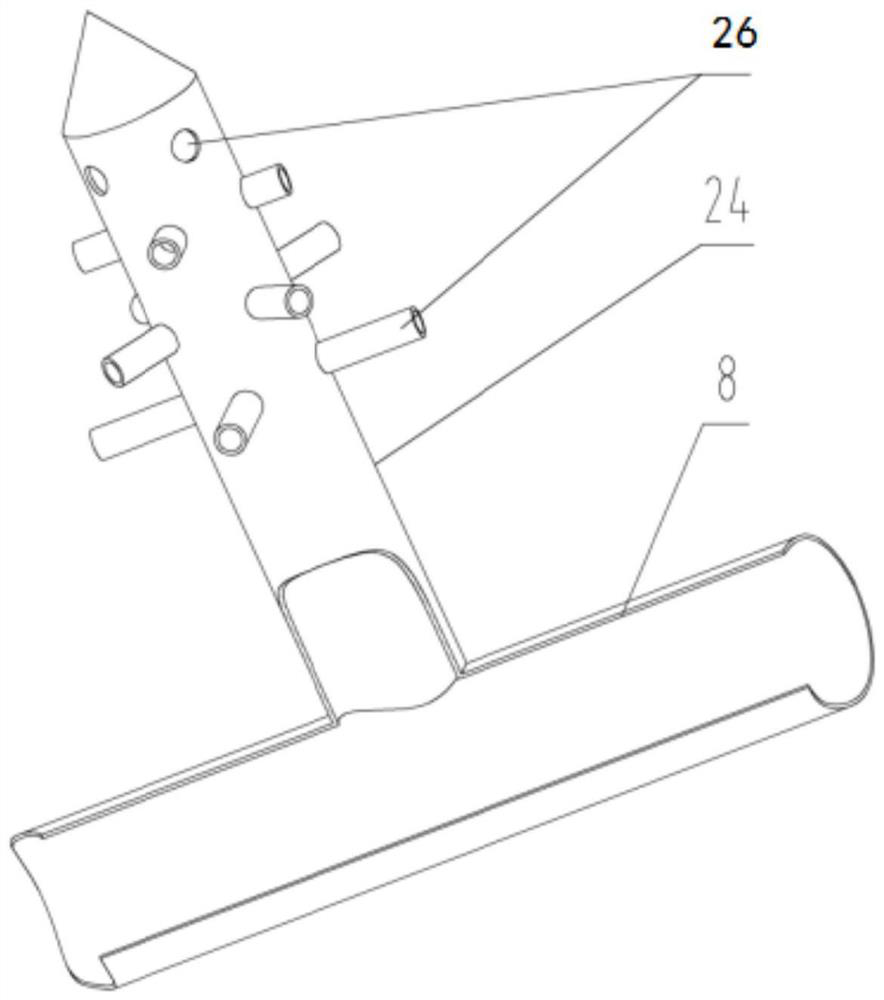

[0070] The second air duct 8 passes through the side wall of the furnace body 1 and extends to the ash chamber 15; the second air duct 8 is prov...

Embodiment 2

[0088] Such as Figure 7-13 As shown, this embodiment proposes an incinerator, including the air distribution system for a small domestic waste pyrolysis gasification incinerator described in Embodiment 1. The incinerator at least includes: a furnace body 1 , a fire grate 17 , and a slag collecting bucket 13 .

[0089]As a preferred implementation of this embodiment, the incinerator includes: a furnace body 1, a fire grate 17, a smoke collecting pipe 34, an exhaust pipe 3, a secondary combustion chamber 35, and a slag collecting hopper 13;

[0090] The interior of the furnace body 1 is a cavity, and the top is provided with a feed port 36 and a feed door 37 capable of sealingly fitting with the feed port 36 .

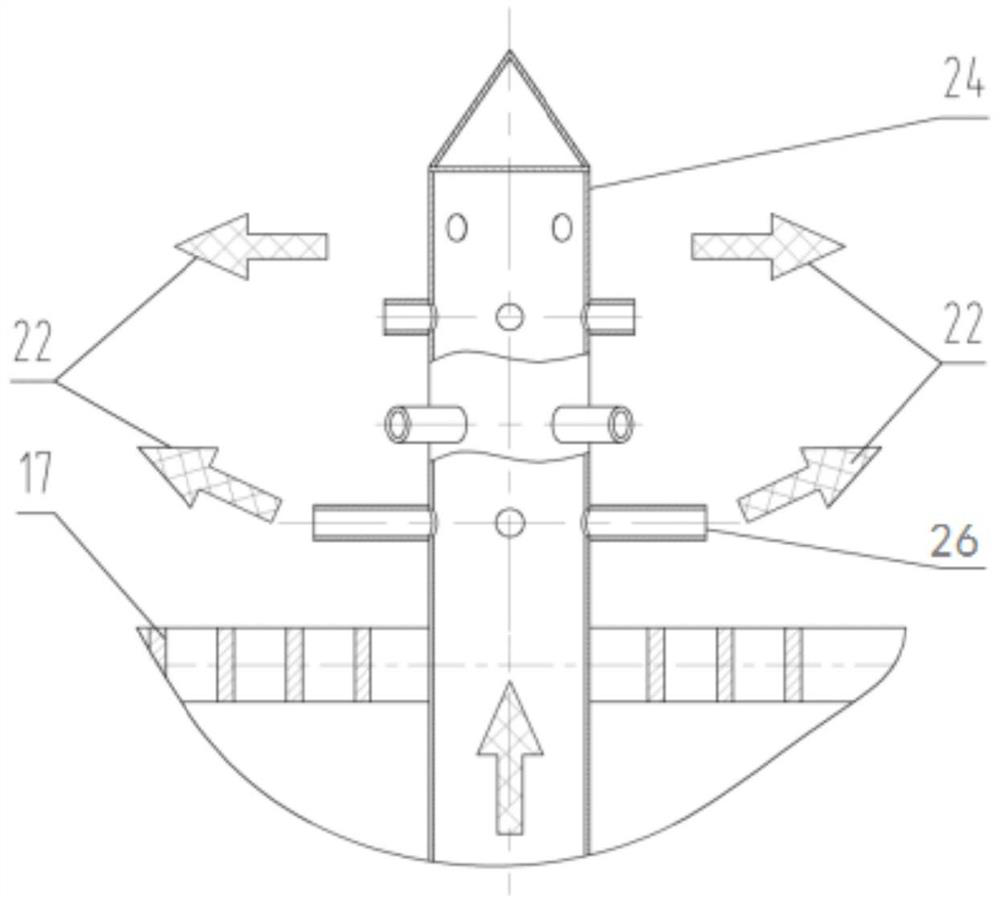

[0091] The fire grate 17 is located in the furnace body 1, and divides the cavity of the furnace body 1 into the upper furnace 2 and the lower ash chamber 15; that is, the fire grate 17 and the furnace body 1 The space enclosed by the inner surface of the side wall, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com