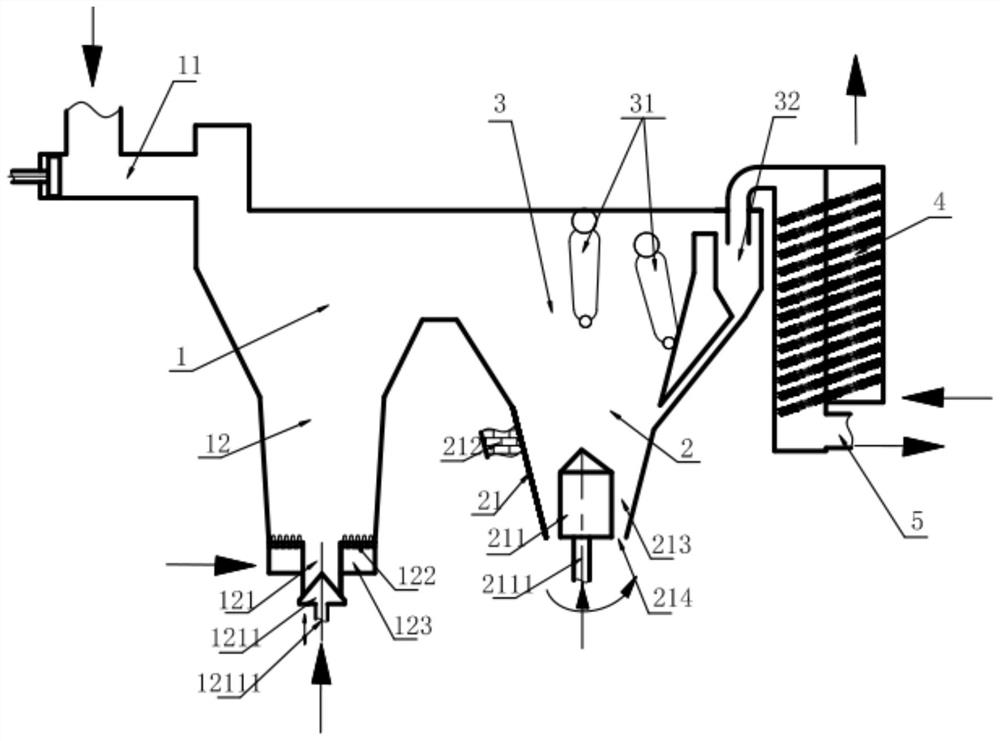

Enamel material resistant to high and low temperature corrosion, its preparation method, application and high temperature boiling rotary grate furnace device

A high-temperature corrosion-resistant, high-temperature boiling technology, used in combustion methods, incinerators, lighting and heating equipment, etc., can solve the problems of insufficient residence time, incomplete combustion, and insufficient furnace temperature, so as to achieve full utilization of thermal energy and save landfill. Use of land, the effect of speeding up the reaction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

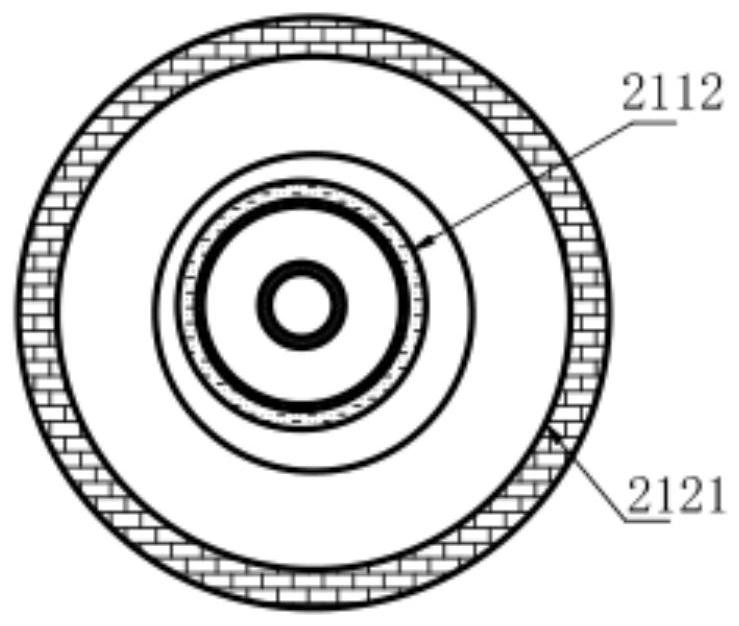

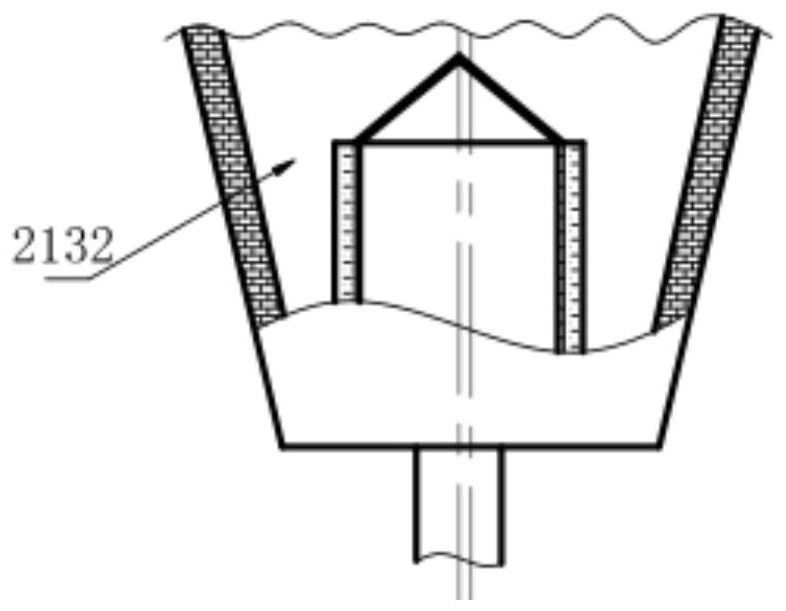

Method used

Image

Examples

Embodiment 1

[0081] Production of high temperature corrosion resistant enamel material layer:

[0082] Firstly, on the P91 substrate, perform mechanical rust removal on the outer surface of the steel pipe, and then do chemical rust removal. The acid solution ratio for chemical rust removal is: 6.0% industrial sulfuric acid, 4.0% industrial nitric acid, 90% industrial hydrochloric acid, The temperature of the acid solution needs to be controlled at 27±5°C, and the soaking time is 8 minutes. After leaving the bath, rinse off the residual acid immediately, and then air-dry at 60±3°C for 3 hours, and then immediately spray the primer. The formula of the primer includes the following weight percentage Content of each component: 54.3% SiO 2 , 0.63% CoO, 0.77% NiO, 13.5% B 2 o 3 , 7.0% Al 2 o 3 , 2.3% MnO 2 , 4.6% CaO, 16.9% Na 2 O, the bottom slurry drying time is 2 hours, the temperature is 105°C, then the temperature is raised to 350°C at a rate of 50°C / hour, the temperature is kept cons...

Embodiment 2

[0086] Production of high temperature corrosion resistant enamel material layer:

[0087] First of all, the bottom material is boiler steel pipe P91. Mechanical derusting is performed on the outer surface of the steel pipe, and then chemical derusting is done. The acid solution ratio for chemical derusting is: 5.0% industrial sulfuric acid, 5.0% industrial nitric acid, 90% industrial Hydrochloric acid, the temperature of the acid solution needs to be controlled at 27±5°C, and the soaking time is 8 minutes. After leaving the bath, rinse off the residual acid immediately, and then air-dry at 60±3°C for 3 hours, and then spray the primer immediately. The formula of the primer includes the following weight Percentage of each component: 53.3% SiO 2 , 0.7% CoO, 0.7% NiO, 14.5% B 2 o 3 , 8.0% Al 2 o 3 , 2.5% MnO 2 , 4.6% CaO, 15.7% Na 2 O, the bottom slurry drying time is 2 hours, the temperature is 105°C, then the temperature is raised to 350°C at a rate of 50°C / hour, the temp...

Embodiment 3

[0091] Production of high temperature corrosion resistant enamel material layer:

[0092] Firstly, on the P91 substrate, perform mechanical rust removal on the outer surface of the steel pipe, and then do chemical rust removal. The acid solution ratio for chemical rust removal is: 6.0% industrial sulfuric acid, 4.0% industrial nitric acid, 90% industrial hydrochloric acid, The temperature of the acid solution needs to be controlled at 27±5°C, and the soaking time is 8 minutes. After leaving the bath, rinse off the residual acid immediately, and then air-dry at 60±3°C for 3 hours, and then immediately spray the primer. The formula of the primer includes the following weight percentage Content of each component: 52.3% SiO 2 , 0.77% CoO, 0.77% NiO, 15.0% B 2 o 3 , 8.0% Al 2 o 3 , 2.7% MnO 2 , 5.0% CaO, 15.46% Na 2 O, the bottom slurry drying time is 2 hours, the temperature is 105°C, then the temperature is raised to 350°C at a rate of 50°C / hour, the temperature is kept con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com