Patents

Literature

31results about How to "Low residual oxygen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

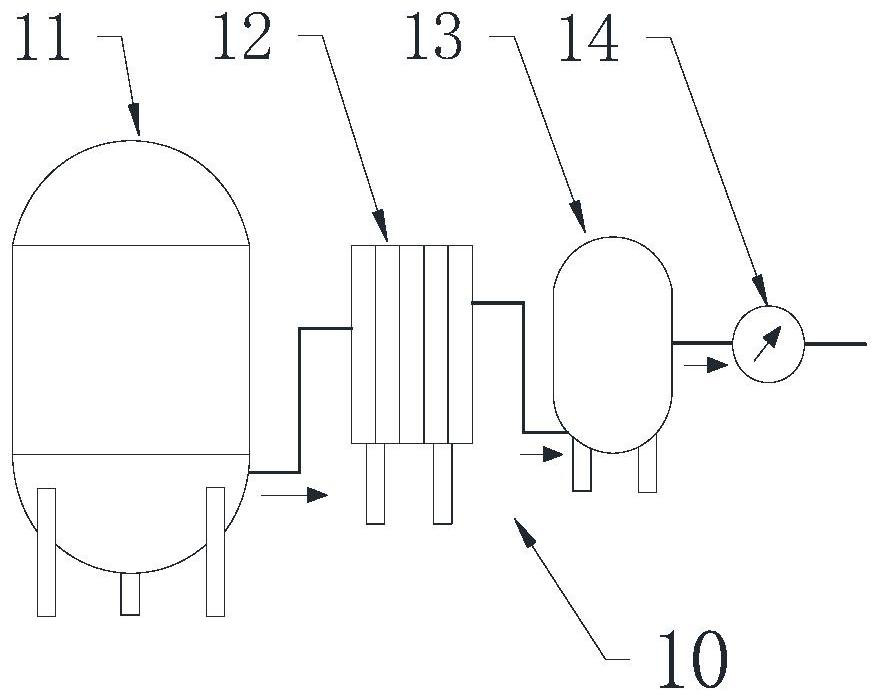

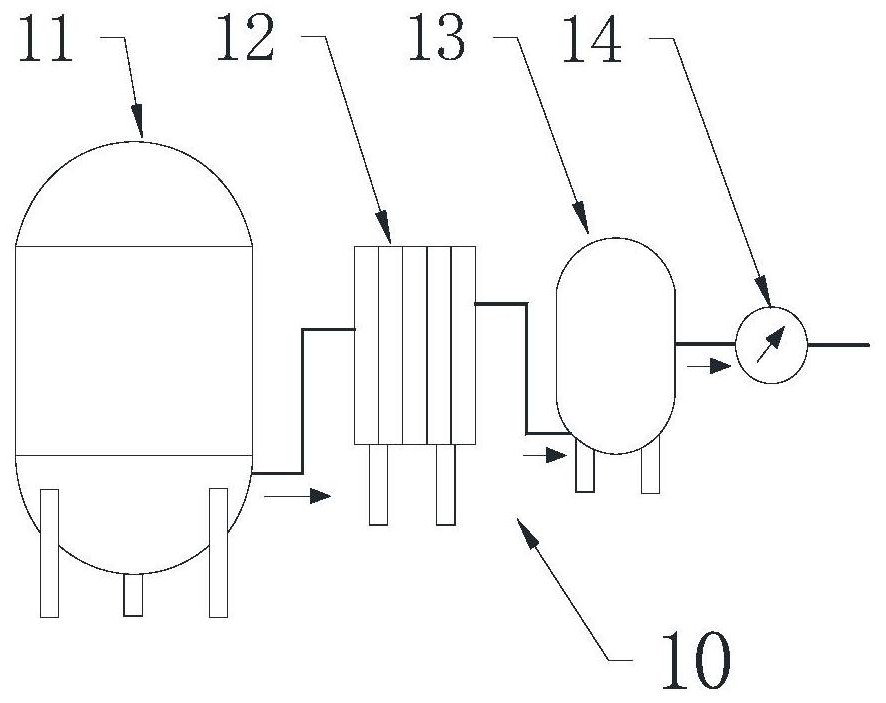

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for refining ferro-titanium on basis of aluminothermy self-propagating gradient reduction and wash heat

The invention provides a method for refining ferro-titanium on basis of aluminothermy self-propagating gradient reduction and wash heat. The method comprises the steps that firstly, aluminothermy self-propagating gradient reduction is carried out, wherein according to the first manner, raw materials are divided into multiple batches, the materials in the first batch are put into a reaction furnace, magnesium powder is ignited from the top of a material so as to trigger the self-propagating reaction, and materials in other batches are added successively until the reaction is finished; according to the second manner, raw materials except for the aluminum powder are evenly mixed and are added into a continuous mixing machine with the uniform flow speed, meanwhile, the aluminum powder is added into the continuous mixing machine with the gradient progressively-decreasing flow sped, and the evenly-mixed raw materials are continuously introduced into a reaction furnace at the same time to be subject to the aluminothermy self-propagating gradient reduction until all the materials are subject to complete reaction; secondly, heat preservation smelting is carried out to obtain upper layer alumina-base slag and lower layer alloy melt; thirdly, refining slag is sprayed and blown into the lower layer alloy melt for stirring, slag washing and refining; fourthly, the high-temperature melt obtained after refining is cooled to the room temperature, and upper layer melting slag is removed so as to obtain the ferro-titanium.

Owner:NORTHEASTERN UNIV

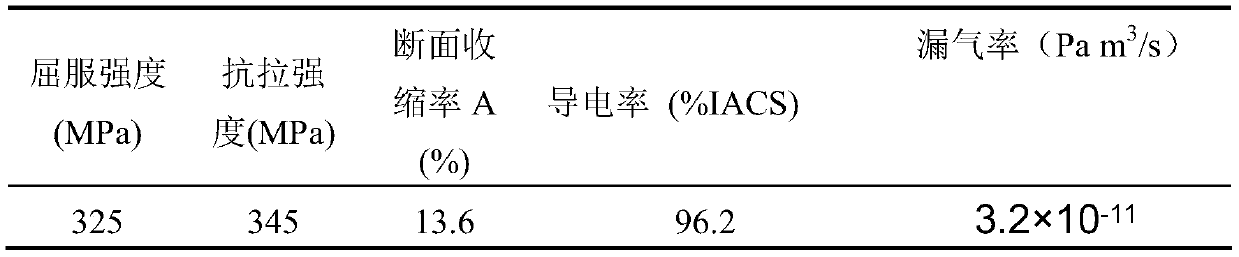

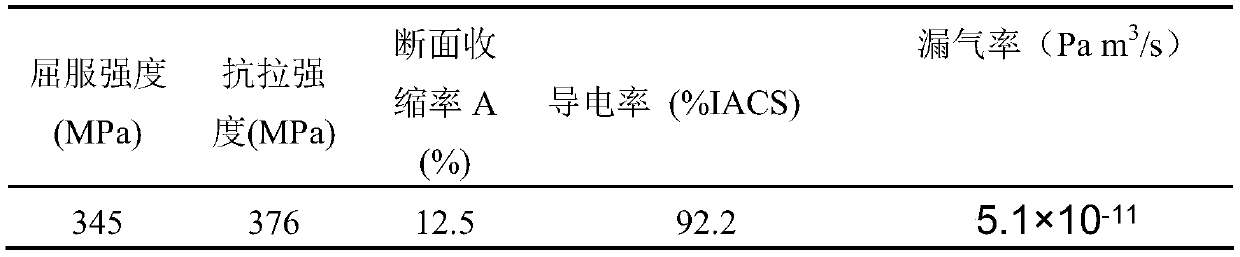

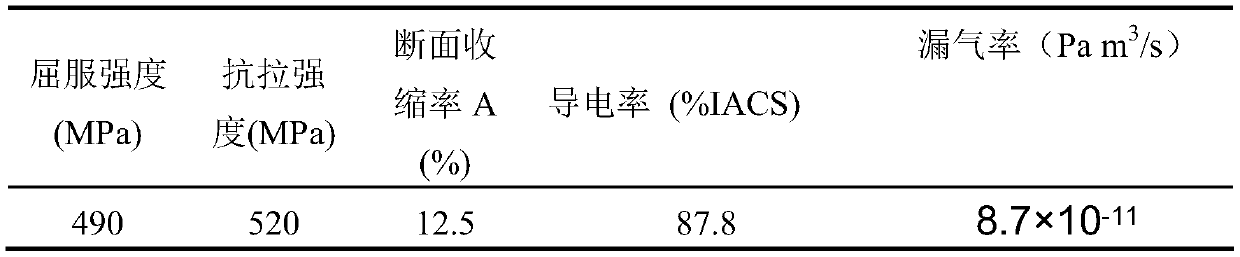

High-air-tightness low-free-oxygen-content nano disperse copper alloy and short-process preparation technology

ActiveCN109897982AReduced free oxygen contentPlay the role of diffusion strengtheningTransportation and packagingMetal-working apparatusInternal oxidationHigh dimensional

The invention discloses a high-air-tightness low-free-oxygen-content nano disperse copper alloy and a short-process preparation technology, and wherein the alloy components comprise Al2O3, Ca and La.The preparation technology is made by the following steps that preparing Cu-Al2O3 alloy powder by adopting an internal oxidation method, and then mixing the Cu-Al2O3 alloy powder with Cu-Ca-La alloy powder, wrap covering the mixed powder under the protection of argon, carrying out hot extrusion at 900-920 DEG C and then rotary forging, after rotary forging, the wrap covering is vacuumized to be less than or equal to 10<-3>Pa, the wrap covering is sealed and is placed in a nitrogen atmosphere with the temperature of 450-550 DEG Cand the pressure intensity of 40-60 Mpa for 3-5 hours. According to the preparation technology disclosed by the invention, the secondary solid reduction of Ca and La is utilized, so that residual free oxygen is effectively removed and the dispersion strengthening effect is achieved, and finally the high density is obtained through vacuum medium-temperature creep deformation. The disperse copper prepared by the invention has the advantages that low free oxygen content (<= 15ppm), high dimensional stability and good air tightness after hydrogen annealing, good in gas tightness, the gas leakage rate is less than or equal to 1.0*10<-10> Pa.m<3> / s, the preparation technology is suitable for industrial production and can be used as a variety of sealing device materials such as an electric vacuum shell sealing device and a novel energy automobile high-voltagedirect-current relay.

Owner:湖南高创科惟新材料股份有限公司

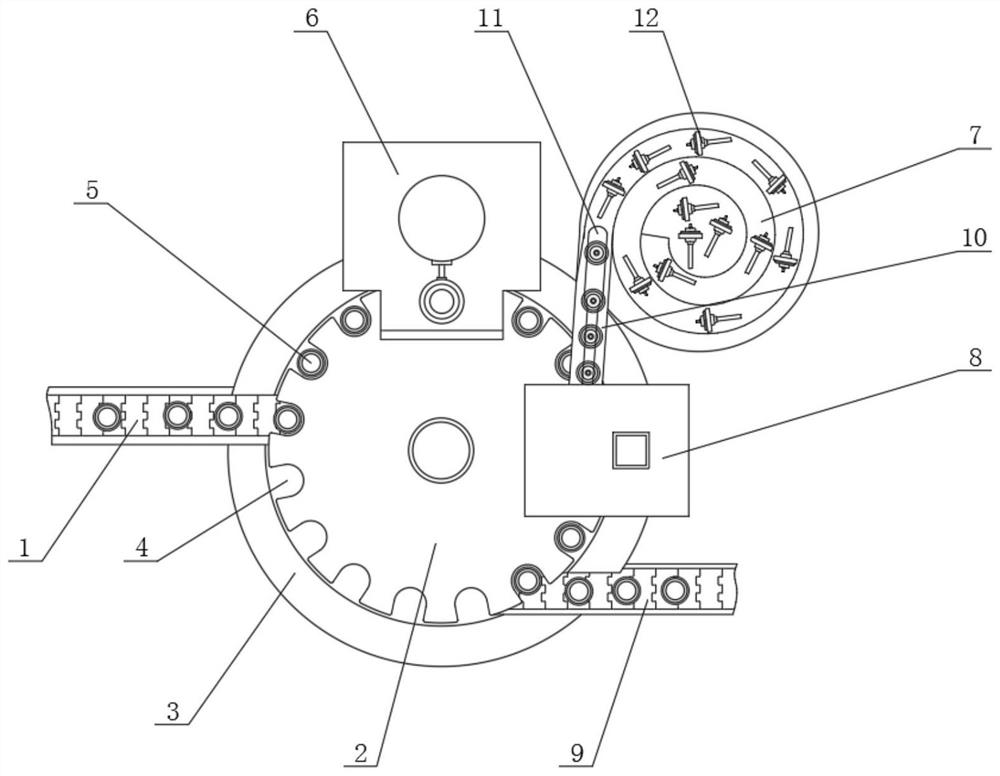

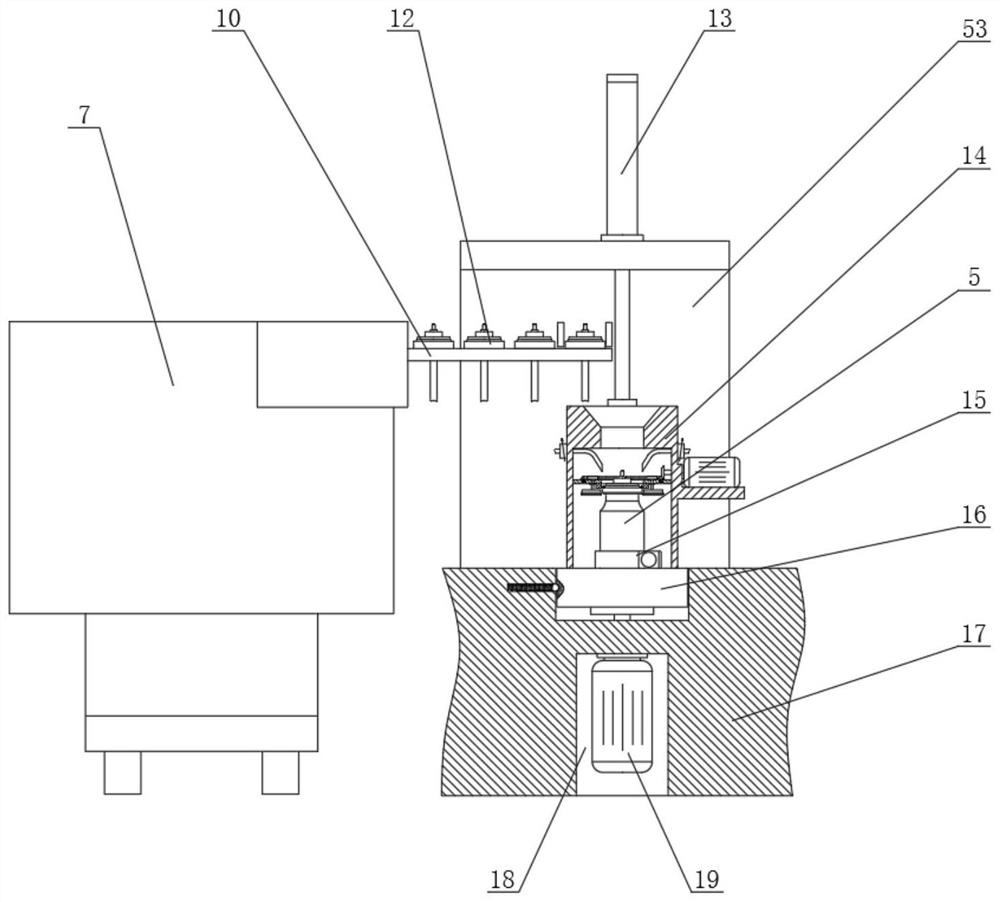

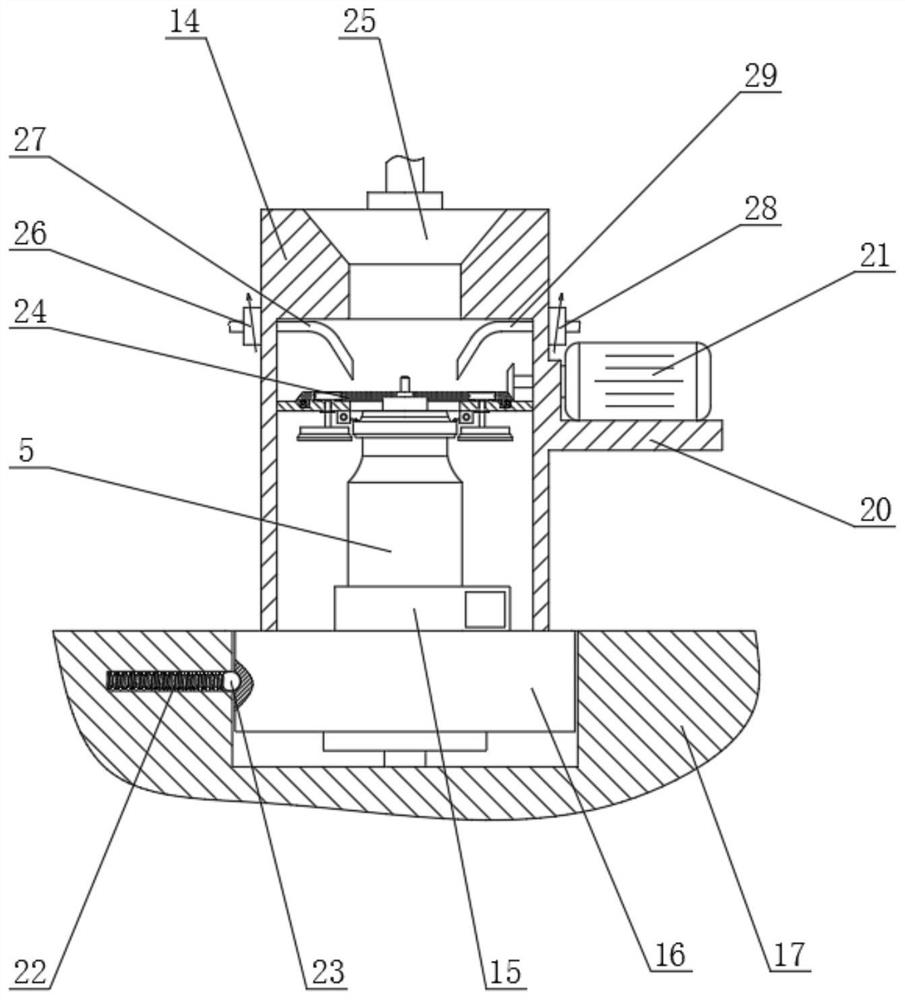

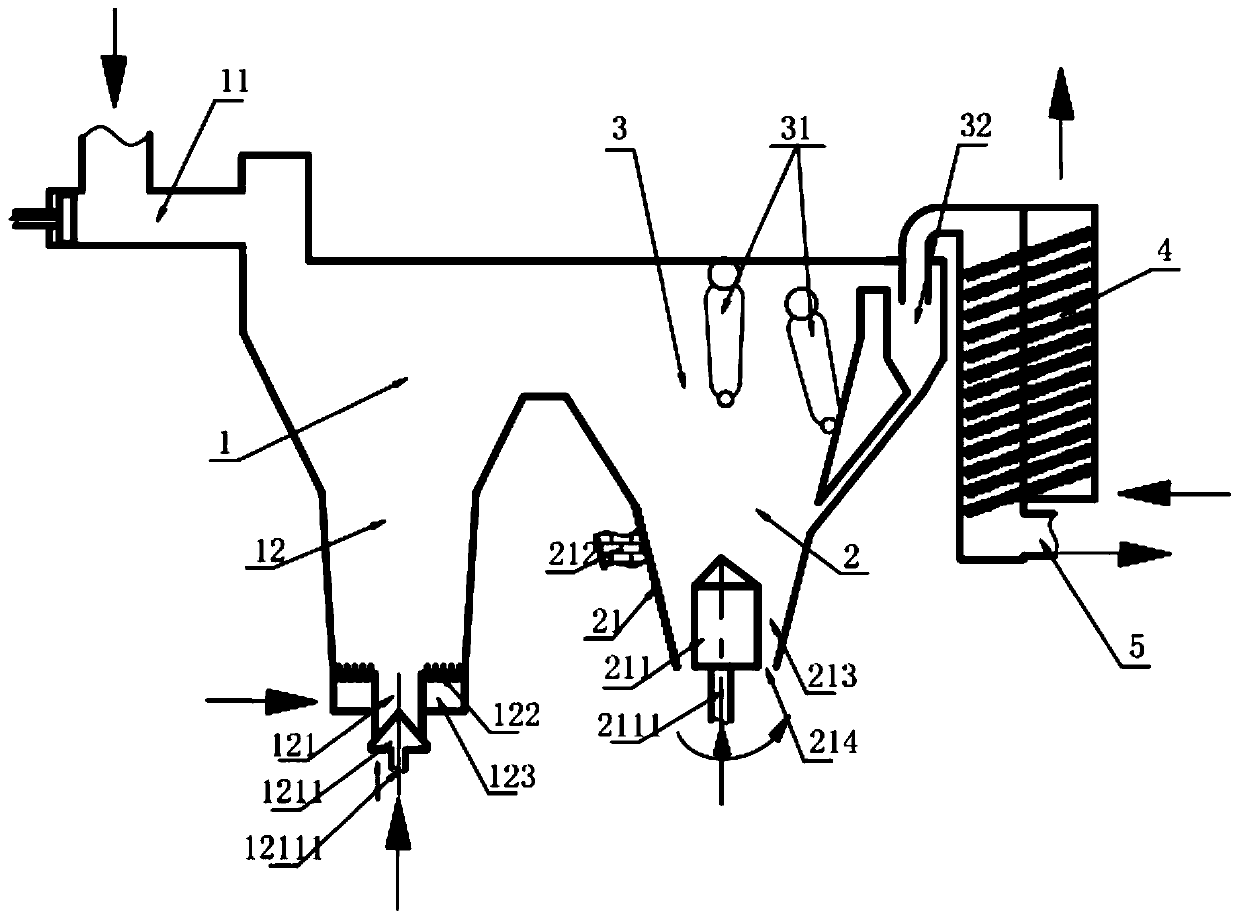

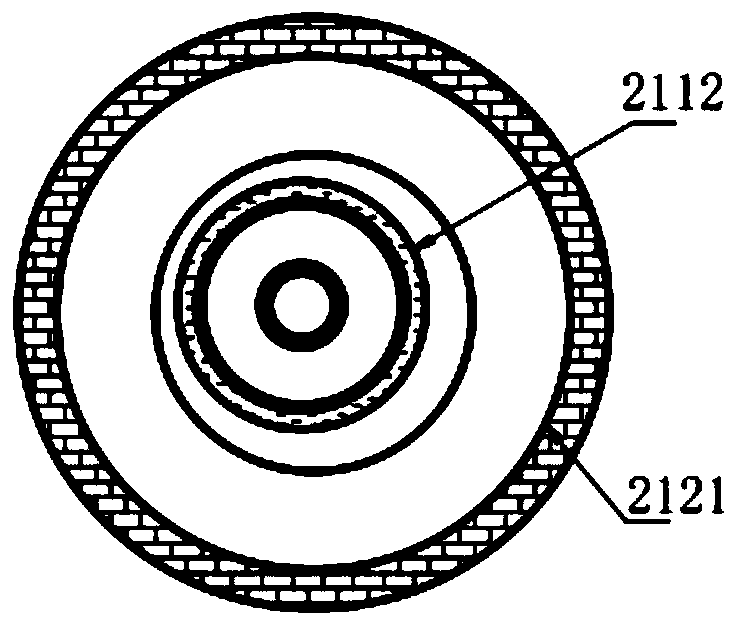

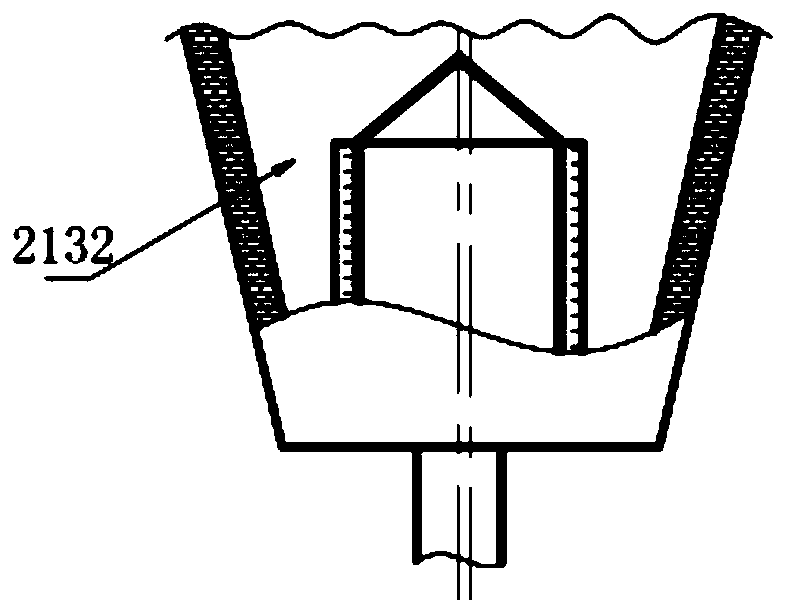

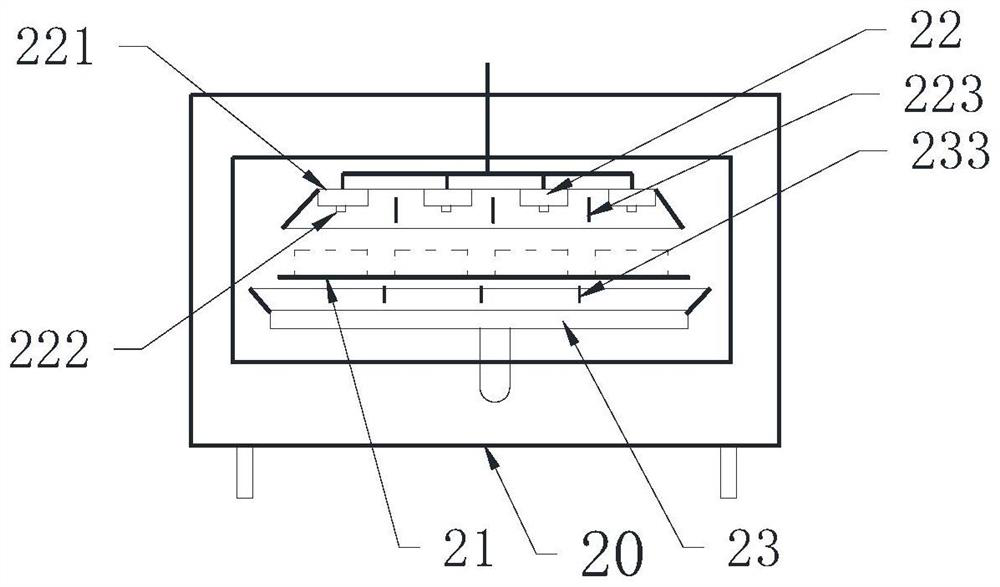

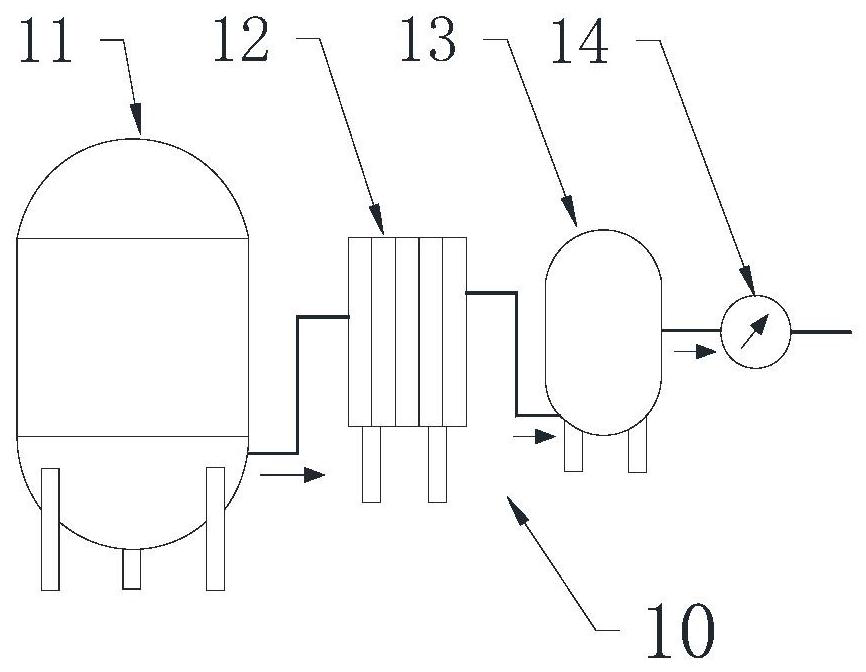

Nitrogen filling equipment and method for nasal spray

ActiveCN114313339AReduce physical impactLow residual oxygenCapsClosure using capsEngineeringNitrogen gas

The invention discloses nitrogen filling equipment and method for a nasal spray, and the equipment comprises a feeding conveying belt, a bottle separation rotating disc, a base, a filling machine, a vibration feeder, a gland nitrogen filling device and a discharging conveying belt; a nitrogen filling method adopting the equipment comprises the following steps that 1, spray bottles are fed through the feeding conveying belt, the empty bottles are conveyed to the station of the filling machine, and the nasal spray is filled into the bottles through the filling machine; secondly, the canned nasal spray bottles are conveyed to a station of a gland nitrogen charging device through a bottle dividing rotary table, a positioning mechanism positions and locks the spray bottles, an air cylinder drives an outer cover to cover the spray bottles, and a nitrogen charging mechanism vacuumizes the bottles and charges nitrogen into the bottles; thirdly, the nitrogen filling mechanism keeps vacuumizing and nitrogen filling, after the vibrating feeder and the capping mechanism framework cover the upper cap, the cap pressing mechanism presses and binds the spraying agent cap, filling of one bottle is completed, and vacuumizing and nitrogen filling are stopped; and fourthly, the spray bottles subjected to filling and capping are conveyed to a discharging conveying belt through a bottle distributing rotary disc to be discharged.

Owner:南昌百济制药有限公司

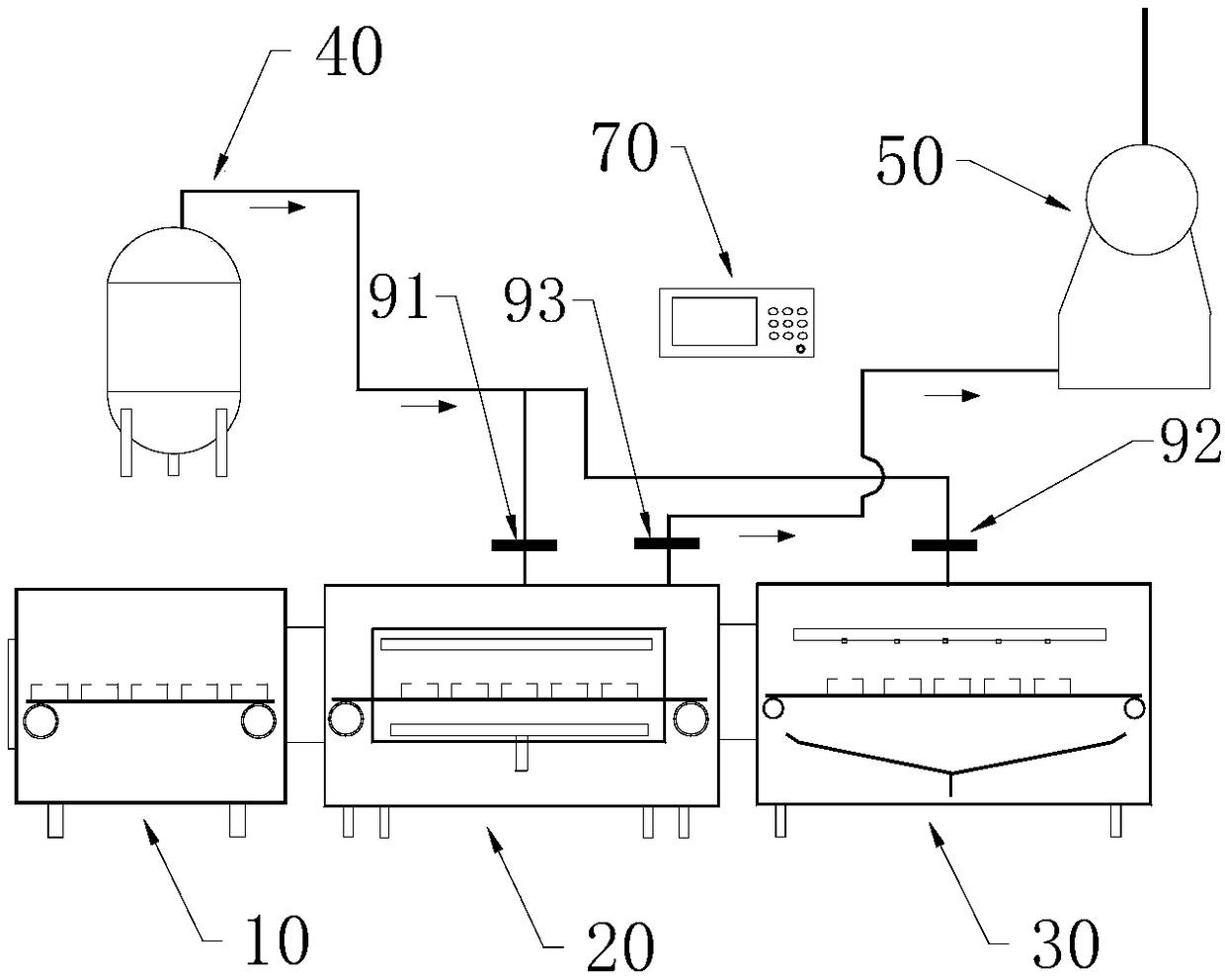

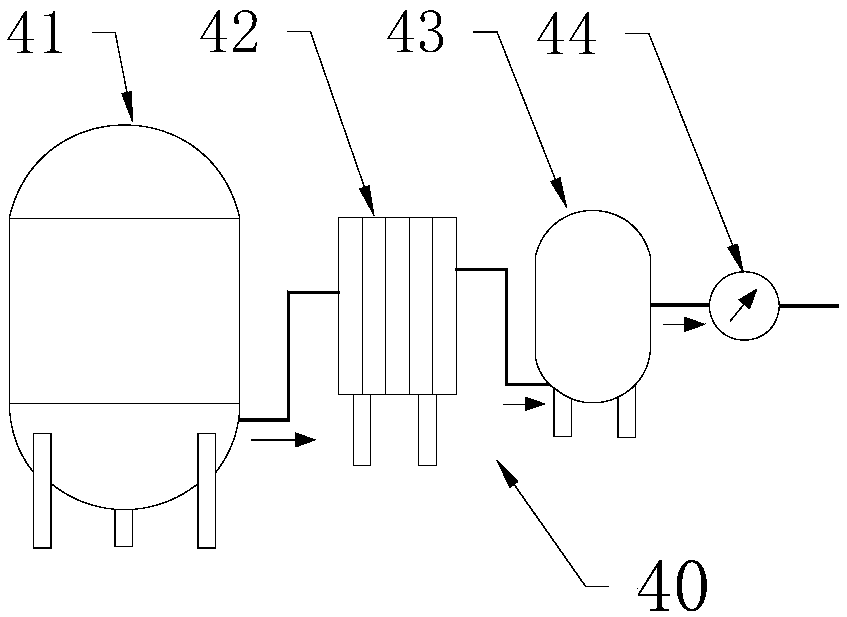

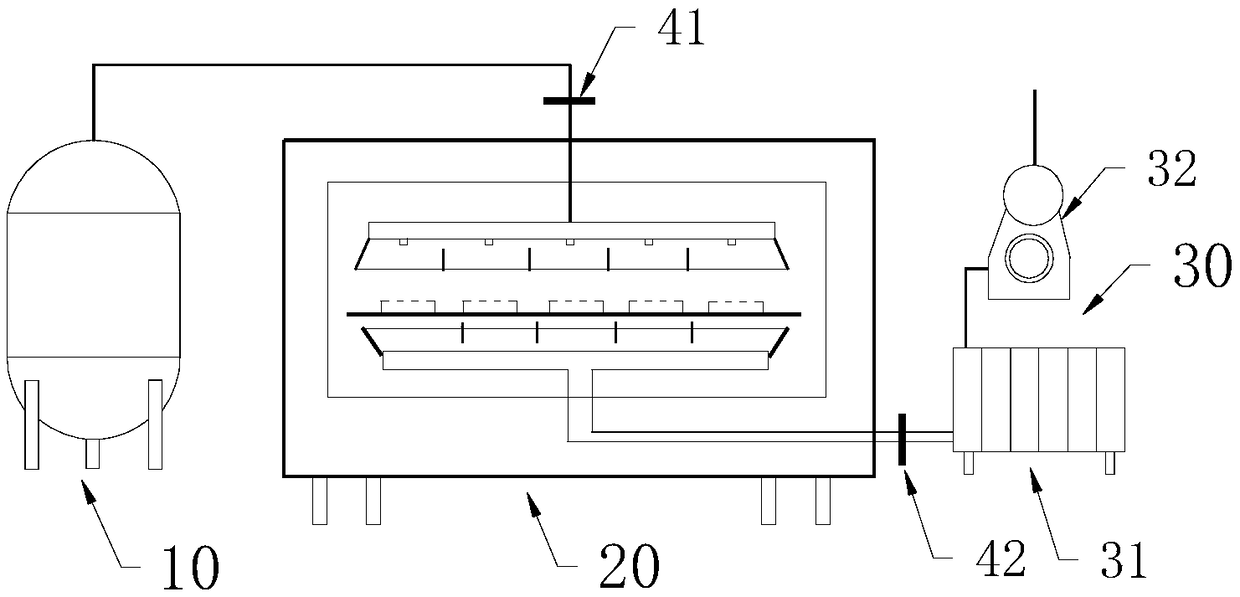

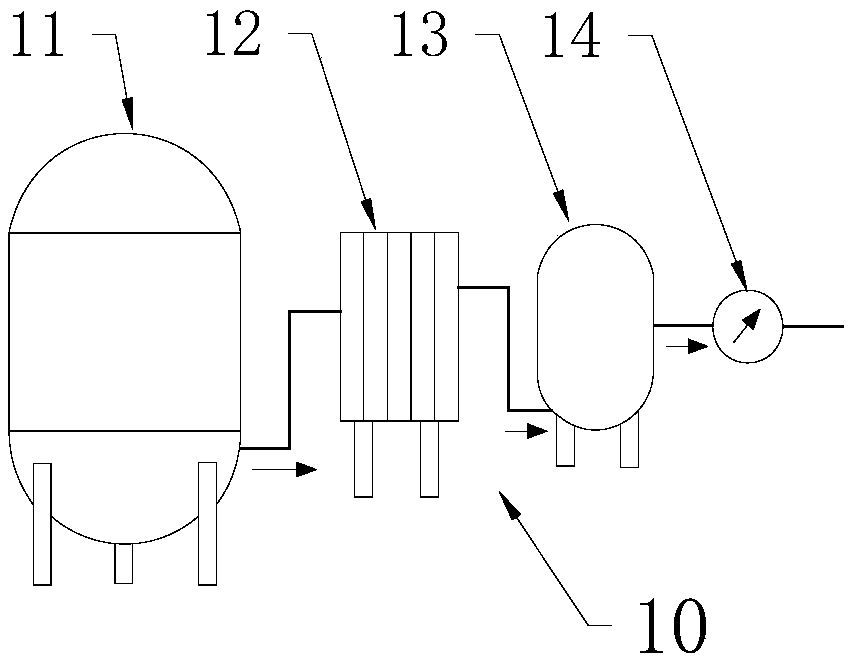

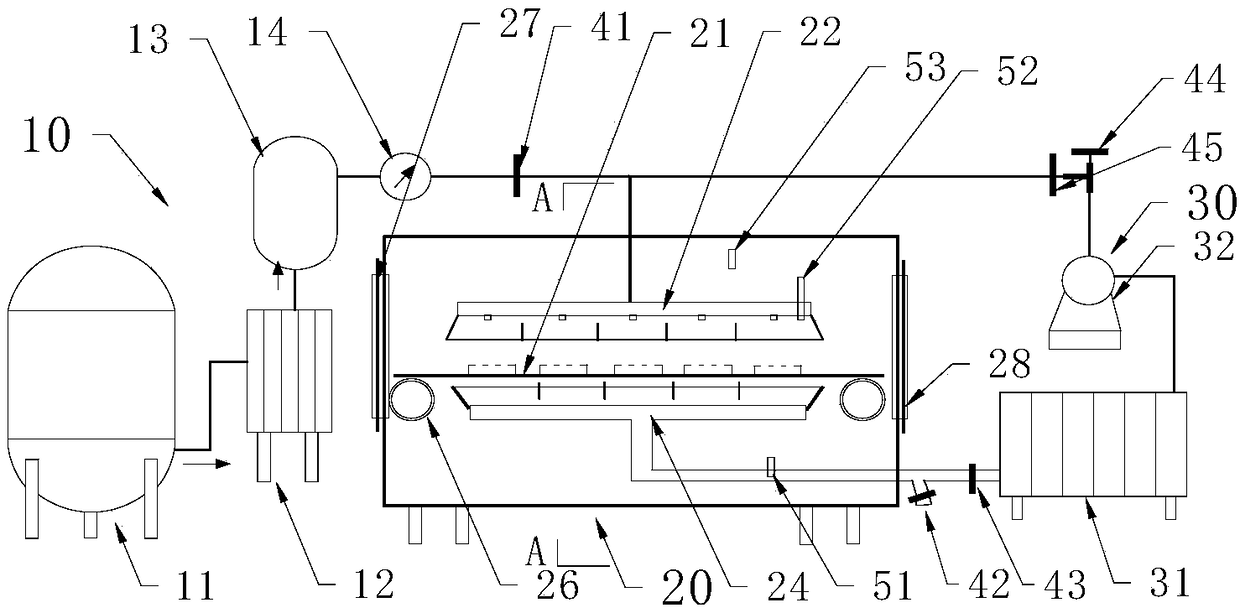

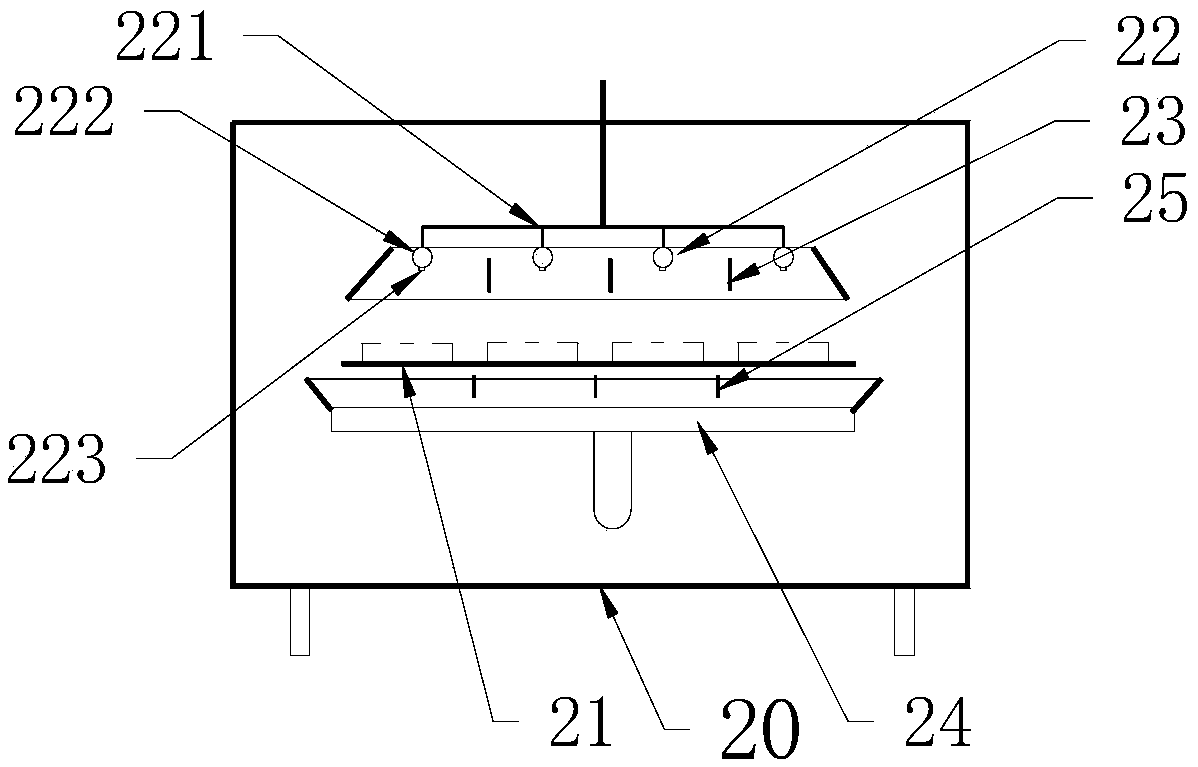

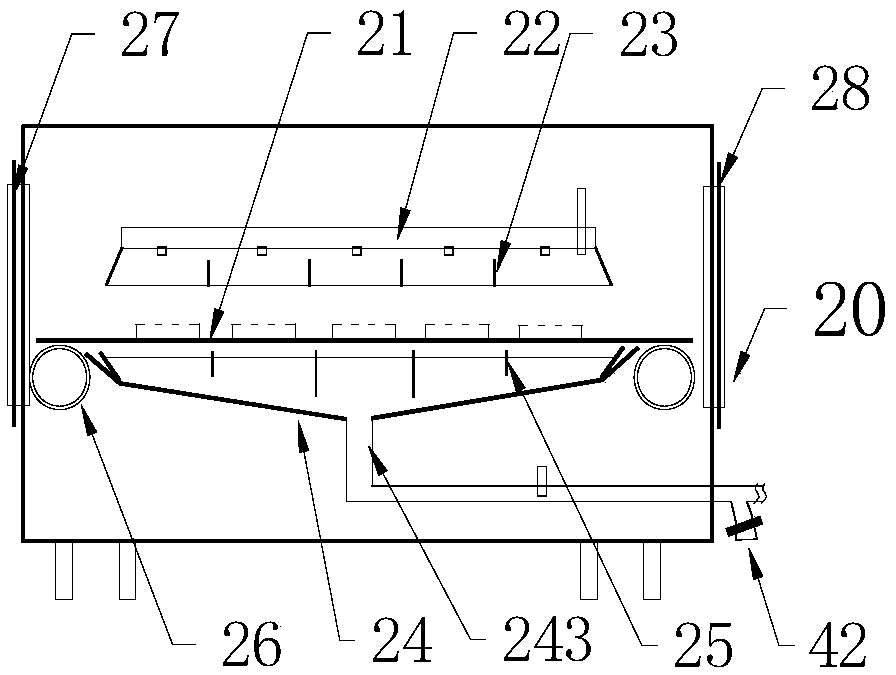

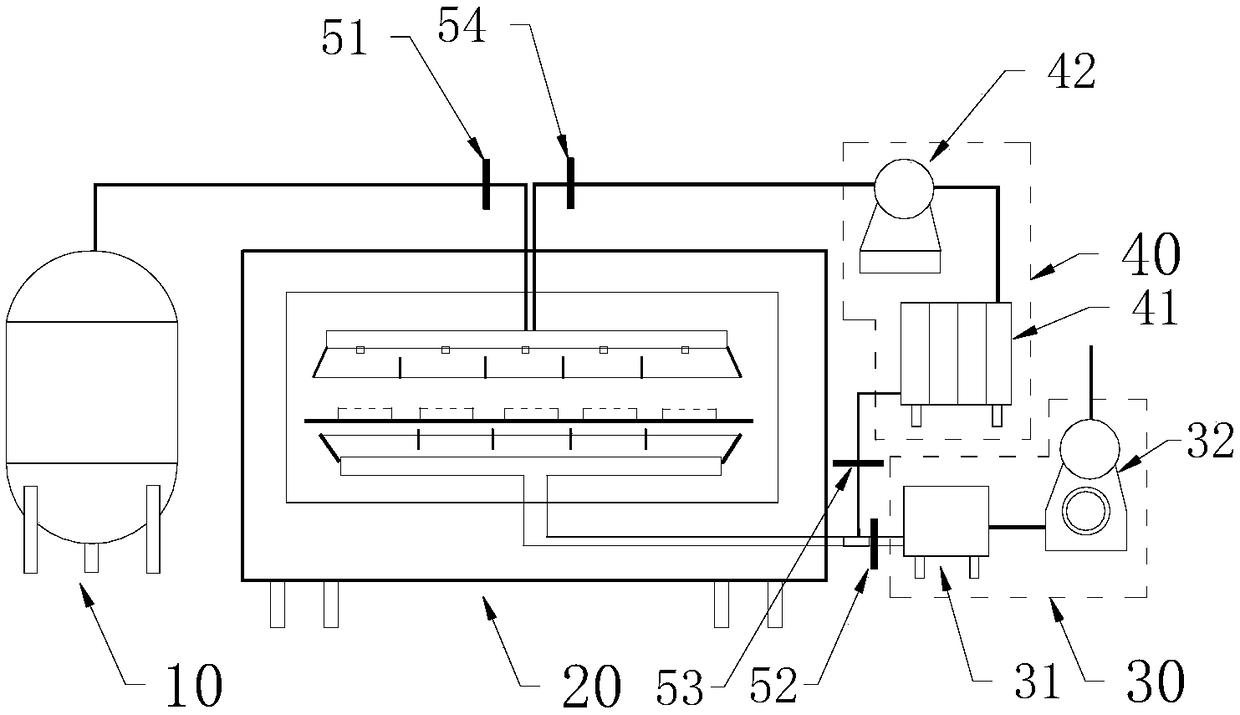

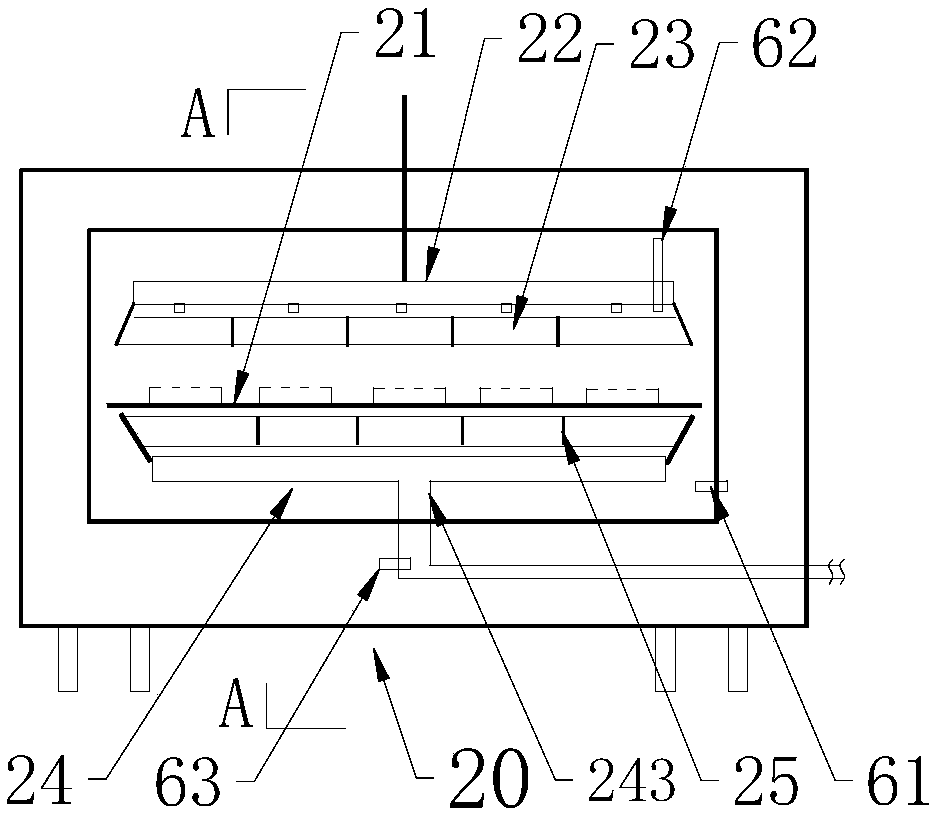

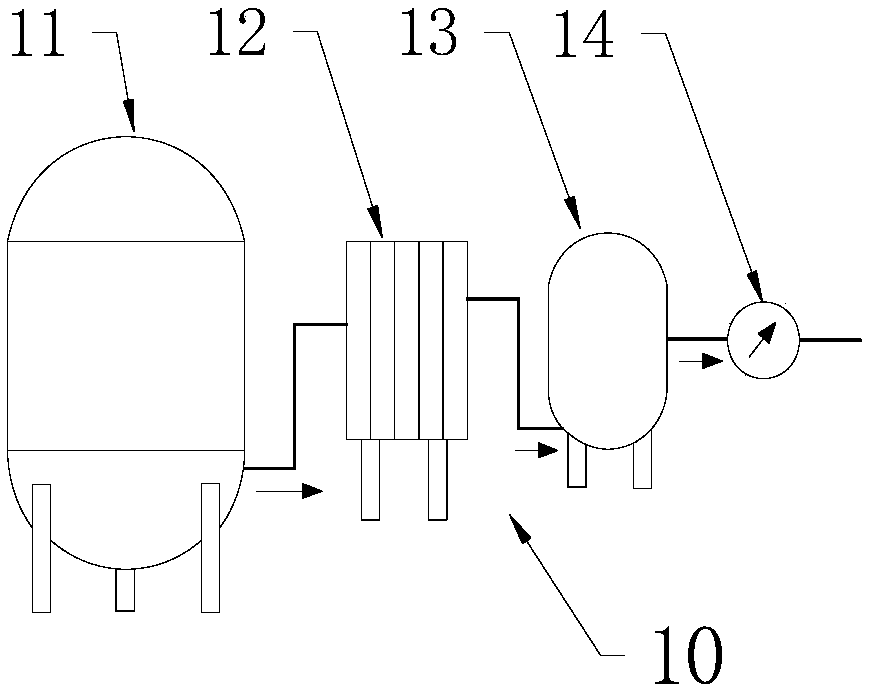

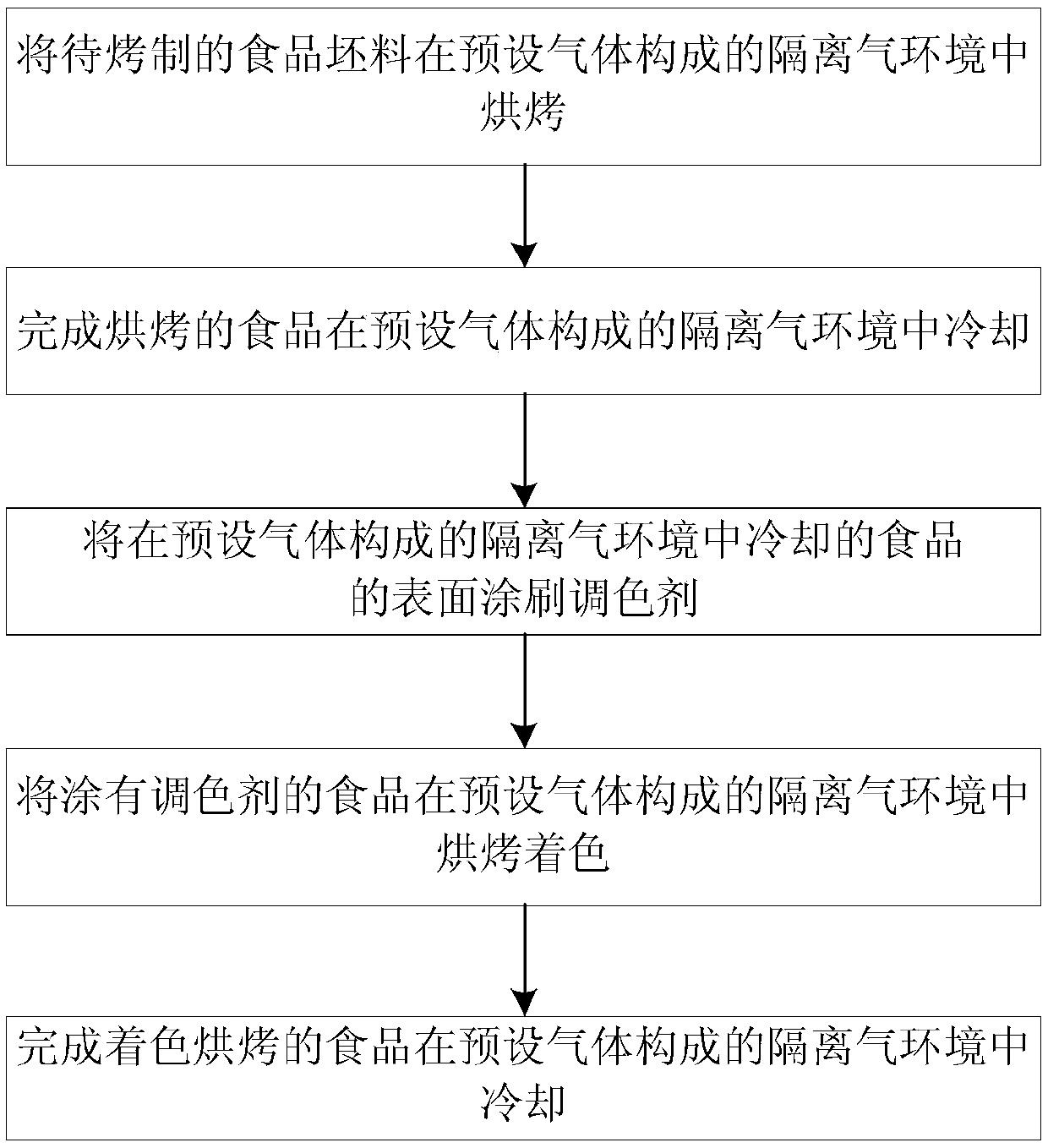

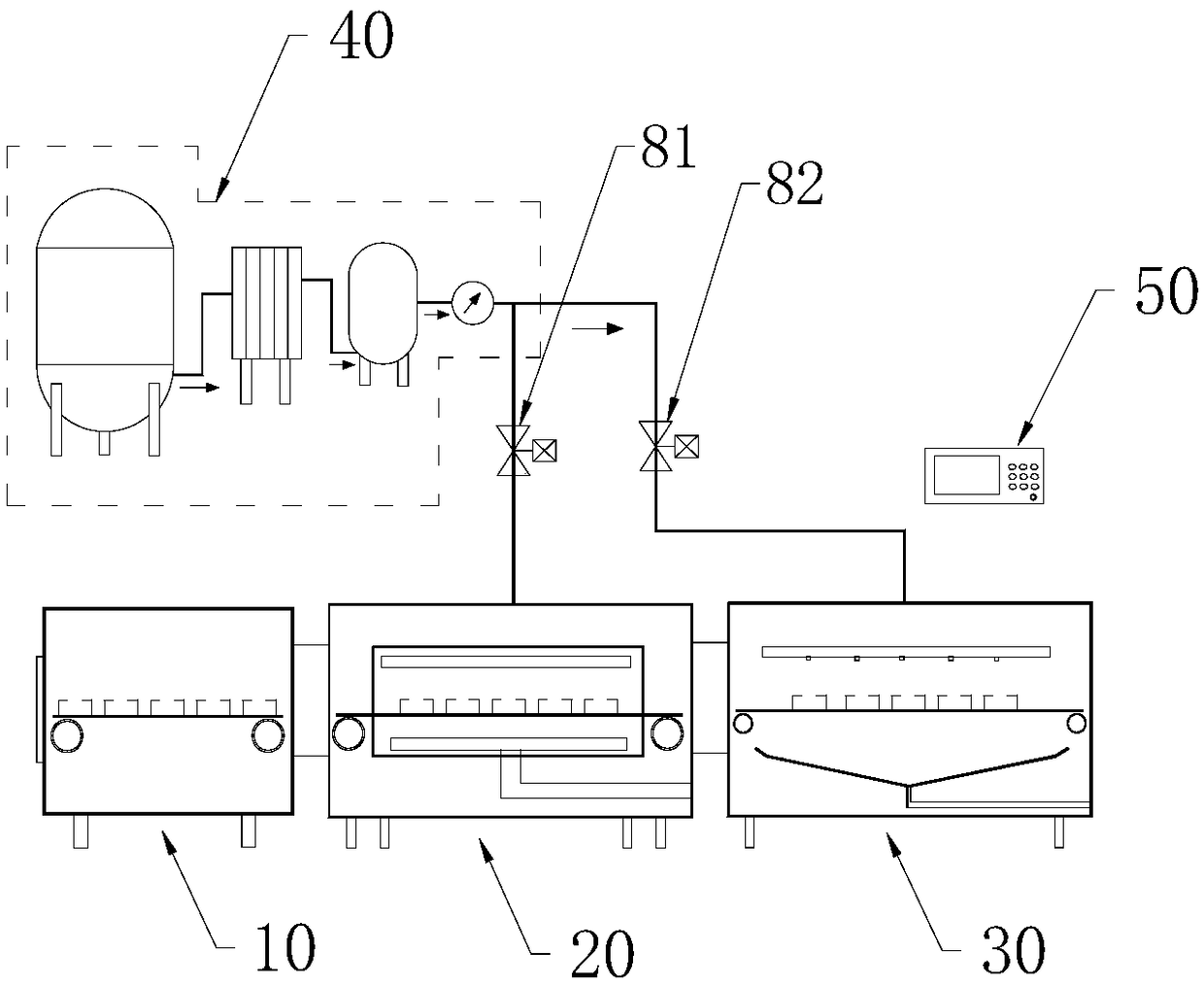

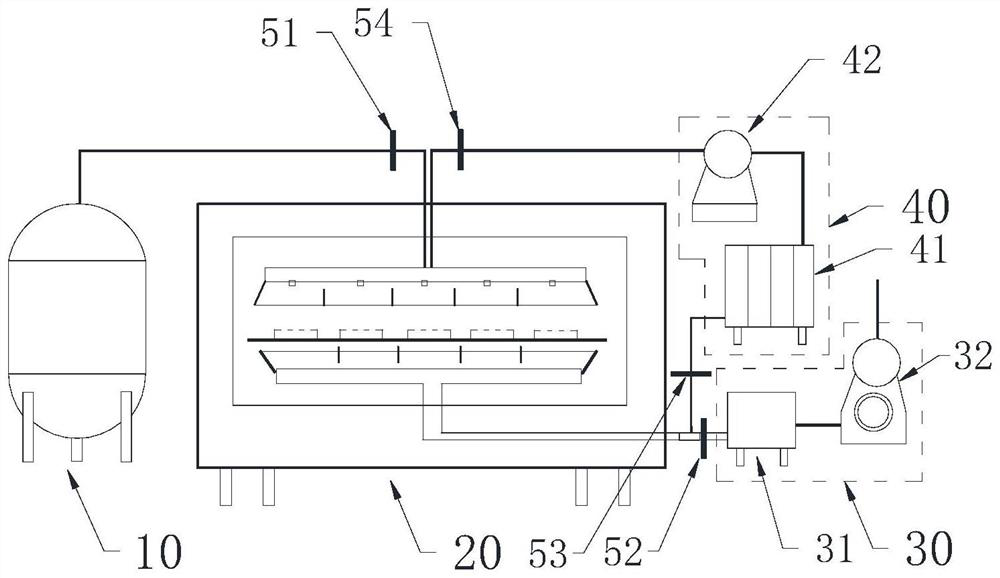

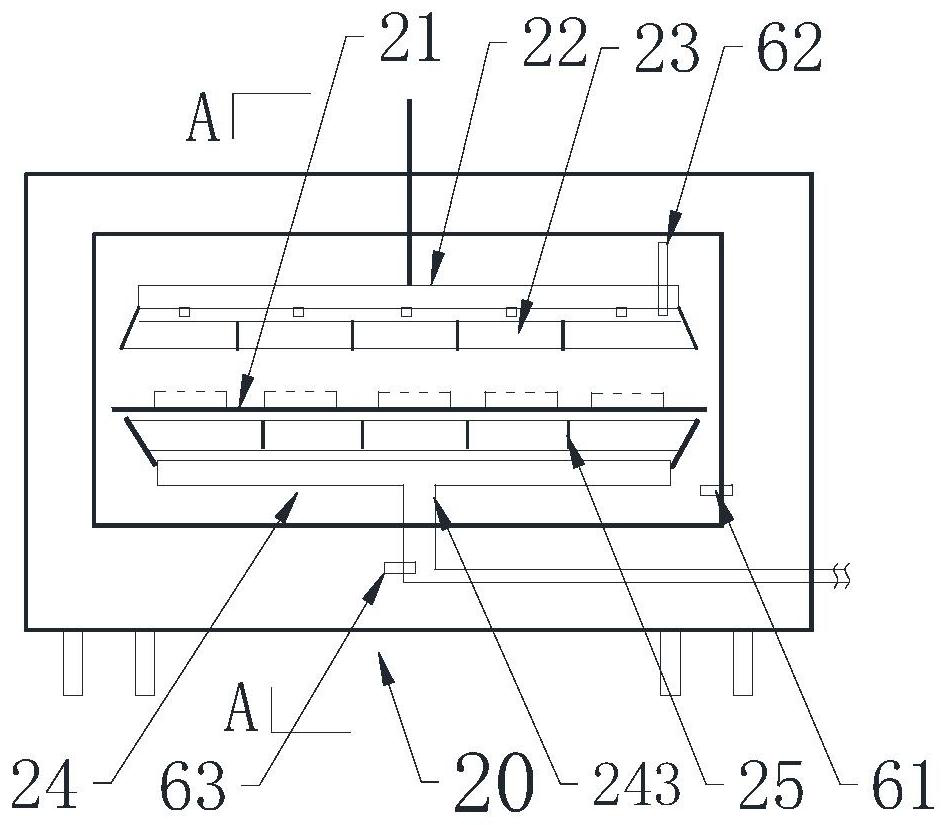

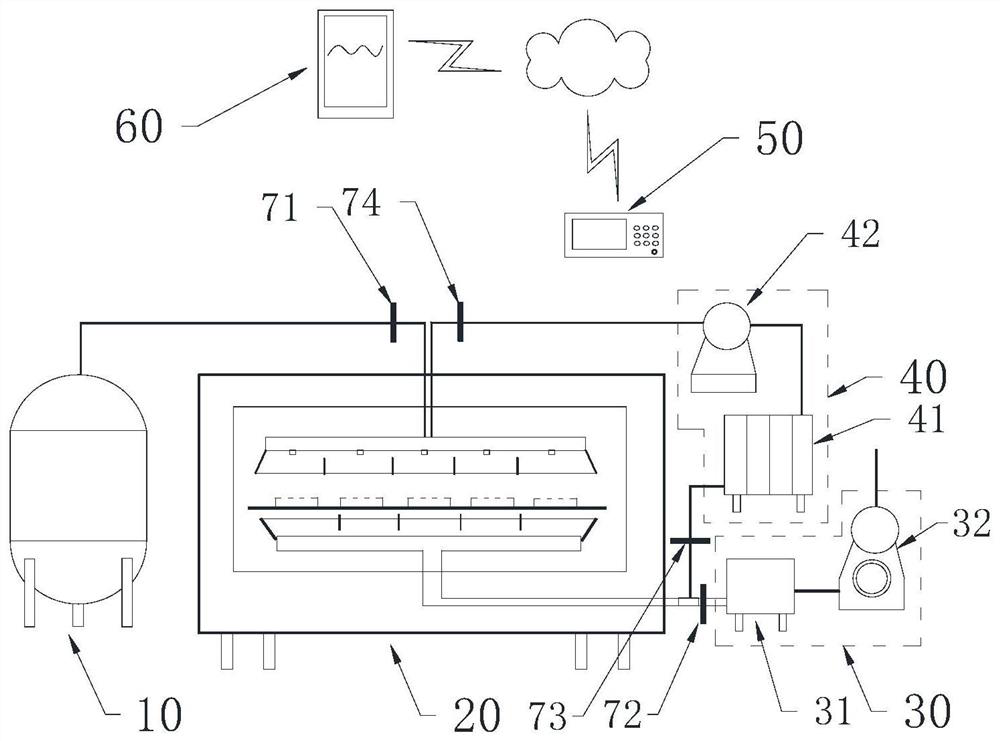

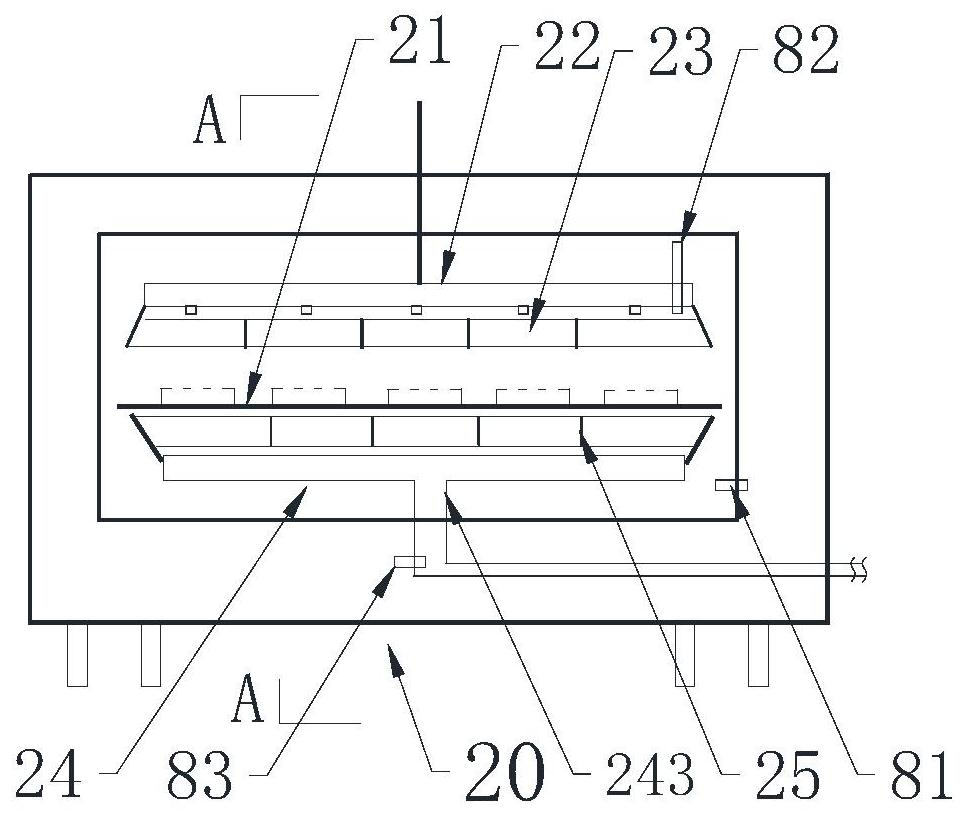

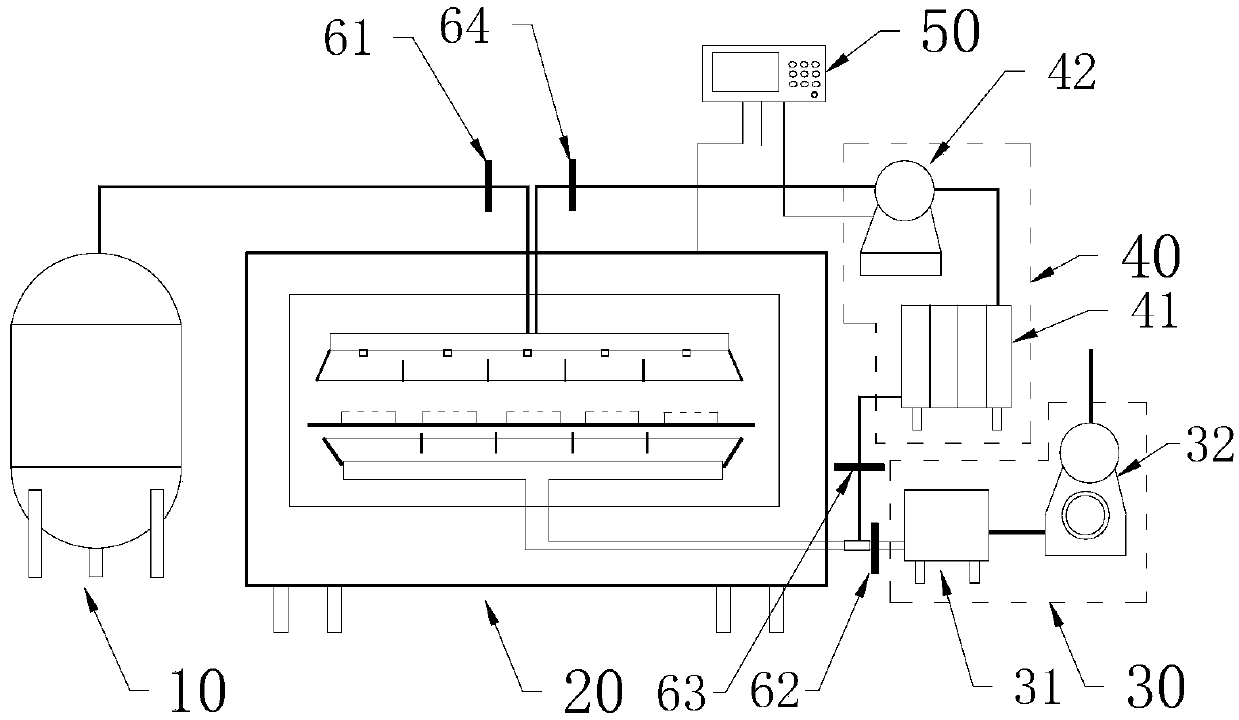

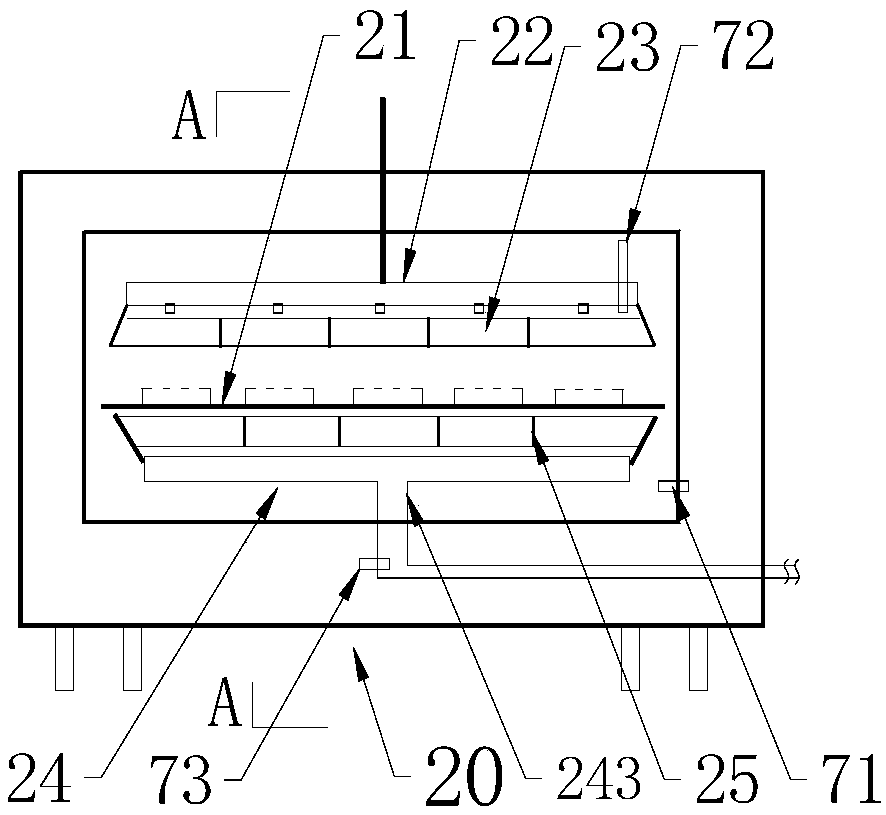

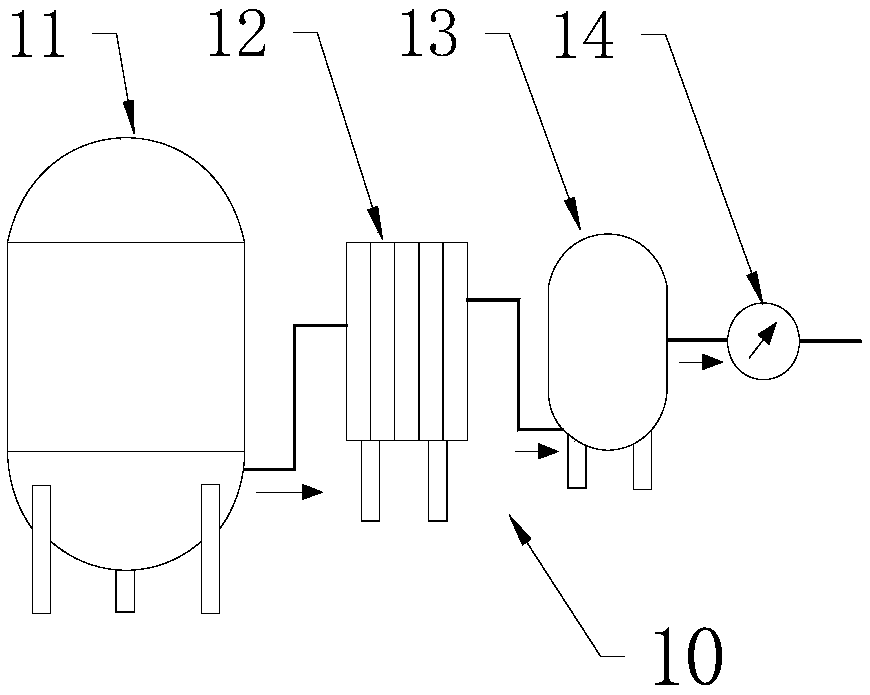

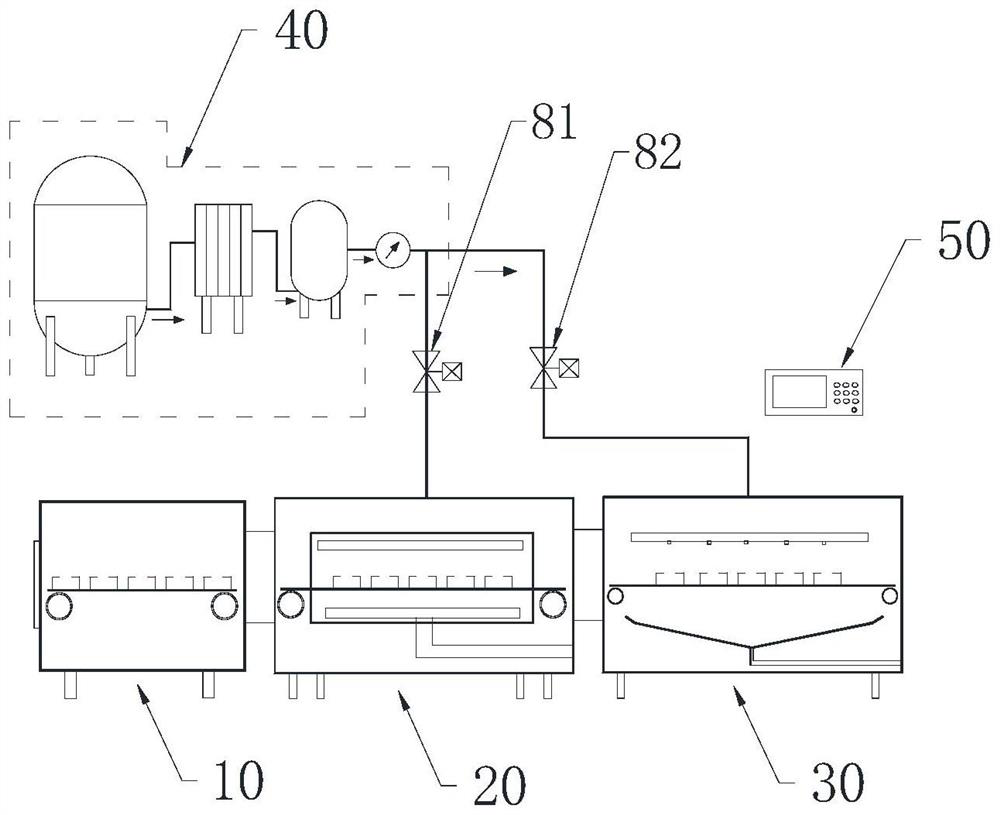

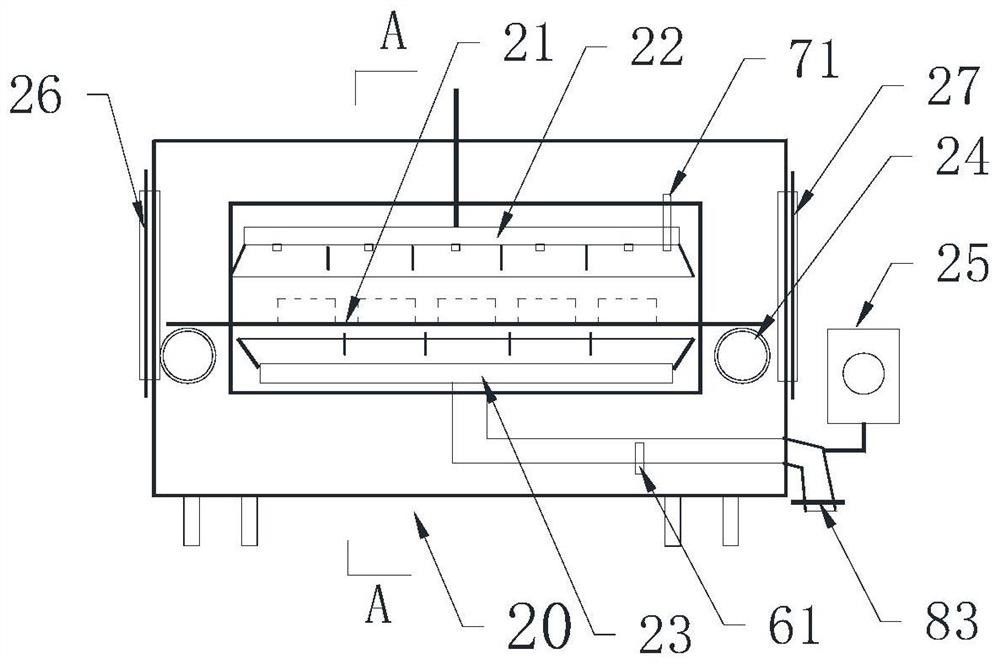

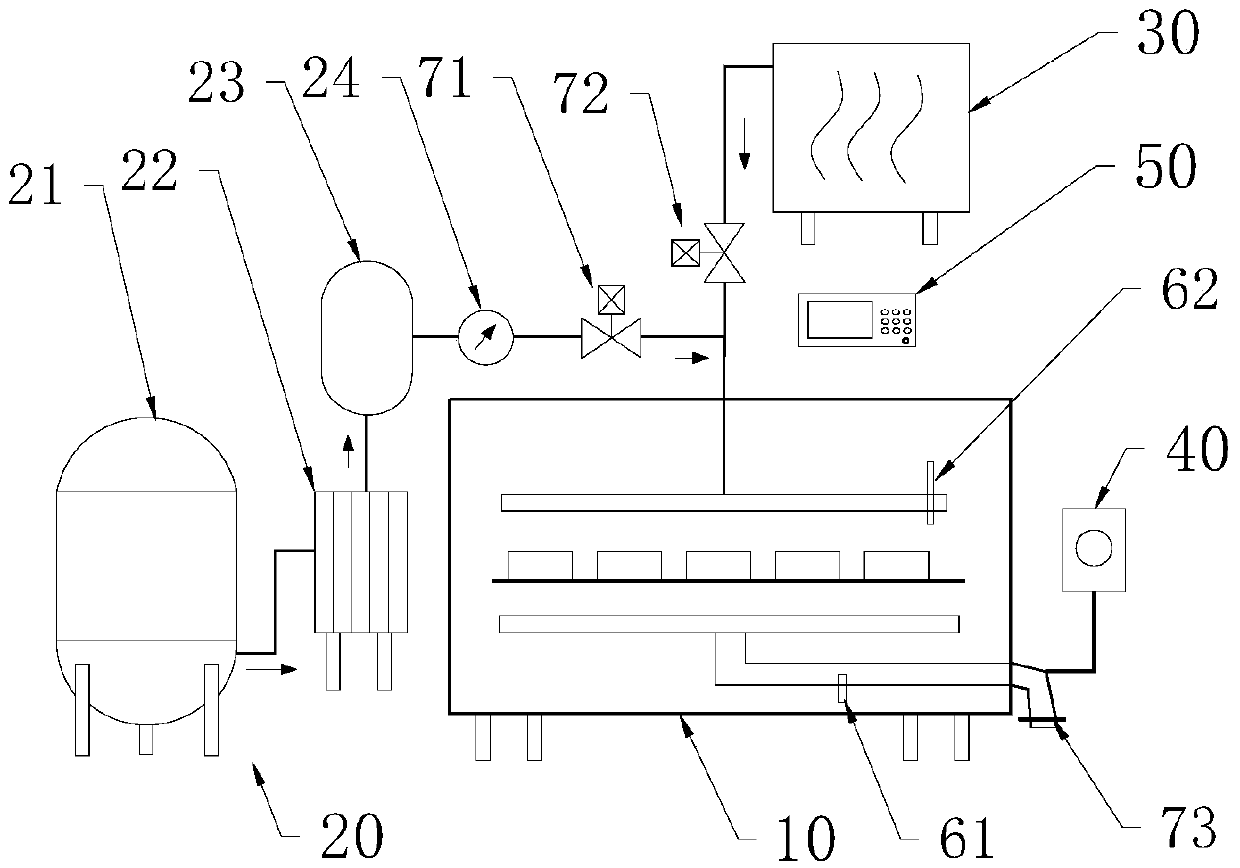

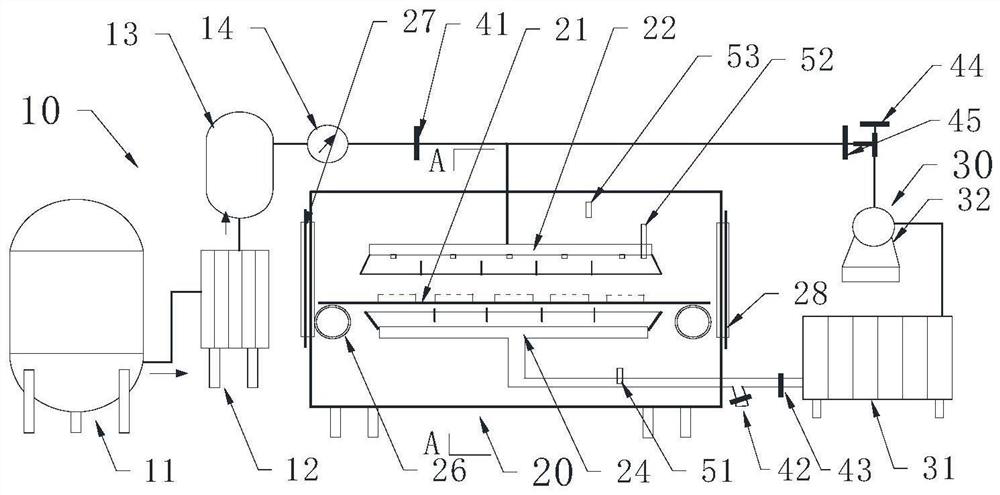

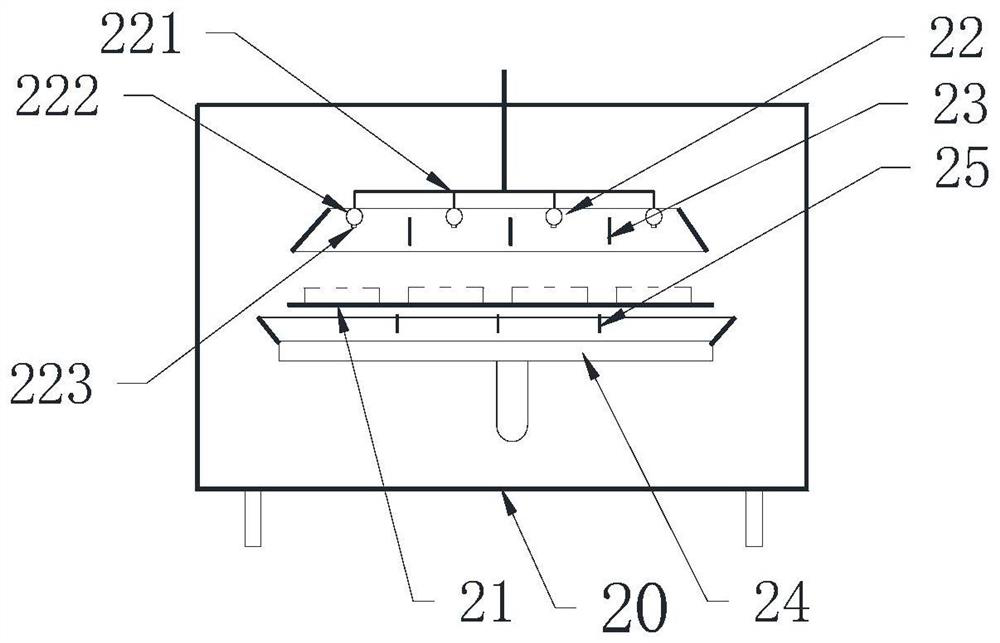

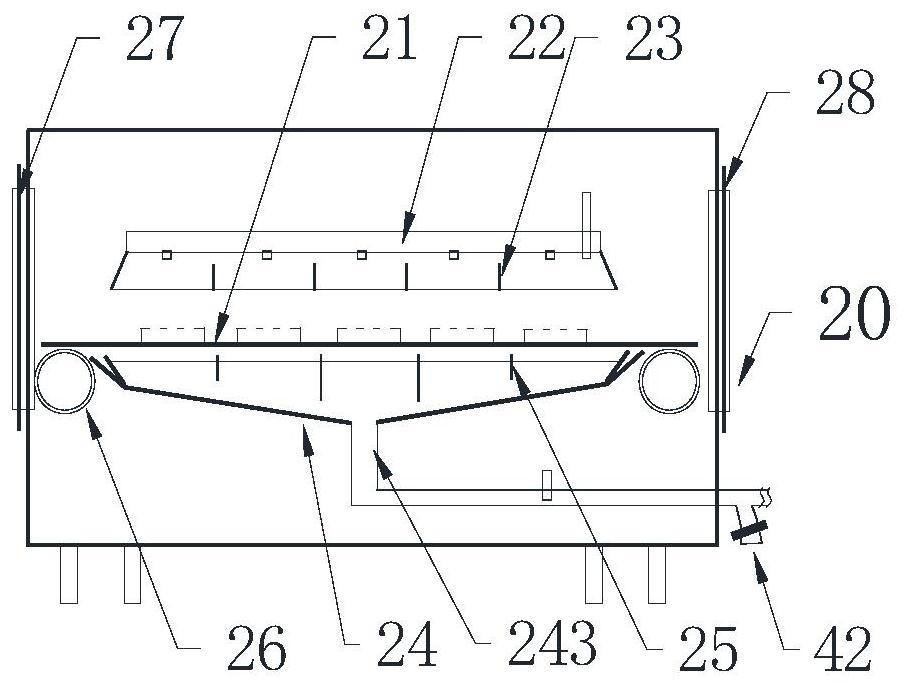

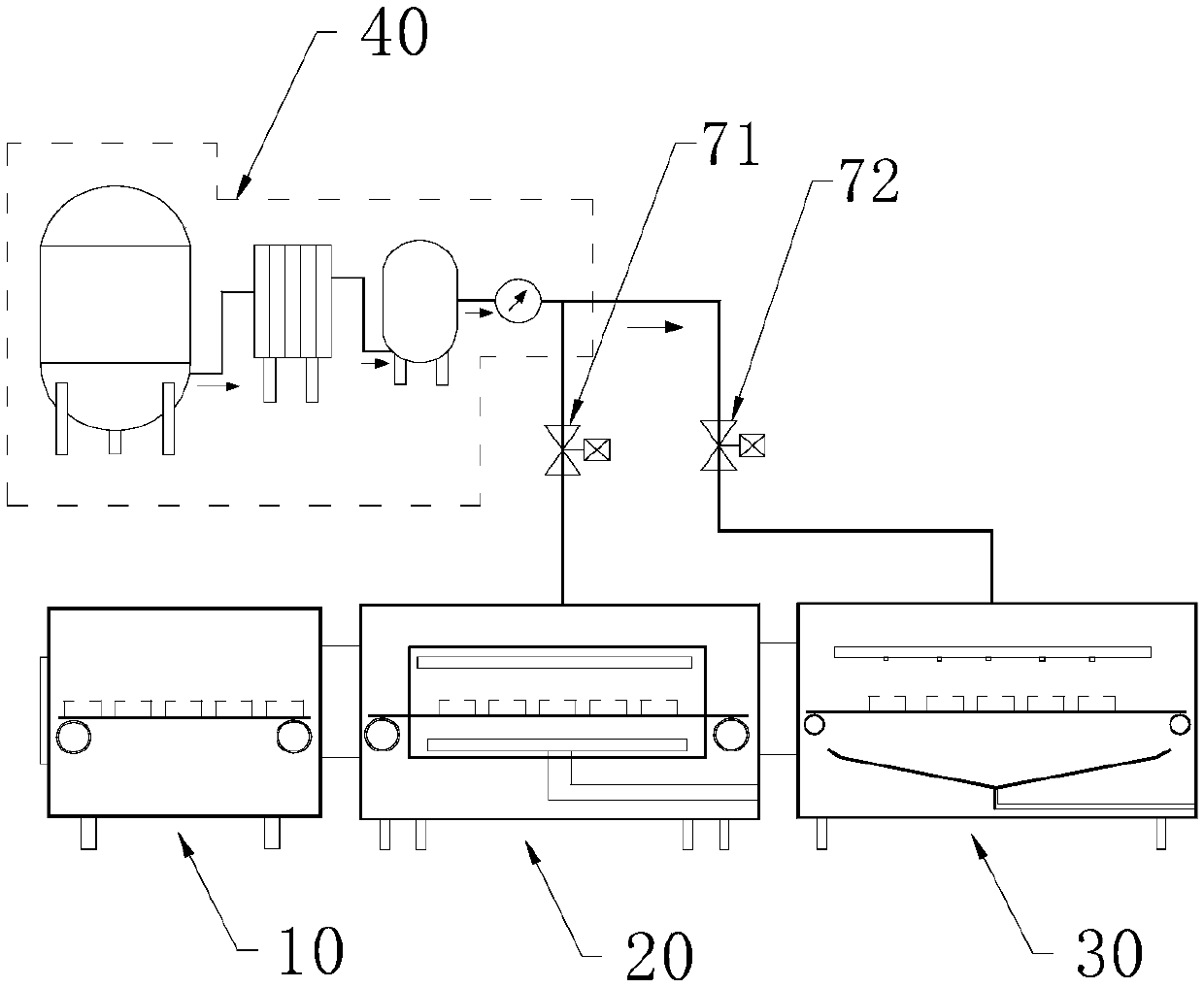

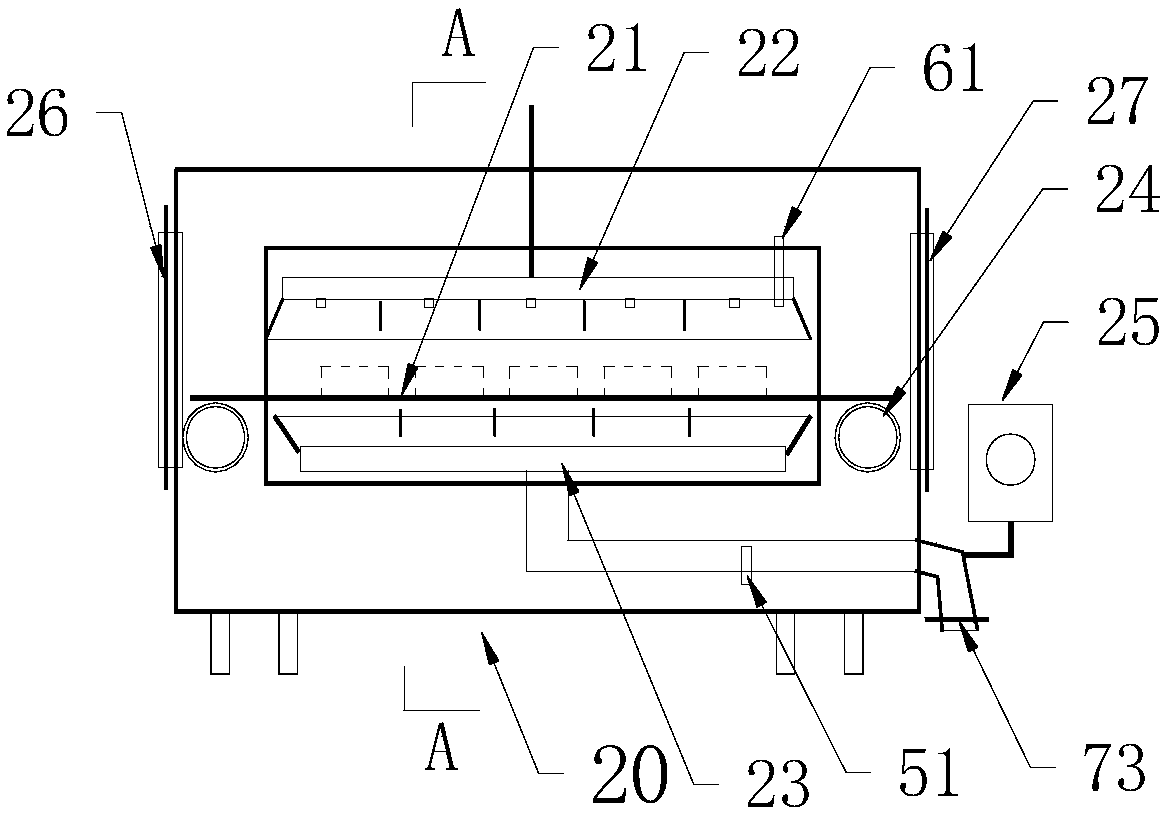

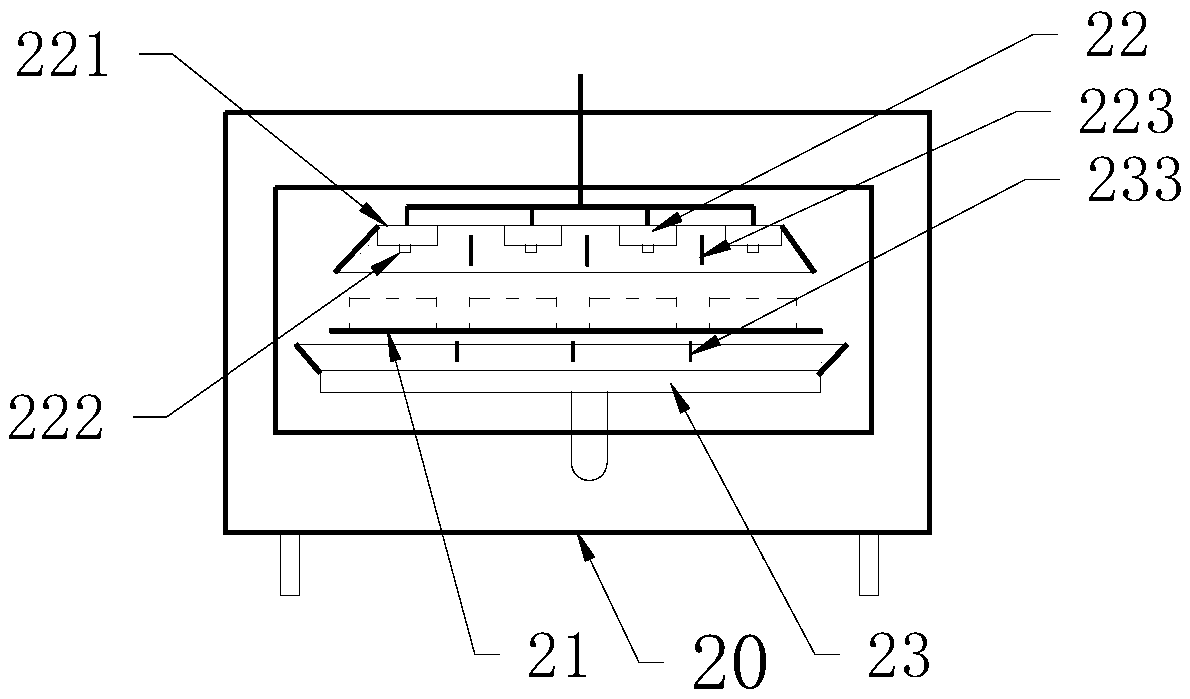

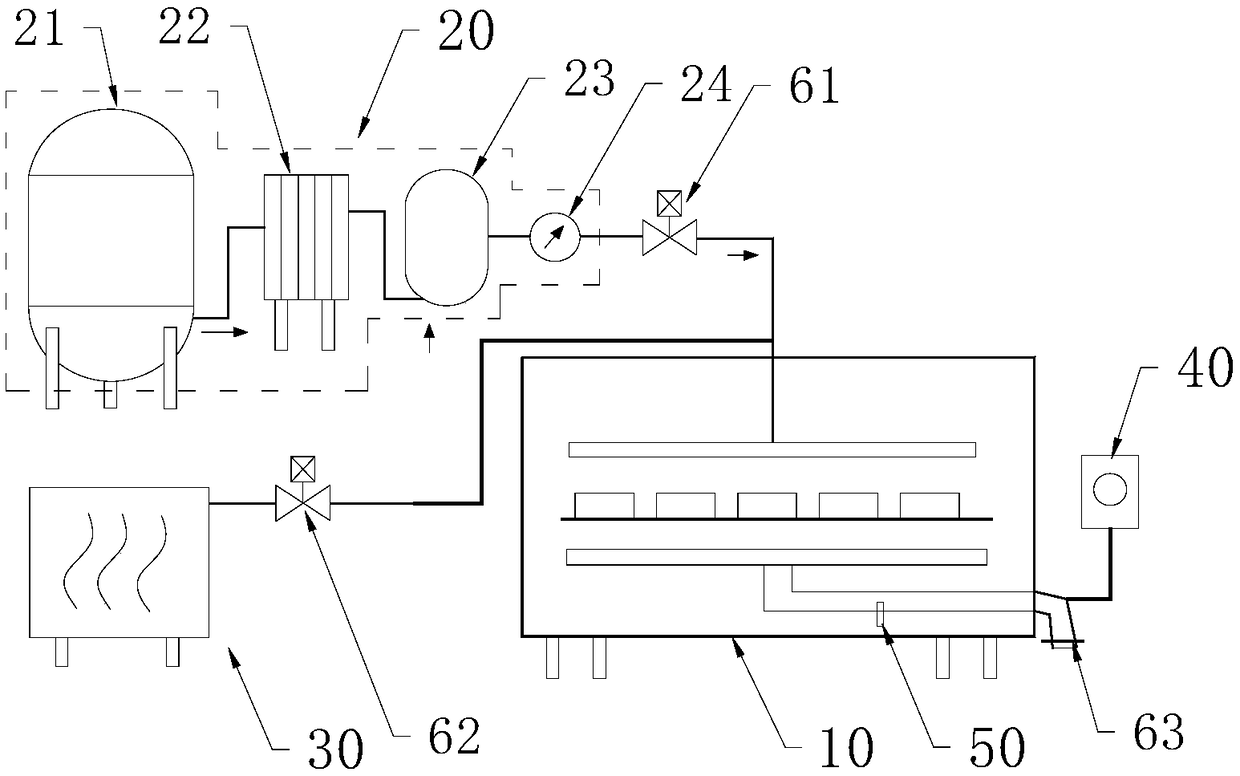

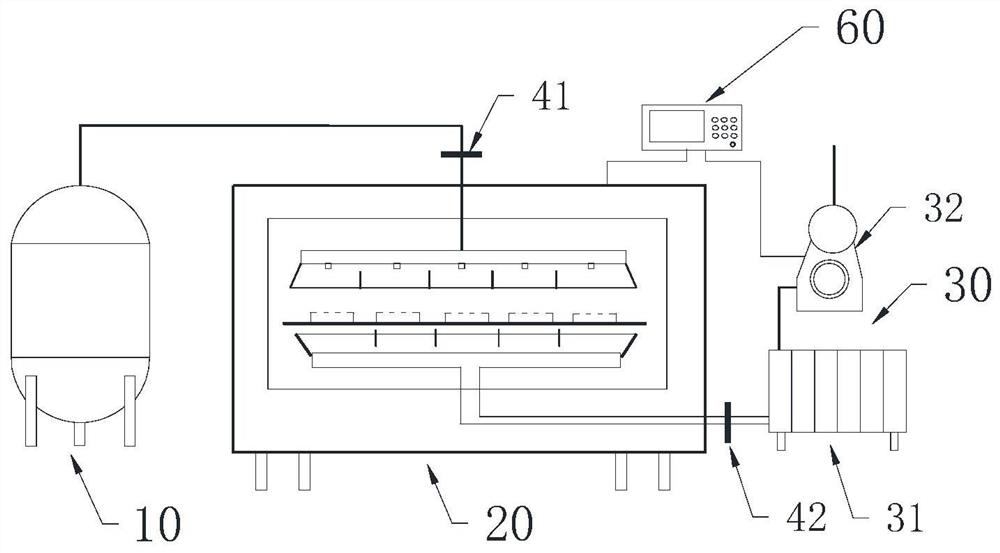

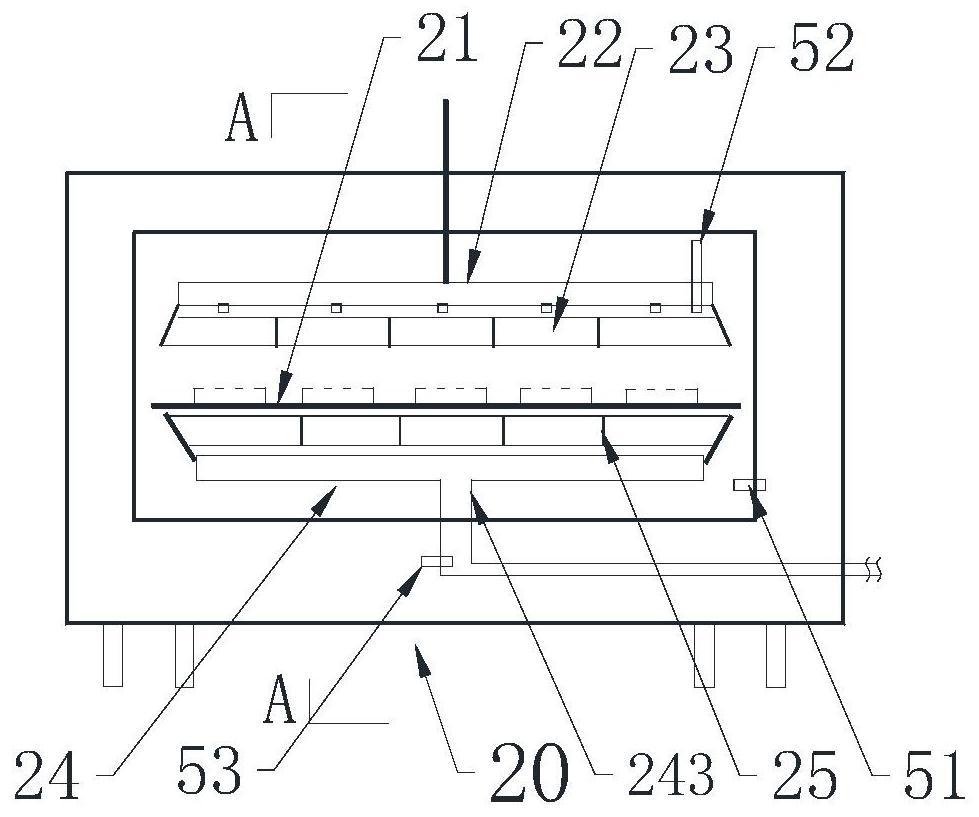

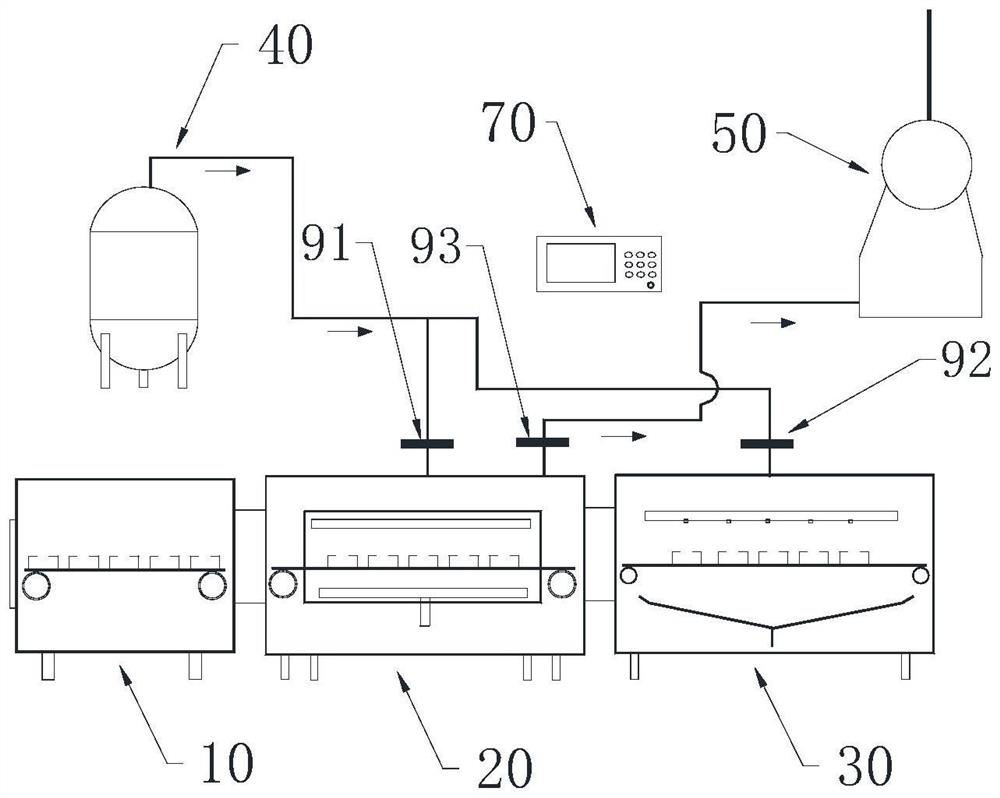

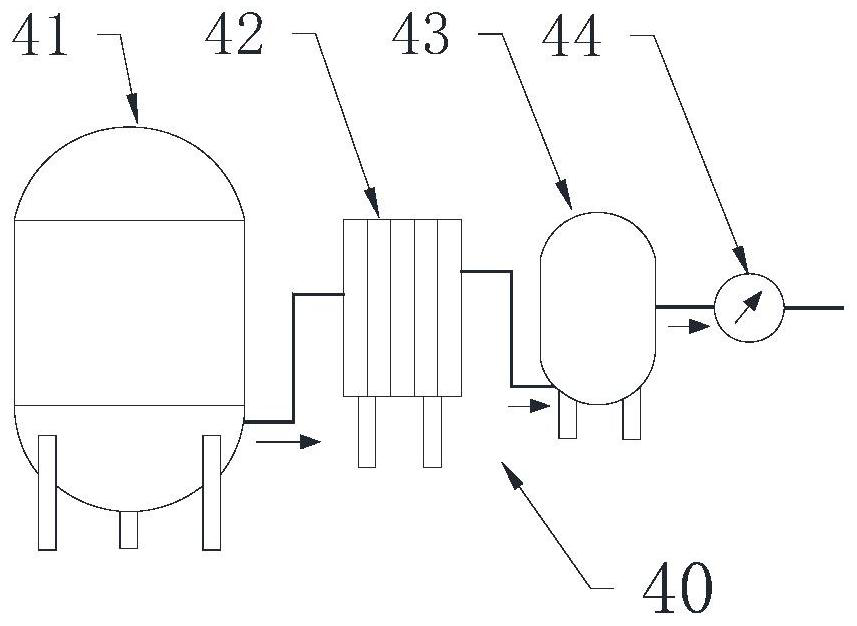

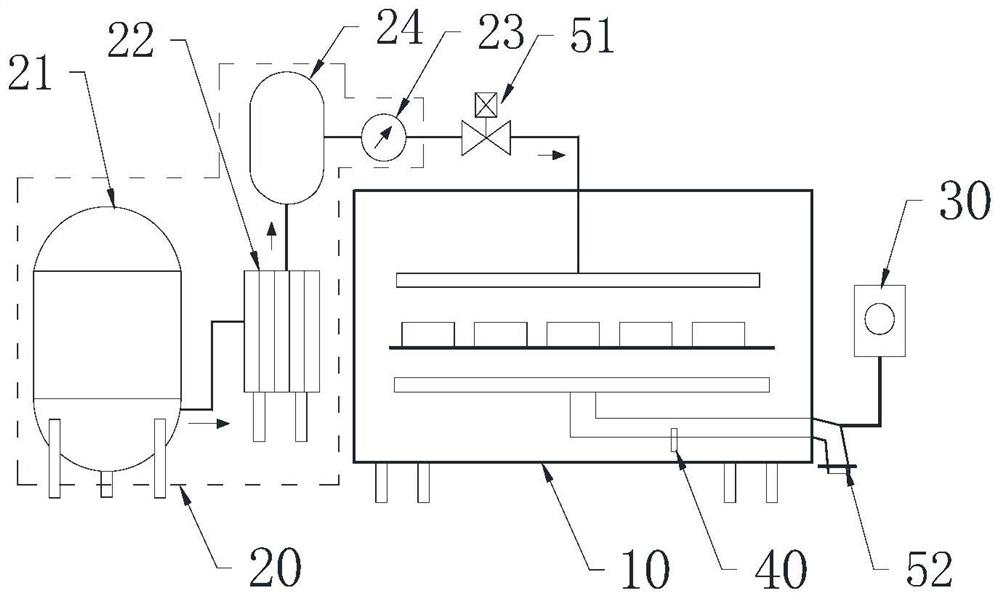

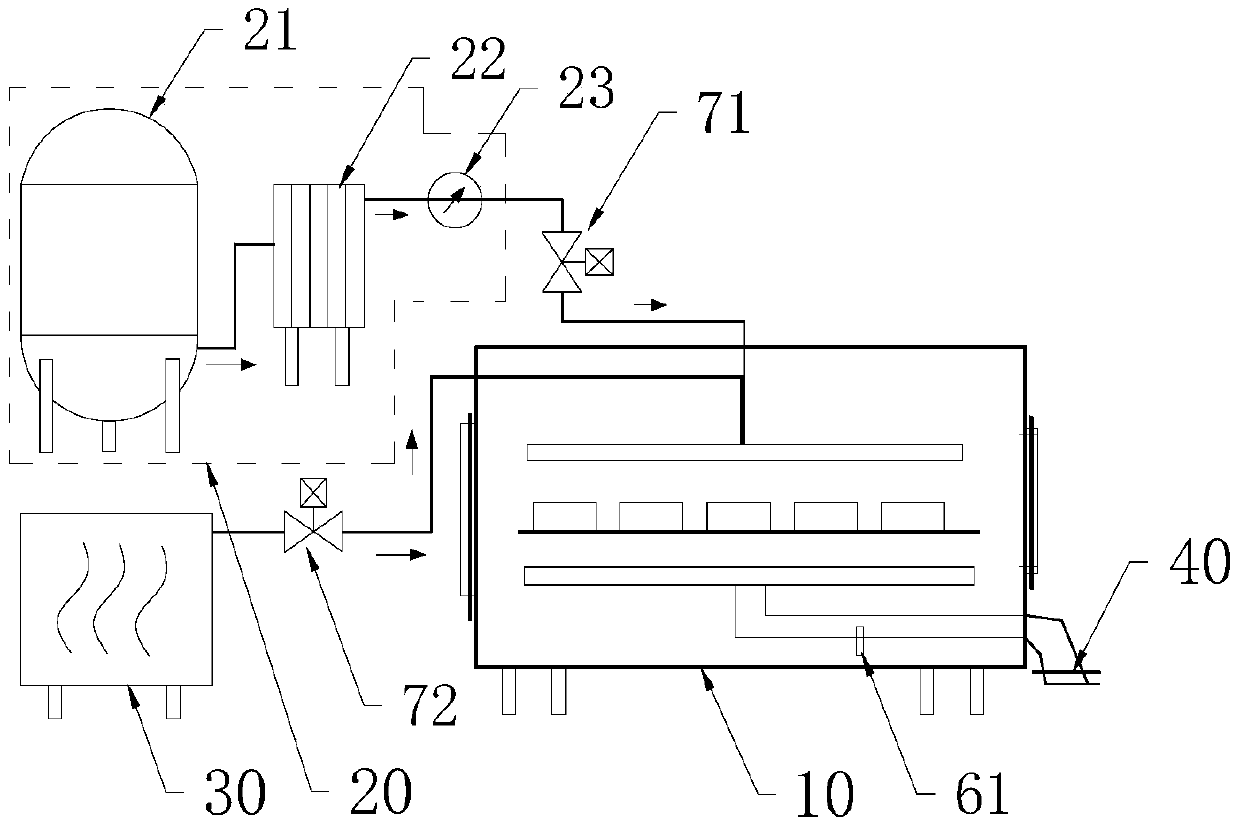

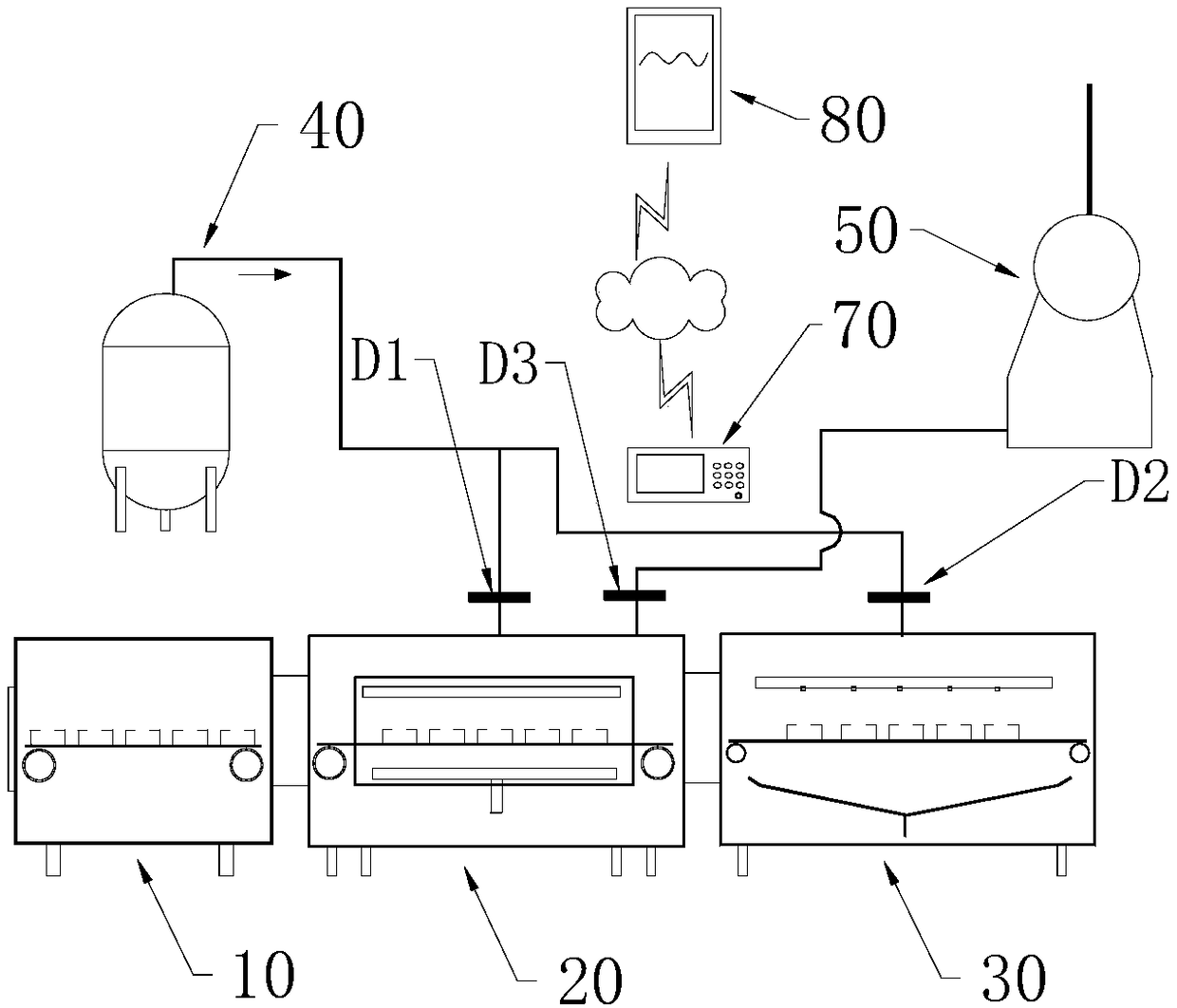

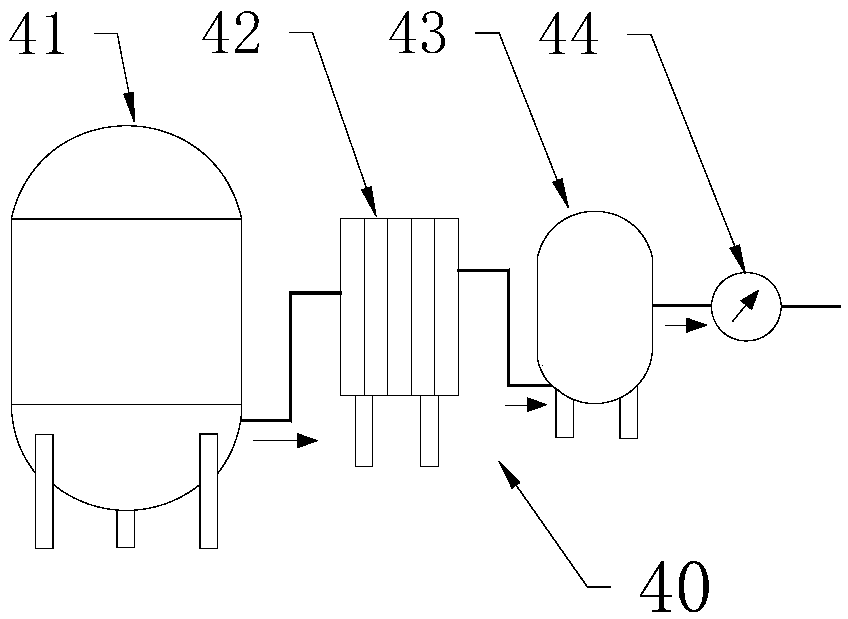

Intelligent food vacuum baking system suitable for improving crispy taste

ActiveCN109105411AImprove crispnessImprove uniformityOven air-treatment devicesCooking & bakingCooling chamber

The invention belongs to the food equipment field and especially discloses an intelligent food vacuum baking system suitable for improving a crispy taste. The system comprises a baking device with a built-in baking chamber, a cooling device with a built-in cooling chamber, a gas supply device suitable for conveying a carrier gas to the baking chamber and the cooling chamber, a vacuum device, a circulating device and a control device. The baking device and the cooling device are sealed and connected, and a gate is arranged through a sealing mode so that the baking chamber is separated from thecooling chamber. The food input port of the baking device and the food output port of the cooling device are provided with the gates through the sealing mode. Based on a built-in baking technology, the control device makes the vacuum device vacuumize the baking chamber so that the food is baked in a vacuum environment having the carrier gas, and makes the circulating device drive the carrier gas in the cooling chamber to circularly flow so as to cool the food. The food is baked in the vacuum environment having the carrier gas and is cooled in the circulating carrier gas, the crispy taste of the food is improved, oxidative deterioration objects and oxygen residues in the food are less, and the quality guarantee period of the food can be increased by 0.5-1 times.

Owner:揭阳市港荣食品发展有限公司

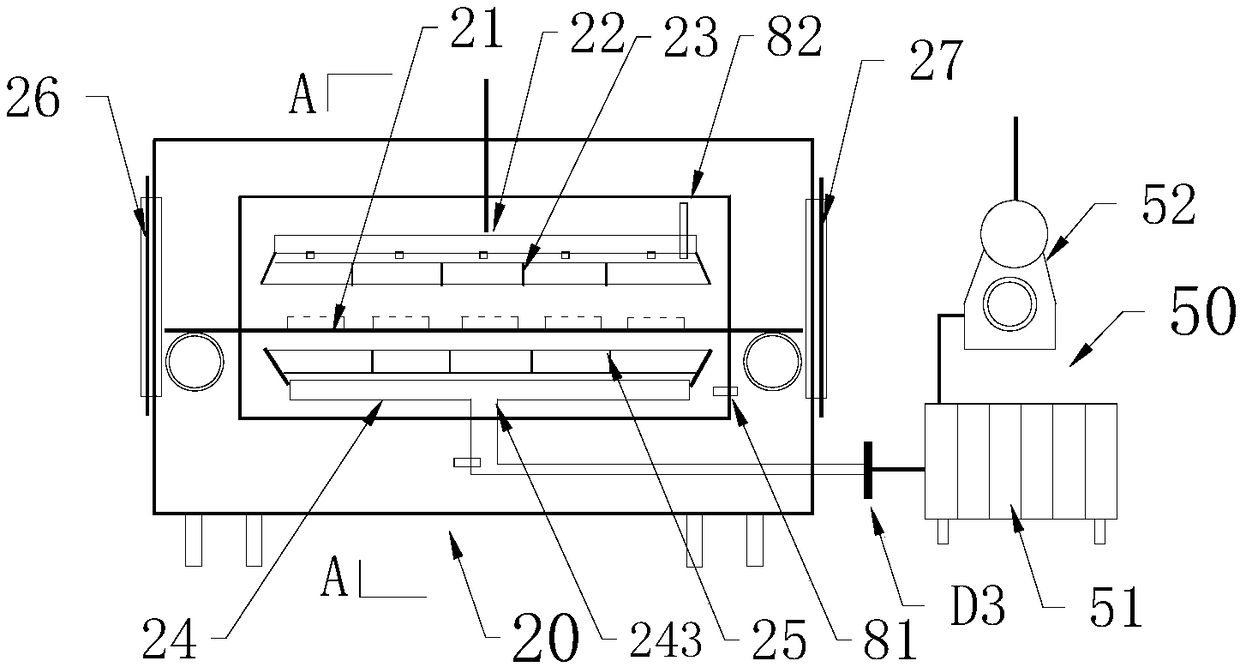

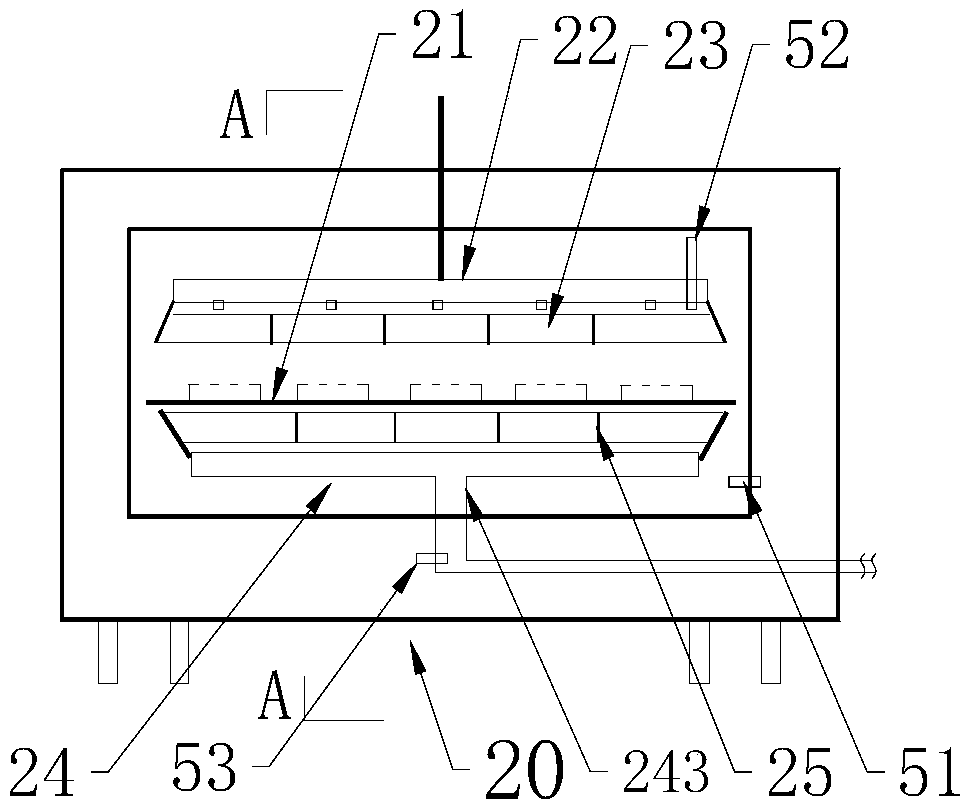

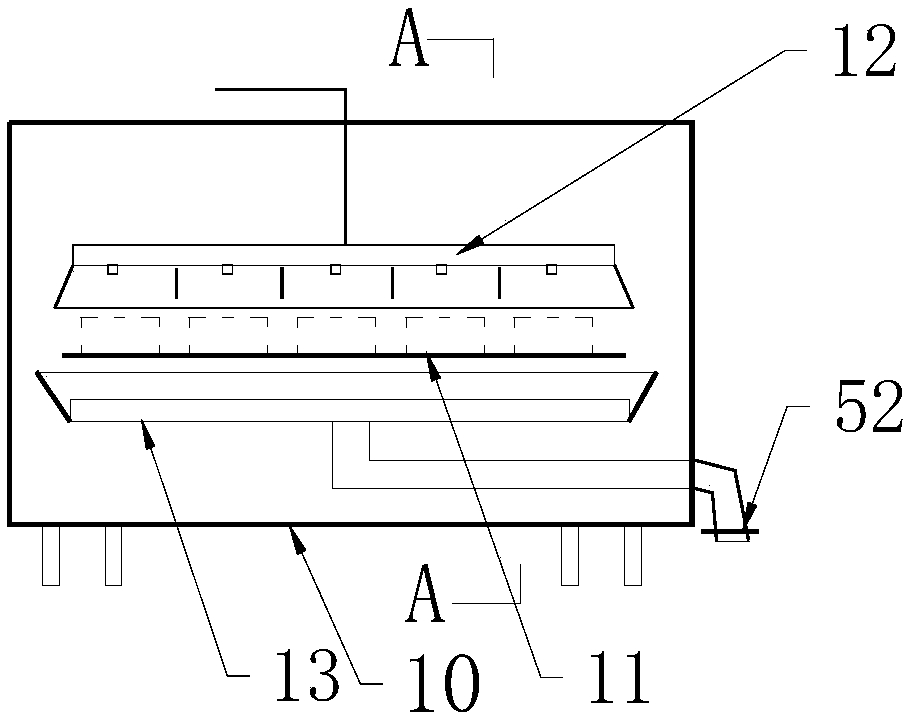

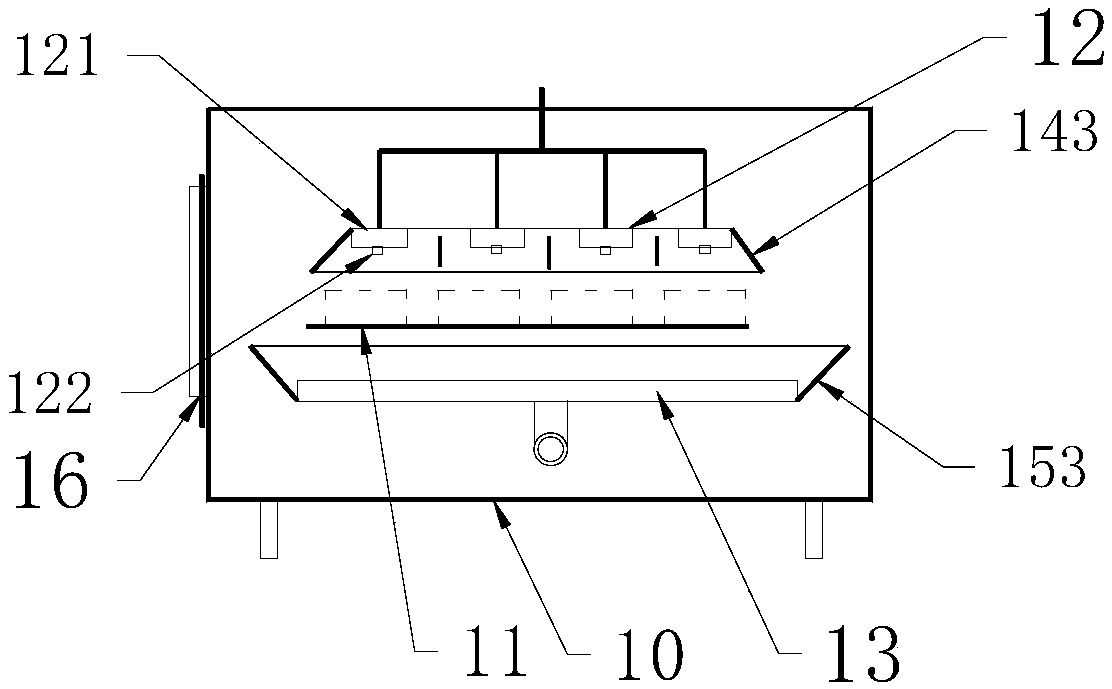

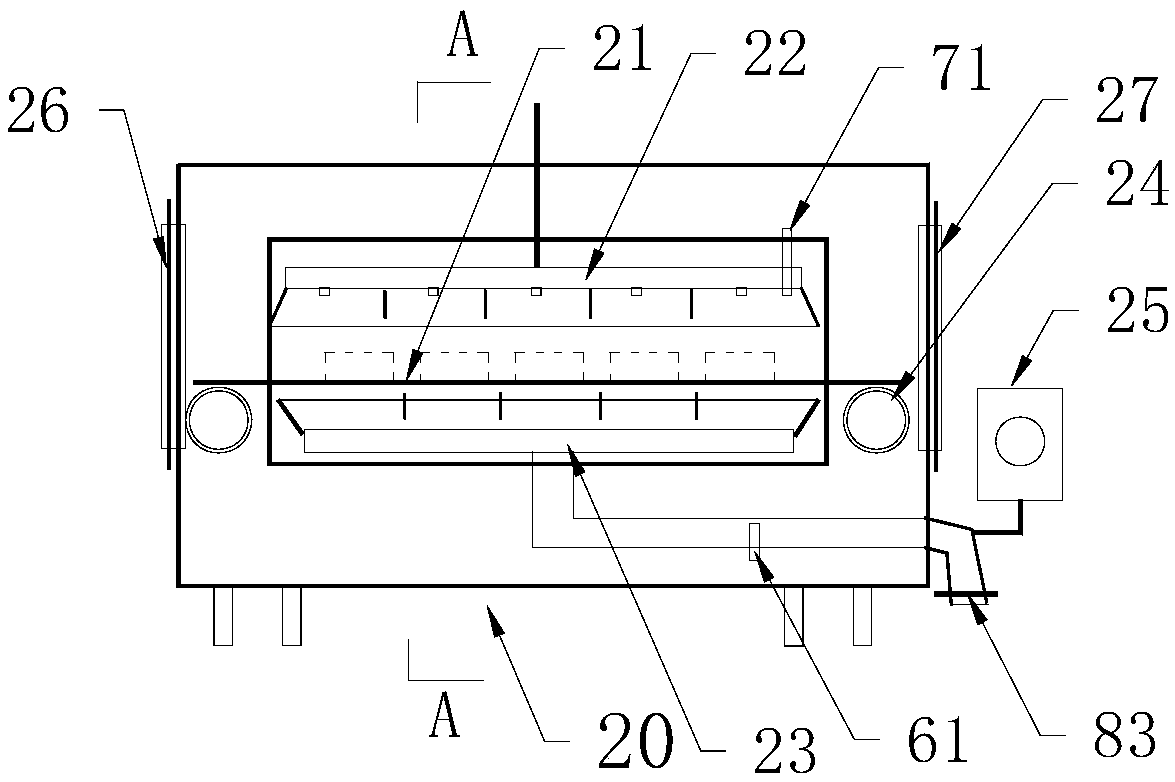

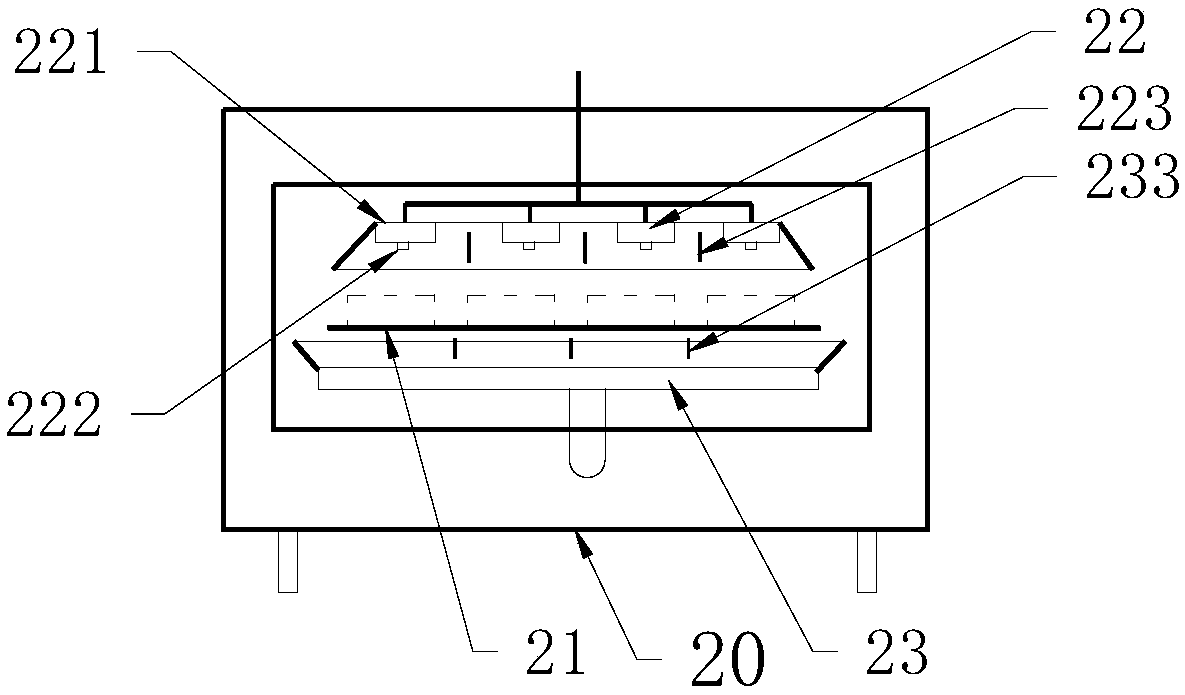

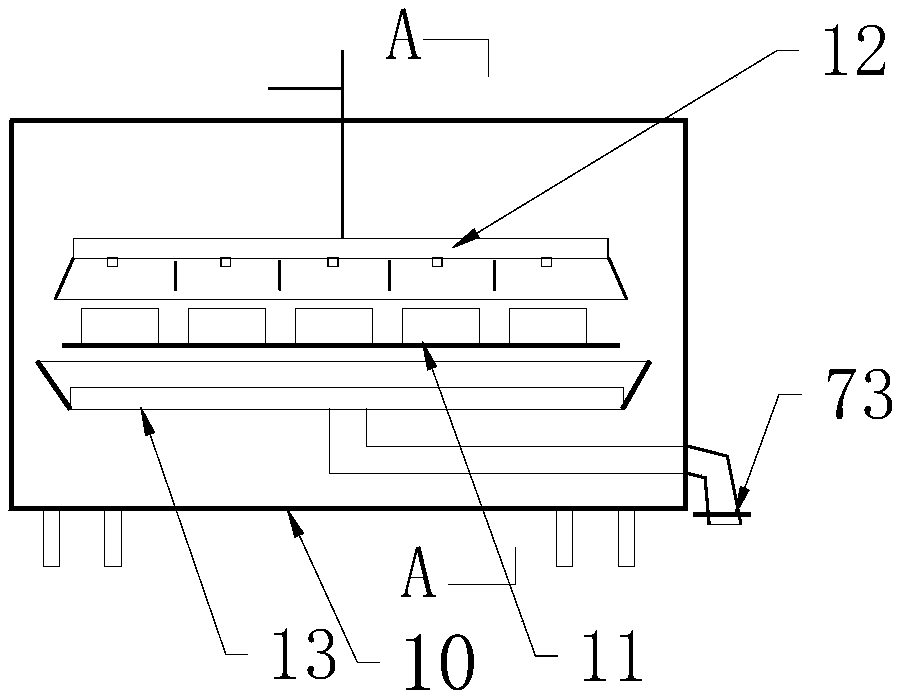

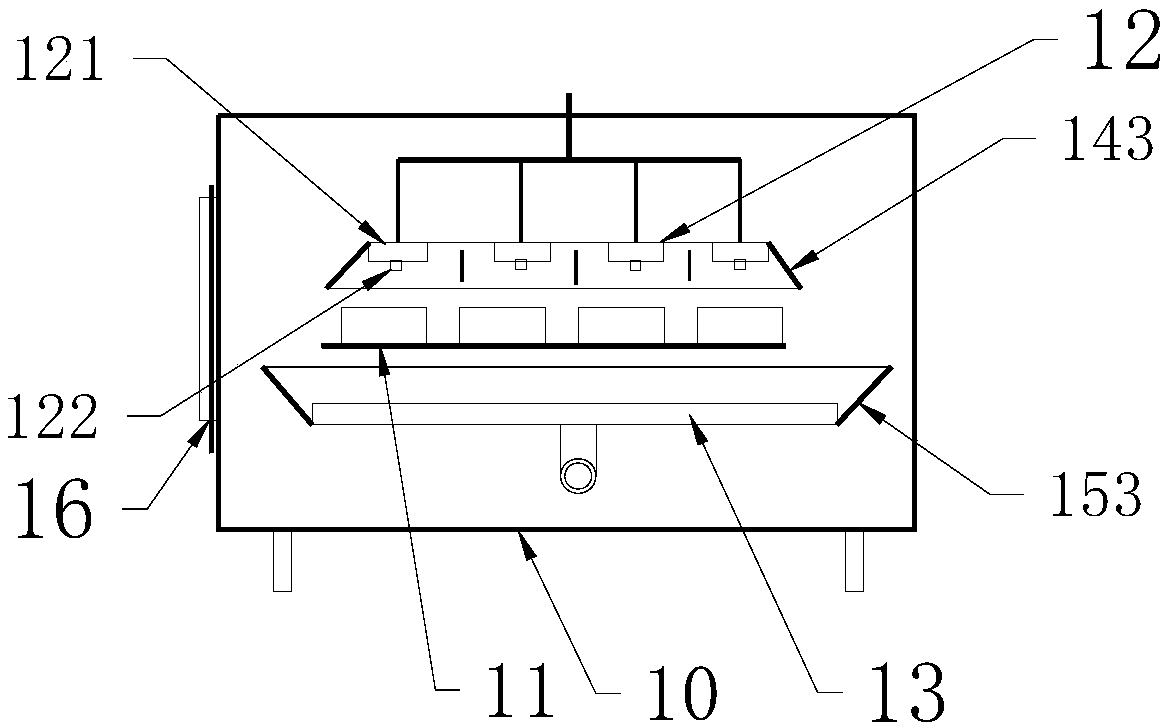

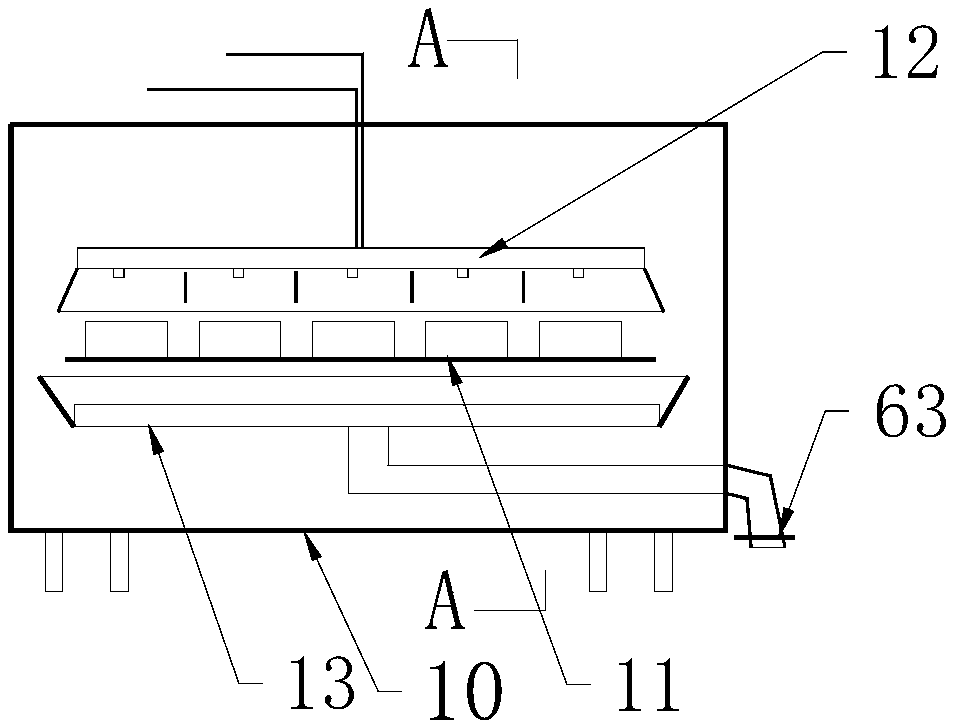

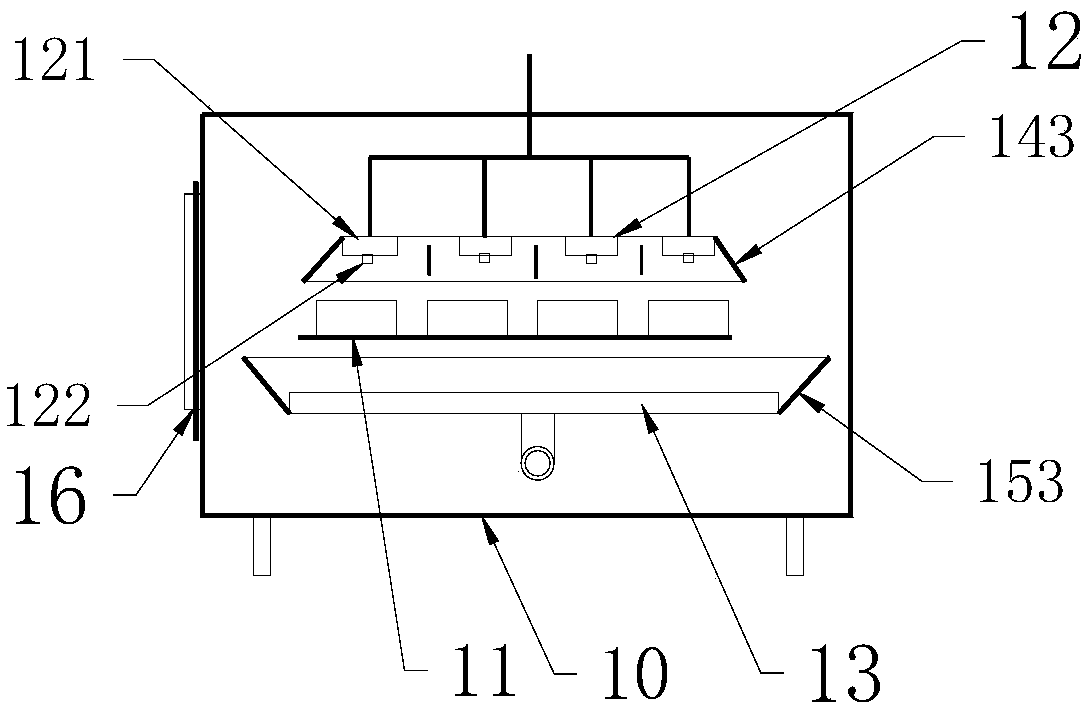

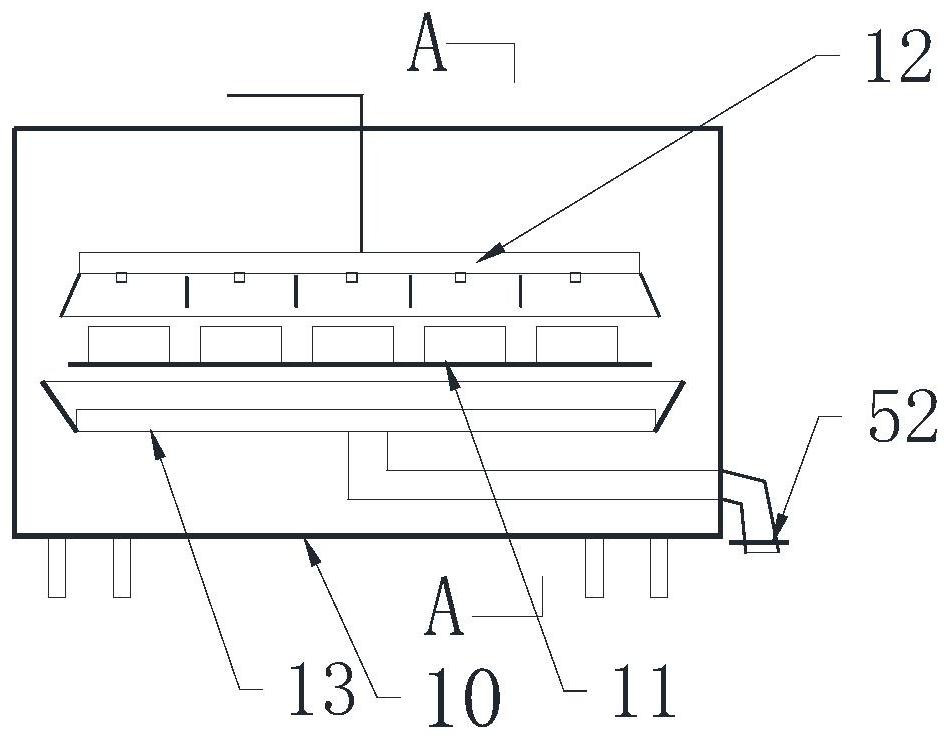

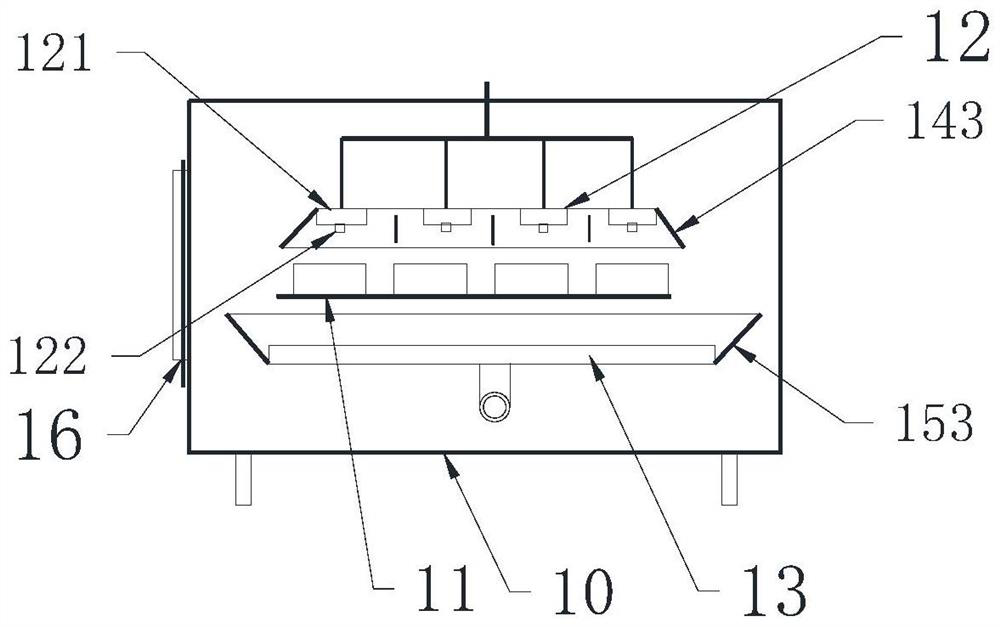

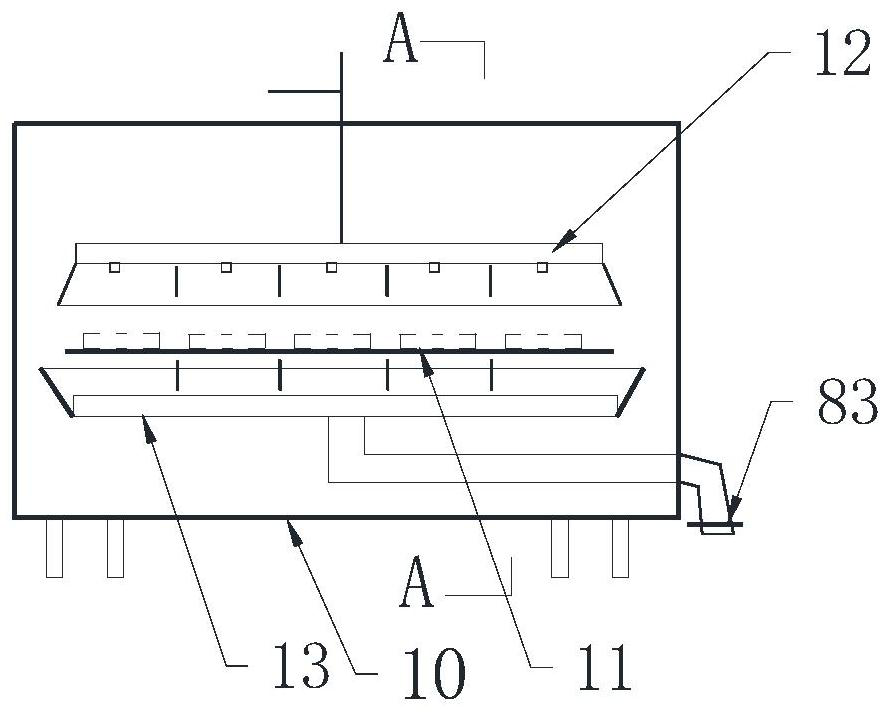

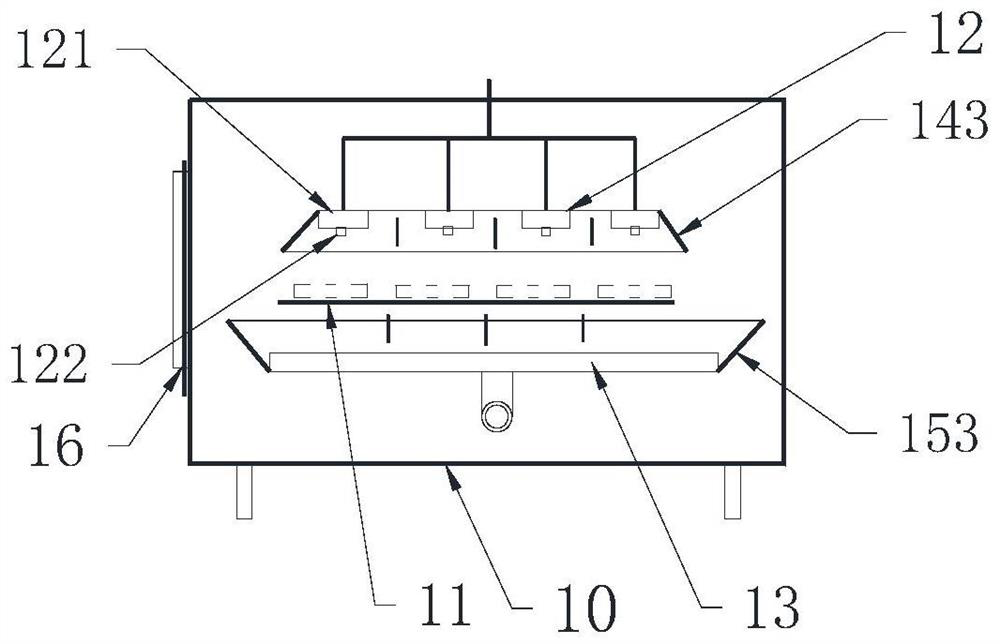

Vacuum food baking equipment

InactiveCN109380457AImprove crispnessImprove uniformityHollow article bakingProcess engineeringOxygen

The invention belongs to the field of food equipment and particularly discloses vacuum food baking equipment. The equipment comprises a gas supply device, a baking device and a vacuum device. A gate is arranged at an access port in a sealing mode, wherein the access port is suitable for food input and output and is formed in one side of the baking device; gas spraying heads and gas collecting heads which are suitable for uniform distribution of carrier gas and a baking tray which is suitable for bearing food are arranged in a baking chamber of the baking device; the gas supply device is communicated with the gas spraying heads and conveys the carrier gas into the baking chamber. The vacuum device is communicated with the gas collecting heads and used for providing a vacuum environment forthe baking chamber and is suitable for baking food in the vacuum environment with the carrier gas. The baking equipment is operated to generate the vacuum environment, and food is subjected to vacuumboiling and puffing treatment and then baked in the vacuum environment with the carrier gas. The crispness and crispness uniformity of the baked food in the vacuum environment are obviously improved,the carrier gas is discharged with baked volatile matters in time, deteriorated fat-oxidative matter and oxygen residues in the food are further reduced, the preservation of the food is facilitated, and the shelf life can be prolonged by 0.5-1 time.

Owner:李明守

Cooling device suitable for improving soft/crispy uniformity of food

ActiveCN109269182AEvenly distributedImprove uniformityLighting and heating apparatusStationary refrigeration devicesCooling chamberSpray nozzle

The invention belongs to the field of food devices, and particularly discloses a cooling device suitable for improving the soft / crispy uniformity of food. The cooling device comprises a gas supply device, a cooling device, a sensor group, a valve group and a circulating device. The gas supply device conveys protection gas to the cooling device and exhausts air in a cooling chamber. The cooling chamber is internally provided with a cold wind spraying nozzle and an exhaust floating nozzle which are suitable for evenly distributing protection gas and a cold supporting belt for transferring and bearing food. The exhaust floating nozzle, the circulating device and the cold wind spraying nozzle are sequentially communicated, and the circulation of the protection gas in the cooling chamber is driven. A food input port and a food output port of the cooling device are each provided with a gate through sealing so that the food can be isolated from the air. The cooling device is controlled to cool the food in the environment of protection gas, the protection gas flow is uniform in distribution, the soft / crispy uniformity of the food is high, the food is not prone to peeling and cracking, thefood is isolated from the air by the protection gas, the residual amount of grease oxidized deterioration objects and oxygen in the food is quite small, the food is easy to store, and the shelf life is remarkably prolonged.

Owner:枣庄市永兴板栗加工有限公司

Vacuum food baking equipment suitable for improving crispness of food

ActiveCN109380455AReduce air pressureNot easy to hardenOven air-treatment devicesCooking & bakingProcess engineering

The invention belongs to the field of food equipment and particularly discloses vacuum food baking equipment suitable for improving crispness of food. The equipment comprises a baking device with a built-in baking chamber, a gas supply device suitable for conveying carrier gas into the baking chamber, a vacuum device suitable for providing a vacuum environment for the baking chamber and a circulating device suitable for cyclic flowing of the carrier gas in the baking chamber in order to cool the food. A gate is arranged at an access port in a sealing mode, wherein the access port is suitable for food input and output and is formed in one side of the baking device; gas spraying heads and gas collecting heads which are suitable for uniform distribution of the carrier gas are arranged in thebaking chamber. The vacuum device is operated to vacuum the baking chamber, the baking device is operated to bake the food in the vacuum environment with the carrier gas, and the circulating device isoperated to make the carrier gas in the baking chamber cyclically flow to cool the food. By baking the food in the vacuum environment, the crispness and crispness uniformity of the food are obviouslyimproved, the carrier gas is discharged with baked volatile matters and leaking air, deteriorated fat-oxidative matter and oxygen residues in the food are further reduced, the preservation of the food is facilitated, and the shelf life can be prolonged by 0.5-1 time.

Owner:龙海优麦嘉食品有限公司

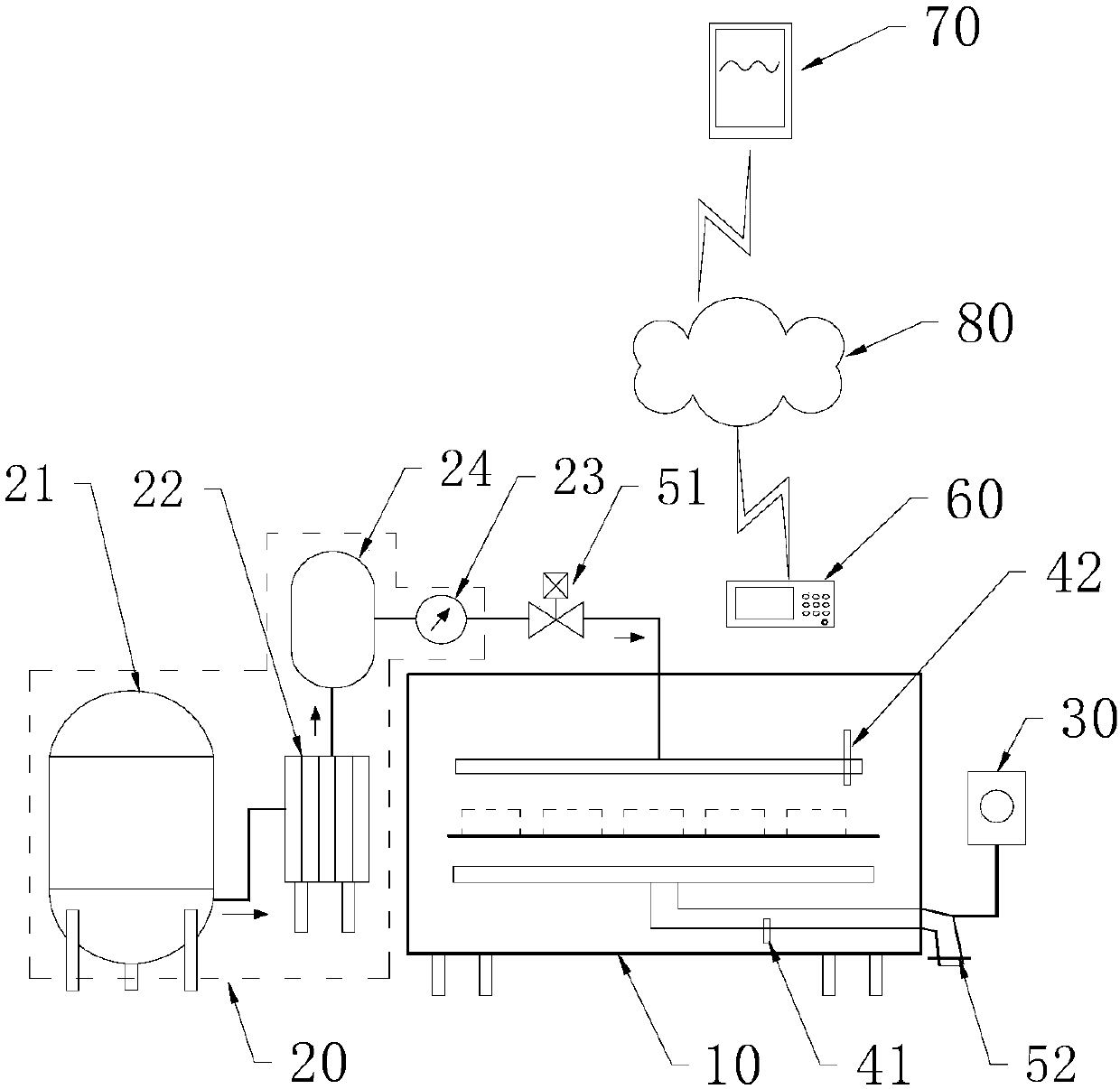

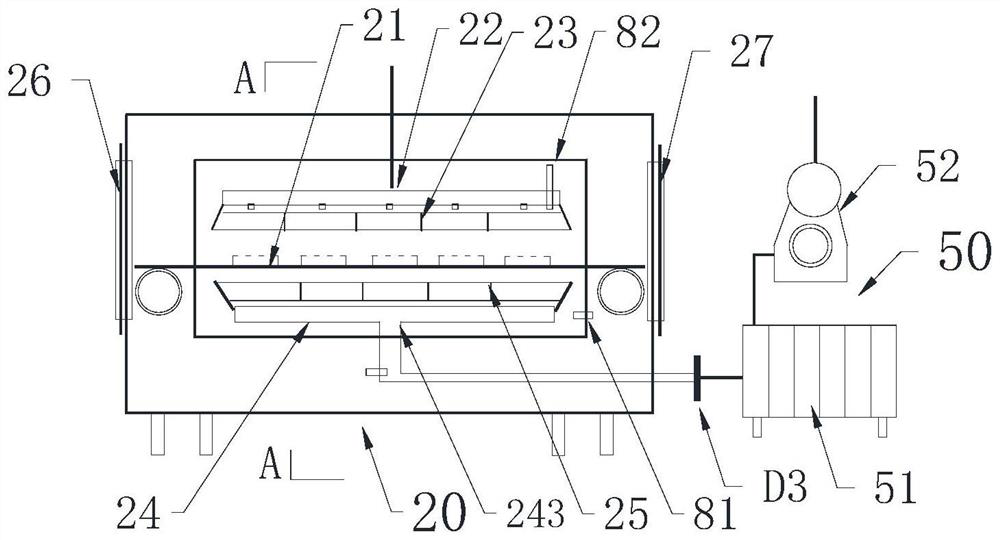

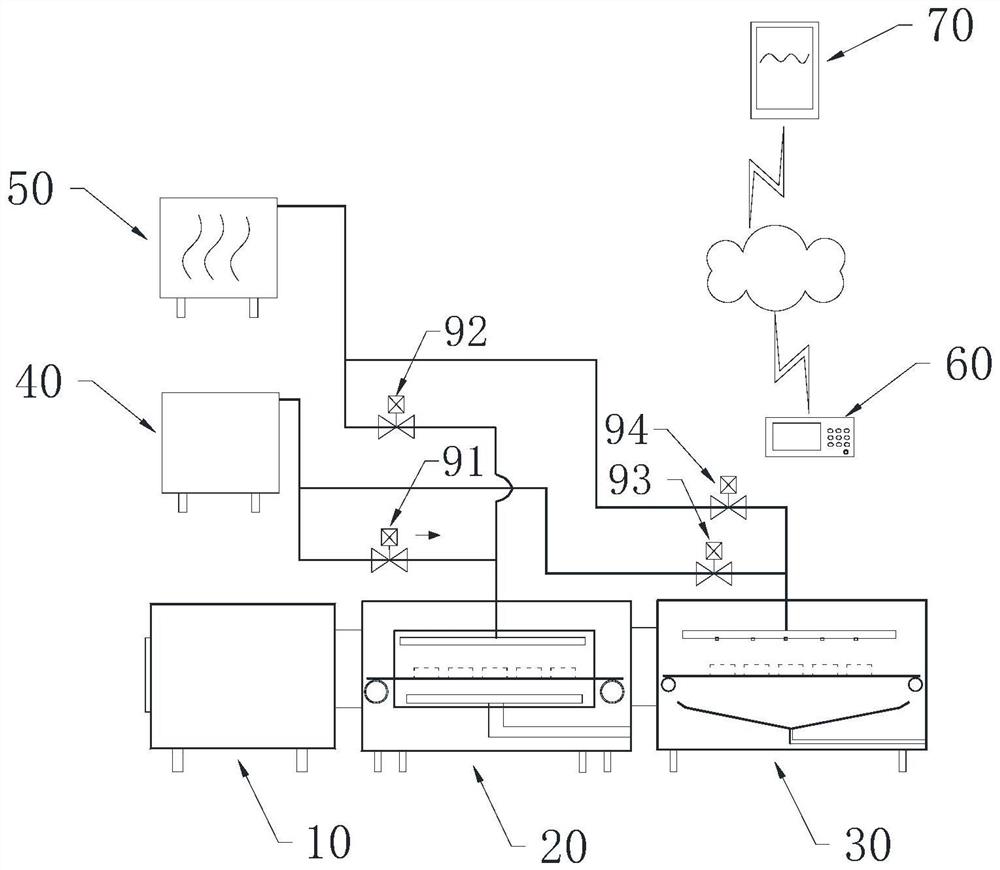

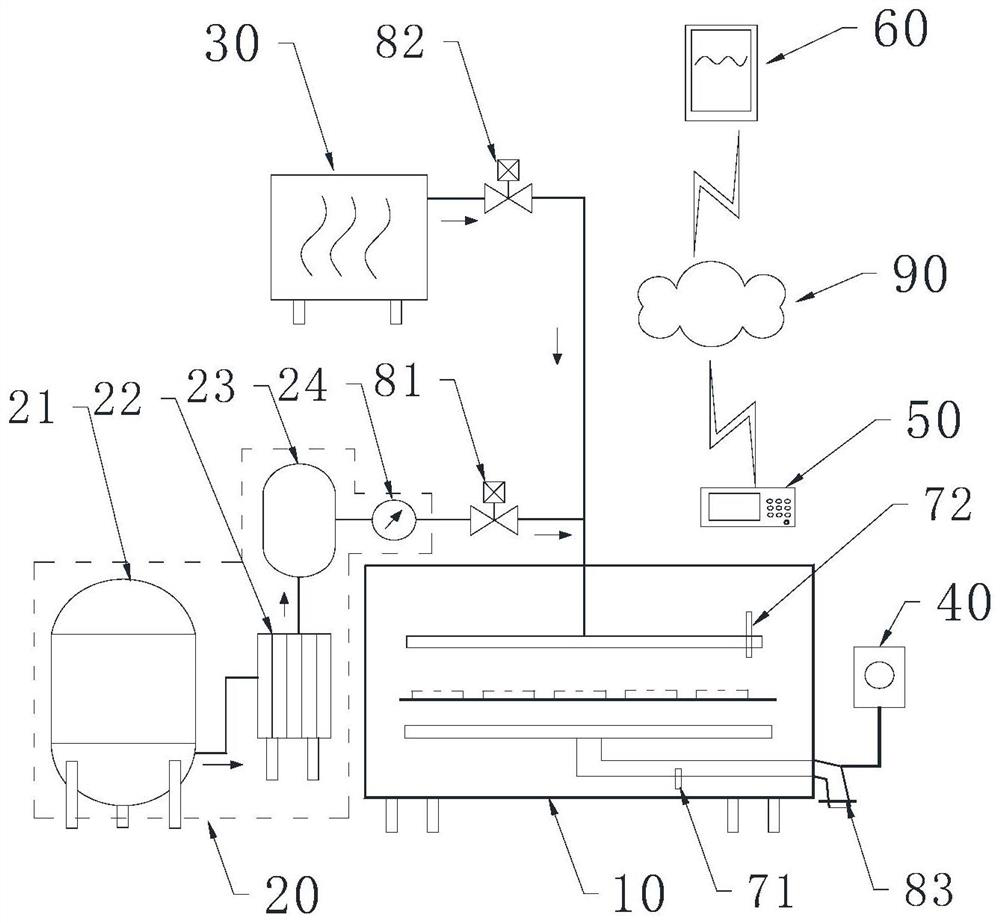

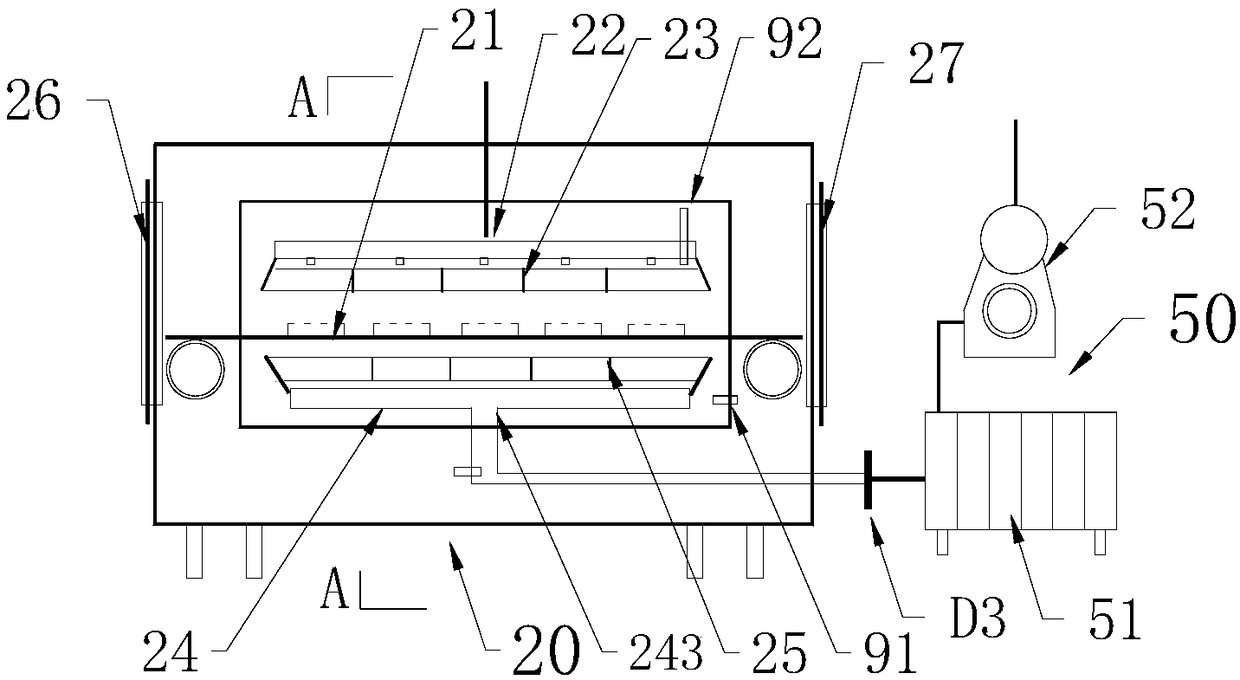

Intelligent baking equipment based on control of internet of things, and baking method

InactiveCN110870489AReduced oxygen uptakeLow residual oxygenBaking ovenOxygen sensorProcess engineering

The invention discloses intelligent baking equipment based on control of internet of things, and a baking method. The intelligent baking equipment comprise a control terminal and a control device which are in communication connection, a baking device internally provided with a baking chamber, an air supply device and an oxygen sensor; air jet heads, a baking tray, and an air collecting head are arranged in the baking chamber in sequence; an air outlet of the air collecting head communicates with an exhaust pipeline; the oxygen sensor is assembled in the exhaust pipeline and is suitable for judging whether air in the baking chamber is completely exhausted; and a gate suitable for moving food in and out is arranged at an opening on one side of the baking device in a sealing manner to isolatethe baking chamber from air. The control terminal is used for operating the control device to set a baking process through internet of things, and the control device is used for operating the bakingdevice to bake and cool the food in a protective gas environment based on the set baking process. Protective gas isolates the food from air, then grease hardly participates in an oxidation reaction during baking and cooling, so that oxidized and deteriorated substances in the food are few and the oxygen residual amount in the food is low, oxygen absorption capacity is low, the food is easy to store, and the shelf life can be improved by 0.5 to 1 time.

Owner:李明守

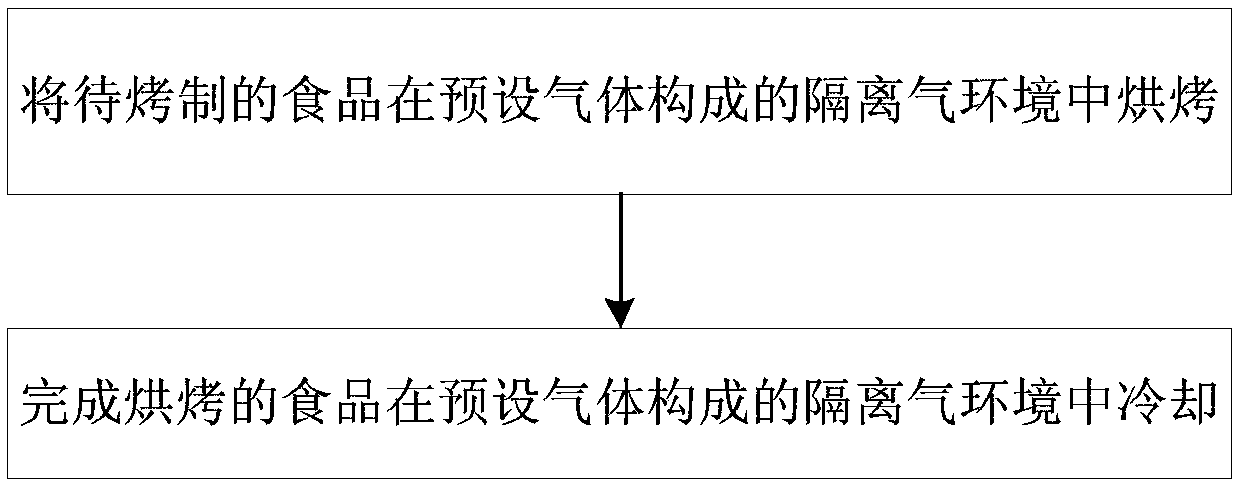

Food baking method and food baking equipment

InactiveCN110881496AReduced oxygen uptakeLow residual oxygen contentOven air-treatment devicesPreservation by coolingProcess engineeringGas supply

The invention belongs to the field of food equipment, and particularly discloses a food baking method and food baking equipment. The baking method comprises the steps that food to-be-baked is baked inan isolation air environment composed of preset gas, the baked food is cooled in the isolation gas environment composed of the preset gas, and the isolation gas isolates the food from air. The bakingequipment comprises a baking device suitable for the baking food and a gas supply device suitable for conveying the isolation gas to the baking device, a cake inlet gate is arranged at a food input port of the baking device in a sealed mode, a cake outlet gate is arranged at a food output port in the sealed mode, and the baking device is suitable for baking the food in the isolated gas environment formed by the preset gas and cooling the food in the isolated gas environment formed by the preset gas. The food is baked and cooled in the isolated gas environment, the food is isolated from the gas, a baking volatile matter is discharged in time through the isolated gas, the residual quantity of grease oxidative metamorphic substances and oxygen in the food is smaller, storage of the food is facilitated, and the quality guarantee period is greatly prolonged.

Owner:李明守

Intelligent food baking equipment suitable for extending shelf life

ActiveCN109122743AReduced oxygen uptakeLow residual oxygenOven air-treatment devicesBaked articles handlingCooking & bakingAbsorption capacity

The invention belongs to the food equipment field and especially relates to intelligent food baking equipment suitable for extending a shelf life. The equipment comprises an air supply device, a baking device, a cooling deice, an oxygen sensor group used for determining whether air is discharged completely and a control device. A baking technology including a protection gas parameter and a bakingtemperature is arranged in the control device. The air supply device conveys a protection gas to the baking device and the cooling device. The baking device and the cooling device are sealed and connected so that food can be transferred into the cooling device from the baking device. The food inlet of the baking device and the food outlet of the cooling device are provided with gates in a sealingmode so that the food is separated from the air. The control device makes the baking device bake and cool the food in a protection gas environment based on the baking technology. The food is separatedfrom the air by the protection gas, a grease in the food is difficult to initiate an oxidation reaction, an oil-oxidation deteriorated substance and oxygen residues in the food are extremely less, anoxygen absorption capacity is poor, the food is easy to preserve, and the shelf life can be increased by 0.5-1 times.

Owner:好运来(福建)食品有限公司

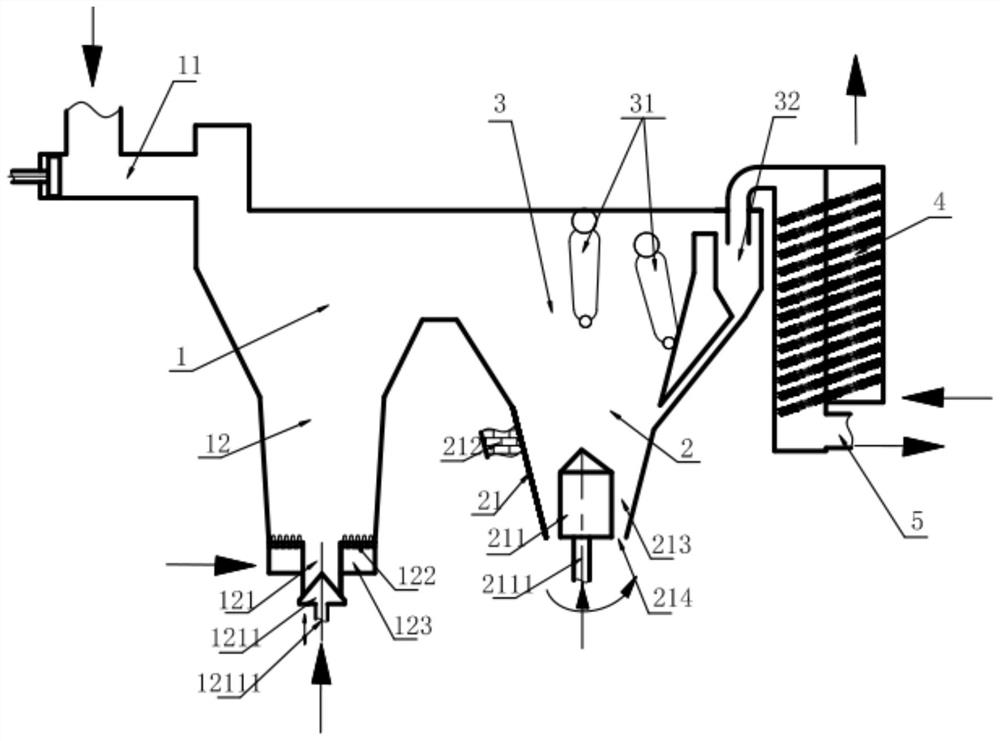

Enamel material resistant to high and low temperature corrosion, its preparation method, application and high temperature boiling rotary grate furnace device

ActiveCN110615615BBurn quicklyIncrease reaction rateIncinerator apparatusAir preheaterCombustion chamber

The invention belongs to the technical field of solid waste incineration engineering for environmental protection and resource utilization, and specifically relates to a high- and low-temperature corrosion-resistant enamel material, its preparation method, application and a high-temperature boiling rotary grate furnace device. The high-temperature boiling rotary grate furnace device of the present invention comprises: a fluidized bed, a garbage feeder is connected to the upper part of one side of the fluidized bed; three combustion chambers and a rotary grate roller are respectively connected to the upper part of the other side of the fluidized bed, and the rotary grate roller is located in the upper part of the fluidized bed. The lower part of the third combustion chamber is connected up and down with the third combustion chamber to reduce the fixed carbon content in the ash entering the rotary grate; the air preheater communicated with the upper part of the third combustion chamber away from the fluidized bed, The air preheater has a flue gas to the aftertreatment port. In the present invention, the boiling section belongs to the fluidized bed, the material can be fully turbulent, the boiling section is high temperature at the temperature of the hot air, the reaction rate is accelerated, the inflammables are rapidly burned, and the inflammable ash residue carbon stays in the rotary grate for a long time. sufficient, reduce carbon residues in ash, and eliminate harmful gas emissions such as dioxins.

Owner:广东生活环境无害化处理中心有限公司

A kind of vacuum baking equipment suitable for improving the crispness of food

ActiveCN109380455BReduce air pressureNot easy to hardenOven air-treatment devicesThermodynamicsEngineering

The invention belongs to the field of food equipment and particularly discloses vacuum food baking equipment suitable for improving crispness of food. The equipment comprises a baking device with a built-in baking chamber, a gas supply device suitable for conveying carrier gas into the baking chamber, a vacuum device suitable for providing a vacuum environment for the baking chamber and a circulating device suitable for cyclic flowing of the carrier gas in the baking chamber in order to cool the food. A gate is arranged at an access port in a sealing mode, wherein the access port is suitable for food input and output and is formed in one side of the baking device; gas spraying heads and gas collecting heads which are suitable for uniform distribution of the carrier gas are arranged in thebaking chamber. The vacuum device is operated to vacuum the baking chamber, the baking device is operated to bake the food in the vacuum environment with the carrier gas, and the circulating device isoperated to make the carrier gas in the baking chamber cyclically flow to cool the food. By baking the food in the vacuum environment, the crispness and crispness uniformity of the food are obviouslyimproved, the carrier gas is discharged with baked volatile matters and leaking air, deteriorated fat-oxidative matter and oxygen residues in the food are further reduced, the preservation of the food is facilitated, and the shelf life can be prolonged by 0.5-1 time.

Owner:龙海优麦嘉食品有限公司

A food intelligent vacuum baking equipment based on Internet of Things control

ActiveCN109287689BEasy to debugEasy to operateOven air-treatment devicesThe InternetProcess engineering

Owner:威海三昌食品有限公司

Intelligent baking equipment beneficial to improving crispness of food

InactiveCN110881486AImprove crispnessImprove uniformityOven air-treatment devicesProcess engineeringPumping vacuum

The invention belongs to the field of food equipment, in particular to intelligent baking equipment beneficial to improving crispness of food. The baking equipment comprises a baking device with a built-in baking chamber, a gas supply device suitable for conveying carrier gas into the baking chamber, a vacuum device suitable for generating a vacuum environment in the baking chamber, a circulatingdevice suitable for the carrier gas in the baking chamber to circularly flow so as to cool food, and a control device is internally provided with a baking process corresponding to to-be-baked food; agate is arranged at an inlet / outlet suitable for food input and output on one side of the baking device in a sealing manner; the control device controls the vacuum device to vacuumize the baking chamber, controls the baking device to bake the food in a vacuum environment with carrier gas, and controls the circulating device to drive the carrier gas in the baking chamber to circularly flow to coolthe food. The food is baked in a vacuum environment, the crispness and crispness uniformity of the food are remarkably improved, a baking volatile matter is discharged in time through the carrier gas,the residual quantity of grease oxidative metamorphic substances and oxygen in the food is smaller, food preservation is facilitated, and the quality guarantee period can be prolonged by 0.5-1 time.

Owner:李明守

High-temperature and low-temperature corrosion resistant enamel material, preparation method and application thereof and high-temperature fluidized-bed rotary grate furnace device

ActiveCN110615615ACorrosion resistanceBurn quicklyIncinerator apparatusCorrosion resistantCombustion chamber

The invention belongs to the technical field of solid waste incineration engineering for environmental protection and resource utilization, and particularly relates to a high-temperature and low-temperature corrosion resistant enamel material, a preparation method and application thereof and a high-temperature fluidized-bed rotary grate furnace device. The device comprises a fluidized bed, with the upper part of one side of the fluidized bed being communicated with a garbage feeder; a third combustion chamber and a rotary grate mill which are communicated with the upper part of the other sideof the fluidized bed respectively, with the rotary grate mill being positioned below the third combustion chamber and being communicated with the third combustion chamber up and down so as to reduce the content of fixed carbon in ash entering the rotary grate mill; an air preheater communicated with the upper part of one side, far away from the fluidized bed, of the third combustion chamber, withthe air preheater being provided with a flue gas post-treatment port. The fluidized section belongs to a fluidized bed, materials can be sufficiently turbulent, the fluidized section is high in temperature on the basis of the temperature of hot air, the reaction rate is increased, combustibles are quickly combusted, the residence time of flame-retardant ash residue carbon in the rotary grate millis sufficient, the ash residue carbon is reduced, and emission of harmful gas such as dioxin is eliminated.

Owner:广东生活环境无害化处理中心有限公司

A food intelligent baking equipment suitable for extending the shelf life

ActiveCN109122743BReduced oxygen uptakeLow residual oxygenOven air-treatment devicesBaked articles handlingOxygen sensorProcess engineering

The invention belongs to the field of food equipment, and specifically discloses an intelligent food baking equipment suitable for extending the shelf life, including an air supply device, a baking device, a cooling device, an oxygen sensor group and a control device suitable for judging whether the air has been fully discharged The control device is built with a baking process including protective gas parameters and baking temperature; the air supply device sends protective gas to the baking device and the cooling device respectively, and the baking device and the cooling device are sealed and connected, which is suitable for food from the baking device to the cooling device. transfer in the cooling device; the food input port of the baking device and the food output port of the cooling device are respectively provided with gates in a sealed manner to isolate the food from the air; the control device manipulates the baking equipment to process the food in a protective gas environment based on the baking process Baking and cooling, the protective gas isolates the food from the air, the oil in the food is difficult to gas and oxidize, the oxidative deterioration of the oil in the food and the residual oxygen are very small, the oxygen absorption capacity is poor, the food is easy to store, and the shelf life can be increased by 0.5 -1 times.

Owner:好运来(福建)食品有限公司

Food intelligent baking equipment beneficial to improving soft and moist mouthfeel

InactiveCN110870488AKeep moist and softGood softness and uniformityOven air-treatment devicesOven doors/gatesOxygen sensorProcess engineering

The invention discloses food intelligent baking equipment beneficial to improving the soft and moist mouthfeel. The equipment includes a gas supply device, a steam device, a baking device in which a baking chamber is arranged, an exhaust fan, an oxygen sensor and a control device; a gas spray head, a baking tray and a gas capture head are sequentially arranged in the baking chamber, the gas supplydevice and the steam device respectively deliver gas into the gas spray head, the oxygen sensor is arranged in a gas discharge pipeline communicating with the gas capture head, and the oxygen sensoris suitable for judging whether the air in the baking chamber is completely discharged; an inlet-outlet through which food moves in and out located in one side of the baking device is provided with agate in a sealed manner, and the gate is suitable for isolating the baking chamber from the air; and the control device controls the baking device to bake the food in the protective gas environment containing water vapor, moisture of the food is uniformly volatilized, and the food is moister and softer. The protective gas isolates the food from the air, an oxidation reaction of grease in the foodis difficult to realize, grease oxidation deteriorated substances and oxygen residues in the food are extremely small, the oxygen absorption capacity is poor, the food is easy to preserve, and the shelf life can be prolonged by 0.5 to 1 time.

Owner:李明守

Food intelligent vacuum baking equipment based on control of Internet of Things

ActiveCN109287689AEasy to debugEasy to operateOven air-treatment devicesThe InternetProcess engineering

The invention belongs to the field of food equipment, and particularly discloses food intelligent vacuum baking equipment based on control of Internet of Things. The food intelligent vacuum baking equipment comprises a baking device in which a roasting chamber is arranged, a gas supply device suitable for transporting carrier gas to the roasting chamber, a vacuum device suitable for producing vacuum environment in the roasting chamber, a circulating device suitable for enabling the carrier gas in the roasting chamber to circulate, a control device and an operation and control terminal, whereina gate is arranged at an entrance and exit suitable for foods to input and output, in one side of the baking device, in a sealing manner; the operation and control terminal is used for manipulating the control device through the Internet of Things in a long-distance manner and setting a corresponding roasting technology; and the control device is used for manipulating the vacuum device to vacuumize the roasting chamber, roasting foods in the vacuum environment with carrier gas and manipulating the circulating device to drive the carrier gas to cool the foods. The foods are roasted in the vacuum environment, so that the crispness of the foods and the uniformity of the crispness are notably improved; the carrier gas is exhausted in time for baking volatile matter; and the quantity of oil oxidative deterioration substances and oxygen residual quantity in the foods are lower, the preservation of the foods is facilitated, and the quality guarantee period can be prolonged by 0.5-1 time.

Owner:威海三昌食品有限公司

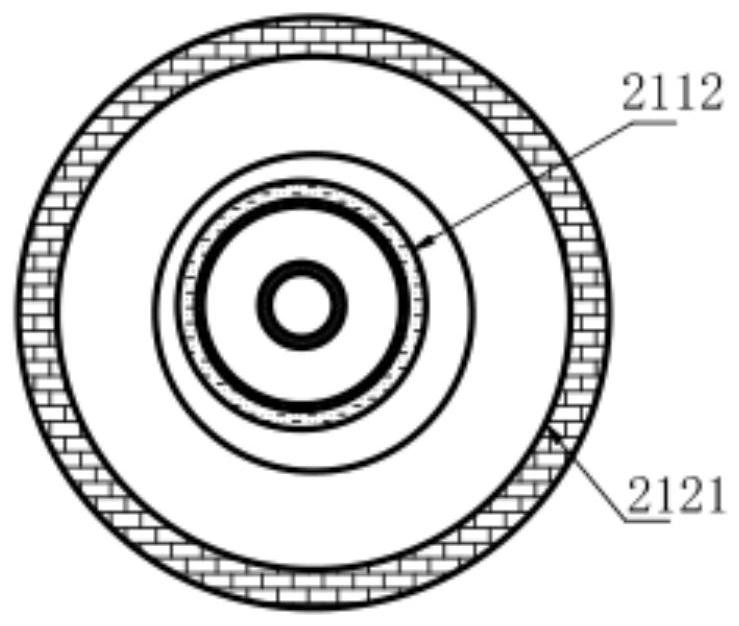

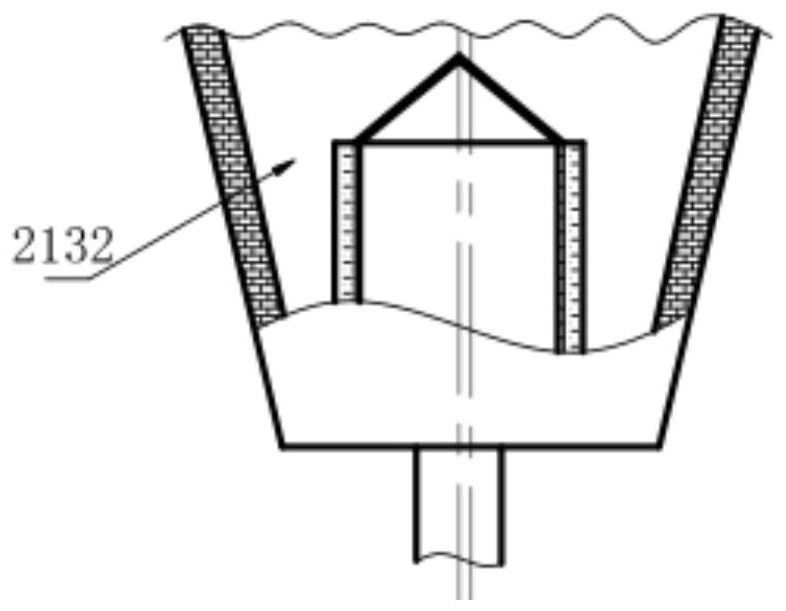

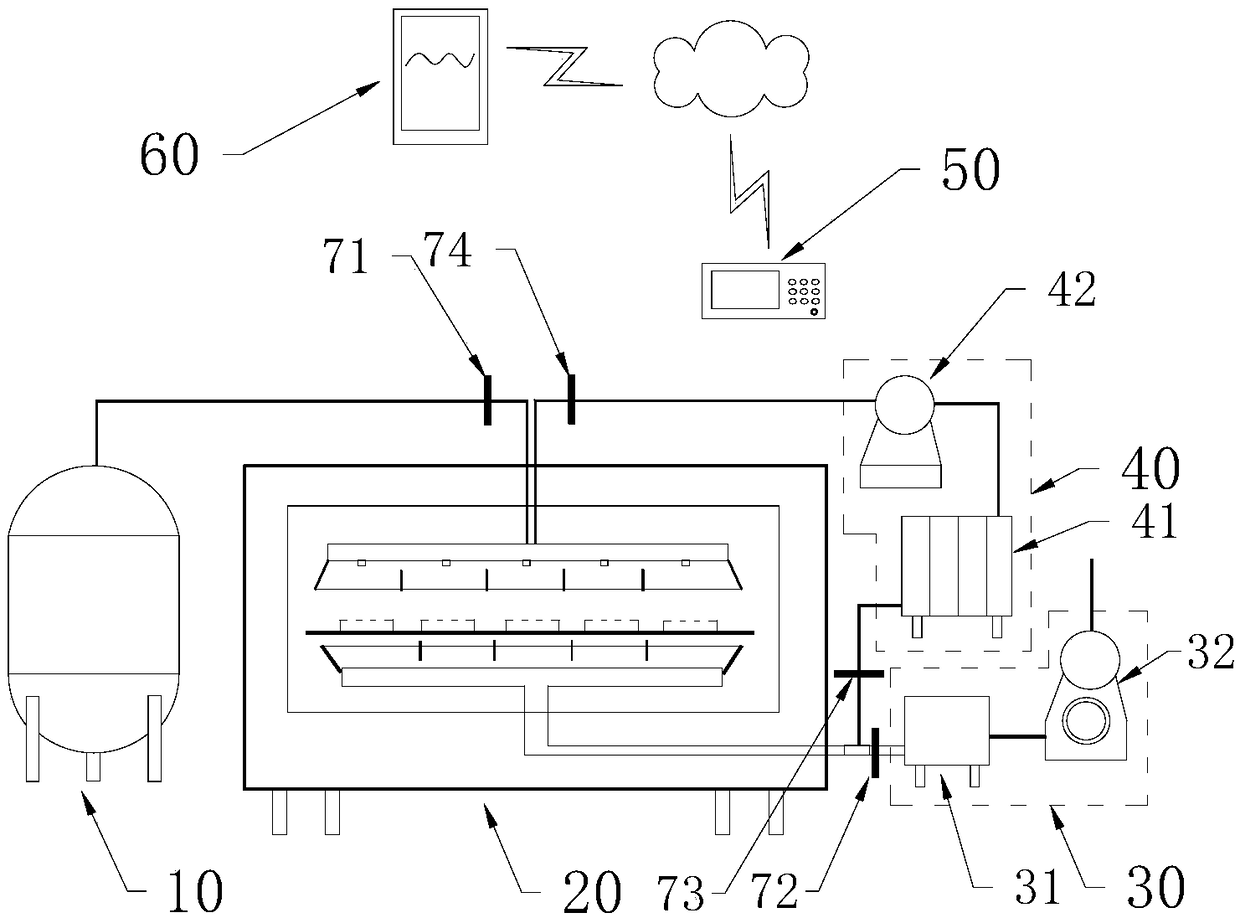

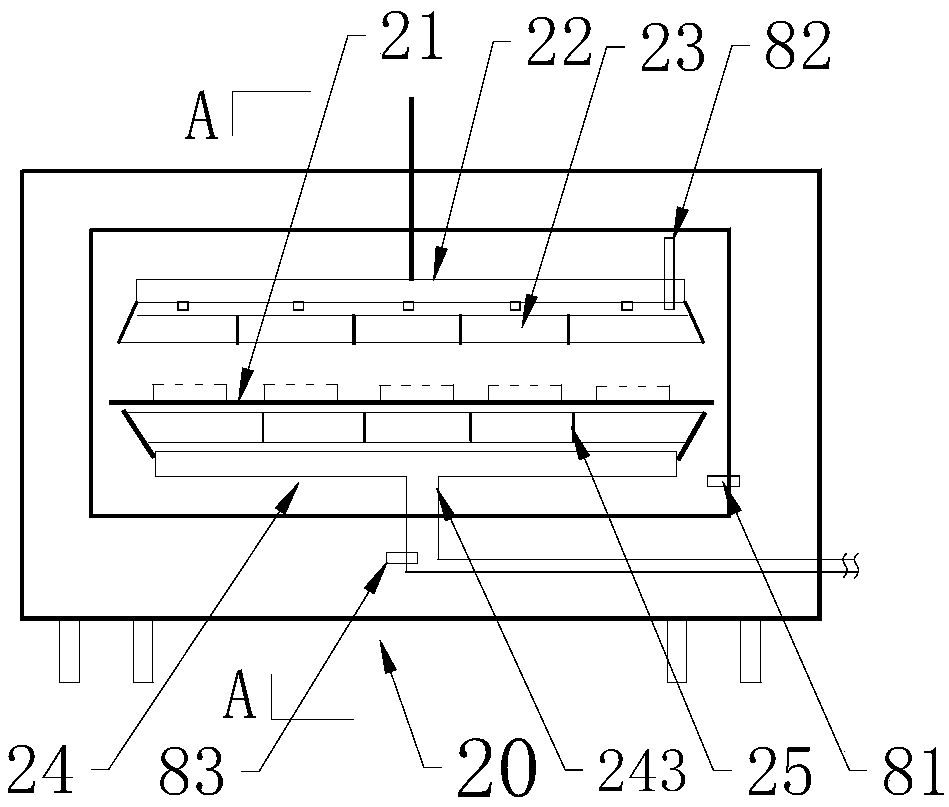

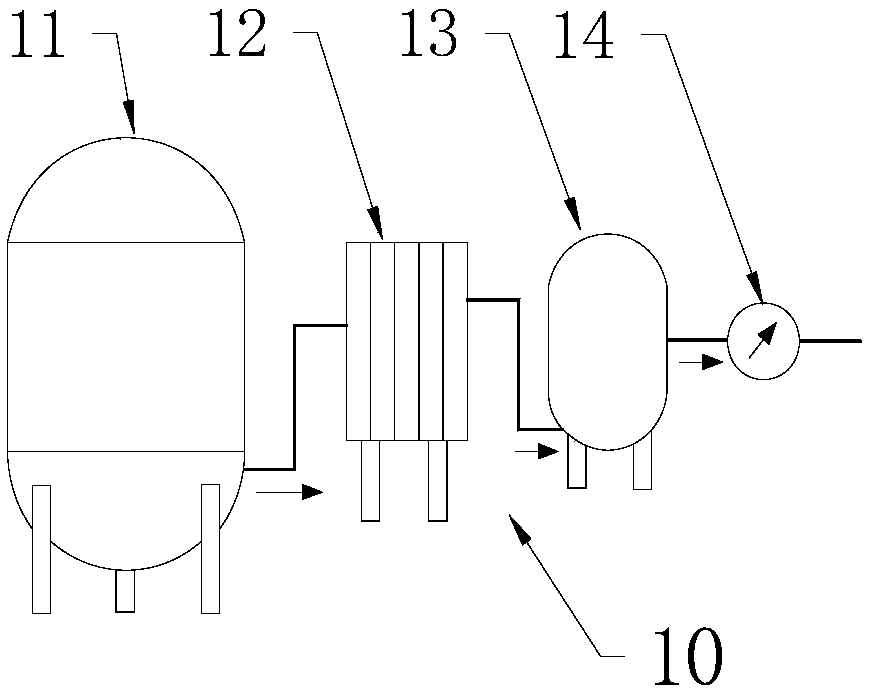

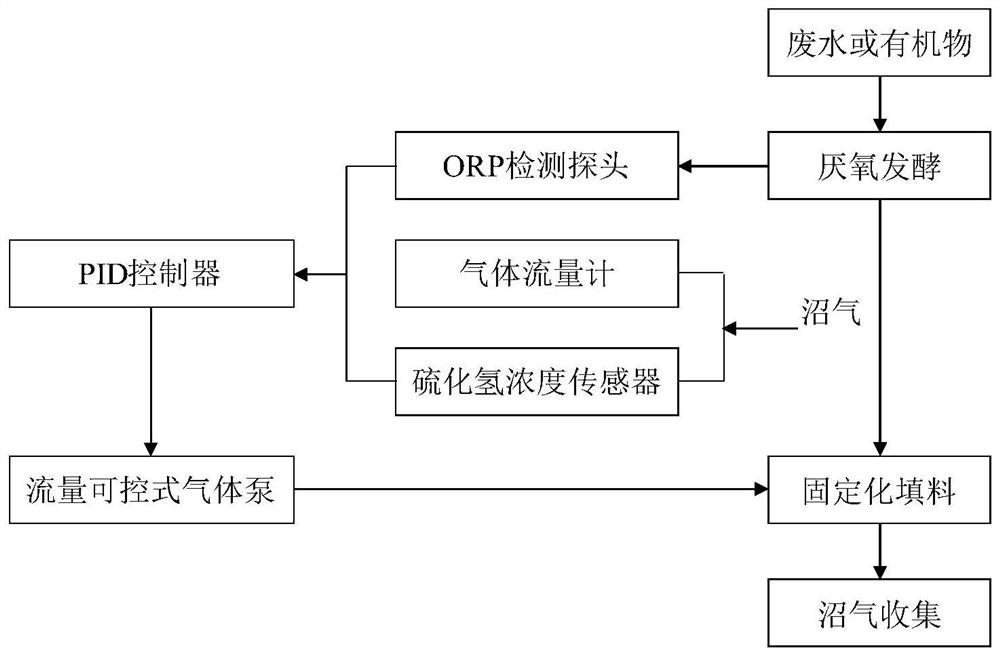

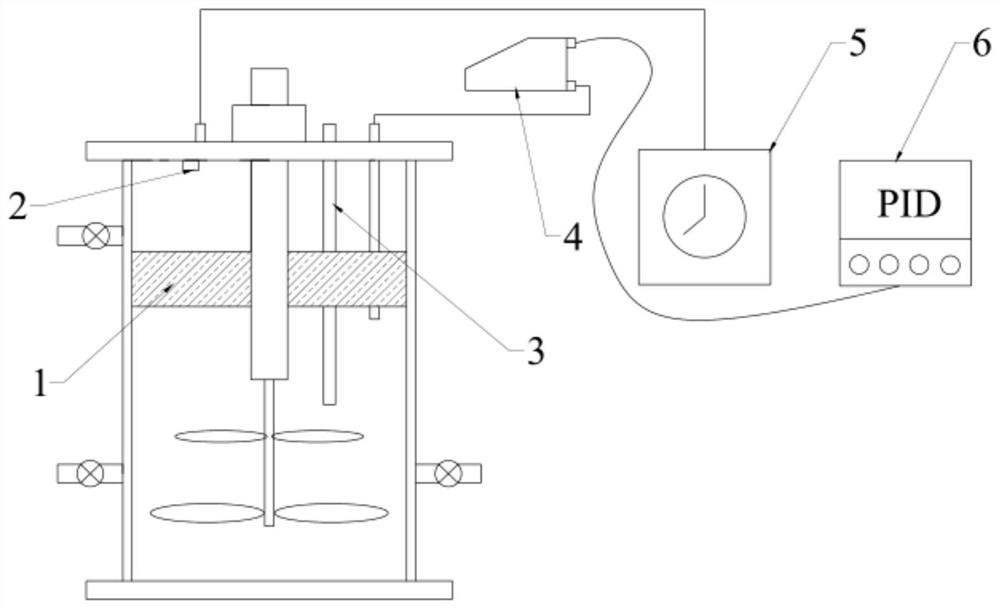

A device and method for improving anaerobic fermentation efficiency and simultaneous in-situ desulfurization

ActiveCN110835159BEfficient removalRealize in-situ desulfurizationBioreactor/fermenter combinationsBiological substance pretreatmentsEnvironmental engineeringFermentation broth

The invention belongs to the technical field of anaerobic fermentation, and specifically relates to a device for improving anaerobic fermentation efficiency and synchronous in-situ desulfurization, comprising an anaerobic fermentation tank, immobilized filler (1), hydrogen sulfide concentration sensor (2), and ORP detection probe ( 3), a flow controllable gas pump (4), a gas flow meter (5) and a PID controller (6); an immobilized filler (1) is arranged above the liquid level of the fermentation liquid inside the anaerobic fermentation tank, and a hydrogen sulfide concentration sensor (2) set on the top of the anaerobic fermentation tank, the ORP detection probe (3) is set in the anaerobic fermentation tank, the flow controllable gas pump (4) is set outside the anaerobic fermentation tank, through the flow controllable gas pump ( 4) Air is introduced into the liquid surface in the anaerobic fermentation tank and the immobilized filler (1); the gas flow meter (5) is arranged outside the anaerobic fermentation tank, and the PID controller (6) and the hydrogen sulfide concentration sensor (2) , a gas flow meter (5), an ORP detection probe (3) and a flow controllable gas pump (4) are electrically connected.

Owner:CHINA AGRI UNIV

A cooling device suitable for improving the uniformity of softness or crispness of food

ActiveCN109269182BEvenly distributedImprove uniformityLighting and heating apparatusStationary refrigeration devicesThermodynamicsCooling chamber

Owner:枣庄市永兴板栗加工有限公司

Food baking equipment suitable for suppressing oxidation of grease during baking

InactiveCN110870493AReduced oxygen uptakeLow residual oxygenOven air-treatment devicesPreservation by coolingOil and greaseOxygen sensor

The invention belongs to the field of food equipment, and specifically discloses food baking equipment suitable for suppressing oxidation of grease during baking. The equipment includes a gas supply device, a baking device, a cooling device, an oxygen sensor group suitable for judging whether the air is completely discharged, and a valve group; the gas supply device conveys a protective gas to thebaking device and the cooling device respectively, a food conveying outlet of the baking device is in sealed communication with a food conveying inlet of the cooling device, an isolation gate is arranged, and the isolation gate is suitable for transferring the food between the baking device and the cooling device; and a food conveying inlet of the baking device and a food conveying outlet of thecooling device are respectively provided with gates in a sealed manner to isolate the food from the air. The baking equipment is operated to bake and cool the food in the protective gas environment, the protective gas isolates the food from the air, an oxidation reaction of the grease in the food is difficult to realize, grease oxidation deteriorated substances and oxygen residues in the food areextremely small, the oxygen absorption capacity is poor, the food is easy to preserve, and the shelf life can be prolonged by 0.5 to 1 time.

Owner:李明守

Baking equipment applicable to wetting type food baking

InactiveCN108850038AImprove uniformityGreat tasteOven air-treatment devicesOil and greaseCooking & baking

The invention belongs to the field of food equipment, and concretely discloses baking equipment applicable to wetting type food baking. The equipment comprises a gas supply device, a steam device, abaking device, an exhaust machine and an oxygen sensor, wherein a gas spraying head, a support baking tray and a gas capture head are built in a baking chamber of the baking device; an output openingof the gas supply device and an output opening of the steam device are respectively communicated with an input opening of the gas spraying head; an oxygen sensor is assembled in an exhaust pipeline communicated with an exhaust opening of the gas capturing head and is suitable for being used for judging whether air in the baking chamber is completely exhausted or not; a gate is arranged in a sealedway in an inlet and outlet opening, suitable for being used for moving in or moving out food, at one side of the baking device and is suitable for being used for isolating the baking chamber away from the air; the baking device performs baking and cooling on the food in the water vapor-comprising protection gas environment; the food is looser, softer and more delicious; the protection gas isolates the food from the air; grease in the food is difficult to generate oxidization reaction; grease oxidization deterioration materials and oxygen residues in the food are very few; the oxygen absorption capability is poor; the food can be easily stored; the shelf life can be prolonged by 0.5 to 1 time.

Owner:李明守

An intelligent food vacuum baking equipment

ActiveCN109122746BImprove crispnessImprove uniformityOven air-treatment devicesThermodynamicsEngineering

The invention belongs to the field of food equipment, and specifically discloses an intelligent food vacuum baking equipment, which includes an air supply device, a baking device, a vacuum device suitable for maintaining a vacuum environment in the baking device, and a control device; the control device has a built-in corresponding baking device. process; the gas supply device delivers the carrier gas to the roasting chamber of the roasting device; the gate on the side of the roasting device that is suitable for food input and output is set in a sealed manner to isolate the food from the air; the roasting chamber is set to be suitable for the carrier gas Evenly distributed air sprinkling heads and air capture heads, and a baking tray suitable for carrying food; the control device operates the baking equipment to generate a vacuum environment, and the food is processed by vacuum boiling and puffing, and then the food is baked in the vacuum environment with carrier gas. Baking food in a vacuum environment, the crispness and uniformity of the food are significantly improved, the carrier gas discharges the baking volatiles in time, the oxidative deterioration of the oil in the food, and the oxygen residue are less, which is conducive to the preservation of the food. The shelf life can be increased by 0.5‑1 times.

Owner:安徽金豪食品科技有限公司

Method for preparing ferro-titanium alloy based on thermite self-propagating gradient reduction and slag washing refining

Owner:NORTHEASTERN UNIV LIAONING

An intelligent food vacuum baking system suitable for improving the crispy taste

ActiveCN109105411BImprove crispnessImprove uniformityOven air-treatment devicesCooling chamberProcess engineering

The invention belongs to the field of food equipment, and specifically discloses an intelligent food vacuum baking system suitable for improving the crispy taste, including a baking device with a built-in baking chamber, a cooling device with a built-in cooling chamber, Gas supply, vacuum, circulation and control for delivery of carrier gas. The roasting device is connected with the cooling device in a sealed manner, and a gate is provided in a sealed manner, which is suitable for isolating the roasting chamber from the cooling chamber. Gates are respectively provided in a sealed manner at the food input port of the roasting device and the food output port of the cooling device. Based on the built-in baking process, the control device operates the vacuum device to evacuate the baking chamber, bakes food in a vacuum environment with carrier gas, and operates the circulation device to drive the carrier gas to circulate in the cooling chamber to cool the food. The food is baked in a vacuum with a carrier gas and cooled in a circulating carrier gas, the crispness of the food is improved, the oxidative deterioration of the oil in the food and the amount of oxygen residue are less, and the shelf life of the food can be increased by 0.5-1 times.

Owner:揭阳市港荣食品发展有限公司

Baking equipment and baking process capable of prolonging food shelf life

ActiveCN108991052BReduced oxygen uptakeLow residual oxygenOven air-treatment devicesOxygen sensorProcess engineering

The invention belongs to the field of food equipment, and specifically discloses a baking device and a baking process capable of prolonging a food warranty period. The device comprises an air supply device, a roast device, an exhaust fan, and an oxygen sensor. A roast cavity of the roast device is provided with a jet head, a roast tray, and an air capture head in sequence from up to bottom. An airoutlet of the air supply device is communicated with an air inlet of the jet head. An exhaust port of the air capture head is communicated with an exhaust air duct. The oxygen sensor is assembled inthe exhaust air duct, and determines whether all air in the roast cavity is discharged. One side of the roast device is provided with an entrance for moving food in and out. The entrance is provided with a gate in a sealing manner, and the gate isolates the roast cavity from air. The roast device bakes and cools food in a shielding gas environment. The shielding gas isolates food from air. Duringbaking and cooling periods, grease in food is difficult to take oxidation reaction, grease oxidative deterioration substances and oxygen residual quantity in the food are very little, oxygen uptake capacity is low, so that the food is easy to store, and warranty period can improve by 0.5-1 time.

Owner:龙海市安得马富机械有限公司

A food intelligent baking system based on Internet of things control

ActiveCN109197927BGood for healthGood moist softnessOven air-treatment devicesBaked articles handlingThermodynamicsThe Internet

The invention discloses a food intelligent baking system based on control of Internet of Things. The food intelligent baking system comprises a control terminal, a control device, a gas supply device,a steam device, a baking device and a cooling device, wherein the control terminal is in communication connection with the control device; the gas supply device is used for transporting shielding gasto the baking device and the cooling device; the steam device is used for transporting steam to the baking device and the cooling device; the baking device is in sealing communication with the cooling device, and is suitable for enabling foods to transfer from the baking device to the cooling device; gates are respectively arranged at a food input opening of the baking device and a food output opening of the cooling device in a sealing manner, so that foods are isolated from air; and the control terminal is used for manipulating the control device and setting a baking technology through the Internet of Things; and the control device manipulates the baking system to bake and cool foods in the shielding gas environment containing vapor, moisture in foods is uniformly volatilized, and foodsare damper and softer. Through the adoption of the food intelligent baking system disclosed by the invention, the foods are isolated from the air, the quantity of fat oxidative deterioration substances and the quantity of residual oxygen in the foods are low, the oxygen sucking capacity is poor, the foods are easy to store, and the quality guarantee period can be prolonged by 0.5-1 time.

Owner:DONGGUAN HUAMEI FOOD

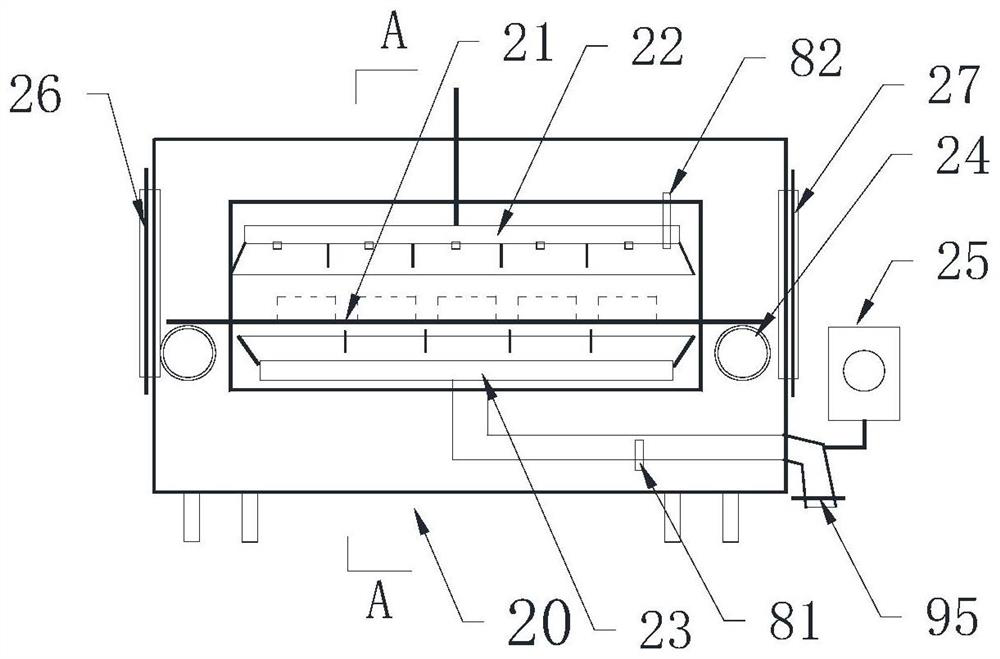

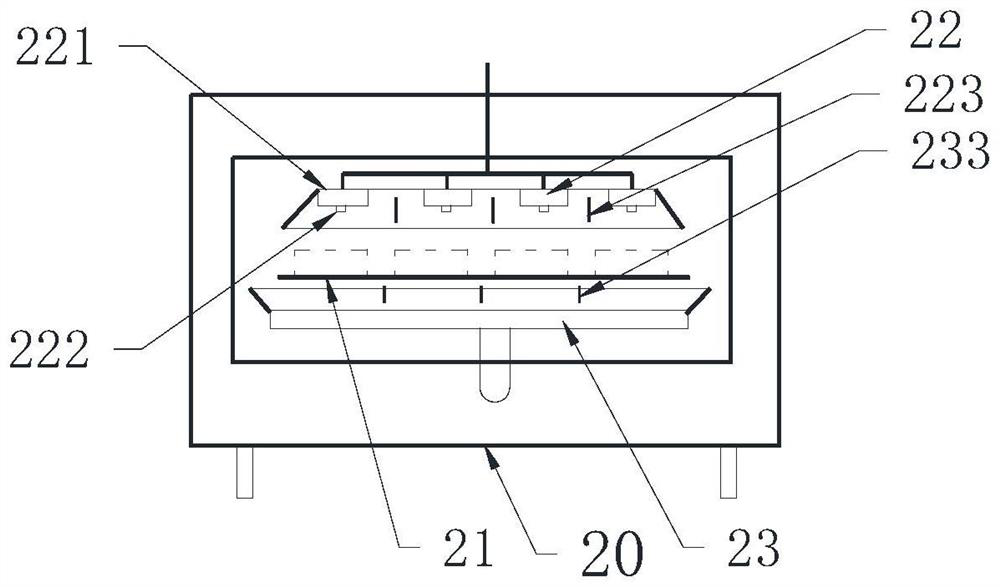

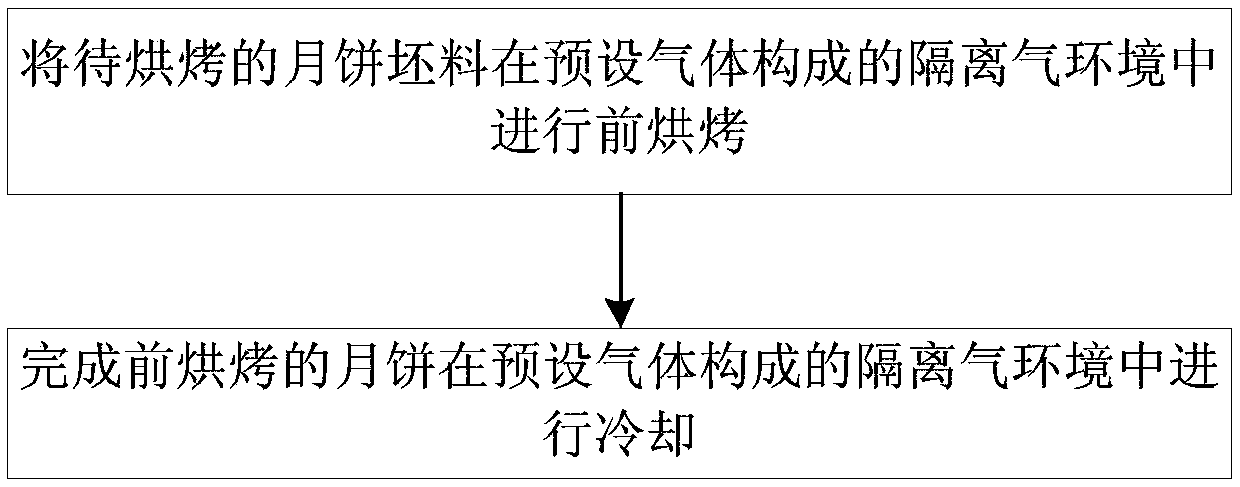

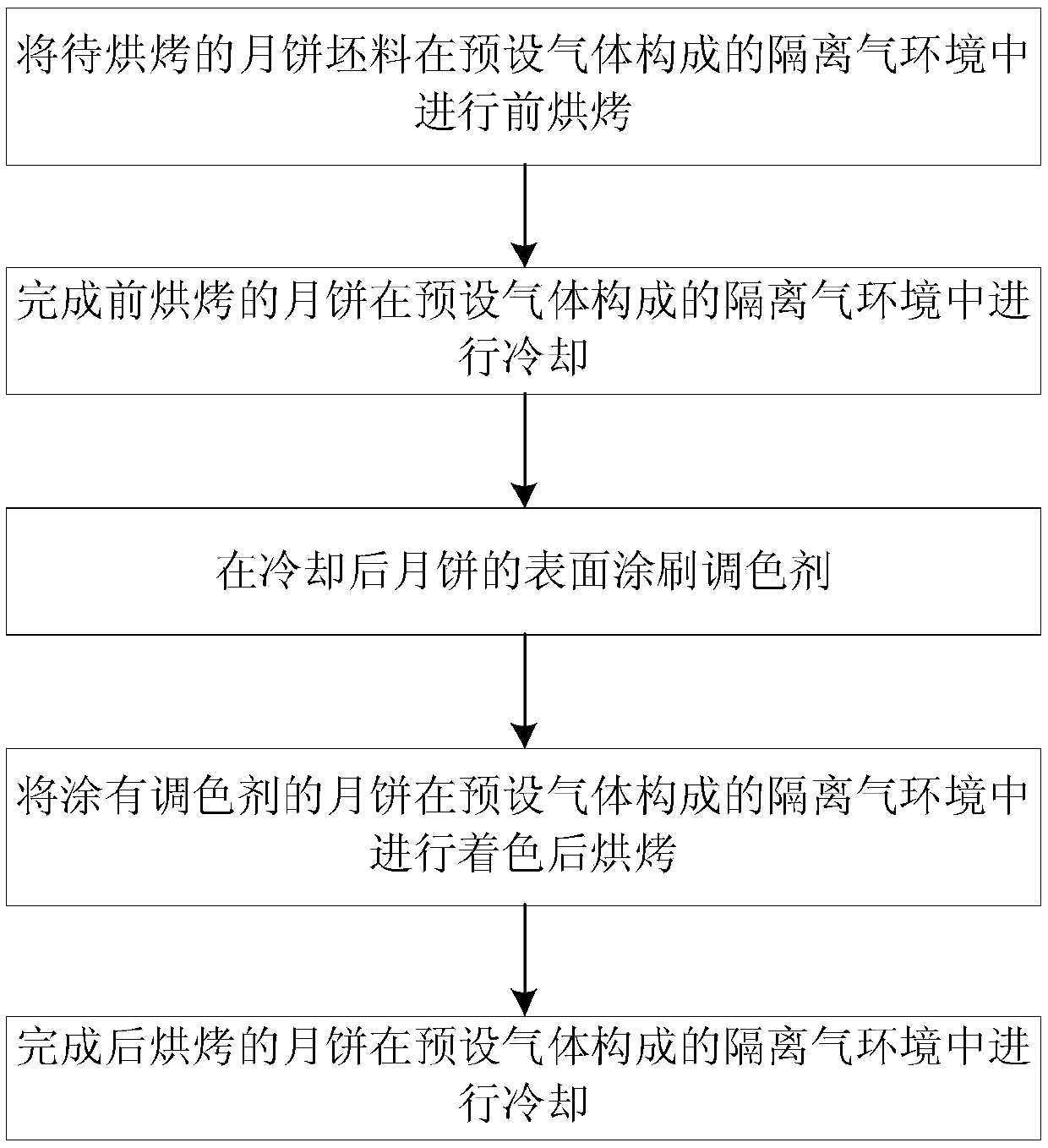

Baking method for moon cakes and baking equipment

InactiveCN110870492AReduced oxygen uptakeLow residual oxygen contentOven air-treatment devicesBaking processesEngineeringOrganic chemistry

The invention belongs to the field of food processing, and specifically discloses a baking method for moon cakes. The method comprises the following steps: baking moon cakes to be baked in an isolatedgas environment composed of a preset gas, and cooling the baked moon cakes in the isolated gas environment. The moon cakes are baked and cooled in the isolated gas environment, the moon cakes are isolated from the air, baking is performed in the oxygen-free environment, so that an oxidation reaction of grease in the moon cakes can be effectively inhibited from generating oxidation deteriorated substances harmful to health; and the moon cakes are baked in the environment isolated from the air, the content of oxygen residues and the oxidation deteriorated substances in the moon cakes is extremely small, the oxygen absorption capacity of the moon cakes is reduced, and the shelf life of the moon cakes is increased by 0.5 time or more. The invention also discloses baking equipment. The bakingequipment includes a baking device and a gas supply device, the gas supply device supplies the preset gas to the baking device to form the isolated gas environment composed of the preset gas in the baking device, the isolated gas environment is isolated from the air, the moon cakes are baked and cooled in the isolated gas environment, the content of the oxidation deteriorated substances and the oxygen residues in the moon cakes is small, and the moon cakes are easier to store.

Owner:李明守

A food baking equipment based on intelligent control of the Internet of Things

ActiveCN109122745BImproved uniformity of wetting and fluffGreat tasteOven air-treatment devicesOxygen sensorThe Internet

The invention discloses food baking equipment based on the intelligent control of Internet of things. The equipment comprises a control terminal, a control device, an air supply device, a steam device, a baking device with a built-in baking chamber, an exhaust fan and an oxygen sensor, wherein the control terminal and the control device are communicated and connected. A jet head, a holding bakingtray and a captive gas head are arranged in the baking chamber. The air supply device and the steam device convey a protection gas to the jet head. The oxygen sensor is arranged in an exhaust pipelineconnected to the captive gas head so as to determine whether air is discharged completely. The inlet and outlet of one side of the baking device, through which food is moved in and out, is provided with a gate in a sealing mode so that the baking chamber is separated from the air. The control terminal controls the control device and sets process parameters through the Internet of things, and thecontrol device makes the baking device bake the food in the protective gas environment containing water vapor, moisture in the food is evenly volatilized, and the food is wet and soft. The food is separated from the air, an oil-oxidation deteriorated substance and oxygen residues in the food are extremely less, an oxygen absorption capacity is poor, the food is easy to preserve, and a shelf life can be increased by 0.5-1 times.

Owner:ANHUI TIANHE FOOD

Food intelligent vacuum baking system based on operation and control of Internet of Things

InactiveCN109287690AEasy to debugEasy to operateOven air-treatment devicesCooling chamberThe Internet

The invention belongs to the field of food equipment, and particularly discloses food intelligent vacuum baking system based on operation and control of Internet of Things. The food intelligent vacuumbaking system comprises a roasting device in which a baking chamber is arranged, a cooling device in which a cooling chamber is placed, a gas supply device suitable for transporting carrier gas to the baking chamber and the cooling chamber, a vacuum device, a circulating device, a control device and a control terminal, wherein the roasting device communicates with the cooling device in a sealingmanner, and is suitable for enabling foods to be transferred from the baking chamber to the cooling chamber; gates are respectively arranged at a food input opening of the roasting device and a food output opening of the cooling device, in a sealing manner; the control terminal is used for manipulating the control device through the Internet of Things and setting a roasting technology; and the control device is used for manipulating the vacuum device to vacuumize the baking chamber, roasting foods in vacuum environment with carrier gas and manipulating the circulating device to drive the carrier gas in the cooling chamber to circulate to cool foods. Foods are roasted in the vacuum environment with the carrier gas and cooled, so that the crispness of the foods is improved; and the quantityof oil oxidative deterioration substances and oxygen residual quantity in the foods are lower, and the quality guarantee period of the foods can be prolonged by 0.5-1 time.

Owner:李明守

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com