Nitrogen filling equipment and method for nasal spray

A technology for nasal spray and filling equipment, which is applied in the field of nasal spray nitrogen filling equipment, can solve the problems of high residual oxygen content, low nitrogen specific gravity, difficulty, etc., and achieves reduction of residual oxygen, low cost, and nitrogen consumption. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

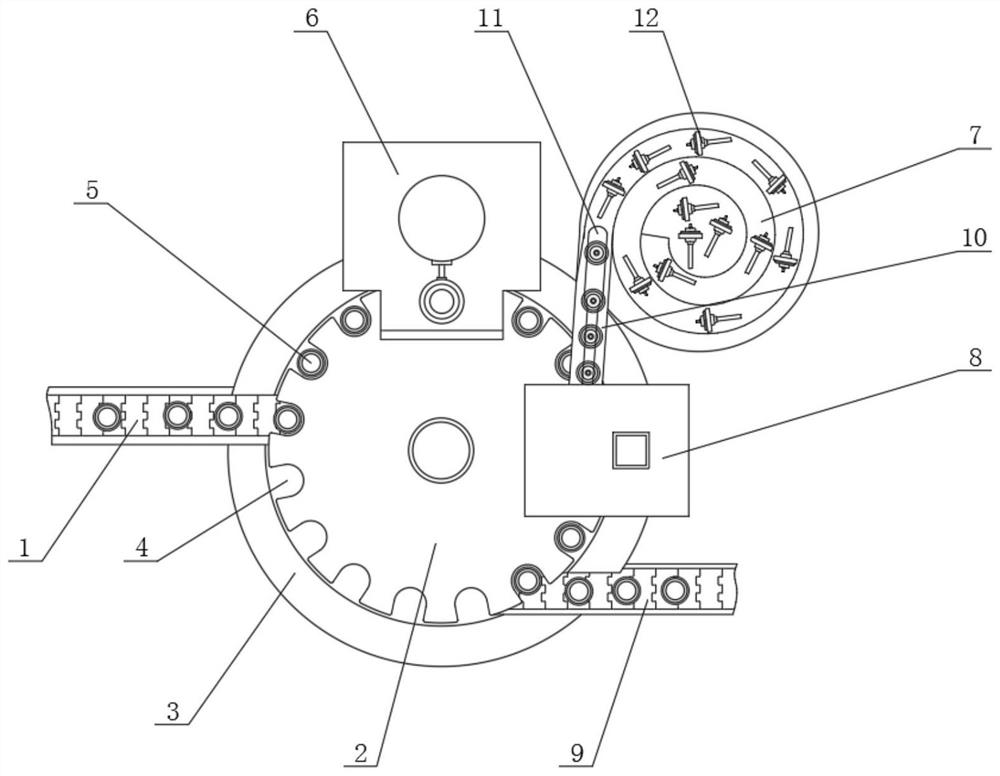

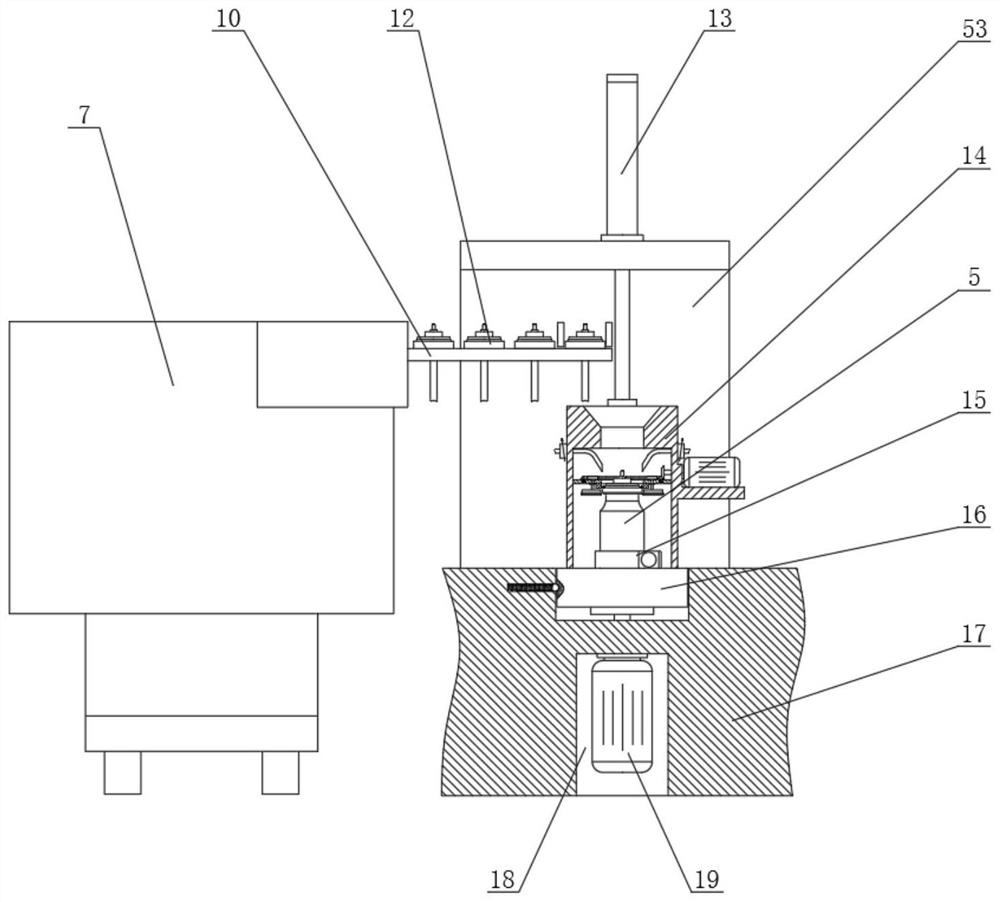

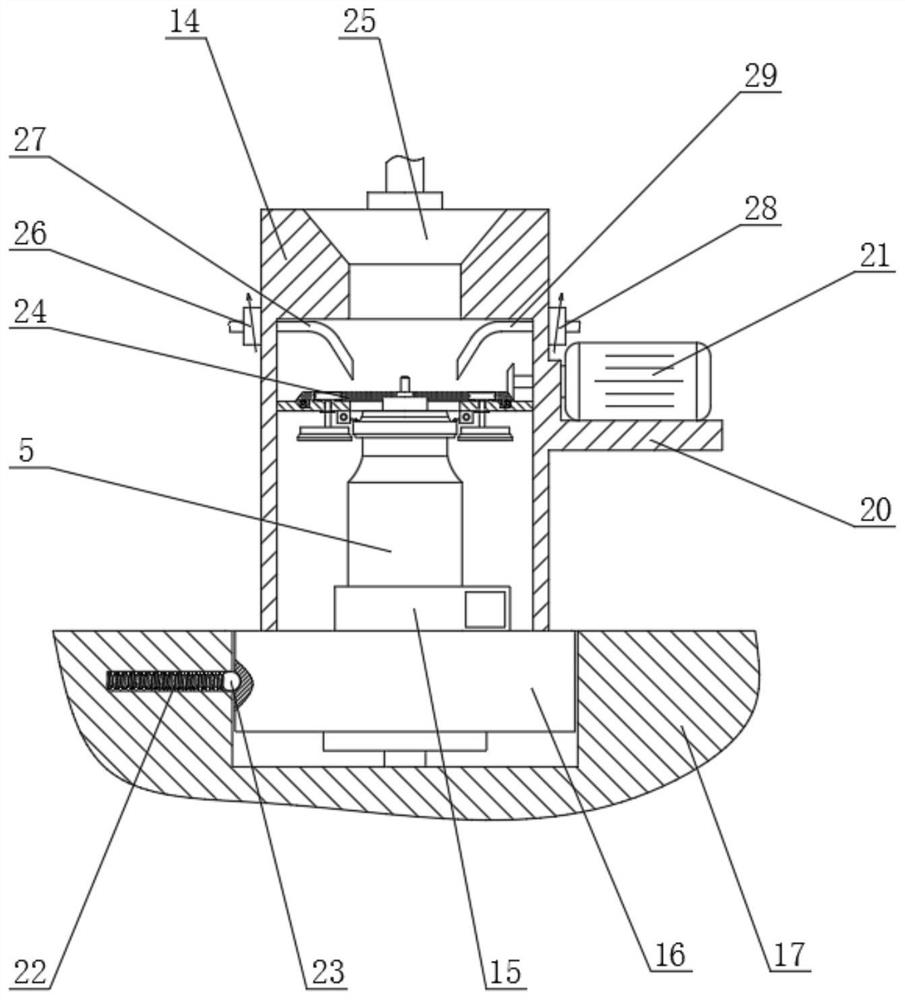

[0030] like Figure 1-Figure 7 As shown, a nitrogen-filled filling equipment for nasal sprays includes a feeding conveyor belt 1, a bottle-separating turntable 2, a base 17, a filling machine 6, a vibrating feeder 7, a gland nitrogen filling device 8 and a feeding Conveyor belt 9, described bottle dividing carousel 2 is installed on the base 17, and can be rotated relative to base 17 by servomotor drive, the circumference of described bottle dividing carousel 2 is provided with evenly distributed bottle dividing groove 4, and described base 17 The outer edge of the outer edge is provided with an outer baffle 3, the feeding conveyor belt 1 is installed on one side of the bottle dividing carousel 2, and the unloading conveyor belt 9 is installed on the other side of the bottle dividing carousel 2, and the filling machine 6. The vibrating feeder 7 and the gland nitrogen charging device 8 are installed on the corresponding station on the outside of the bottle dividing carousel 2 b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com