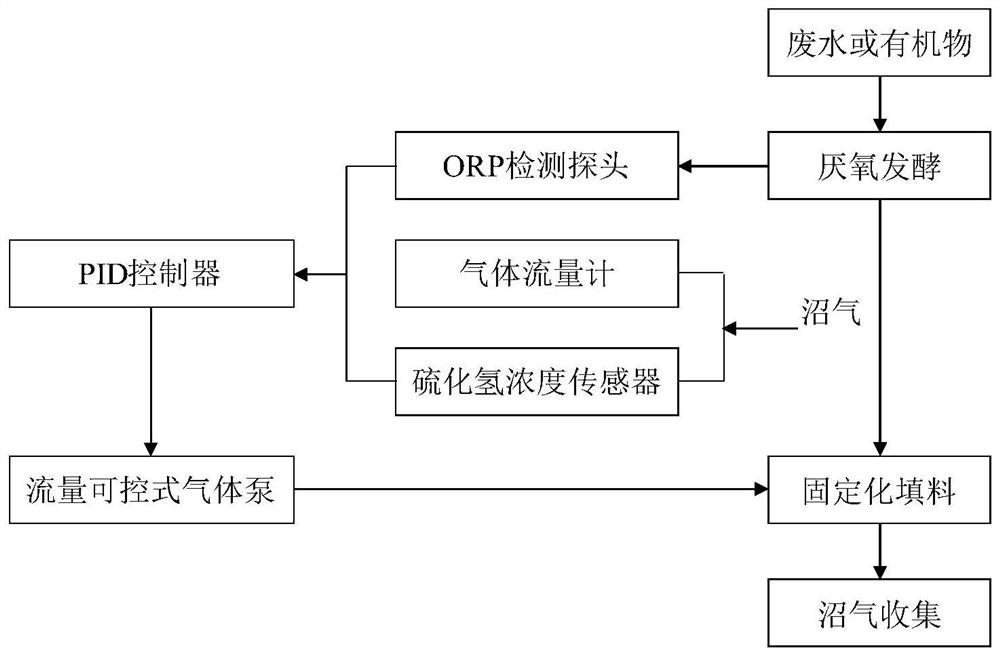

A device and method for improving anaerobic fermentation efficiency and simultaneous in-situ desulfurization

An anaerobic fermentation and anaerobic fermentation tank technology is applied in the field of devices for improving fermentation efficiency and synchronous biogas in-situ desulfurization, which can solve the problems of high cost, poisoning of methanogens, corrosion of transportation pipelines, etc. The effect of improving capacity, promoting anaerobic fermentation and hydrolysis, and low residual oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Example 1: Improvement of anaerobic fermentation efficiency and in-situ desulfurization of cultured manure

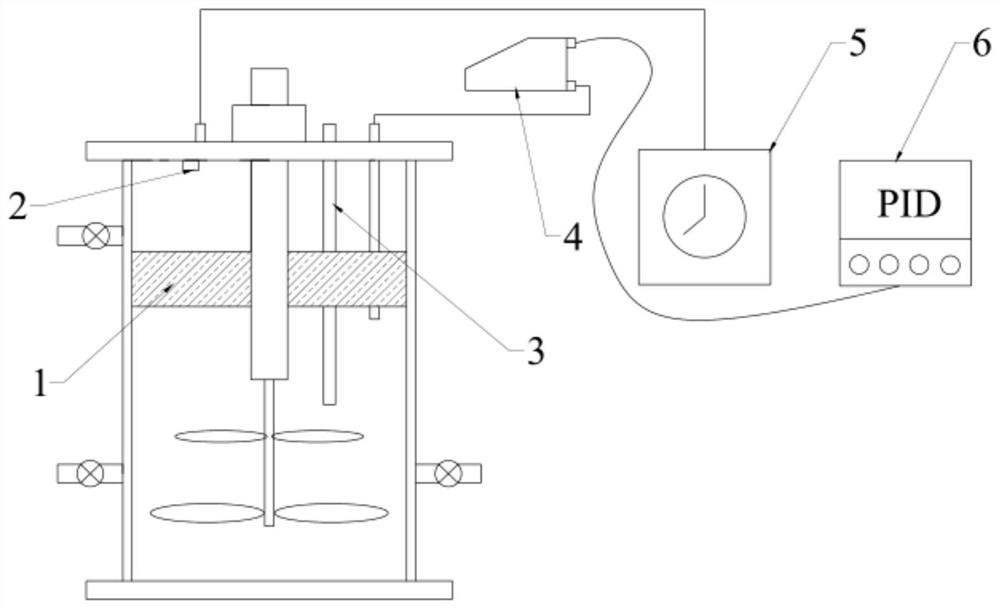

[0055] The chicken manure is processed by a medium temperature anaerobic fermentation device, the total volume of the raw material tank is 8 liters, and the effective volume is 6 liters. The total volume of the fully mixed medium-temperature anaerobic fermentation tank is 15 liters, the effective volume is 10 liters, the height of the immobilized packing is 12 cm, and the diameter is 10 cm.

[0056] After testing, when the total solid concentration of the chicken manure feed is 10%, and the hydraulic retention time is 40 days, the concentration of hydrogen sulfide in the biogas produced by the fully mixed anaerobic reactor is 5000-6000ppm. Under the same fermentation conditions, an in-situ desulfurization full-mixed reactor was run in parallel. The filler is immobilized with a network structure of organic polymer materials, with a cross-sectional area of 0.008...

Embodiment 2

[0057] Example 2: High-concentration organic wastewater anaerobic treatment efficiency improvement and in-situ desulfurization

[0058] The upflow anaerobic reactor is used for anaerobic treatment of beer wastewater. The upflow reactor is 1m high, 30cm in diameter, and the residence time is 3d. The influent COD is about 3000mg / L, the effluent COD is about 400mg / L, and the COD is removed. The efficiency is higher than 80%, the immobilized packing height is 10cm, and the diameter is 30cm; the maximum supply capacity of the air supply pump is 1000mL / day.

[0059] After testing, when the hydraulic retention time of beer wastewater is 3 days, the concentration of hydrogen sulfide in the biogas produced by the upflow reactor is 4000-5000ppm. Under the same fermentation conditions, an upflow reactor for in situ desulfurization with air was run in parallel. Use polypropylene fiber as the material to immobilize the filler with a mesh structure, with a cross-sectional area of 0.07m ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com