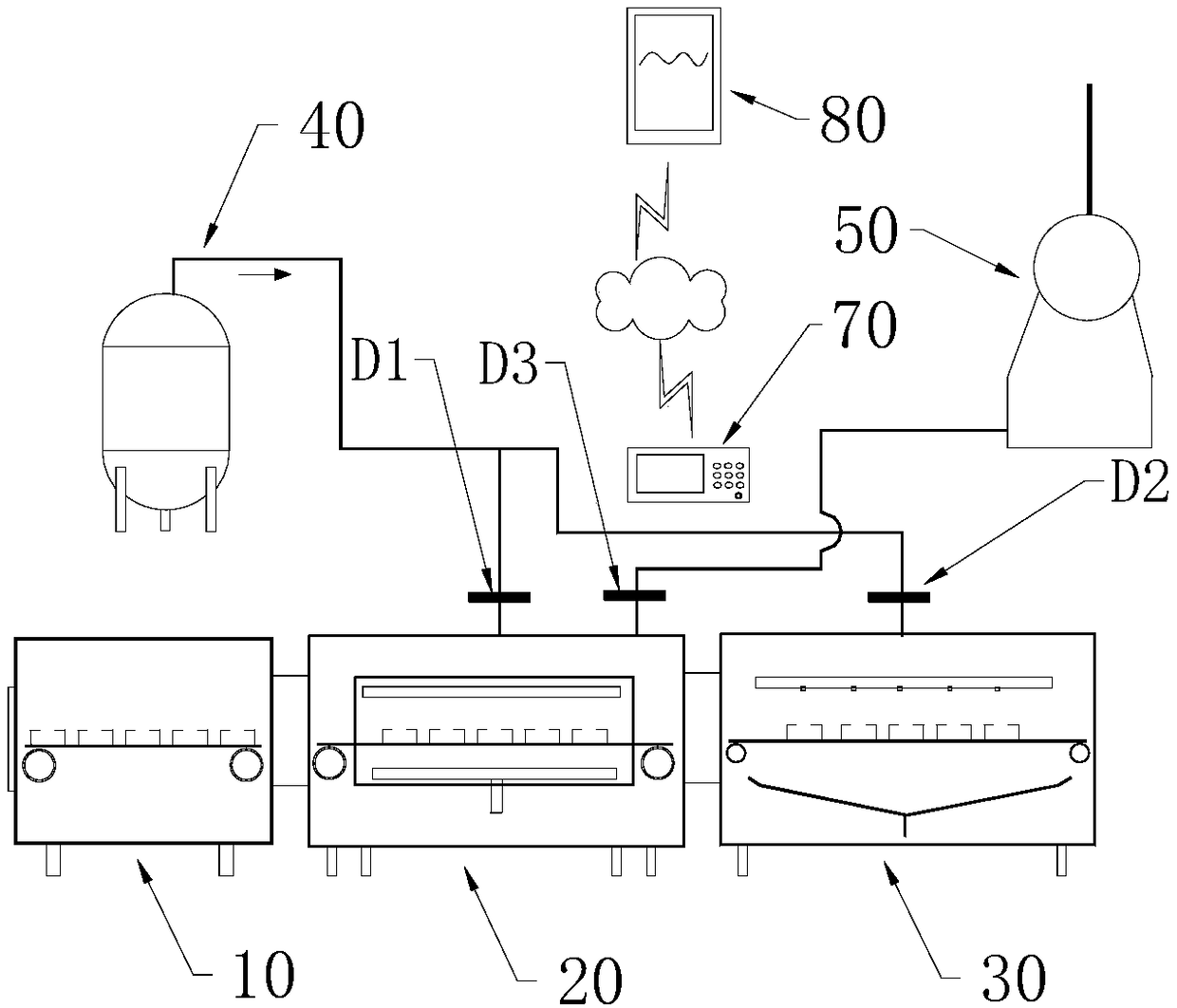

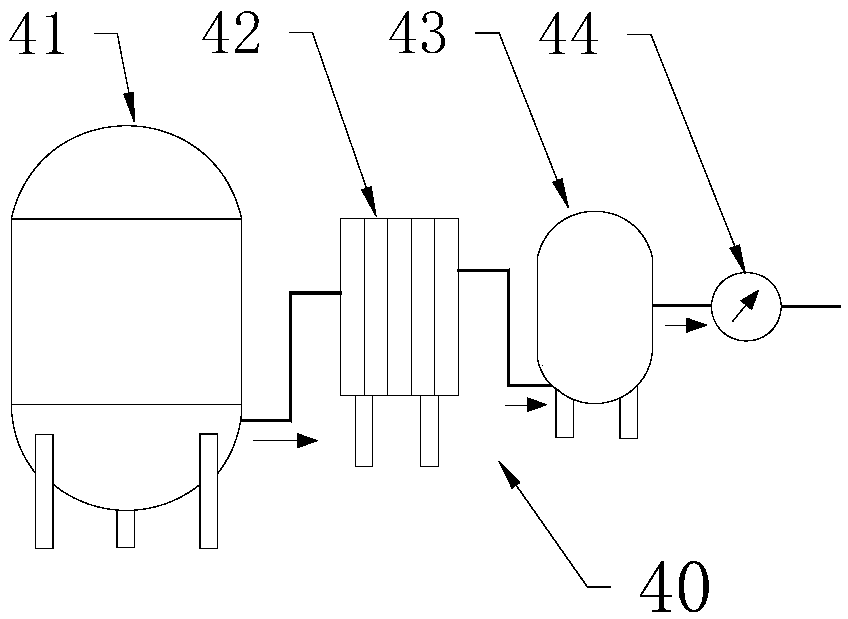

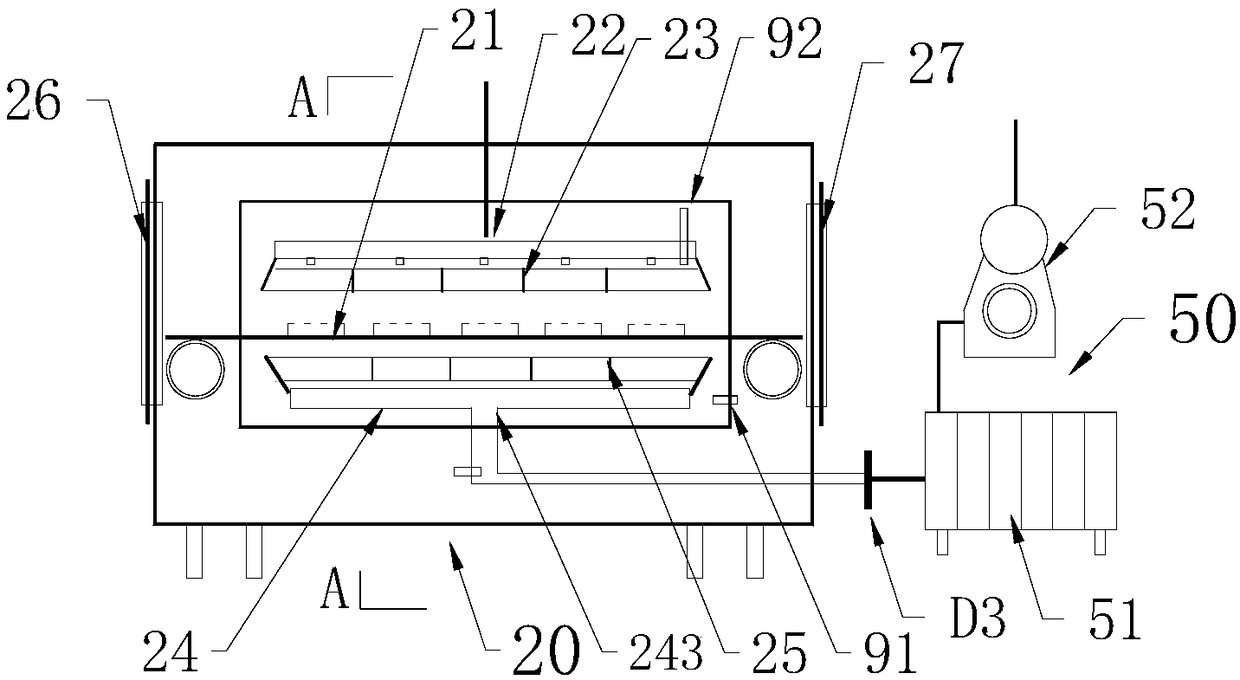

Food intelligent vacuum baking system based on operation and control of Internet of Things

An Internet of Things and food technology, applied in food ovens, oven air treatment devices, baking, etc., can solve the problems of short shelf life, spoilage, poor quality; high baking temperature, etc., to achieve crispness and crispness uniformity Effects of improvement, reduction of oxygen absorption capacity, and improvement of shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] This example of peach cakes shows two batches of peach cakes baked. The ratio of raw materials and ingredients and the production process of the two batches of peach cakes are the same, and no preservatives are added. The above-mentioned food intelligent vacuum baking system is used for baking. Bake and cool. The first batch of peach cakes was baked and cooled in the air environment, sealed and vacuum-packed in the air environment, and 10 samples of peach cakes were randomly selected from the baked peach cakes for testing, and 5 samples were reserved for preservation Periodic test, and the other 5 samples were tested for oil oxidative deterioration and hardness; the second batch of peach crisps was baked and cooled in a vacuum environment with carrier gas, and sealed in vacuum packaging in an air environment, and the baked peach cakes Ten samples of peach crisps were randomly selected from the crisps for testing, among which 5 samples were reserved for storage period te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com