Wet air turbine power generation system based on recycling of garbage gasifying synthesis gas

A technology of gas recovery and power generation system, which is applied in the direction of gasification process, chemical industry, and the manufacture of combustible gas. It can solve the problems of easy ash accumulation, lower heat conversion efficiency, and large input volume, and achieve low heat exchange efficiency loss. , Improve the heat recovery efficiency, the effect of high recovery efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

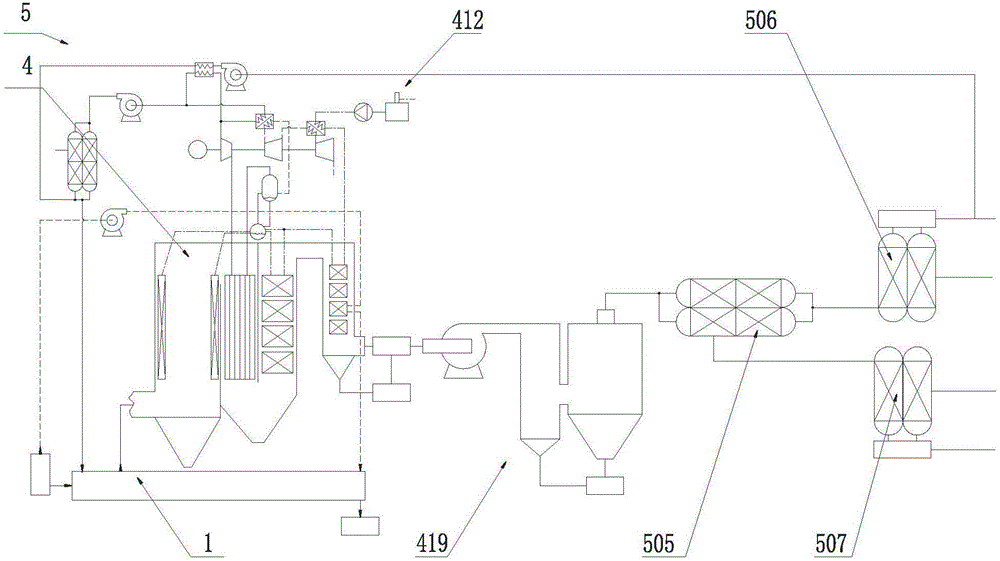

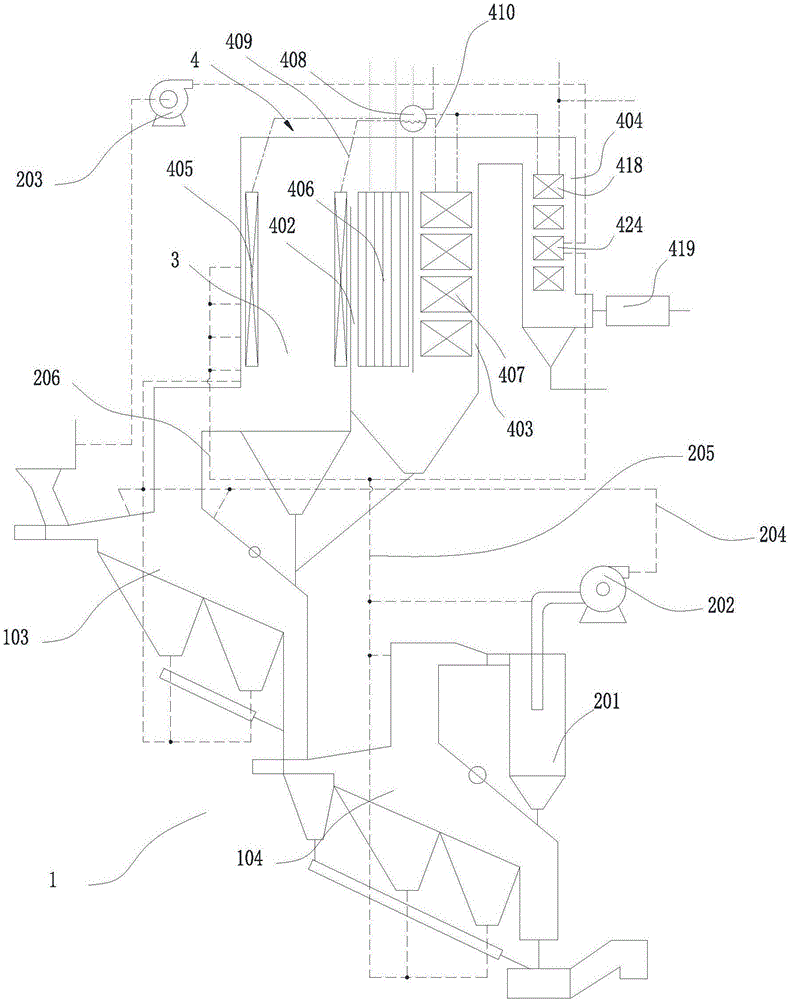

[0044] See figure 1 , Is a preferred embodiment of a humid air turbine power generation system based on waste gasification synthesis gas recovery, including a waste gasification incineration system, a boiler system, and a circulating power generation system 5. The boiler system has a steam drum 408, overheating 器406.

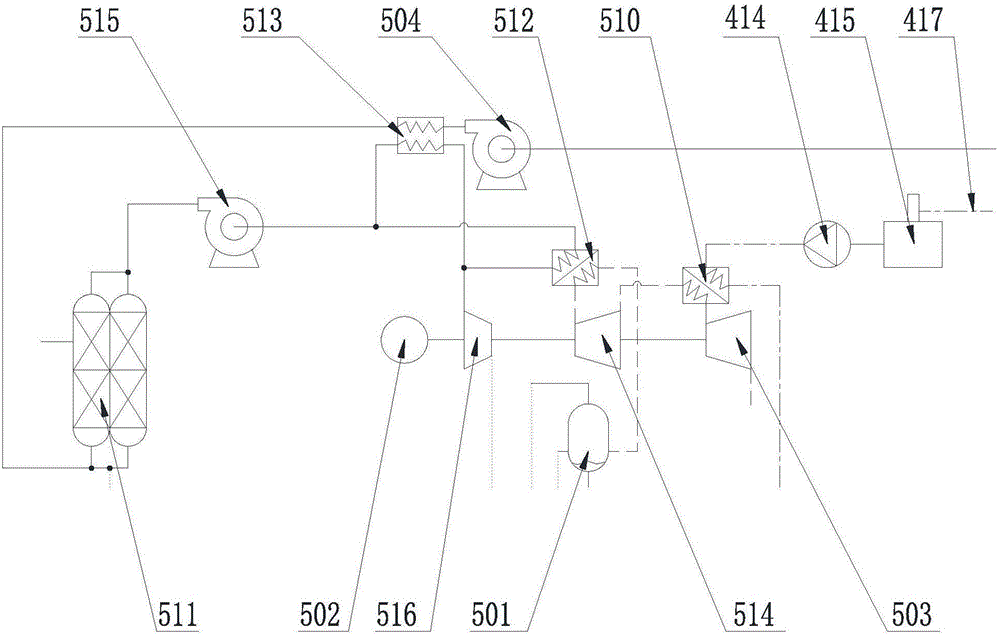

[0045] See figure 2 , The cycle power generation system includes a mixer 501, a low pressure air compressor 503, a high pressure air compressor 514, a turbine 516, a generator 502, an air vapor heat exchanger 512, CO 2 Steam gas heat exchanger 513, gas water heat exchanger 510, CO 2 Fan 504, recirculation fan 515, mixing separator 511, CO 2 The separator and the feed water input system 412 of the boiler system, the low-pressure air compressor 503, the high-pressure air compressor 514, the turbine, and the generator 502 are sequentially connected for power and rotate synchronously to form a gas turbine. In this embodiment, the mixing separator 511 adopts a membrane s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com