Mechanical grate type garbage gasification incineration system and its treatment method

A mechanical grate and garbage technology, applied in the combustion method, incinerator, combustion type, etc., can solve the problems of reducing heat conversion efficiency, backward heat treatment mode, easy ash accumulation, etc., to improve heat exchange efficiency and ensure heat reduction. efficiency, and the effect of preventing secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

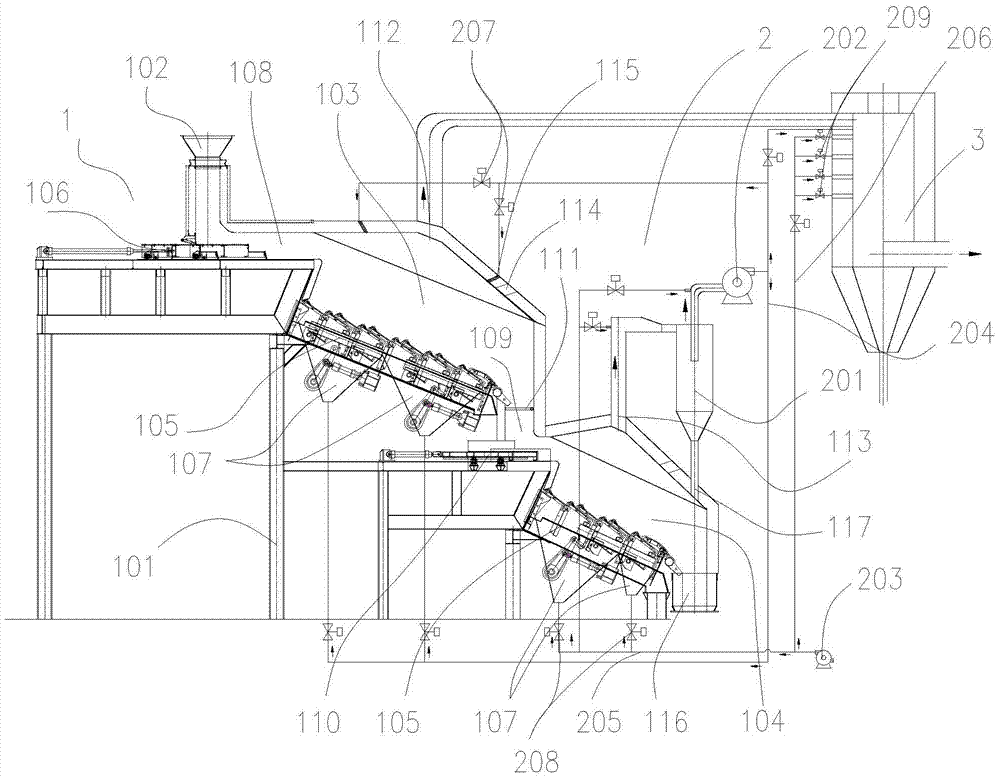

[0039] see figure 1 , is a preferred embodiment of the mechanical grate type garbage gasification incineration system, including a gasification incinerator 1, the gasification incinerator 1 includes a grate 101, and on the grate 101 along the feeding direction The feed bin 102, the gasifier 103 and the ember furnace 104 are arranged, the rear of the ember furnace 104 is the slag outlet of the ember furnace 104, the gasifier 103 mainly gasifies the charcoal part of the garbage, and The combustible gasification flue gas and garbage residues are discharged, and the ember furnace 104 mainly performs combustion treatment of residual charcoal and discharges harmless ash. The hearth 105 of the gasification furnace 103 and the ember furnace 104 adopts a mechanical grate type movable hearth 105 independently driven by sections. The plates are stacked front and back, arranged alternately and gathered together. Multiple groups of adjacent movable grate plates are connected by tie rods a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com