Spiral flocculator and application to folded plate type flocculation reaction tank

A flocculator and reaction tank technology, applied in the direction of flocculation/sedimentation water/sewage treatment, settling tank, etc., can solve the problems of insufficient stirring intensity, low water treatment capacity, and large application limitations, and achieve high mixing intensity and promote mixing and responsive, easy-to-operate effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

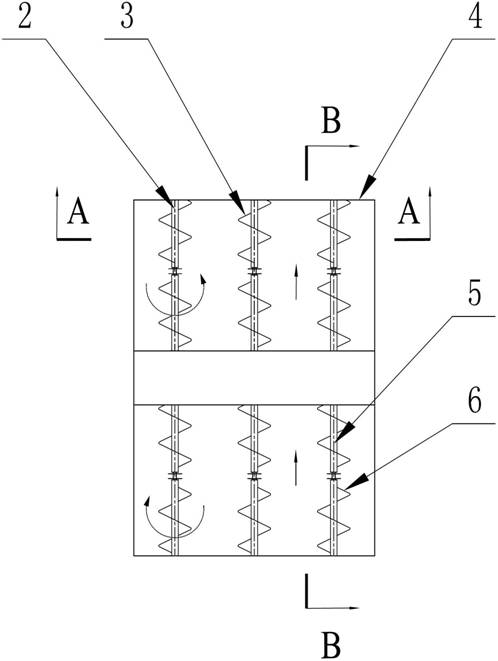

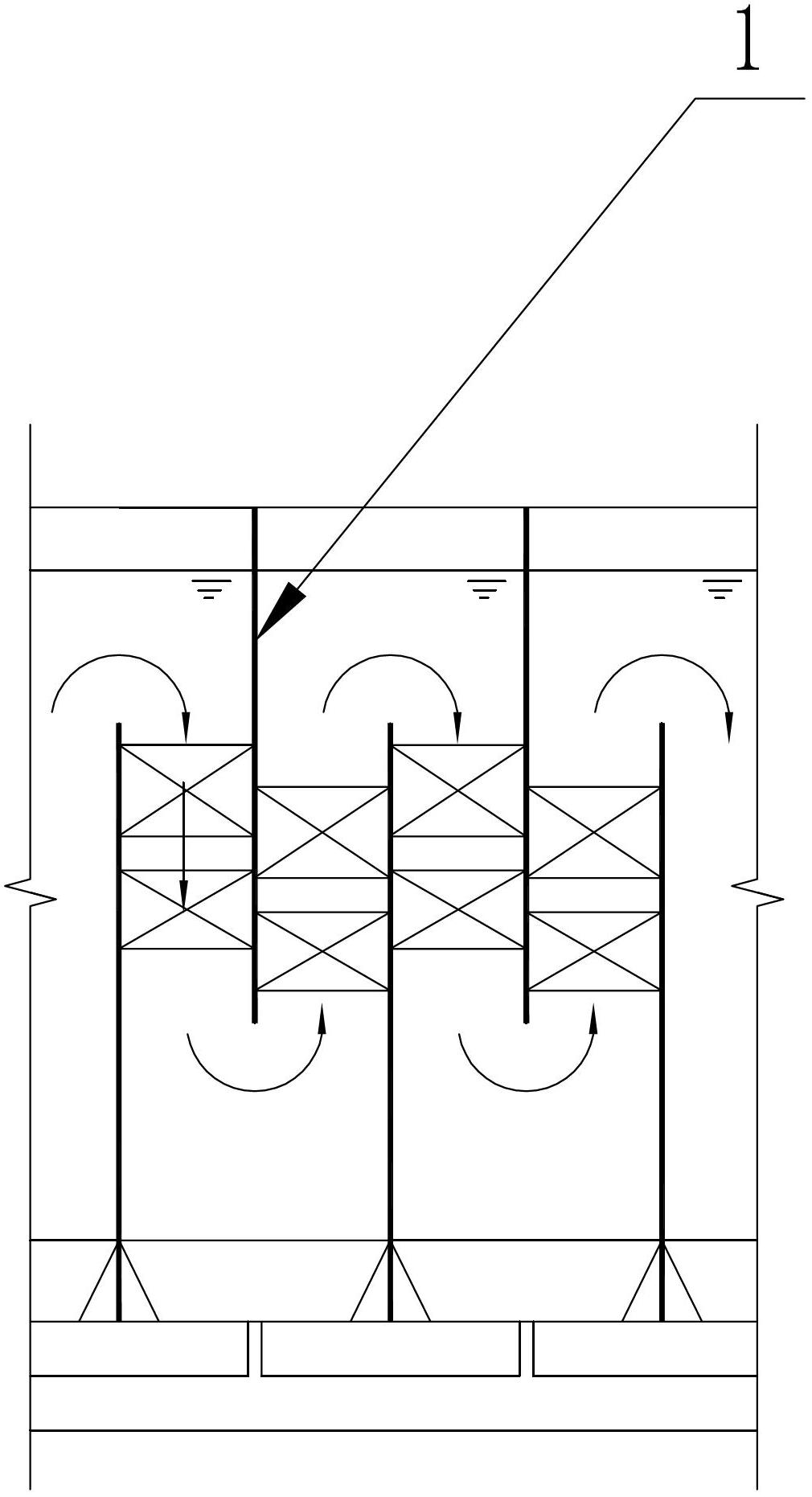

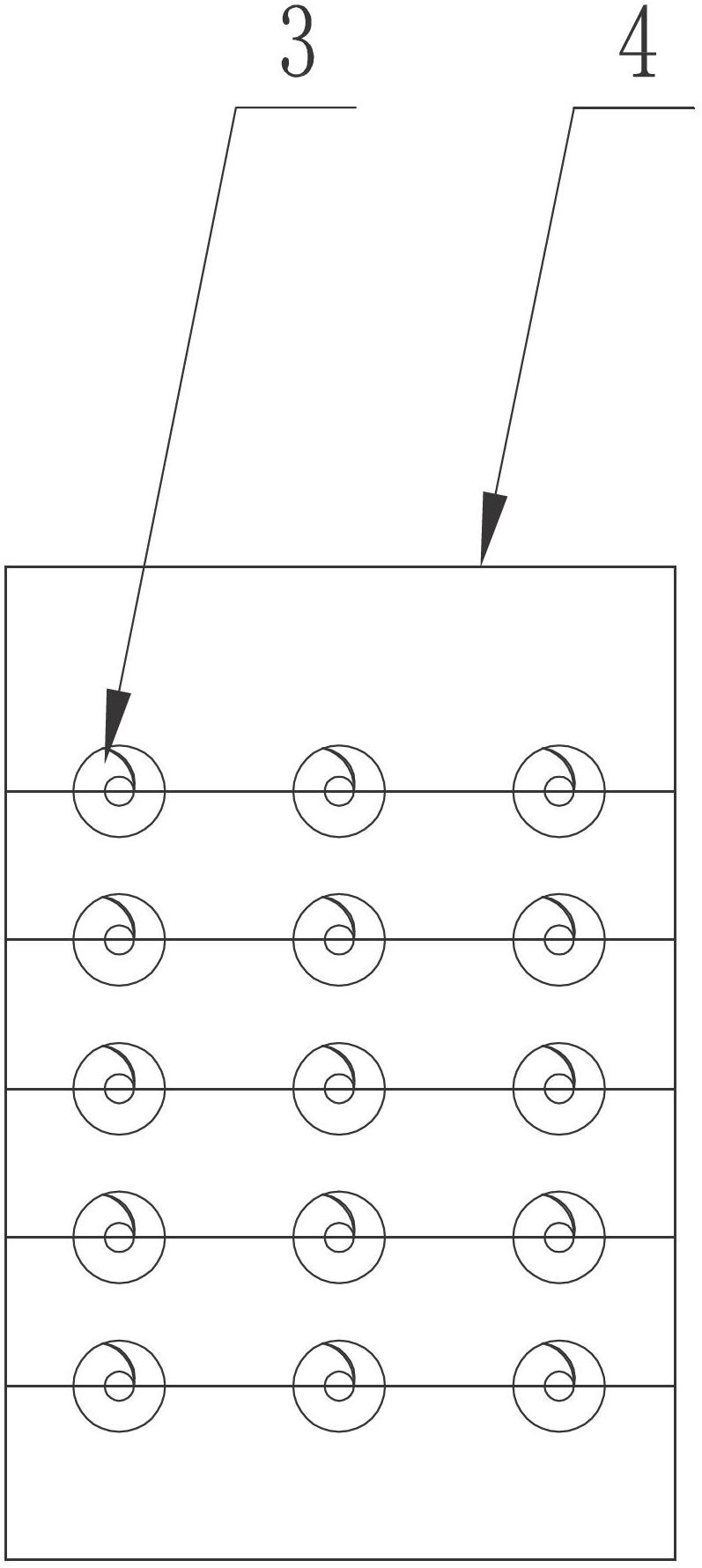

[0039] The overall structure of this embodiment is as Figure 1-6 As shown, the spiral flocculator includes a support 4, and at least two groups of spiral sheets with opposite rotations are arranged at longitudinal intervals on the support 4. The upper and lower ends of the spiral sheets and the support 4 are assembled by rotation, and the spiral Strip blades 7 are radially fixed on the outer edge of the sheet.

[0040] For the application of the spiral flocculator in the folded plate flocculation reaction tank, the spiral flocculator is installed between two adjacent partitions 1 in the folded plate flocculation reaction tank.

[0041] Considering that it can have a good disturbing effect on the water body, one spiral flocculator can be installed between two adjacent partitions, and multiple vertical or horizontal intervals can be installed as required.

[0042] The strip blades 7 are fixedly assembled at equiangular intervals on the outer edge of the spiral piece.

[0043]...

Embodiment 2

[0051] In this embodiment, the installation of the spiral flocculator in the folding plate flocculation reaction tank is as follows: Figure 7 shown. The axial direction of the spiral flocculator is perpendicular to the water flow direction in the folded plate flocculation reaction tank. All the other structures are as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com