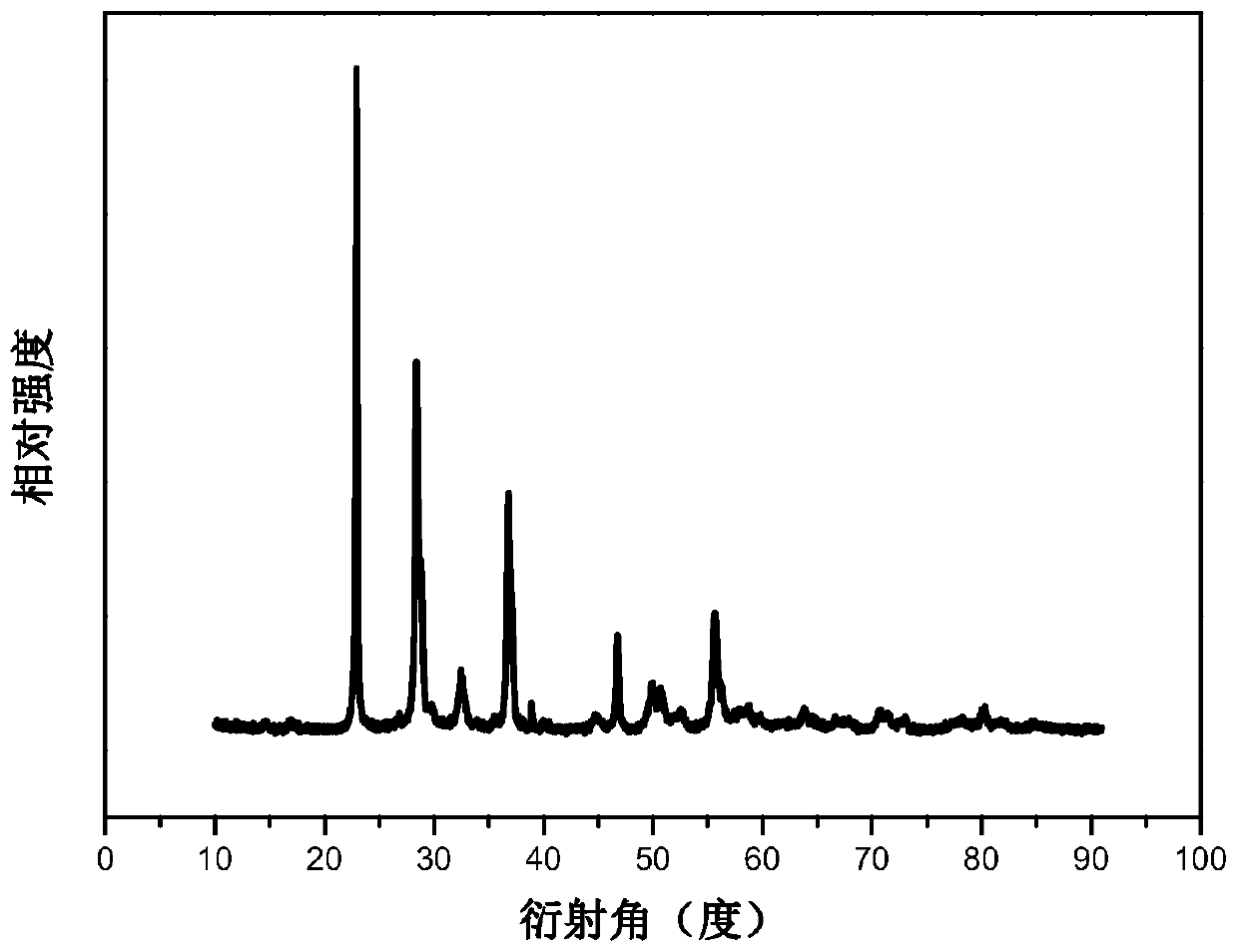

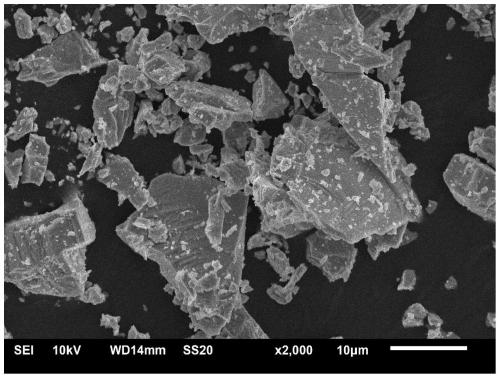

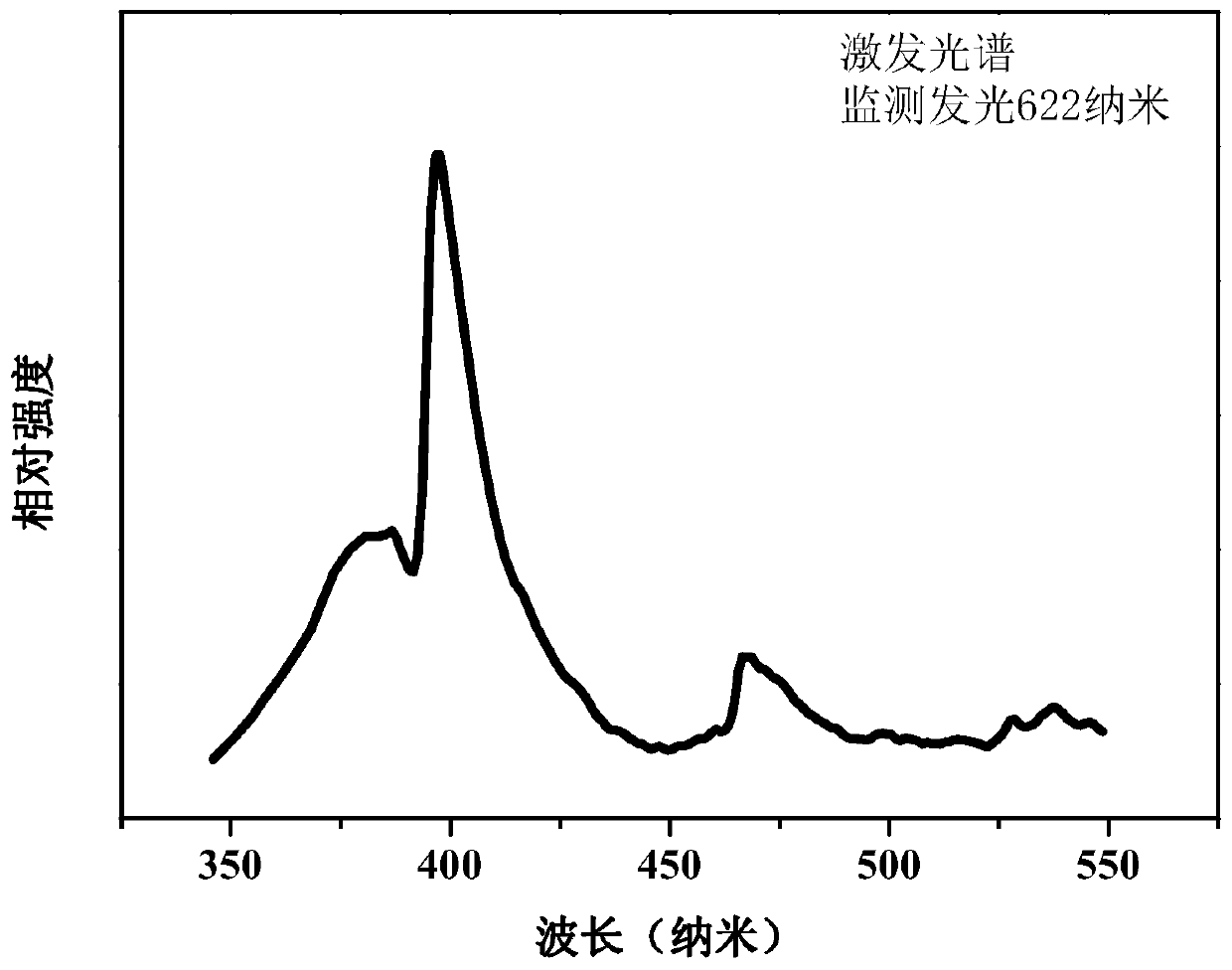

Eu<3+> ion activated tantalate fluorescent powder, and synthesis method and application thereof

A synthesis method and phosphor technology, applied in the field of tantalate phosphor and its synthesis, can solve the problems of expensive synthesis equipment, complex synthesis process, poor thermal stability, etc., achieve excellent thermal stability, simple synthesis process, and equipment requirements low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] According to the chemical formula Na 1.7 Eu 0.3 Ta 1.7 Ga 0.3 NbO 6 f 5 The stoichiometric ratio of several elements in: Na 2 CO 3 : 3.71 g; Eu 2 o 3 : 5.279 grams; Ta 2 o 5 : 34.84 g; Ga 2 o 3 : 2.812 g; Nb 2 o 5 : 13.29 grams; the weighed raw material is put into an agate mortar and ground, and the mixed raw material obtained is calcined for the first time in an air atmosphere. The calcining temperature is 1250° C., and the calcining time is 5 hours;

[0027] The obtained primary calcined product was put into an agate mortar for grinding, pressed into a block, and then calcined for the second time in an air atmosphere. The calcining temperature was 1400° C. and the calcining time was 1 hour.

[0028] The obtained calcined product is cooled naturally for the second time, put into an agate mortar and grind until it becomes powdery, and the powder and the pre-weighed NaF: 4.2 grams and NH 4 F: 14.8 grams of grinding and mixing, the obtained mixture is pres...

Embodiment 2

[0034] According to the chemical formula Na 1.998 Eu 0.002 Ta 1.998 Ga 0.002 NbO 6 f 5 The stoichiometric ratio of several elements in: Na 2 CO 3 : 5.2894 g; Eu 2 o 3 : 0.035 grams; Ta 2 o 5 : 40.95 g; Ga 2 o 3 : 0.019 g; Nb 2 o 5 : 13.29 grams; the weighed raw material is put into an agate mortar and ground, and the mixed raw material obtained is calcined for the first time in an air atmosphere. The calcining temperature is 800° C., and the calcining time is 1 hour;

[0035] The obtained primary calcined product was put into an agate mortar for grinding, pressed into a block, and then calcined for the second time in an air atmosphere. The calcining temperature was 1200° C. and the calcining time was 10 hours.

[0036] The obtained calcined product is cooled naturally for the second time, put into an agate mortar and grind until it becomes powdery, and the powder and the pre-weighed NaF: 4.2 grams and NH 4 F: 14.8 grams of grinding and mixing, the obtained mixtu...

Embodiment 3

[0039] According to the chemical formula Na 1.9 Eu 0.1 Ta 1.9 Ga 0.1 NbO 6 f 5 The stoichiometric ratio of several elements in: Na 2 CO 3 : 4.77 g; Eu 2 o 3 : 1.759 grams; Ta 2 o 5 : 38.94 g; Ga 2 o 3 : 0.94 g; Nb 2 o 5 : 13.29 grams; the weighed raw material is put into an agate mortar and ground, and the mixed raw material obtained is calcined for the first time in an air atmosphere. The calcining temperature is 1000° C., and the calcining time is 10 hours;

[0040] The obtained primary calcined product was put into an agate mortar for grinding, pressed into a block, and then calcined for the second time in an air atmosphere. The calcining temperature was 1350° C. and the calcining time was 3.5 hours.

[0041] The obtained calcined product is cooled naturally for the second time, put into an agate mortar and grind until it becomes powdery, and the powder and the pre-weighed NaF: 4.2 grams and NH 4 F: 14.8 grams of grinding and mixing, the obtained mixture is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com