a kind of EU 3+ Ion activated vanadium phosphoniobate red phosphor, preparation method and application thereof

A technology of red phosphor and niobate, which is applied in the field of vanadium phospho-niobate red phosphor, can solve the problems of high operation and equipment requirements, increased production cost, poor thermal stability, etc., and achieve low equipment requirements and convenient operation , the effect of strong excitation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Preparation of Ca 0.8 Eu 0.2 Nb1.8 Ti 0.2 V 2 P 4 o 21

[0033] Weigh according to the stoichiometric ratio of each element in the chemical formula: CaCO 3 : 1.6 g, Eu 2 o 3 : 0.704 g, Nb 2 o 5 : 4.784 g, V 2 o 5 : 3.64 g, P 2 o 5 : 5.68 g, TiO 2 : 0.32 g. Put the weighed raw materials into an agate mortar and carefully grind and mix them evenly. The mixture is pre-calcined in an air atmosphere. The pre-calcination temperature is 350°C and the calcination time is 5 hours. Uniform, calcined again in the air atmosphere, the calcining temperature is 850°C, and the calcining time is 6 hours; the powder obtained in this step is naturally cooled, ground and mixed, and calcined for the third time in the air atmosphere, the calcining temperature is 1100°C, and the calcining time is for 5 hours, after natural cooling and grinding to obtain a kind of Eu 3+ Ionically activated vanadium phosphoniobate red phosphor.

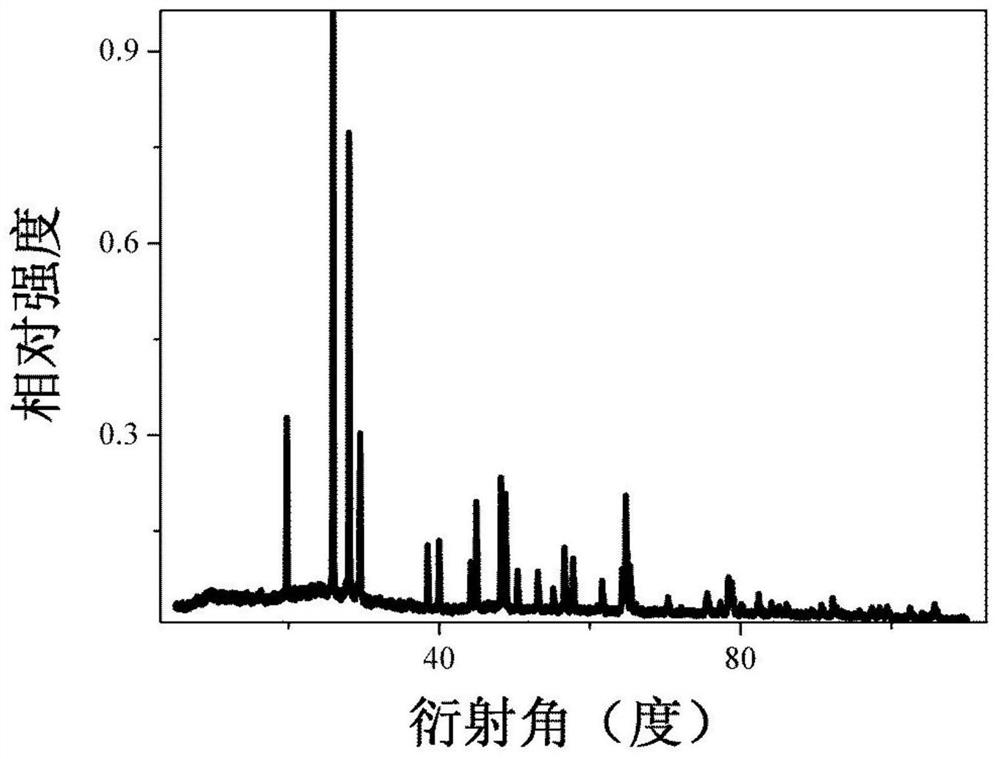

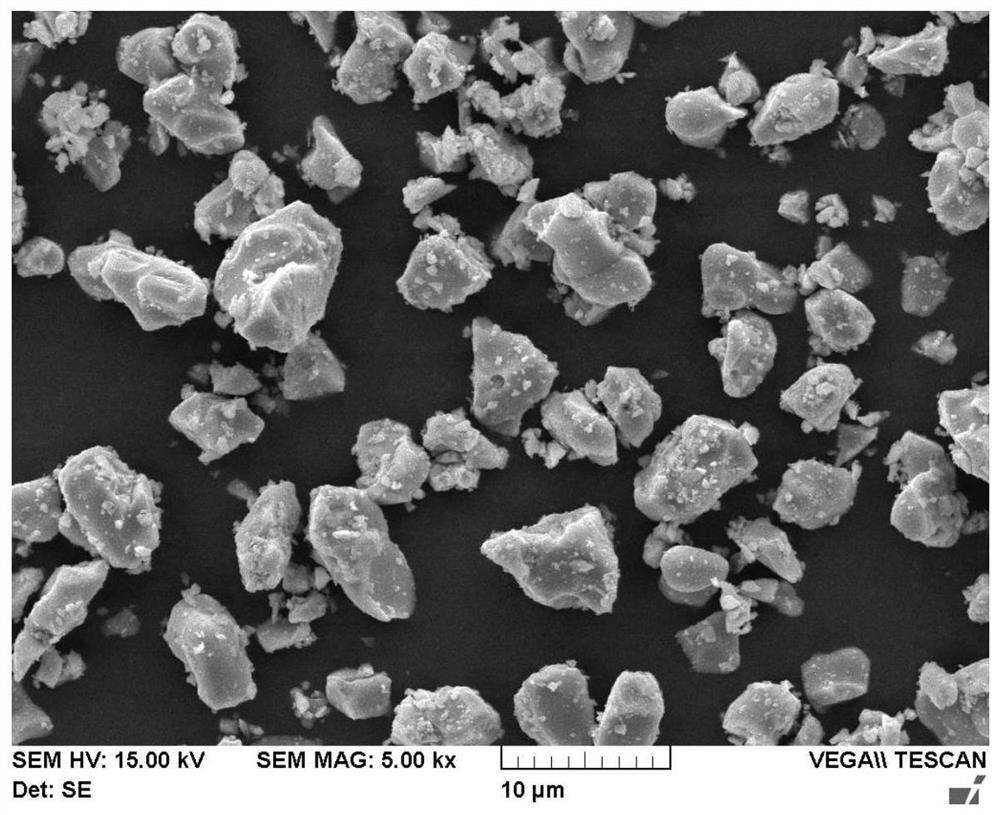

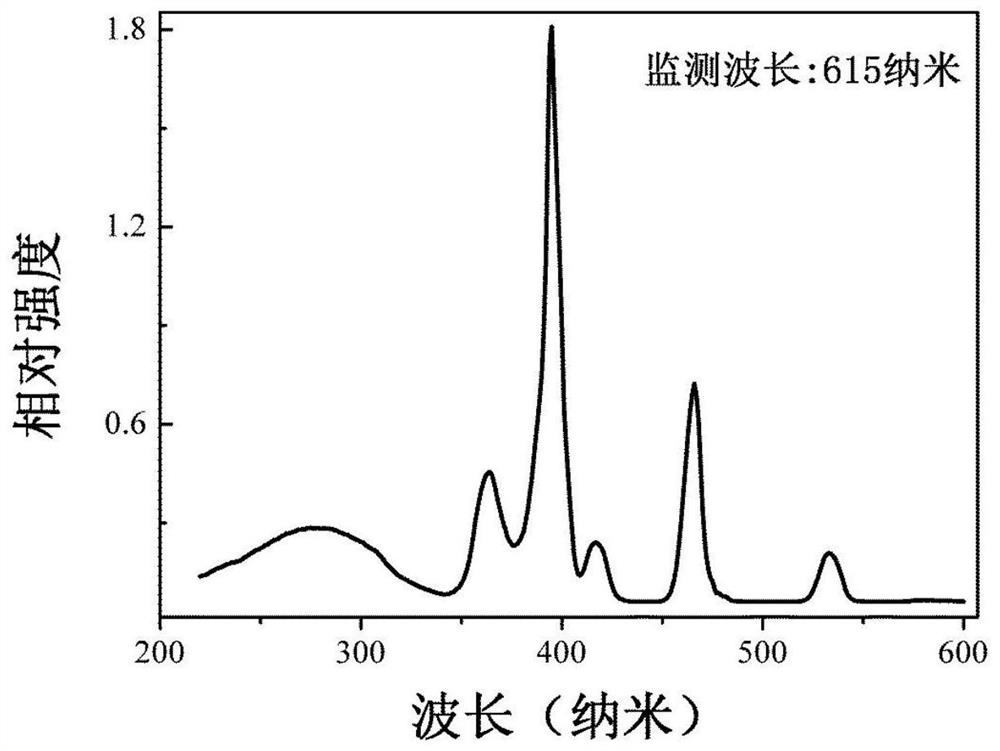

[0034] See attached figure 1 , which is the X-...

Embodiment 2

[0040] Preparation of Ca 0.999 Eu 0.001 Nb 1.999 Ti 0.001 V 2 P 4 o 21

[0041] Weigh according to the stoichiometric ratio of each element in the chemical formula: Ca(NO 3 ) 2 : 3.277 g, Eu 2 o 3 : 0.004 g, Nb 2 o 5 : 5.313 g, NH 4 VO 3 : 4.68 g, NH 4 h 2 PO 4 : 9.2 g, TiO 2 : 0.0016 g. Put the weighed raw materials into an agate mortar and carefully grind and mix them evenly. Pre-calcine the mixture in an air atmosphere. The pre-calcination temperature is 300°C and the calcination time is 10 hours. Uniform, calcined again in the air atmosphere, the calcining temperature is 900°C, and the calcining time is 1 hour; the powder obtained in this step is naturally cooled, ground and mixed, and calcined for the third time in the air atmosphere, the calcining temperature is 950°C, and the calcining time is For 10 hours, after natural cooling, ground to obtain a kind of Eu 3+ Ionically activated vanadium phosphoniobate red phosphor.

[0042] Its main structure is...

Embodiment 3

[0044] Preparation of Ca 0.9 Eu 0.1 Nb 1.9 Ti 0.1 V 2 P 4 o 21

[0045] Weigh according to the stoichiometric ratio of each element in the chemical formula: CaCO 3 : 3.15 g, Eu 2 o 3 : 0.616 g, Nb 2 o 5 : 8.378 g, NH 4 VO 3 : 8.19 grams, (NH 4 ) 2 ·HPO 4 : 18.48 g, TiO 2 : 0.28g. Put the weighed raw materials into the agate mortar and carefully grind and mix them evenly, pre-calcine the mixture in the air atmosphere, the calcination temperature is 450°C, and the calcination time is 1 hour; after the obtained product is naturally cooled, mix it evenly in the agate mortar , calcined again in an air atmosphere, the calcining temperature is 450°C, and the calcining time is 10 hours; the powder obtained in this step is naturally cooled, ground and mixed, and calcined for the third time in an air atmosphere, the calcining temperature is 1250°C, and the calcining time is 1 hour, after natural cooling, grind to obtain a kind of Eu 3+ Ionically activated vanadium pho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| fluorescence lifetime | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com