Hollow fibrous membrane reactor integrating gas distribution and enzyme catalysis and application of hollow fibrous membrane reactor

A fiber membrane reactor and fiber membrane technology are applied in the fields of enzyme catalysis, bioreactor, and chemical technology, which can solve the problems of reaction rate and reaction balance, difficulty in recycling and reuse, and catalyst soluble in water, etc. Compact, fast and efficient dispersion and mixing, easy to control separately

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

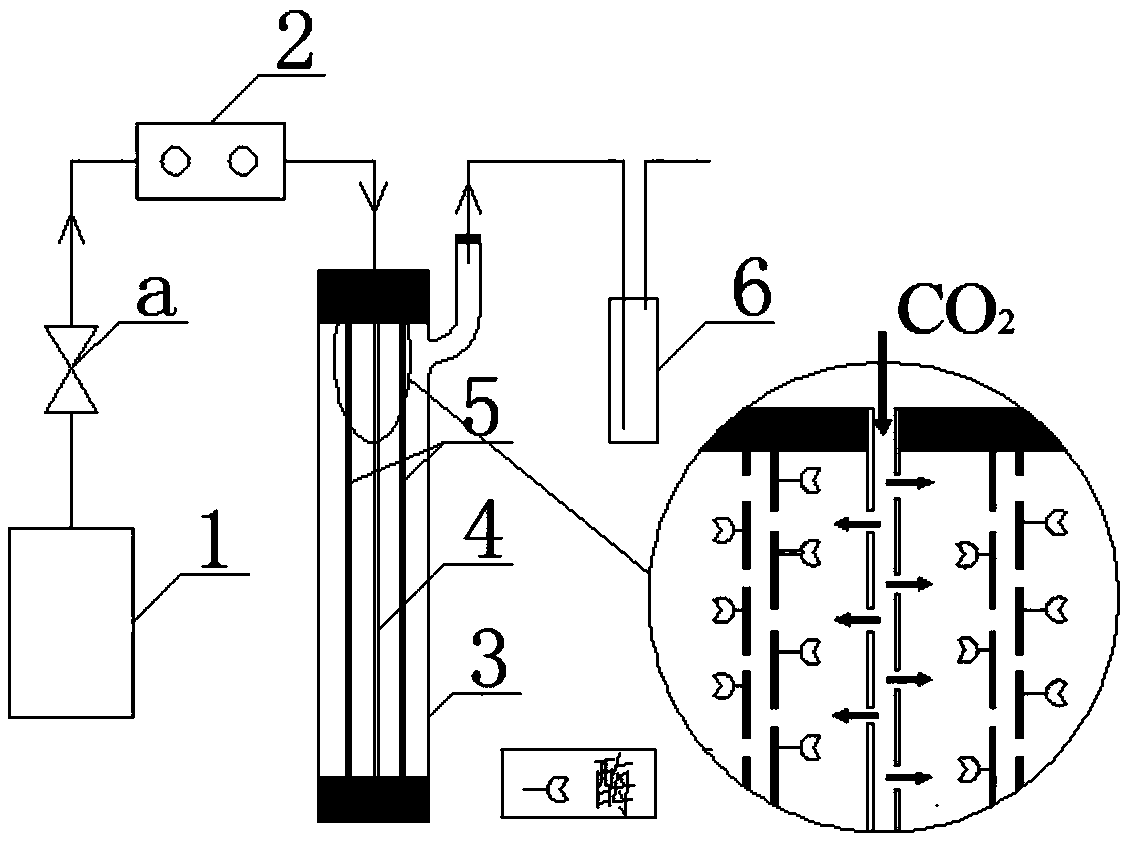

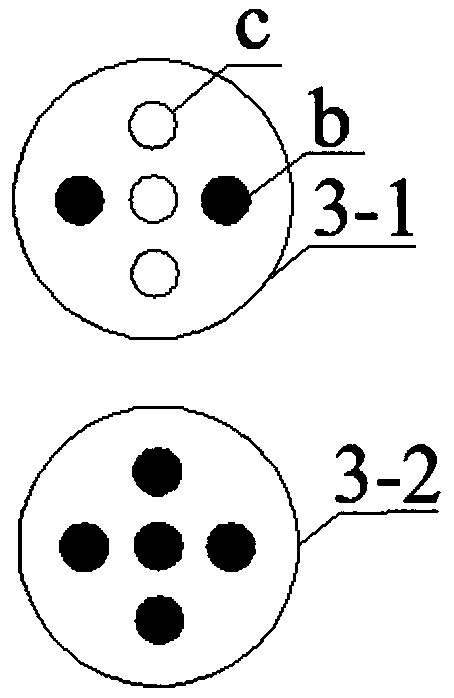

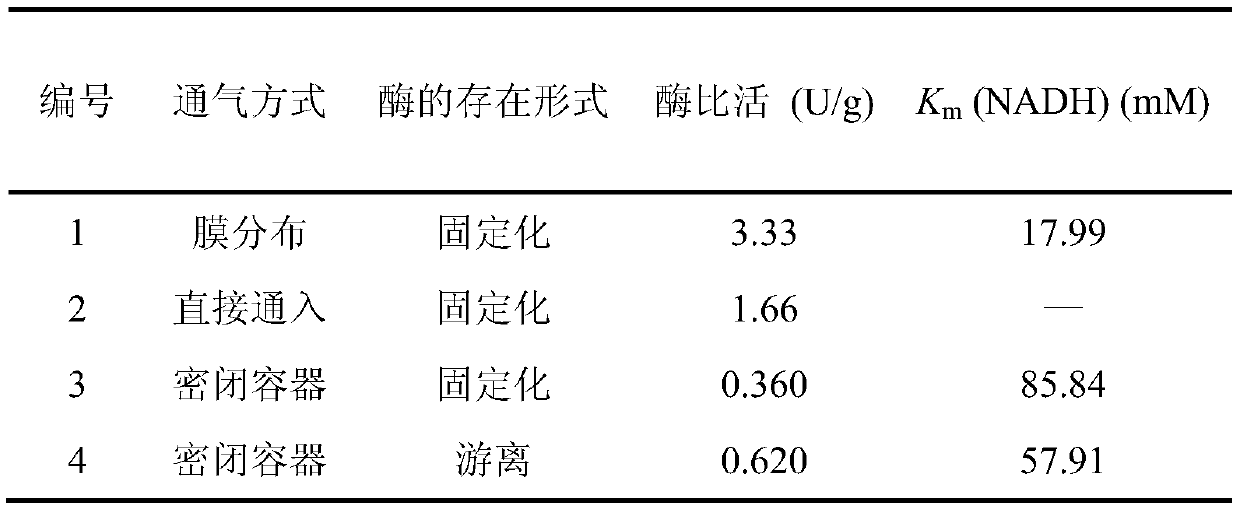

[0034] Application of hollow fiber membrane reactor to formate dehydrogenase (FDH) catalyzed CO 2 Synthetic formic acid system: 2 PE hollow fiber membranes (pore size 0.569μm, porosity 58%) with gas distribution and 1 PP hollow fiber membrane immobilized with FDH are encapsulated in the same module to form membrane reactor 3; Add 10mM NADH phosphate buffer solution to reactor 3, heat in a water bath, and control the temperature to 37℃; open the pressure reducing valve a of the gas storage tank 1, adjust the mass flow meter 2 to make CO 2 The gas flows into the inner cavity of the hollow fiber membrane 4 at a certain flow rate (the liquid should not overflow the side branch of the membrane module as the upper limit). Under the action of the pressure difference, the gas passes through the membrane pores to bubble with the enzyme immobilized in the membrane module The enzyme catalyst carried on the surface of the hollow fiber membrane 5 contacts and reacts with other reactants in th...

Embodiment 2

[0038] Application of hollow fiber membrane reactor to FDH catalyzed CO 2 Synthetic formic acid system: Two gas-distributed PTFE hollow fiber membranes (pore size 0.892μm, porosity 65%) and two FDH-immobilized PE hollow fiber membranes are encapsulated in the same module to form membrane reactor 3; Add 5mM NADH phosphate buffer solution to reactor 3, heat in a water bath, and control the temperature to 37℃; open the pressure reducing valve a of the gas storage tank 1, adjust the mass flow meter 2 to make CO 2 The gas flows into the inner cavity of the hollow fiber membrane 4 at a certain flow rate (the liquid should not overflow the side branch of the membrane module as the upper limit). Under the action of the pressure difference, the gas passes through the membrane pores to bubble with the enzyme immobilized in the membrane module. The enzyme catalyst supported on the surface of the hollow fiber membrane 5 contacts and reacts with other reactants in the shell side solution, and...

Embodiment 3

[0040] Application of hollow fiber membrane reactor to FDH catalyzed CO 2 Synthetic formic acid system: 4 gas-distributed PP hollow fiber membranes (pore size 0.384μm, porosity 20%) and 3 PVDF hollow fiber membranes immobilized with FDH are encapsulated in the same module to form membrane reactor 3; Add 30mM NADH phosphate buffer solution to reactor 3, heat in a water bath, and control the temperature to 37℃; open the pressure reducing valve a of the gas storage tank 1, adjust the mass flow meter 2 to make CO 2 The gas flows into the inner cavity of the hollow fiber membrane 4 at a certain flow rate (the liquid should not overflow the side branch of the membrane module as the upper limit). Under the action of the pressure difference, the gas passes through the membrane pores to bubble with the enzyme immobilized in the membrane module. The enzyme catalyst carried on the surface of the hollow fiber membrane 5 contacts and reacts with other reactants in the shell side solution. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com