Double-output middle sealing full-automatic bag-making apparatus and bag-making method thereof

A bag-making device and fully automatic technology, which is applied in the field of double-out and middle-sealing automatic bag-making devices, can solve the problems of low efficiency, waste of energy, unfavorable market competition, etc., and achieve the effect of saving cost and improving production capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the drawings.

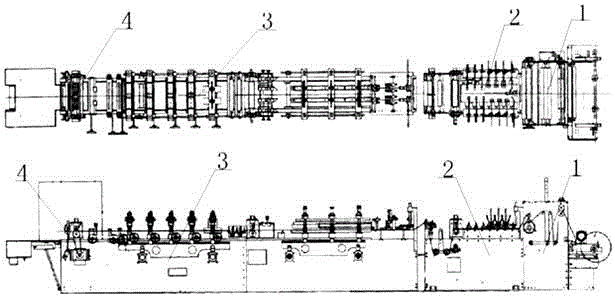

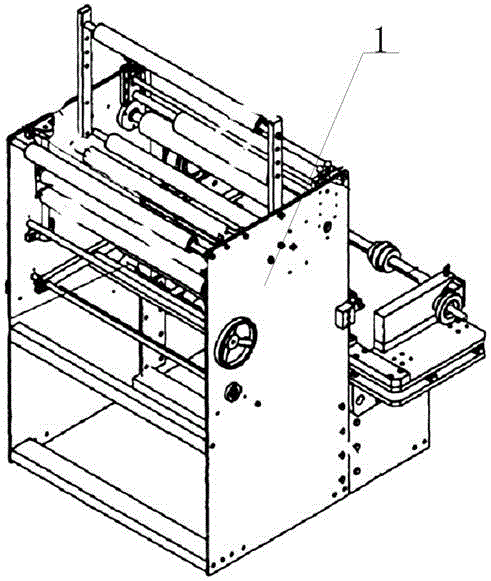

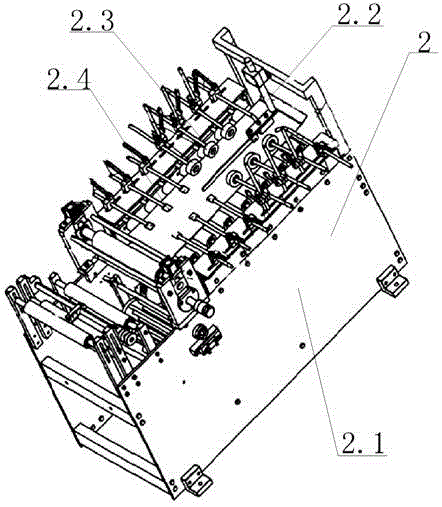

[0027] Such as Figure 1 to 5 As shown, a double-out and middle-seal fully automatic bag-making device includes a feeding device 1, a folding device 2, a heat sealing device 3, and a discharging device 4 that are sequentially connected from front to back; the feeding device 1 includes a back fold Device 1.1, said back folding device 1.1 includes a first baffle 1.1.1, a second baffle 1.1.2, a third baffle 1.1.3, a fourth baffle 1.1.4, and a fifth baffle 1.1.5, The first baffle 1.1.1, the second baffle 1.1.2, the third baffle 1.1.3, the fourth baffle 1.1.4, and the fifth baffle 1.1.5 are alternately arranged up and down; The device 2 includes a turning device body 2.1, a cutter 2.2, a pressing wheel 2.3, and a plurality of turning plates 2.4. The cutting knife 2.2, a pressing wheel 2.3 and a plurality of turning plates 2.4 are installed on the turning device body 2.1.

[0028]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com