Patents

Literature

116results about How to "Keep it bright" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

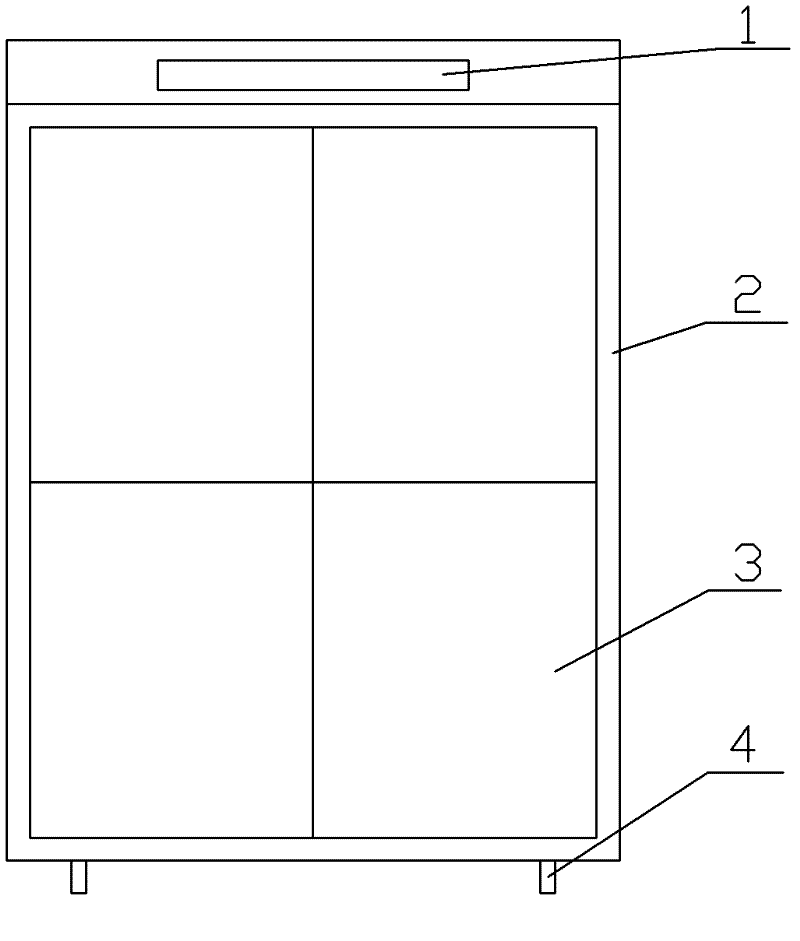

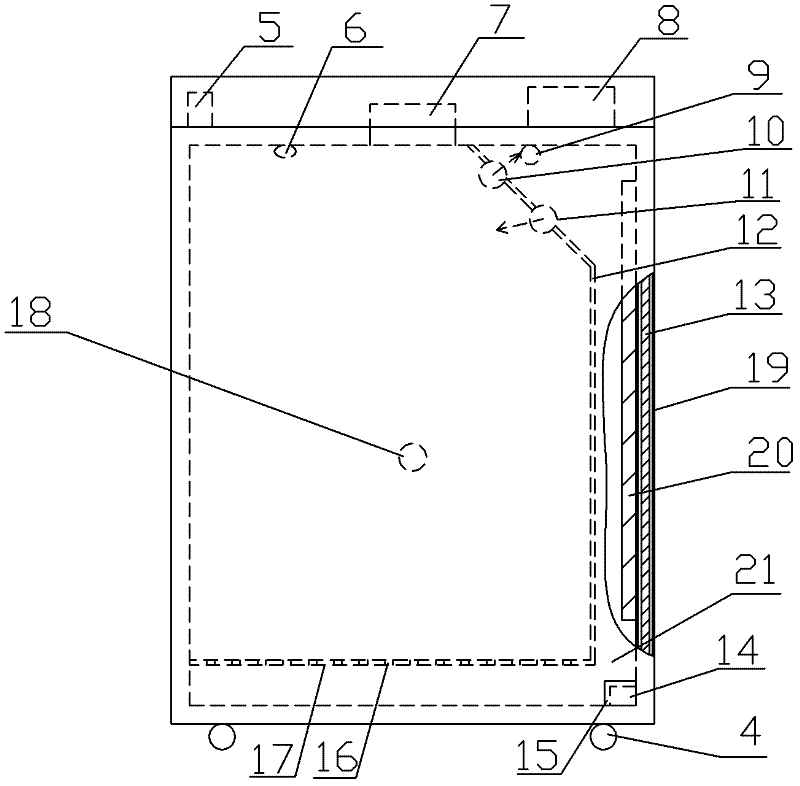

Constant temperature and humidity storage box of gingers

InactiveCN102344019AKeep it brightLow costLiving organism packagingDomestic cooling apparatusElectricityEngineering

The invention discloses a constant temperature and humidity storage box of gingers, which belongs to article storage boxes. The structure of the constant temperature and humidity storage box of the gingers comprises a box body, a box door, a refrigerating unit, a control panel, a microcomputer control circuit, an ultraviolet sterilizing lamp, an electric heating pipe and an evaporator, wherein the back part and bottom of the box body are respectively provided with a back part partition board and a bottom partition board; an air inlet fan and an air exhaust fan are respectively arranged at the top of the back part partition board; a ventilating hole is formed on the bottom partition board; a water tank is formed at the lower part of the evaporator; a water tank outer cover is arranged on the outer wall of the box body corresponding to the water tank; a ventilating cover is arranged in the middle of the top of the box body; the ultraviolet sterilizing lamp is arranged on the box top in the interior of the box body; a temperature and humidity sensor is arranged on the side wall of the middle part of the box body; and the microcomputer control circuit is electrically connected with the control panel, the temperature and humidity sensor, the refrigerating unit, the air inlet fan, the electric heating pipe, the air exhaust fan, the ultraviolet sterilizing lamp and the evaporator respectively. The constant temperature and humidity storage box of the gingers has the characteristics of good ventilating and heat radiation condition and no generation of stuffiness and decayed gingers; and the temperature and humidity as well as plant diseases and insect pests can be effectively controlled.

Owner:VEGETABLE RES INST OF SHANDONG ACADEMY OF AGRI SCI

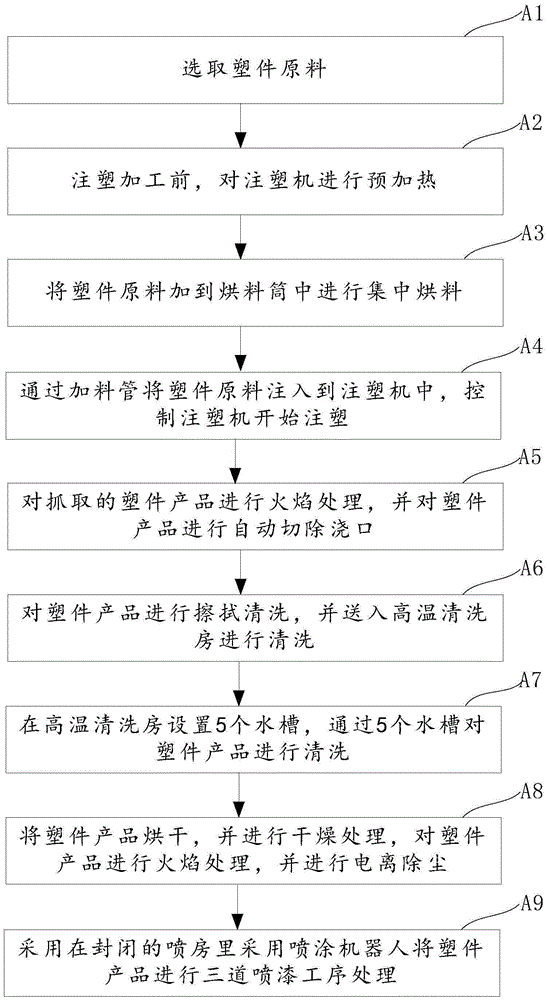

Method for producing colored bumpers

InactiveCN105413979AImprove impact resistanceAvoid defectsPretreated surfacesCoatingsFlame treatmentEngineering

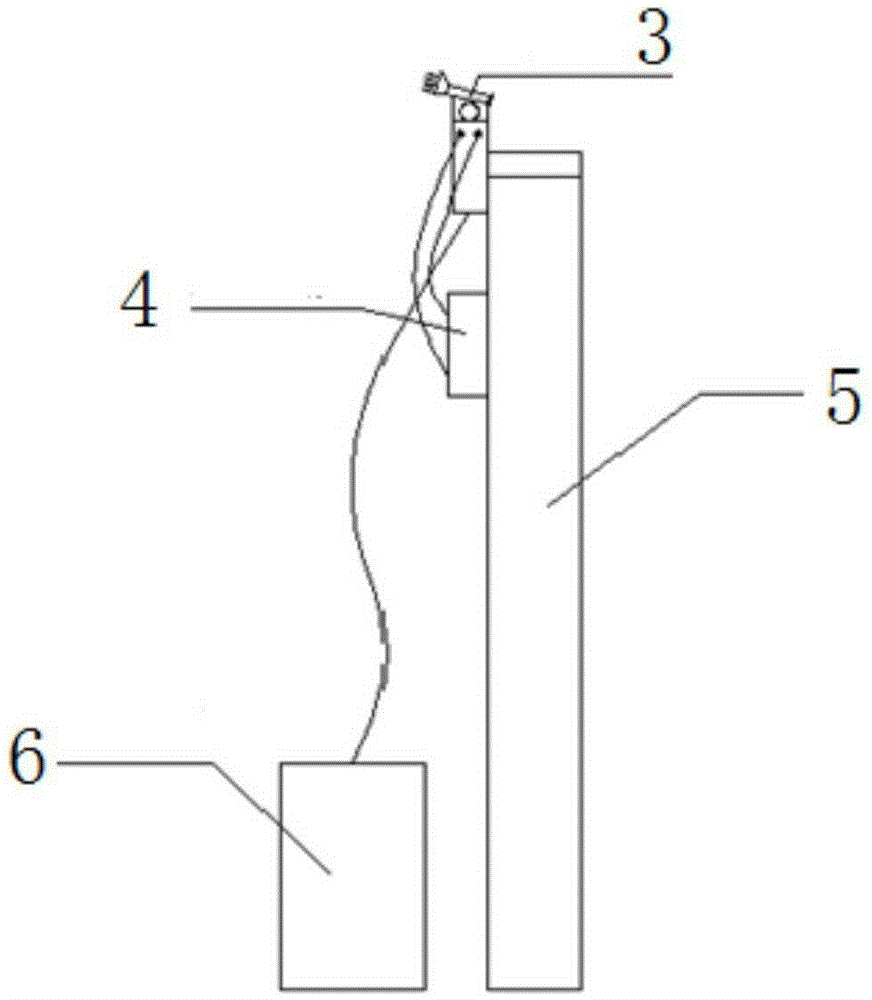

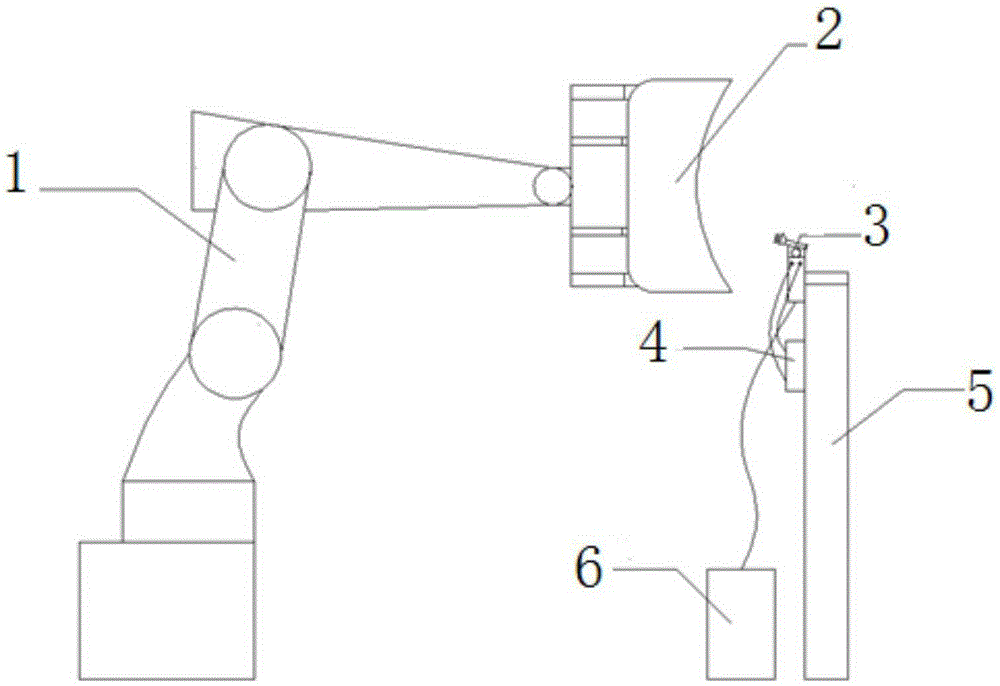

The invention discloses a method for producing colored bumpers. The method includes the steps that A1, plastic part raw materials are selected; A2, an injection molding machine is preheated; A3, the plastic part raw materials are fed into a drying barrel to be dried in a concentrated mode; A4, the injection molding machine is controlled to start injection molding; A5, flame treatment is conducted on a grabbed plastic part product, so that flash and burrs on the surface of the product are removed, and a pouring gate is automatically cut off; A6, the plastic part product is wiped and cleaned and fed into a high-temperature cleaning room to be cleaned; A7, the plastic part product is cleaned; A8, the cleaned plastic part product is dried and fed into a drying room to be dried, then flame treatment is conducted on the plastic part product, and the plastic part product subjected to flame treatment is fed into an ionization dust removal chamber to be subjected to ionization dust removal; and A9, a spraying robot is used for conducting three paint spraying procedures on the plastic part product in a sealed spraying booth. According to the method, the production efficiency is high, the production safety is high, and the percent of pass of products is increased.

Owner:SHENYANG MINGHUA MOULD & PLASTIC TECH CO LTD

Method for constructing anti-pollution durable colored thin anti-skid road surfaces

ActiveCN102776816AImprove adhesionImprove crack resistanceIn situ pavingsPaving detailsEpoxyBasement

The invention provides a method for constructing anti-pollution durable colored thin anti-skid road surfaces, comprising the following steps: (1) preparing cementing materials and aggregates, wherein the cementing materials adopt wet-mixing modified epoxy resin adhesives; the aggregates adopt colored pottery particle aggregates; the modified epoxy resin adhesives are used for painting prior to the use of the aggregates; and the thickness of the coating is 0.1 to 0.3mm; (2) treating basements of the constructed road surfaces; (3) scraping and paving modified epoxy resin cementing materials; (4) spreading the colored pottery particle aggregates; and (5) blocking the dead corners of the colored road surfaces with fog seals. The wet-mixing modified epoxy resin adhesives are used for color matching; with the utilization of a small spraying mechanical device, the locations of the dead corners of the non-traffic colored road surfaces are effectively blocked by the fog seal method in advance; and the covering thicknesses of the colored fog seals are 0.1 to 0.3mm. The method for constructing the anti-pollution durable colored thin anti-skid road surfaces can improve the adhesion, the crazing resistance property, and the anti-skid property of the colored road surfaces, and moreover, the colors can be fresh for a long time.

Owner:NORTH CHINA MUNICIPAL ENG DESIGN & RES INST

Watercolor canvas and method of processing the same

InactiveCN101117078AImprove adsorption capacityNot easy to peel offDuplicating/marking methodsOther artistic work equipmentsWater colorChemistry

The invention relates to water color canvas and the processing method thereof. When a water color pattern is printed on the surface of the water color canvas made according to the processing method, the water color pattern has bright colors and can be modified at will depending on requirements. The water color canvas comprises a basic material of which a clear adhesive coat, a bottom coat and a face coat are in turn covered on the surface and is characterized in that the basic material is textile fabric. The specific processing steps are that: the clear adhesive layer, the bottom coat and the face coat are respectively made, the clear adhesive layer is coated on the surface of the textile fabric and dried in an oven in which the temperature is kept between 100 to 120 DEG C, then the bottom coat is coated on the surface of the clear adhesive layer and dried in the oven in which the temperature is kept between 60 to 70 DEG C, then the bottom coat is coated again and dried in the oven in which the temperature is kept between 65 to 80 DEG C, then the face coat is coated on the surface of the bottom coat and dried in the oven in which the temperature is kept between 80 to 100 DEG C, the speed at which the textile fabric passes through the oven is 6 to 6.5 m / s, at last the textile fabric with four coats is calendered.

Owner:WUXI PHOENIX ARTIST MATERIALS

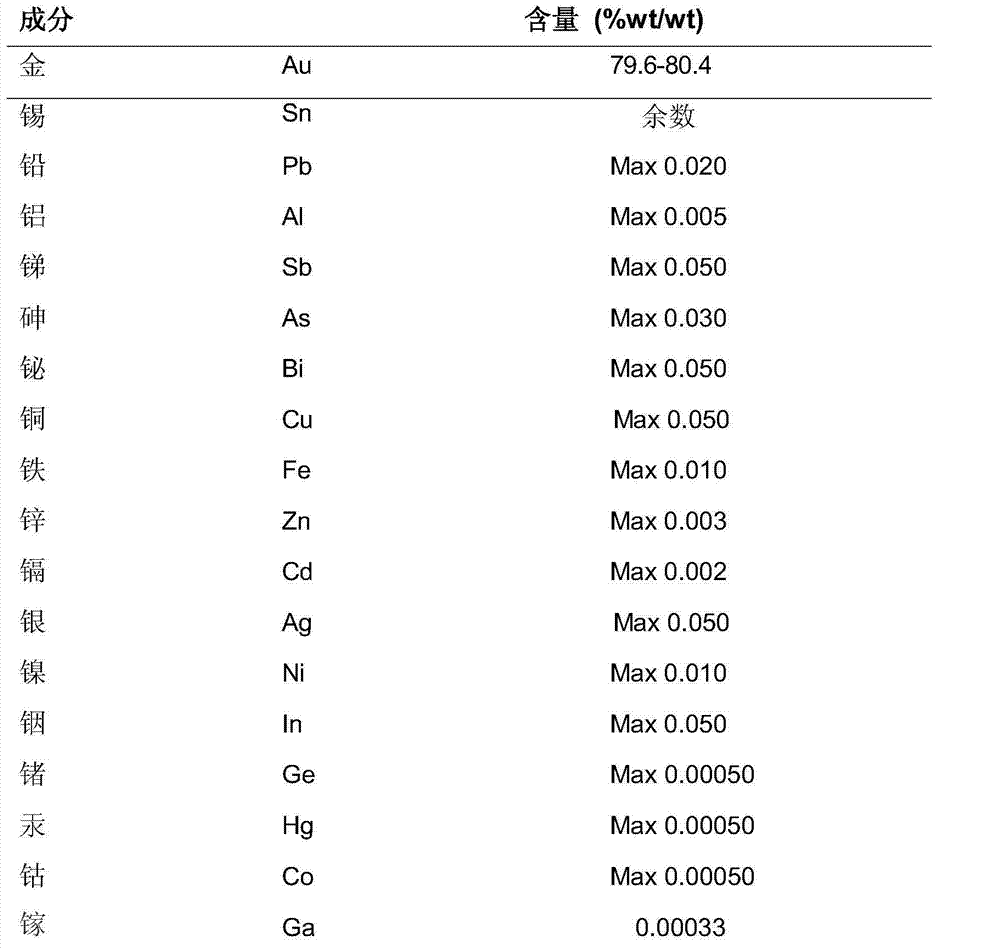

Production method of gold-tin wire, foil belt and preforming welding piece

ActiveCN103753057AMake sure the surface is shinyEnsure that the oxide layer is reducedWelding/cutting media/materialsSoldering mediaMaterials scienceExtrusion

The invention provides a production method of a gold-tin wire, a foil belt and a preforming welding piece and belongs to the welding technical field. The production method comprises step 1, smelting gold and tin into alloy and casting the gold and the tin into an alloy rod; step 2, performing annealing; step 3, performing extrusion forming which comprises arranging a tin wire die with a circular hole at the position of the outlet of an extruding machine first when the ally rod needs to be extruded into a tin wire and arranging a foil belt die with a square hole at the position of the outlet of the extruding machine first when the ally rod needs to be extruded into the foil belt, then placing the product in the step 2 into the extruding machine, adjusting the intensity of pressure of the extruding machine to 250 to 350 Mpa and adjusting the temperature to 150 to 230 DEG C; step 4, cutting the foil belt which is obtained through extrusion in the step 3 into the preforming welding piece. According to the production method of the gold-tin wire, the foil belt and the preforming welding piece, the problem that the machining forming is difficult due to the high brittleness of the gold-tin alloy in the prior art is solved, the technological process is simple and convenient, the mass production can be performed, the product accuracy is good, and the product consistency is good.

Owner:SHENZHEN FUMOSUO METAL PROD

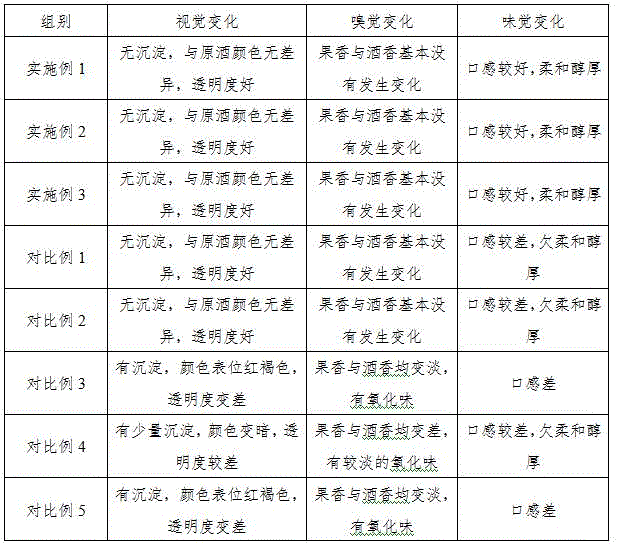

Mulberry wine making technology and mulberry wine obtained through same

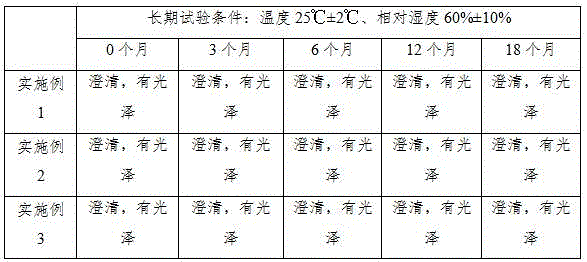

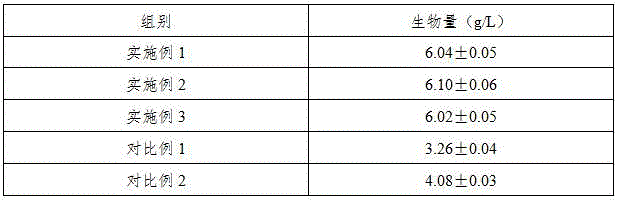

ActiveCN106047551ALarge biomassImprove fermentation effectAlcoholic beverage preparationYeastAdditive ingredient

The invention belongs to the technical field of wine making, and particularly relates to a mulberry wine making technology and the mulberry wine obtained through the same. The mulberry wine making technology comprises the steps of fruit selecting, sterilizing, yeast liquid preparing, initial fermenting, sealing fermenting, magnetization aging accelerating and the like. According to the mulberry wine making technology, heating and sulfur dioxide adding are not needed in the mulberry wine making process, the aging accelerating effect is achieved through a strong magnetic field, therefore, nutritional ingredients in mulberry fruits can be effectively prevented from being destroyed, the growth cycle is shortened to about 3 months from 6-12 months in traditional fermentation, and the production efficiency of the mulberry wine is improved. The made mulberry wine is full in wine body, has the inherent color of the mulberry fruits, is clear and transparent, has the pure, quiet and tasteful, pleasant and harmonious mulberry fruit aroma and wine aroma and accords with the taste of modern people.

Owner:江门桑科氏生物技术有限公司

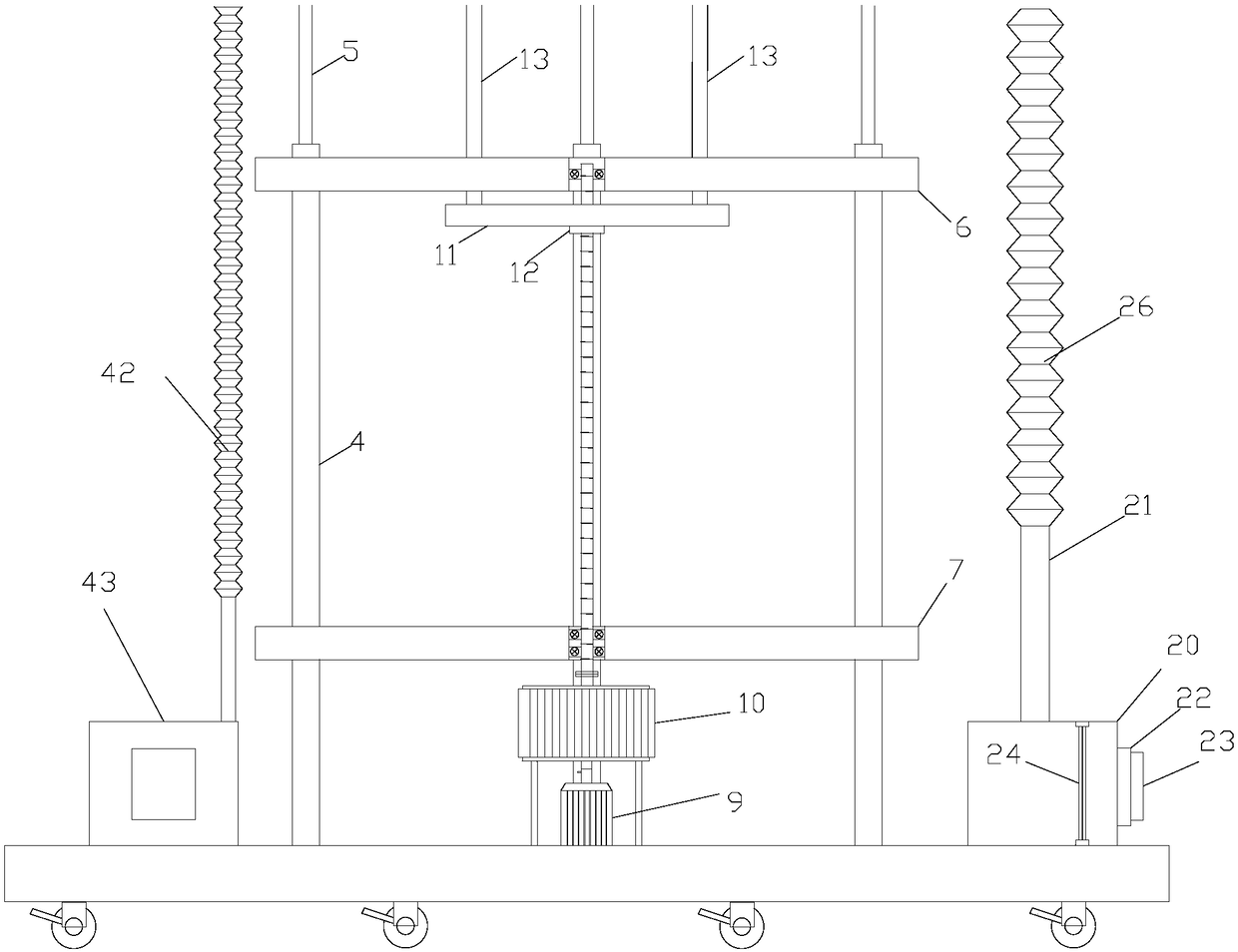

Rotary type cleaning device for crystal lamp and cleaning method thereof

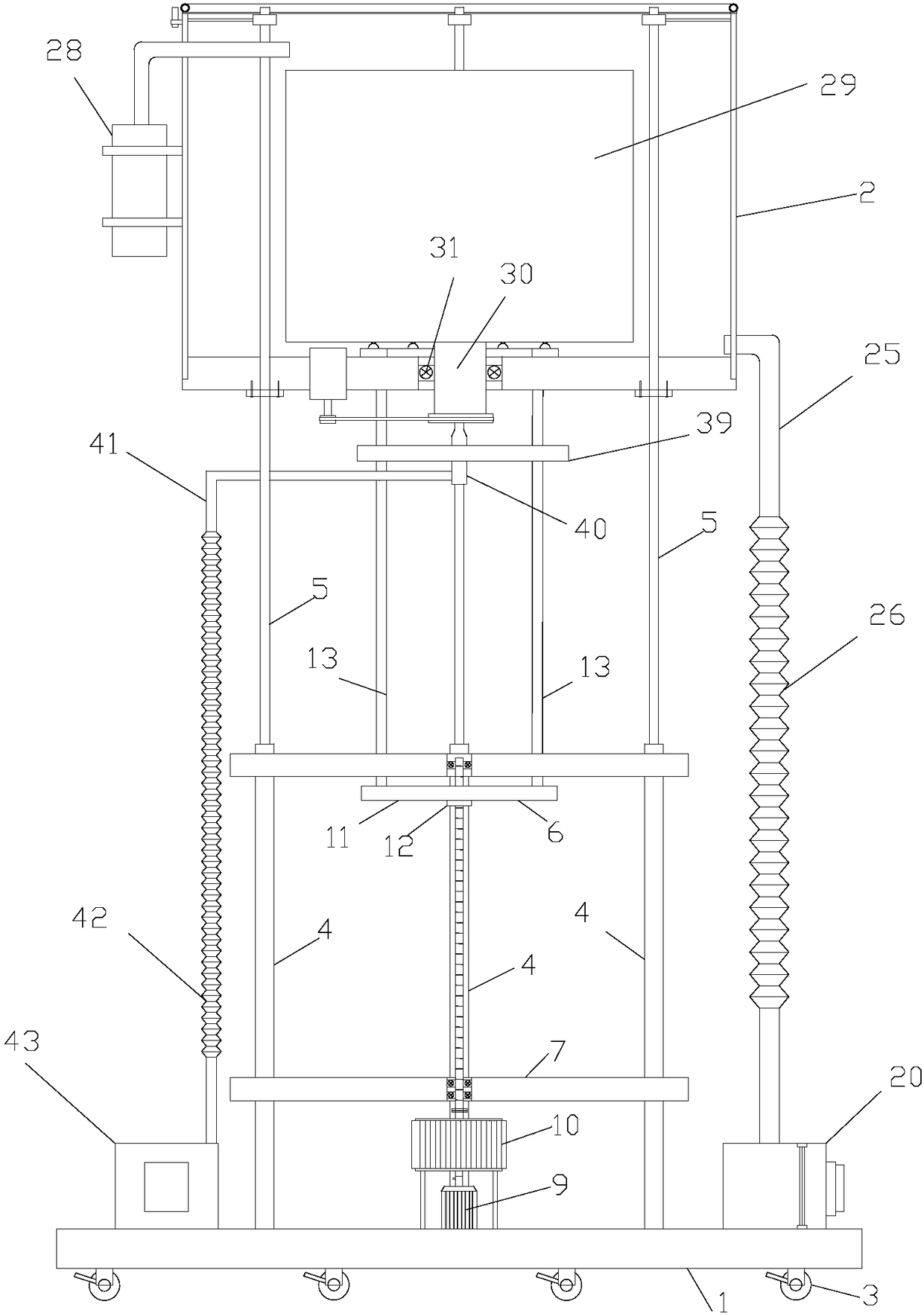

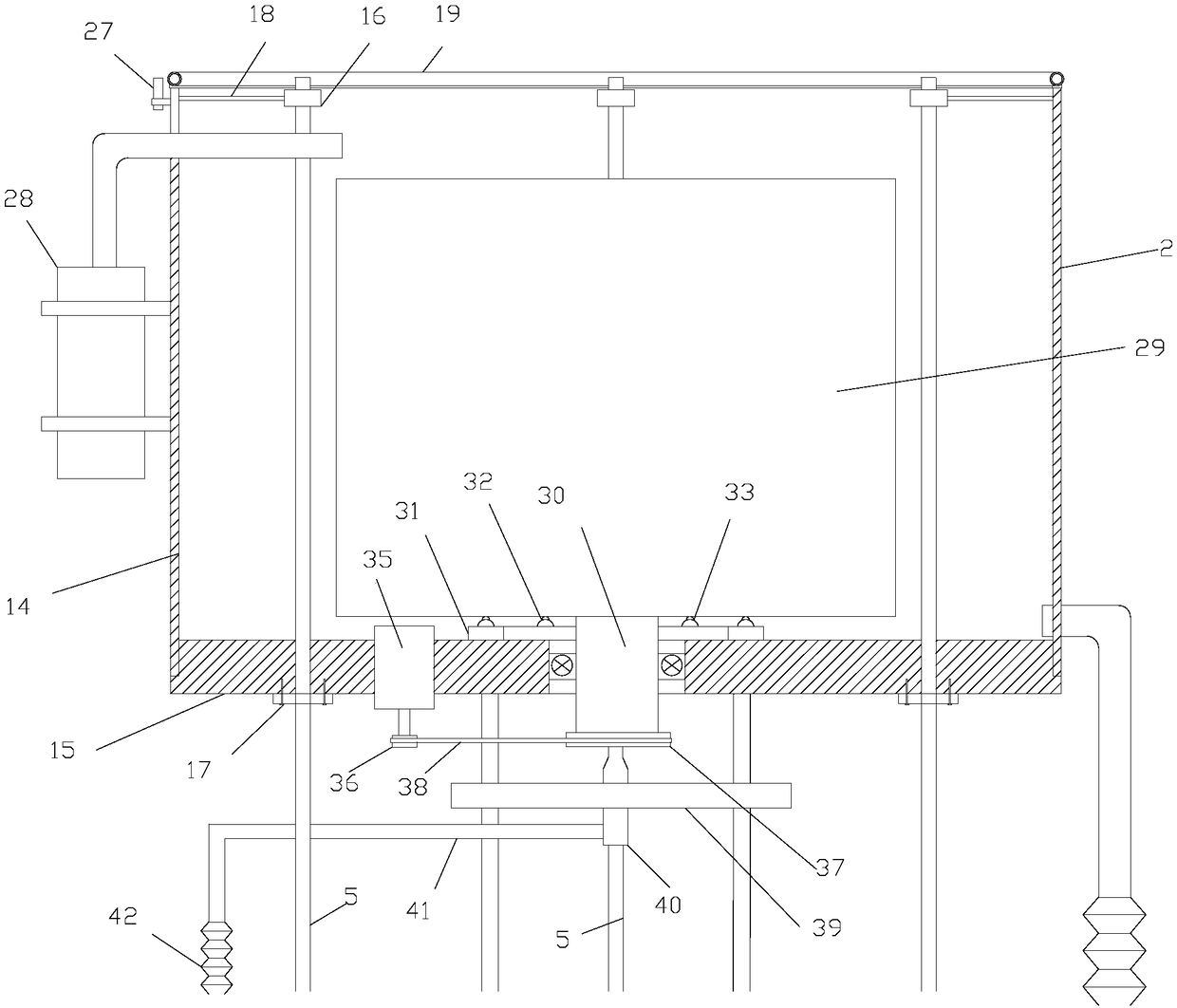

ActiveCN108080349AEasy to cleanKeep it brightDrying gas arrangementsHousehold cleanersCleaning methodsEngineering

The invention discloses a rotary type cleaning device for a crystal lamp. The rotary type cleaning device for the crystal lamp comprises a base and a cleaning cover, sleeve pipes are arranged on the upper end surface of the base, guide rods are embedded in the sleeve pipes, a lifting motor is further arranged on the base, and the lifting motor is in transmission connection with the bottom of a screw rod; the upper portions of the guide rods are fixedly connected with the cleaning cover, the cleaning cover comprises an outer sealing cylinder and a bottom plate positioned on the bottom surface of the outer sealing cylinder, a sprayer is fixedly arranged on the outer wall of the outer sealing cylinder, a cleaning cylinder is further arranged in the cleaning cover, and the bottom of the cleaning cylinder is provided with an air inlet pipe; and the cleaning cylinder is provided with an annular hollow interlayer, a plurality of nozzles are distributed on the inner wall of the hollow interlayer, an air injection pipe is arranged on a seat board, the air injection pipe extends into the air inlet pipe, the air injection pipe and the air inlet pipe can rotate relative to each other, and an air compressor is further arranged on the left side of the top surface of the base. According to the rotary type cleaning device for the crystal lamp, the crystal lamp can be cleaned conveniently, thecleaning efficiency is high, and dust accumulation of the crystal lamp can be prevented. The invention further discloses a cleaning method of the rotary type cleaning device for the crystal lamp.

Owner:绍兴兴裕门窗有限公司

Preparation method of flat viscose filament yarns and spinning nozzle used in preparation process

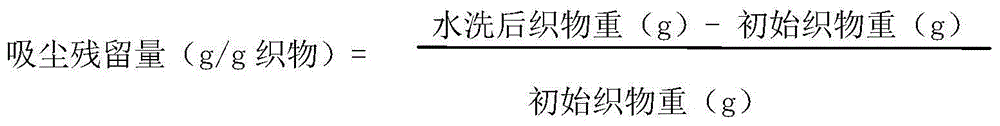

ActiveCN106283223AFeel strongNot easy to fall offNew-spun product collectionArtificial filaments from viscoseMoisture absorptionViscose fiber

The invention relates to the field of viscose, in particular to a preparation method of flat viscose filament yarns and a spinning nozzle used in the preparation process. The production method comprises a process for preparing a spinning original solution, a spinning process, a post-treatment process and a post-processing process. The invention also relates to application of the flat viscose filament yarns to preparation of cleaning cloth, and the spinning nozzle used in the preparation method. The flat viscose filament yarns provided by the invention are widely applied and can be used for preparing the cleaning cloth; the cleaning effect of the cleaning cloth can be well matched with that of cleaning cloth prepared from superfine chemical fiber, and the cleaning cloth is susceptible to moisture absorption and quick drying; the cleaning cloth is easy to clean, has good hand feel and special gloss, is insusceptible to bacterial breeding, and can meet the requirements of people on high-grade furniture supplies.

Owner:吉林化纤股份有限公司

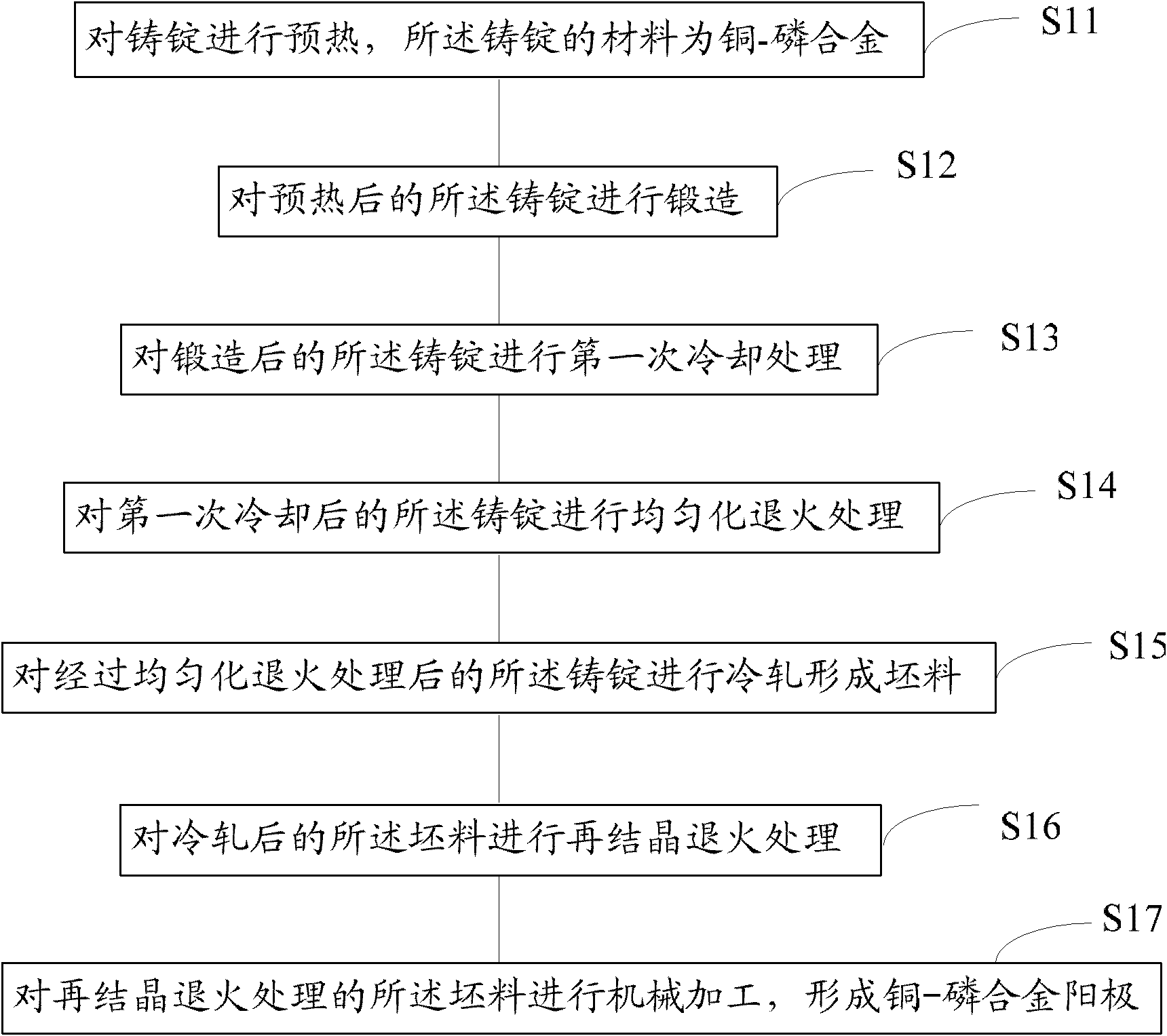

Method for preparing anode made of copper-phosphorus alloy

A method for preparing an anode made of a copper-phosphorus alloy comprises the following steps in sequence: preheating an ingot made of the copper-phosphorus alloy; forging the ingot; conducting homogenized annealing treatment on the ingot; conducting cold rolling on the ingot to form a blank; conducting recrystallization annealing treatment on the blank; and machining the blank, so as to form the anode made of the copper-phosphorus alloy. According to the method, the combination of repeated plastic deformation with a specific deformation rate and annealing treatment under specific temperature is mainly adopted, and the deformation rate of the plastic deformation, the temperature during the annealing treatment, and the time of the annealing treatment are controlled, so as to produce the anode meeting the requirements on compact and uniform internal structure and no lamination for electroplating.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

Non-ferrous metal surface treatment agent and preparation method thereof

InactiveCN105624703APrevent oxidationAvoid corrosionMetallic material coating processesEcological environmentPhenol

The invention discloses a non-ferrous metal surface treatment agent and a preparation method thereof. The non-ferrous metal surface treatment agent is characterized in that all components of raw materials are composed of, by weight, 15-20 parts of sodium polyacrylate, 18-22 parts of trifluoroethanol, 3-4 parts of nonyl phenol polyoxyethylene ether, 1-2 parts of sodium dodecyl sulfate, 2-4 parts of sodium citrate, 2-4 parts of EDTA tetrasodium salt, 5-7 parts of chitosan, 4-6 parts of a rust remover, 3-5 parts of a corrosion inhibitor, 3-5 parts of an alkaline cleaner and 2-3 parts of silicon dioxide. The non-ferrous metal surface treatment agent is high in detergency power, good in cleaning effect, free of phosphorus and organic solvent and capable of preventing metal from oxidation and corrosion and keeping the surface of the metal bright, residual liquor generated after cleaning is free of pollution to the ecological environment, a layer of compact protective film can be formed on the surface of the metal, the surface tension and the interfacial tension are lowered, metal ions can be fixed, sensitivity to temperature variation is low, and stability is good; the situation that the mechanical performance of the metal is lowered is avoided, and the strength of steel can be maintained; and the influence on the environment is small, and treatment is more convenient.

Owner:YANGZHONG HUYANG SHIPPING CO LTD

Horn mesh enclosure

ActiveCN101616346AReduce processThe production process is simpleTransducer detailsLacquerEngineering

The invention provides a horn mesh enclosure which is characterized by comprising a transparent plastic piece, silk screen cloth and double faced adhesive tape that are fixed and overlapped together from outside to inside; wherein a decorative paint layer is clamped between the transparent plastic piece and the silk screen cloth, and the decorative paint layer and a mouth of a horn of a device are arranged in a staggered way; the plastic piece corresponds to the decorative paint layer, and is at least provided with meshes at the part where the plastic piece corresponds to the mouth of the horn of the device. Image-text used for advertising promotion can be combined into the horn mesh enclosure to form a whole, so that a large number of working procedures are reduced, the manufacturing cost is simple, the cost is saved, the attractive effect of identification image-text is maintained for a long time, and the appearance effect of the product is improved.

Owner:石狮市鑫达工业有限公司

Production process for coil nails

The invention discloses a production process for coil nails, comprising the following steps of: removing an oxide skin, drawing a wire, producing nails, and coiling the nails. According to the invention, via change for the process steps, the process of removing an oxide skin is added before the process of drawing a wire, thus ensuring the brightness and no burrs of the drawn wire; and because the process of producing nails and the process of coiling the nails are implemented simultaneously, and paint dipping is performed during the process of coiling the nails, decrease for the loss of raw materials and increase for production efficiency are contributed, and labour loss can be reduced and environmental pollution can be reduced while product quality is ensured. The production process disclosed by the invention is simple, obvious in effect, and suitable for industrialized production.

Owner:SUZHOU XINGYA NAIL IND CO LTD

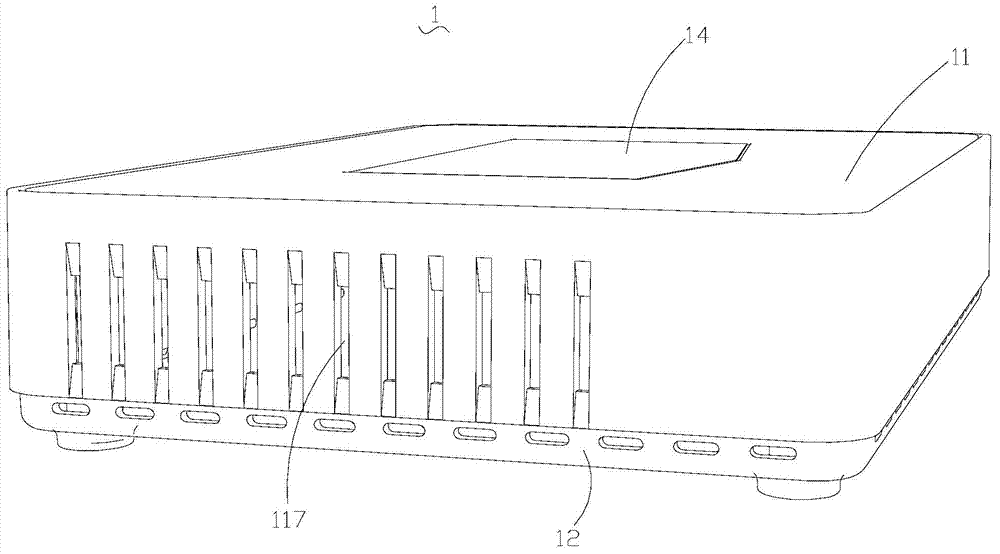

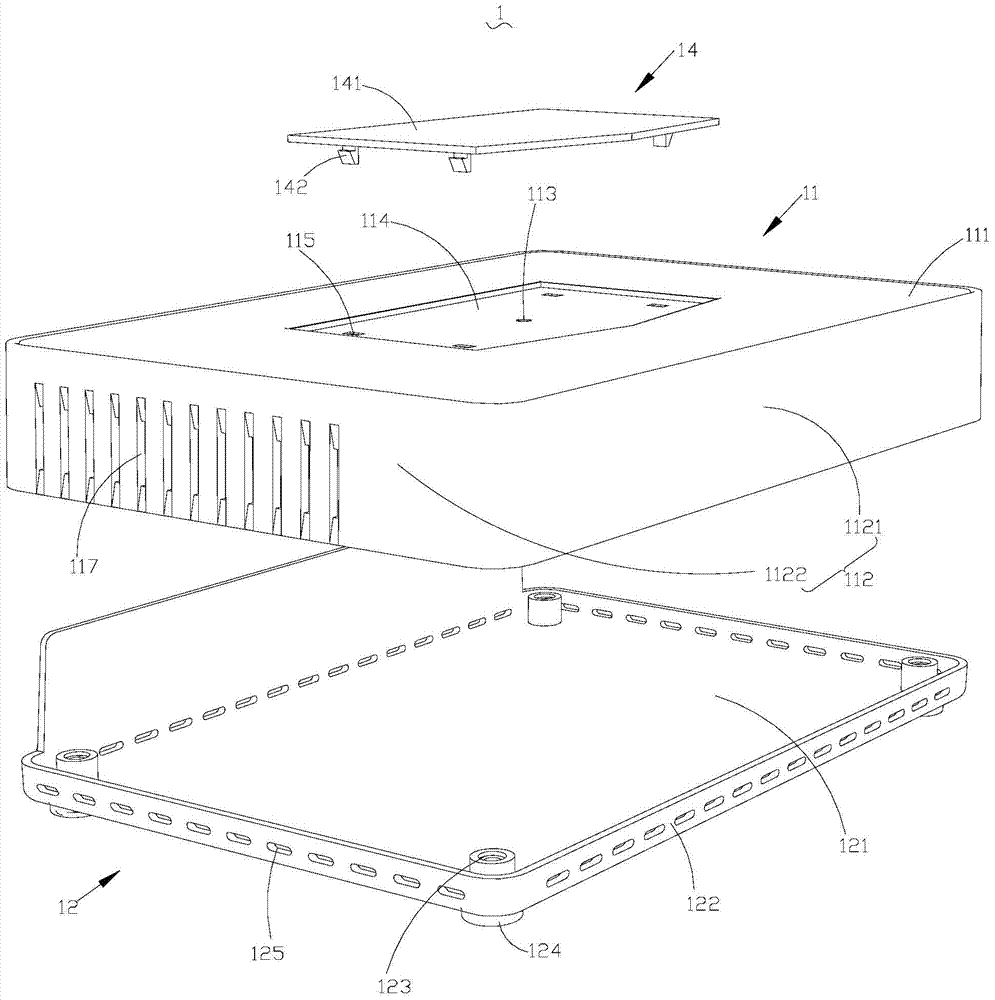

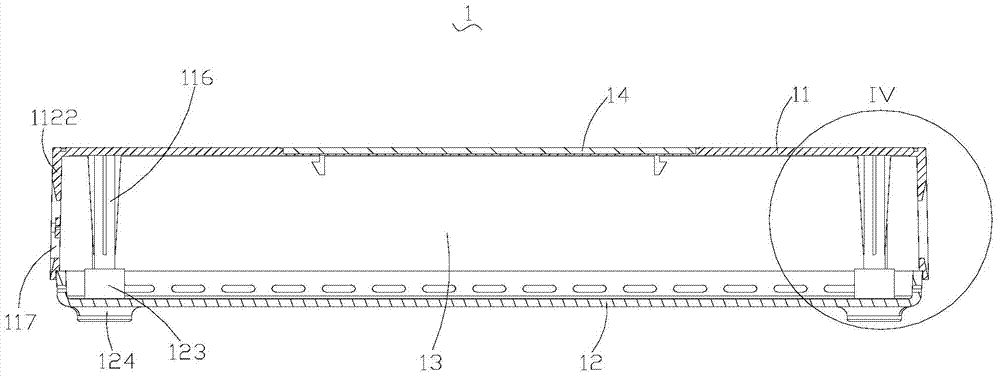

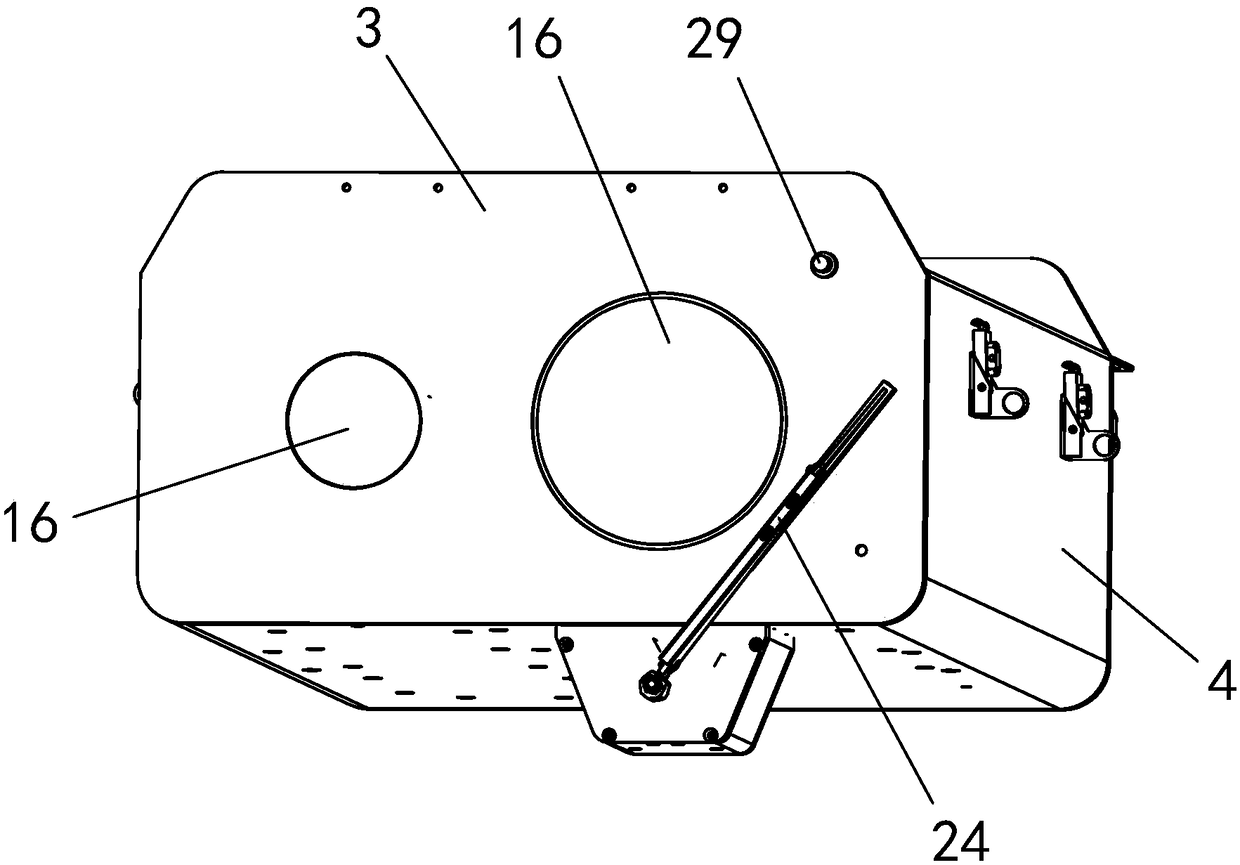

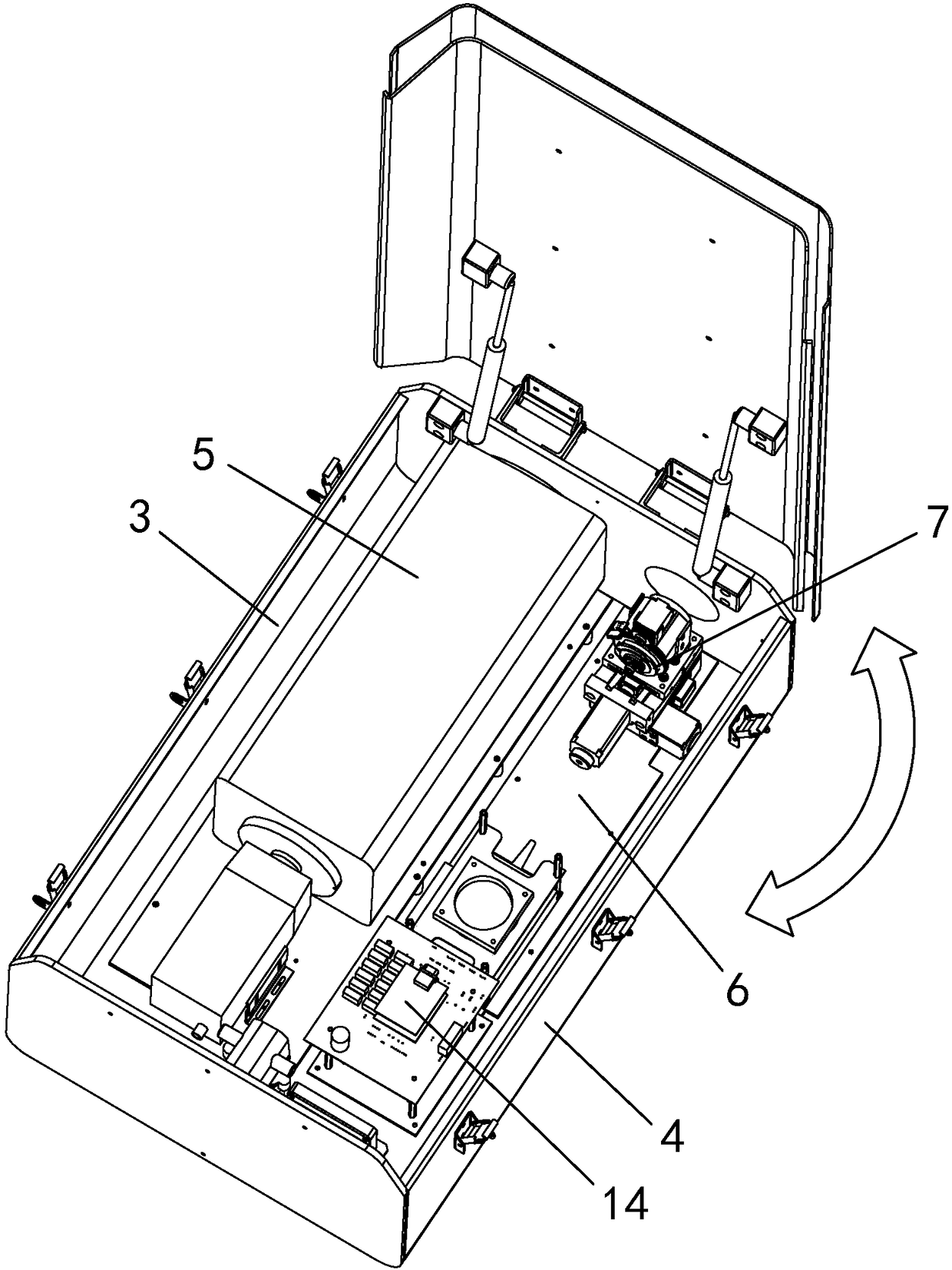

Set-top box

InactiveCN103546784AEasy to control directionEasy to control lengthSelective content distributionCooling/ventilation/heating modificationsEngineeringMechanical engineering

The invention is applicable to the technical field of plastic products and provides a set-top box, aiming to solve the problem that a weld line appears outside a plastic shell of a set-top box in the prior art. The set-top box comprises a first shell and a second shell which are made of plastics and formed by a point plastic filling mode. The first shell and the second shell are arranged oppositely and form an accommodating cavity for accommodating an electronic device. The first shell comprises an upper cover and a first enclosure wall, and the second shell comprises a lower cover and a second enclosure wall. The upper cover is provided with a plastic filling port allowing a mould to perform external plastic filling treatment, the plastic filling port is located at the center of the upper cover, and the set-top box further comprises a cover plate which is arranged above the upper cover in a covering manner so as to cover the plastic filling port. Through the first shell and the second shell formed by the point plastic filling mode, direction and length of a weld line are controlled conveniently, and the cover plate is arranged on the upper cover of the first shell to cover the plastic filling port, so that the weld line formed on the surface of the first shell is hidden, namely, brightness of the outer surface of the set-top box is guaranteed.

Owner:SHENZHEN JIUZHOU ELECTRIC

Metal cleaning agent and preparation method thereof

The invention discloses a metal cleaning agent. The metal cleaning agent comprises the following raw materials by weight ratio: 10-15 parts of sodium polyacrylate, 4-6 parts of trifluoroethyl alcohol, 4-6 parts of polyoxyethylene nonyl phenyl ether, 4-6 parts of sodium citrate, 2-4 parts of EDTA tetrasodium, 2-4 parts of chitosan, 2-4 parts of sodium dodecanesulphonate, 3-5 parts of acetic acid, 3-5 parts of glycol, 3-5 parts of triethanolamine, 3-5 parts of di-o-tolyl-thiourea, 3-5 parts of sodium gluconate, 3-5 parts of carboxymethyl cellulose, 3-5 parts of sodium oleate, 3-5 parts of sodium pyrophosphate, 3-5 parts of silica, 3-5 parts of a nonionic surfactant, 2-4 parts of a anionic surfactant, 2-4 parts of an antifoaming agent, 2-4 parts of trisodium phosphate, and 2-4 parts of a stabilizing agent; wherein the stabilizing agent is selected from one or more of DPDP, PDDP, butyl epoxystearate, and dioctyl ethylenediamine tetramethylene sodium phosphate. The metal cleaning agent has good cleaning effect.

Owner:WUXI CITY SHANGXIN METAL PROD

Metal surface decontamination agent proportioning method

The invention discloses a metal surface decontamination agent comprising the following raw materials by weight: 10-30 parts of sodium polyacrylate, 2-4 parts of trifluoroethanol, 2-4 parts of nonylphenol polyoxyethylene ether, 2-4 parts of sodium citrate, 4-6 parts of EDTA tetrasodium, 4-6 parts of chitosan, 4-6 parts of sodium dodecyl sulfate, 3-5 parts of acetic acid, 3-5 parts of ethylene glycol, 3-5 parts of triethanolamine, 3-5 parts of di-o-tolyl-thiourea, 3-5 parts of sodium gluconate, 3-5 parts of carboxymethyl cellulose, 3-5 parts of sodium oleate, 3-5 parts of sodium pyrophosphate, 3-5 parts of silica, 3-5 parts of a nonionic surfactant, 2-4 parts of an anionic surfactant, 2-4 parts of a defoaming agent, 2-4 parts of trisodium phosphate and 2-4 parts of a stabilizer, wherein the anionic surfactant is selected from one or more of the nonylphenol polyoxyethylene ether, high carbon fatty alcohol polyoxyethylene ether, Polyoxyethylene fatty acid and Sorbitan Esters. The metal surface decontamination agent has good cleaning effect.

Owner:WUXI CITY SHANGXIN METAL PROD

Nickel-based alloy wire for welding of LNG storage tank as well as preparation method and welding process

InactiveCN110480208AUniform compositionFlat surfaceWelding/cutting media/materialsSoldering mediaAlloyElectro-slag remelting

The invention relates to a nickel-based alloy wire for welding of an LNG storage tank as well as a preparation method and a welding process. The nickel-based alloy wire comprises the following components in percentage by mass: 20.0%-23.0% of Cr, 0.0%-10.0% of Mo, 3.15%-4.15% of Nb, not more than 5.0% of Fe, not more than 1.0% of Co, not more than 0.50% of Mn, not more than 0.40% of Al, not more than 0.40% of Ti, not more than 0.50% of Si, not more than 0.10% of C, not more than 0.015% of S and the balance of Ni. The preparation method comprises the following steps of A, alloy smelting and casting into electrode rods; B, electroslag remelting; C, hammer cogging; D, hot roll annealing; E, acid pickling and grinding; F, drawing; G, dehydrogenation and straightening after hydrogen annealing treatment; and H, winding to be disc-like. The welding process is that the welding current is 360-380 A, the voltage is 26-28 V, and the welding speed is 50-100 cm / min and the current type is alternating current.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

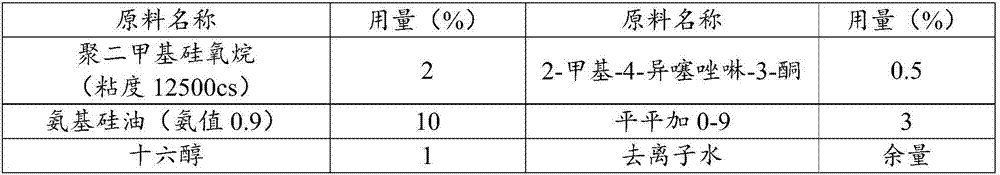

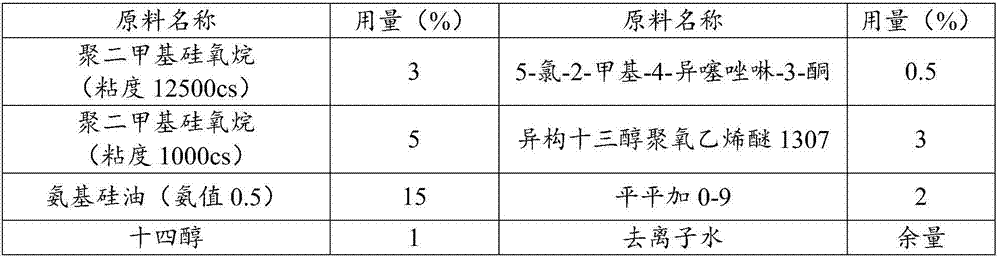

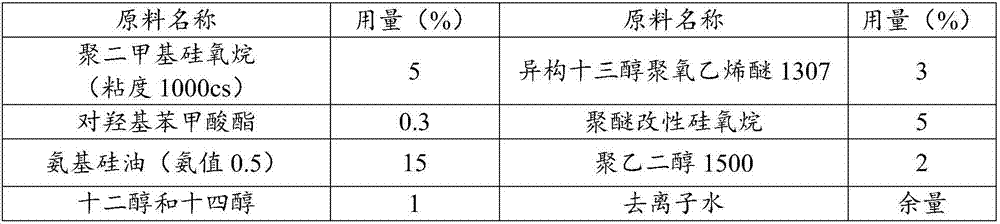

Durable fur hand feeling improvement agent and preparation method and application thereof

InactiveCN107245539AKeep it brightImprove qualityLeather surface finishingPreservativeSurface-active agents

The invention provides a durable fur hand feeling improvement agent and a preparation method and application thereof. The durable fur hand feeling improvement agent comprises the following components of, in percentage by mass, 5-30% of silicone oil, 0.1-5% of fatty alcohol, 1-10% of a non-ionic surface active agent, 0.1-1% of preservative and 54-93.8% of deionized water. A scientific and environmentally friendly formula design concept is adopted for the durable fur hand feeling improvement agent, furs can maintain bright, soft and smooth performance durably in various environments, and the fur quality is improved remarkably. The durable fur hand feeling improvement agent can be used for hand feeling improvement processing of sheep furs, raw fox skins, raw raccoon skins, mink skins and rabbit skins, energy consumption is lowered, and the durable fur hand feeling improvement agent meets the market requirements.

Owner:北京泛博清洁技术研究院有限公司

Metal treating agent and production method thereof

The invention discloses a metal surface treating agent. The agent is composed, by weight, 15-20 parts of sodium polyacrylate, 2-4 parts of trifluoroethanol, 2-4 parts of nonylphenol polyoxyethylene ether, 2-4 parts of sodium citrate, 4-6 parts of EDTA tetrasodium, 4-6 parts of chitosan, 4-6 parts of of sodium dodecyl sulfate, 3-5 parts of acetic acid, 3-5 parts of ethylene glycol, 3-5 parts of triethanolamine, 3-5 parts of di-o-tolyl-thiourea, 3-5 parts of sodium gluconate, 3-5 parts of carboxymethyl cellulose, 3-5 parts of sodium oleate, 3-5 parts of sodium pyrophosphate, 3-5 parts of silicon dioxide, 3-5 parts of non-ionic surfactants, 4 parts of anionic surfactants, 4 parts of defoaming agents, 4 parts of trisodium phosphate and 4 parts of stabilizers, wherein the defoaming agents are nonyl phenol polyoxyethylene ether or polyvinyl ether. The treating agent is good in cleaning effect.

Owner:WUXI CITY SHANGXIN METAL PROD

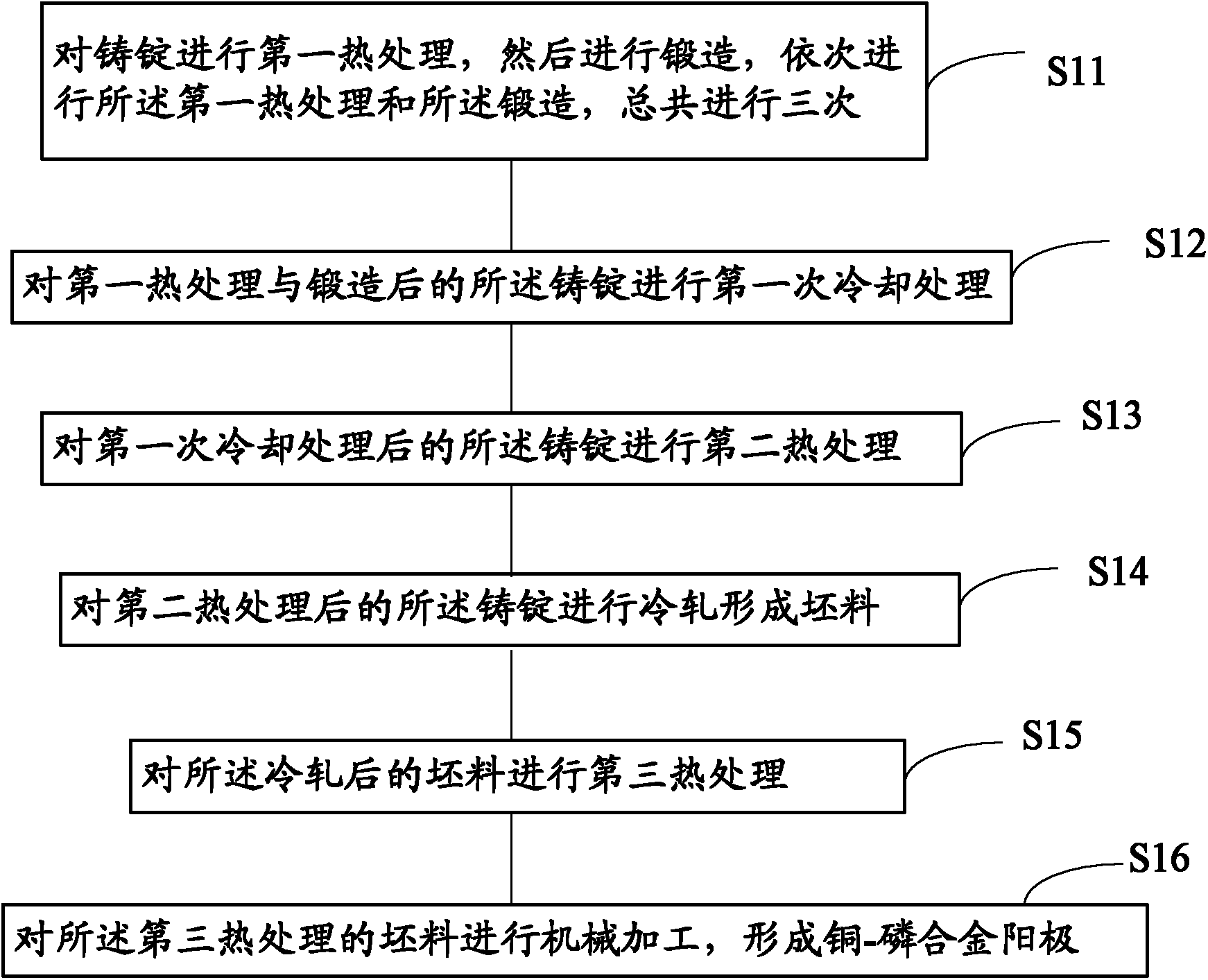

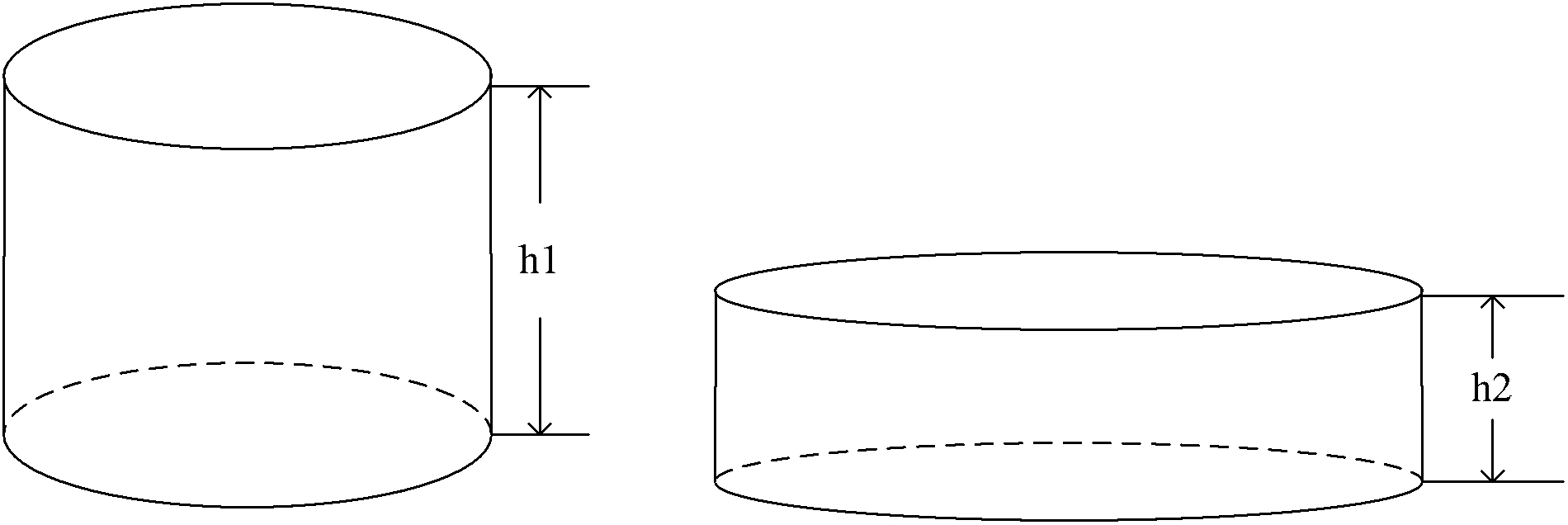

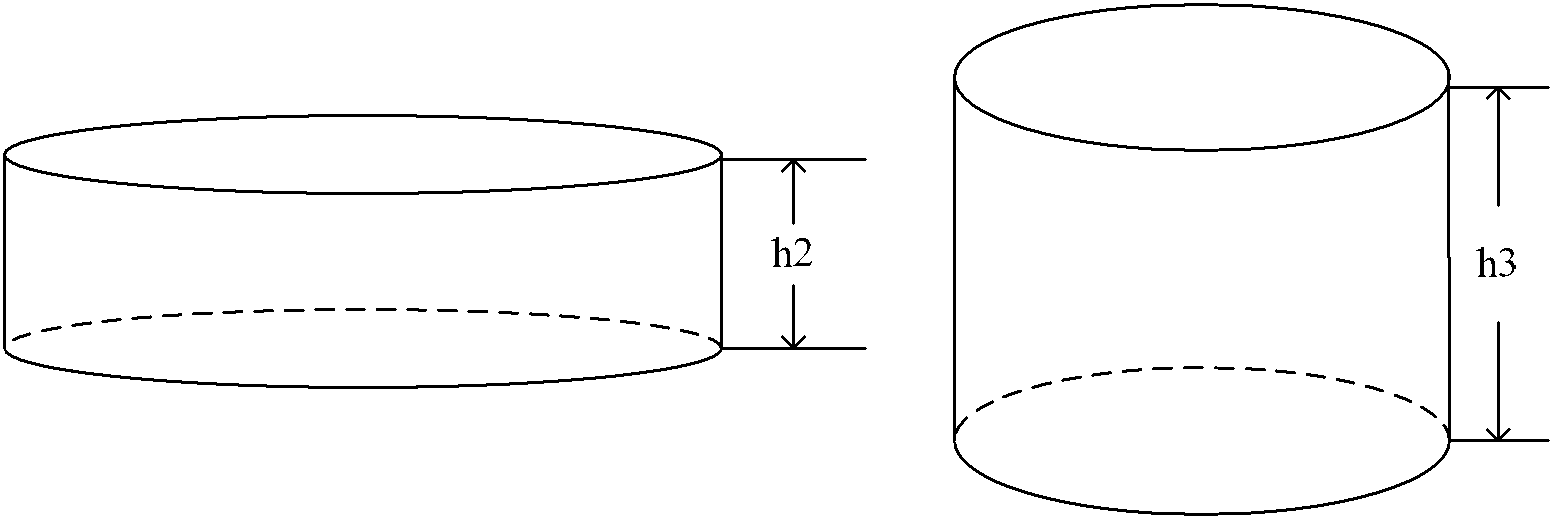

Method for preparing anode made of copper-phosphorus alloy

ActiveCN102517621AMeet electroplating requirementsImprove organizational structureElectrodesIngotCopper

A method for preparing an anode made of a copper-phosphorus alloy comprises the following steps in sequence: conducting first heat treatment on an ingot and forging in sequence for three times; conducting second heat treatment on the ingot after the last time of forging; conducting cold rolling on the ingot to form a blank; conducting third heat treatment on the blank; and machining the blank after the third heat treatment, so as to form the anode made of the copper-phosphorus alloy. According to the method, the combination of repeated plastic deformation with a specific deformation rate and annealing treatment under specific temperature is mainly adopted, and the deformation rate of the plastic deformation, the temperature during the annealing treatment, and the time of the annealing treatment are controlled strictly, so that the anode meeting the requirements on internal grain size and grain orientation for electroplating can be produced.

Owner:KONFOONG MATERIALS INTERNATIONAL CO LTD

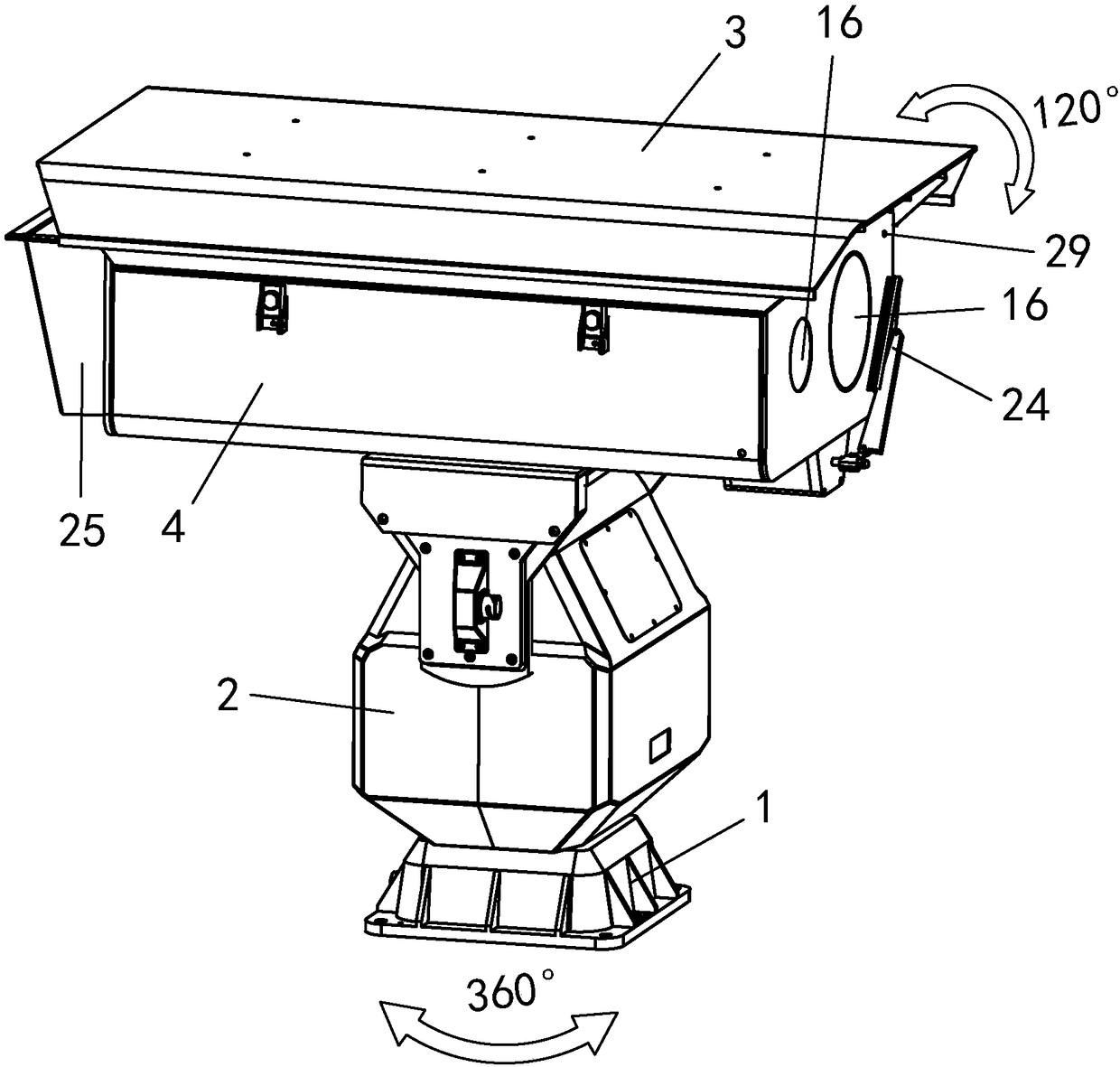

Heavy-load pan-tilt camera with high camera quality stability

PendingCN108419001AFlexible adjustment of rotation rangeGood location effectTelevision system detailsColor television detailsCamera lensOptical glass

The invention discloses a heavy-load pan-tilt camera with high camera quality stability. A camera assembly and a zoom laser are arranged inside a shield of a camera, the zoom laser includes a zoom laser lens and a macro precision electric adjustment mechanism, and the macro precision electric adjustment mechanism includes a first adapter plate, a first motor, a second adapter plate and a second motor; the first motor is fixed relative to the shield and drives the first adapter plate to rotate horizontally; the second motor is fixed relative to the first adapter plate to drives the second adapter plate to rotate up and down; the zoom laser lens is fixed relative to the second adapter plate; a piece of electrically heated optical glass is arranged at the front end of the shield; a resistivecoating film is adhered to the surface of the optical glass, and two sides of the optical glass are electrically connected with a first electrode and a second electrode; a wiper is arranged corresponding to the optical glass and is used for cleaning the optical glass; a water storage container is also arranged on the shield, a waterway component is arranged inside the shield, and the waterway component includes a water pump, a water suction pipe and a water outlet pipe; and the water suction pipe is connected to the water storage container, and the water outlet pipe extends out of the front end of the shield to form a nozzle for cleaning the optical glass.

Owner:JIANGSU MINJIA ELECTRONICS TECH

High finish-degree epoxy modified hydroxyl group aliphatic resin radical anti-pollution corrosion-proof coating material

InactiveCN101096569AStrong adhesionGood flexibilityAntifouling/underwater paintsPaints with biocidesEpoxyAdjuvant

The invention discloses a dirt resistance and corrosion prevention paint material of a highly polished epoxide modified hydroxyl fatty group resin radical in the paint field, which doesn't have the bibliographical information in the industry field. The component A of the invention comprises the following parts: an epoxide modified hydroxyl fatty group resin, a nanometer anatase TIO2 with photocatalysis function, a highly polished adjuvant, a modified nanometer amorphous SiO2, a color, a filler and the other adjuvant, wherein the filler comprises French chalk and ultra-fine calcinations kaolin, the other adjuvant comprises thickener- the organic alta-mud and the film former-dibutylphthalate, the white color material is titanium dioxide, the component B is isocyanate resin, isocyanate resin : butyl acetate: dimethylbenzene is 4:1-6:1, A:B is 8:1-7:1. The invention has acid-resistant, alkaliresistant, salt-mist-resistance and chemical corrosion resistance, which can avoid the dust pollution.

Owner:BEIJING UNIV OF TECH

Environment-friendly detinning liquid and preparation method thereof

The invention discloses environment-friendly detinning liquid and a preparation method thereof. The environment-friendly detinning liquid comprises the following components of, by volume concentration, 50-300g / L of concentrated sulfuric acid, 1-20g / L of hydrogen peroxide, 5-30g / L of a tin ion complexing agent, 0.5-50g / L of a hydrogen peroxide accelerator, 1-20g / L of a hydrogen peroxide stabilizer,0.1-5g / L of a copper surface corrosion inhibitor and the balance water. The concentrated sulfuric acid is slowly added into the water, after the concentrated sulfuric acid and the water are mixed andcooled to the normal temperature, the copper surface corrosion inhibitor, the tin ion complexing agent, the hydrogen peroxide accelerator, the hydrogen peroxide stabilizer and the hydrogen peroxide are added in sequence and then stirred to dissolve completely, then, constant volume is achieved with the water, and the environment-friendly detinning liquid can be obtained. The environment-friendlydetinning liquid can effectively remove the tin layer and the tin-copper alloy layer, harmful gas is not generated in the reaction process, the metal copper layer is not corroded, sludge sediment is not generated, waste liquid generated in the reaction process is easy to process, and metal tin recycling is facilitated.

Owner:上海昕沐化学科技有限公司

Metal surface treating agent and preparation method thereof

The invention discloses a metal surface treating agent which consists of the following raw materials in parts by weight: 15-20 parts of sodium polyacrylate, 2-4 parts of trifluoroethanol, 2-4 parts of nonylphenol polyoxyethylene ether, 2-4 parts of sodium citrate, 4-6 parts of EDTA tetrasodium, 4-6 parts of chitosan, 4-6 parts of sodium dodecyl sulfate, 3-5 parts of acetic acid, 3-5 parts of ethylene glycol, 3-5 parts of triethanolamine, 3-5 parts of di-o-tolyl-thiourea, 3-5 parts of sodium gluconate, 3-5 parts of carboxymethyl cellulose, 3-5 parts of sodium oleate, 3-5 parts of sodium pyrophosphate, 3-5 parts of silicon dioxide, 3-5 parts of a nonionic surfactant, 4 parts of an anionic surfactant, 4 parts of a defoaming agent and 4 parts of a stabilizer, wherein the anionic surfactant is selected from one or more of octaphenyl polyoxyethyiene, higher aliphatic alkanol polyoxyethylene ether, polyoxyethylene stearate and sorbitan ether. The metal surface treating agent disclosed by the invention is good in cleaning effect.

Owner:WUXI CITY SHANGXIN METAL PROD

Preparation method of aqueous transparent heat-insulating glass coating

ActiveCN108912871AStrong light transmittanceLow critical surface tensionAntifouling/underwater paintsPaints with biocidesCarbon dioxidePolytetrafluoroethylene

The invention relates to a preparation method of an aqueous transparent heat-insulating glass coating, and belongs to the technical field of preparation of architectural coatings. Modified polytetrafluoroethylene resin is creatively used as a matrix, and nano titanium dioxide is used as filler so as to prepare the glass coating, wherein the polytetrafluoroethylene resin which is modified by an adhesion promoter has ultra-high adhesion so that the performance of the aqueous transparent heat-insulating glass coating is more comprehensive, and organic pollutants adsorbed on the surface of the nano titanium dioxide are decomposed into carbon dioxide and oxygen through selection of the nano titanium dioxide as the filler, so that the original brightness of glass is maintained, and a good heat insulating effect is achieved without influence on the transparency of the glass. The aqueous transparent heat-insulating glass coating has the advantages of strong adhesion, long service life, good water resistance, strong viscosity resistance, strong anti-staining performance, strong UV resistance, high transparency and a good thermal insulation effect, formaldehyde and other indoor harmful organic compounds can be decomposed, and therefore the coating has a very broad application prospect and advantage.

Owner:上海金泰子建筑装饰工程有限公司

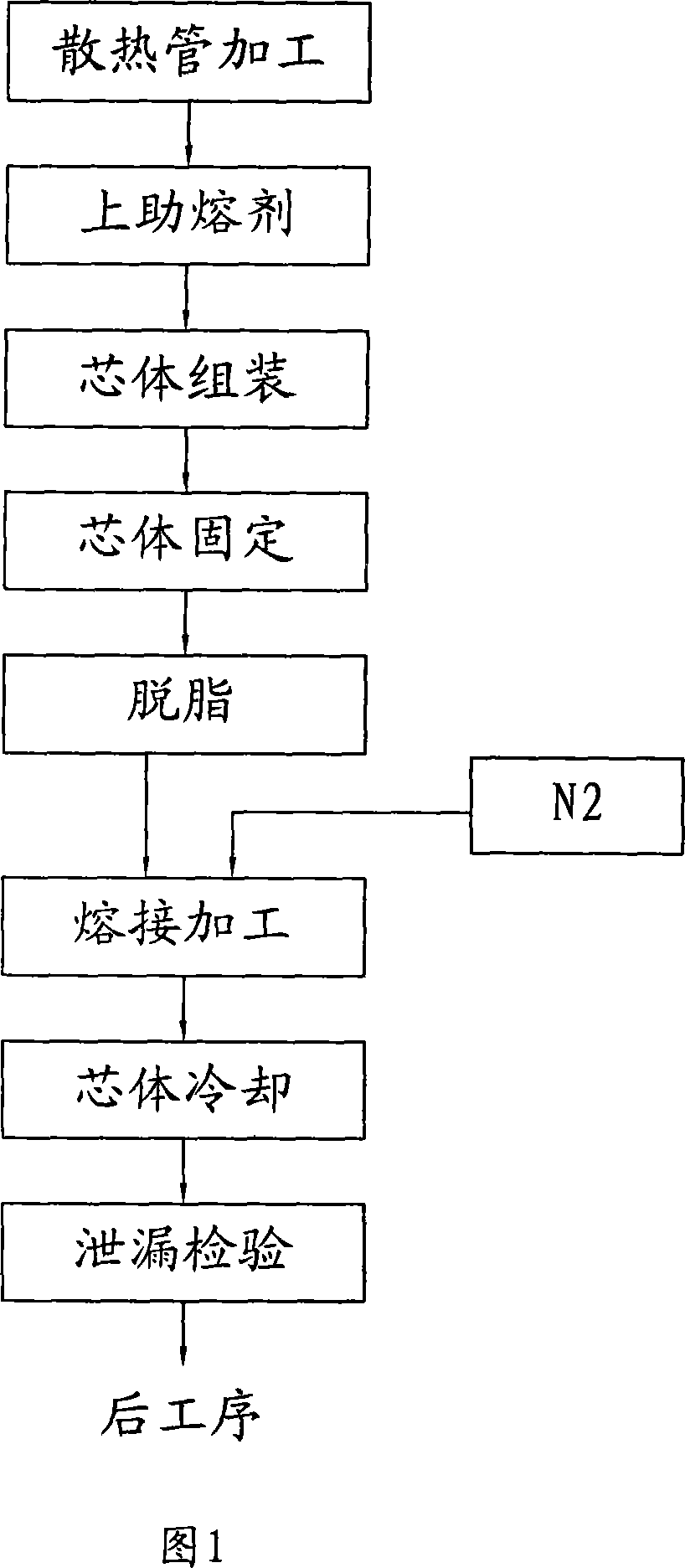

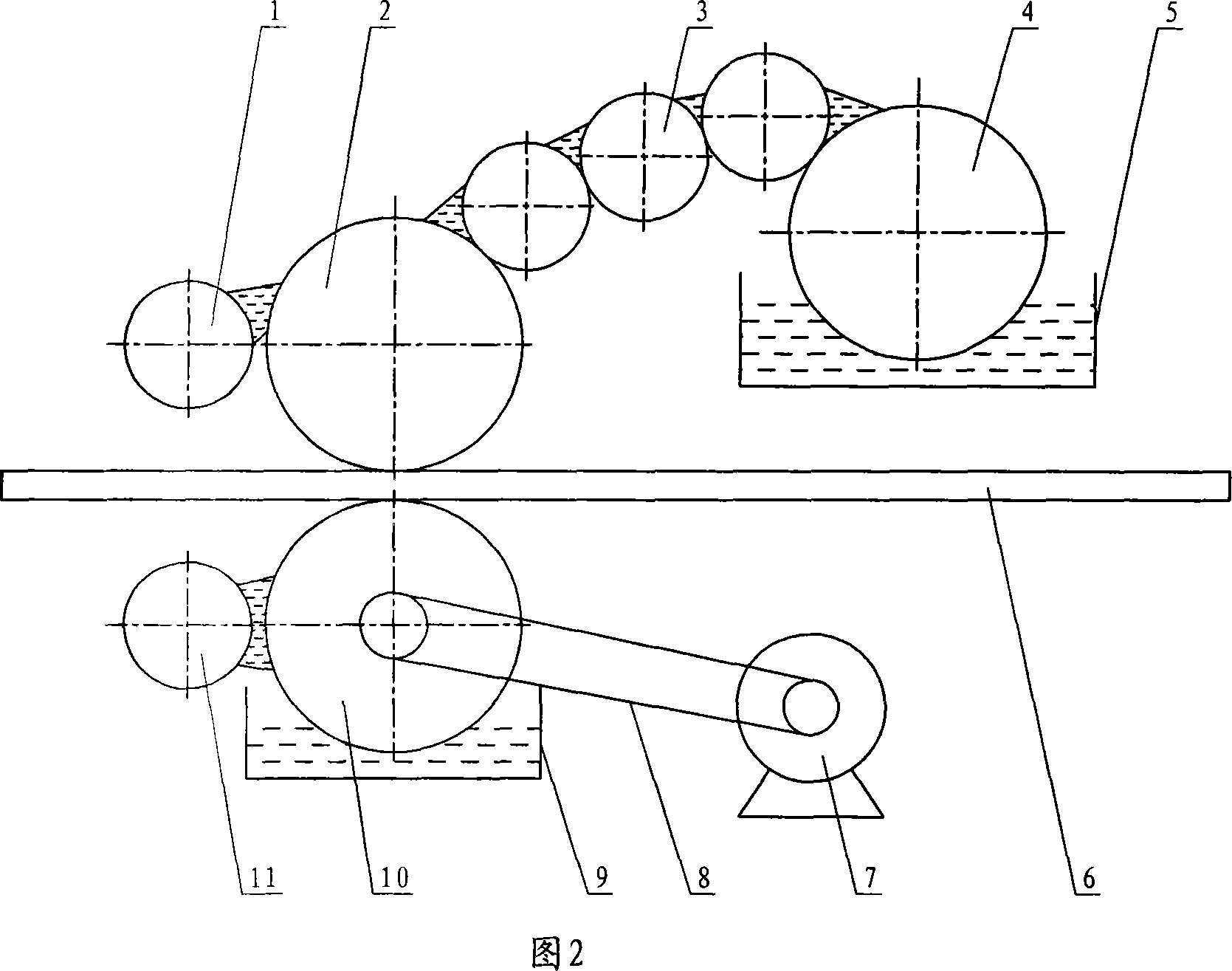

Method for fabricating radiating pipes of water tank in car heat exchanger made from aluminum alloy, and dedicated device

InactiveCN101092000AShorten the processing flowShorten processing timeLiquid surface applicatorsWelding/cutting media/materialsEngineeringMachining process

The invention relates to a machining method and special device for vehicle aluminum alloy heat exchange water tank radiator pipe. It puts the machining radiator pipe between two rollers of special device, which has flux on the surface. The flux would coat equally onto the surface of radiator pipe. The special device includes upper roller and down roller. The down part of driving upper roller drainage wheel and down roller is dipped in stock solution slot containing flux solution. The invention decreases a machining process, shortens machining time, improves producing efficiency, and decreases pollution to environment. The defective fraction of using the method could be under 0.3%. And the surface of the product is smoothing and bright.

Owner:林世东

Metal cleanser and preparation method thereof

The invention discloses a metal cleanser, which is composed of, by weight, 10-15 parts of sodium polyacrylate, 4-6 parts of trifluoroethanol, 4-6 parts of nonylphenol polyoxyethylene ether, 4-6 parts of sodium citrate, 2-4 parts of EDTA tetrasodium, 2-4 parts of chitosan, 2-4 parts of sodium dodecyl sulfonate, 3-5 parts of acetic acid, 3-5 parts of ethylene glycol, 3-5 parts of triethanolamine, 3-5 parts of di-o-tolyl-thiourea, 3-5 parts of sodium gluconate, 3-5 parts of carboxymethylcellulose, 3-5 parts of sodium oleate, 3-5 parts of sodium pyrophosphate, 3-5 parts of silicon dioxide, 3-5 parts of a nonionic surfactant, 2-4 parts of an anionic surfactant, 2-4 parts of a defoamer, 2-4 parts of trisodium phosphate, and 2-4 parts of a stabilizing agent. The anionic surfactant herein is one or more selected from octyl phenol polyoxyethylene ether, high-carbon fatty acid polyoxyethylene ether, fatty acid polyoxyethylene ester, and sorbitan ester. The cleanser has good cleaning effect.

Owner:WUXI CITY SHANGXIN METAL PROD

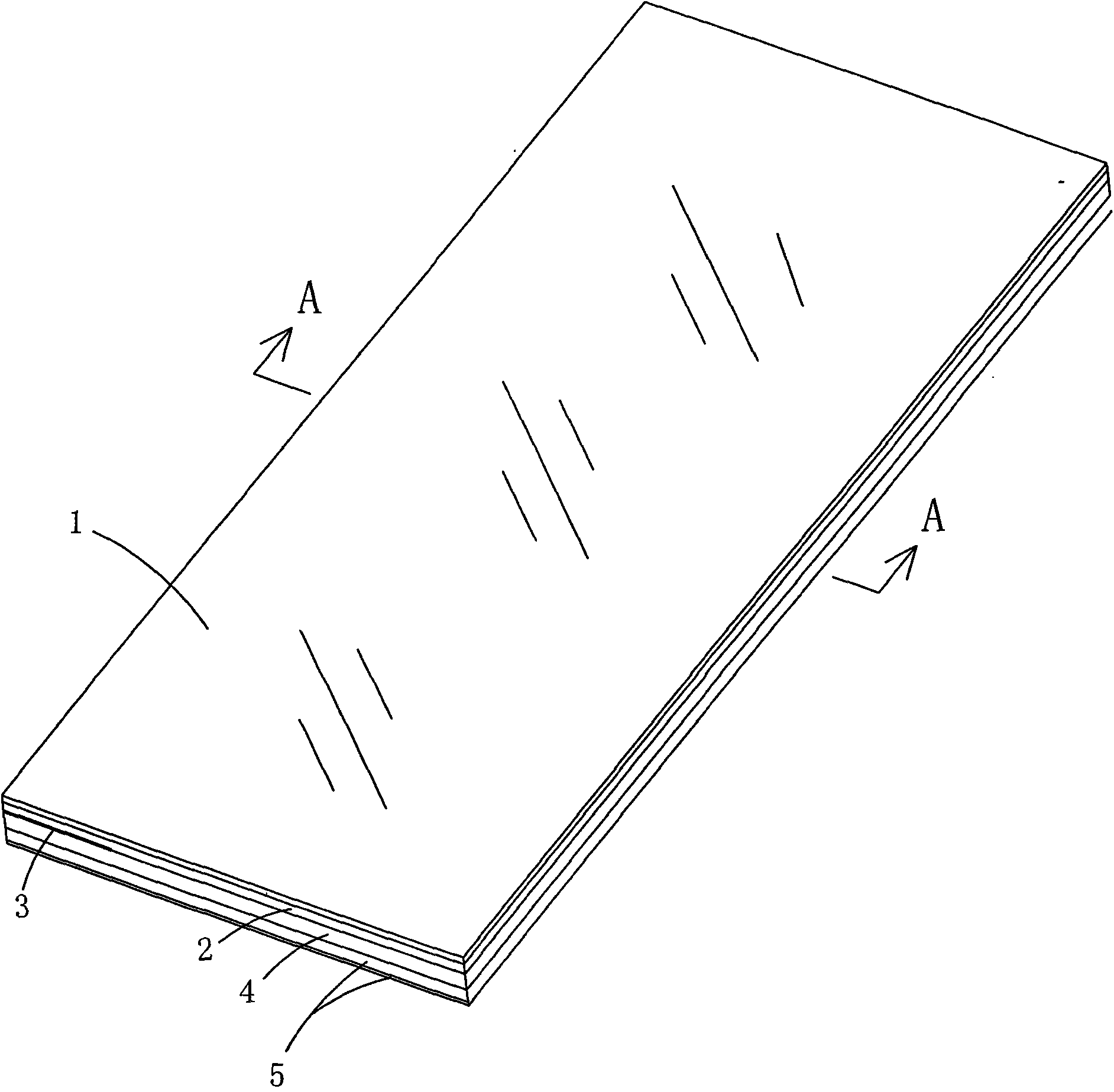

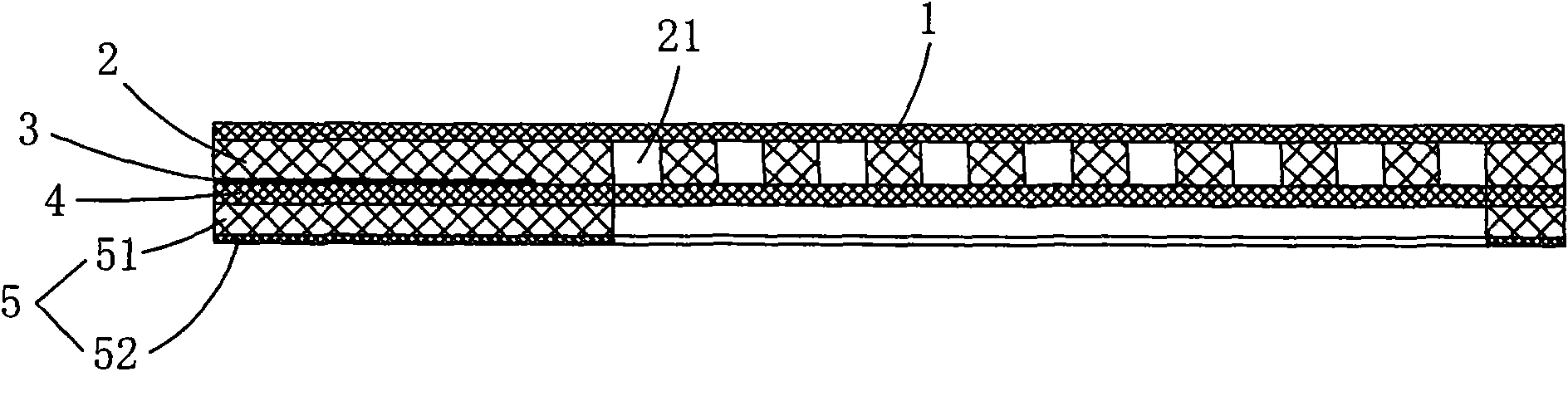

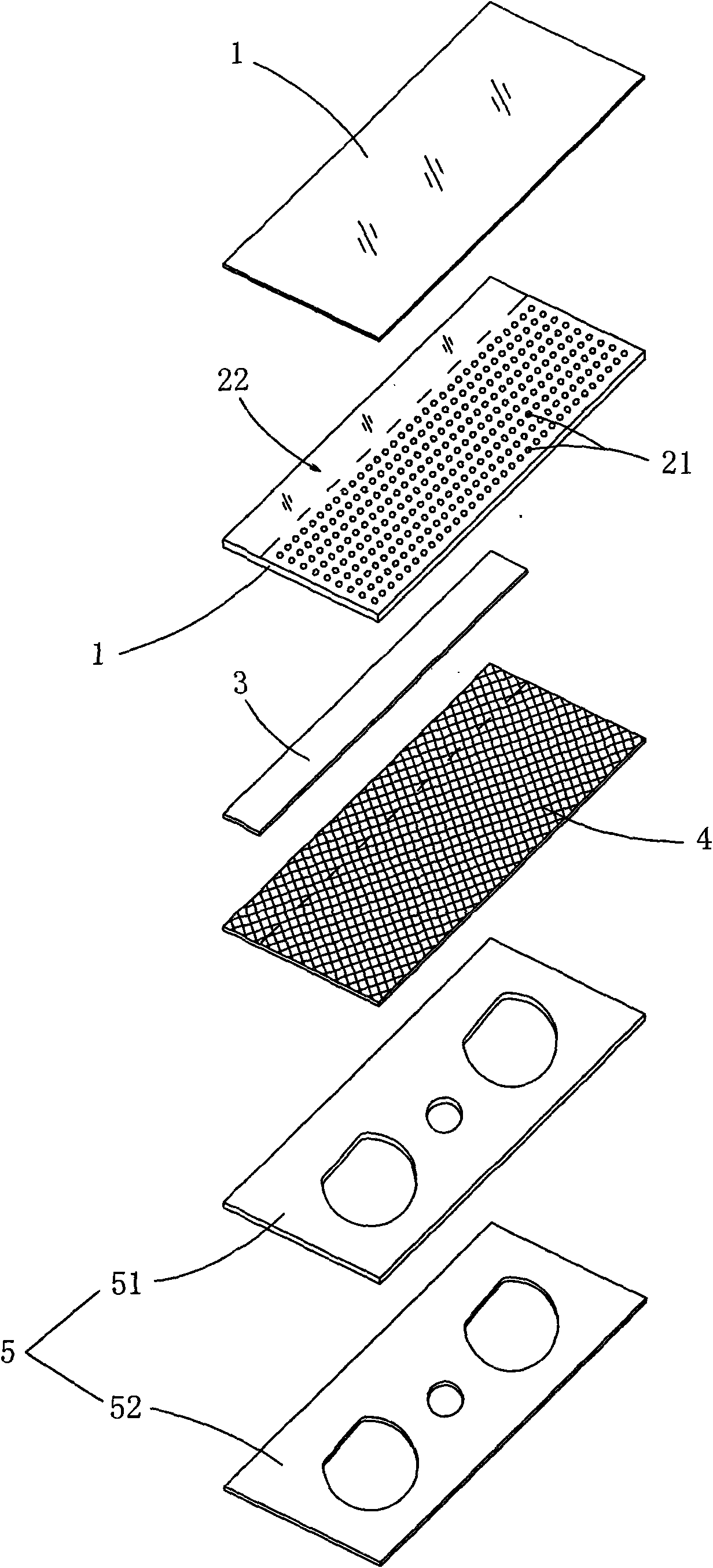

Composite board for cabinet veneering and manufacturing method thereof

InactiveCN104669732ANot prone to delamination cracksNot easy to fadeSynthetic resin layered productsFurniture partsMasterbatchPlasticulture

The invention relates to a composite board for cabinet veneering and a manufacturing method of the composite board. The composite board has a four-layer board structure, wherein the first layer consists of PMMA, UV, a silicon oxide scratch resistant agent, and a stearic acid surfactant, the second layer and the fourth layer consist of ABS, UV and titanium dioxide color masterbatch, and the third layer consists of PMMA, ABS, UV and titanium dioxide color masterbatch. The manufacturing method of the composite board comprises the following steps: evenly mixing and stirring raw materials of all the layers in respective mixing hoppers, after drying, plasticizing, melting and extruding the raw materials into corresponding runners of distributors at a certain temperature by three extrusion machines, extruding the raw materials out by T-shaped die heads, calendering by a calendering system, drawing, carrying out corona, and carrying out longitudinal and transverse size shearing to obtain the composite board. According to the four-layer structure of the composite board provided by the invention, the board cannot produce delamination or crack easily, meanwhile, the board has the advantages of being not easy to fade, scratch resistant and the like, and can be widely applicable to high-end furniture veneering and other indoor and outdoor decoration.

Owner:CHANGZHOU MINGDAO TECH

A formula of a metal rust remover

A metal rust remover is disclosed. The metal rust remover includes following raw materials by weight: 25-30 parts of sodium polyacrylate, 2-6 parts of trifluoroethanol, 2-6 parts of polyoxyethylene nonylphenol ether, 2-6 parts of sodium citrate, 4-6 parts of tetrasodium EDTA, 4-6 parts of chitosan, 4-6 parts of sodium dodecanesulphonate, 3-5 parts of acetic acid, 3-5 parts of glycol, 3-5 parts of triethanolamine, 3-5 parts of di(o-tolyl)thiourea, 3-5 parts of sodium gluconate, 3-5 parts of carboxymethylcellulose, 3-5 parts of sodium oleate, 3-5 parts of sodium pyrophosphate, 3-5 parts of silica, 3-5 parts of a nonionic surfactant, 2-4 parts of an anionic surfactant, 2-4 parts of a defoamer, 2-4 parts of trisodium phosphate and 2-4 parts of a stabilizer. The anionic surfactant is one or more selected from a group consisting of octylphenol polyoxyethylene ether, higher aliphatic alcohol polyoxyethylene ether, fatty acid polyoxyethylene ester and sorbitan esters. The cleaning effect of the metal rust remover is good.

Owner:WUXI CITY SHANGXIN METAL PROD

Leather care agent for removing harmful gas smell

InactiveCN106755640AHigh glossExtend the life cyclePolishing compositionsLeather surface finishingHazardous substanceMoisture

The invention discloses a leather care agent for removing harmful gas smell. The leather care agent for removing the harmful gas smell comprises grease, polyacrylic acid amide, protease, an ammonia silver solution, isooctyl-polyoxyethylene, propylene glycol monoethyl ether, dodecanol, a curing agent, iron magnesium tourmaline, nano titanium dioxide, a PH adjuster and distilled water. Harmful matter such as formaldehyde is removed through negative ions released by the leather care agent, the peculiar smell is removed, and the photooxidation is retarded; and an effective protective film is formed for locking the oil and moisture, so that leather is durable in use, resistant to wear and resistant to oxidation, and the leather care agent is capable of increasing the leather softness and lustrousness, keeping the surface cleanliness and prolonging the service life of the leather.

Owner:GUANGXI UNIV

Metal surface detergent and preparation method thereof

The invention discloses a metal surface detergent. The metal surface detergent is composed of, by weight ratio, raw materials including 10-30 parts of sodium polyacrylate, 2-4 parts of trifluoroethanol, 2-4 parts of nonylphenol polyoxyethylene ether, 2-4 parts of sodium citrate, 4-6 parts of EDTA tetrasodium, 4-6 parts of chitosan, 4-6 parts of sodium dodecyl sulfate, 3-5 parts of acetic acid, 3-5 parts of ethylene glycol, 3-5 parts of triethanolamine, 3-5 parts of 1,3-di(o-tolyl)thuiyrea, 3-5 parts of sodium gluconate, 3-5 parts of carboxymethylcellulose, 3-5 parts of sodium oleate, 3-5 parts of sodium pyrophosphate, 3-5 parts of silicon dioxide, 3-5 parts of nonionic surfactant, 2-4 parts of anionic surfactant, 2-4 parts of an antifoaming agent, 2-4 parts of trisodium phosphate and 2-4 parts of stabilizer, wherein fatty acid arkanol amide polyglycol ether is selected as the nonionic surfactant. The metal surface detergent is good in washing effect.

Owner:WUXI CITY SHANGXIN METAL PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com