Production method of gold-tin wire, foil belt and preforming welding piece

A technology of solder preforms and gold-tin tin wires, applied in welding equipment, metal processing equipment, welding media, etc., can solve the problems of high brittleness and difficult processing of gold-tin alloys, so as to ensure bright surface, reduce oxide layer, easy molding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

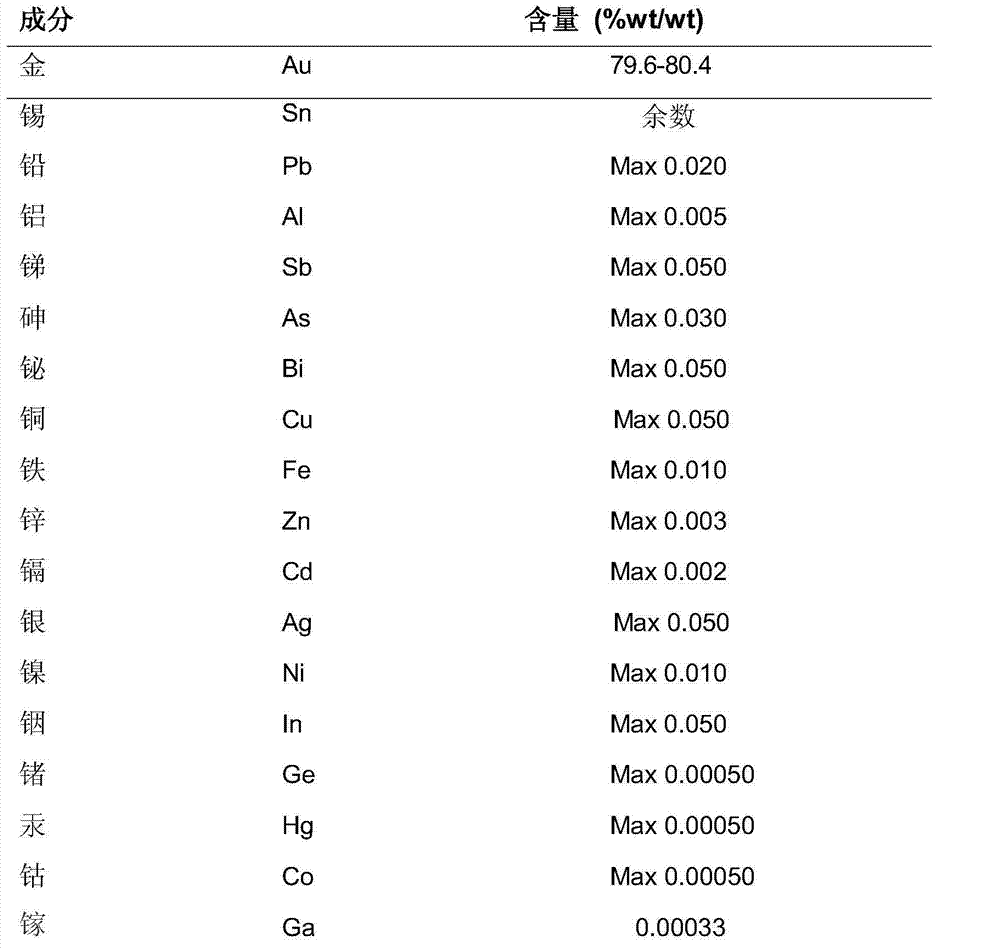

[0030] Step 1: Put 0.08 tons of gold with a purity of 99.99% and 0.02 tons of tin with a purity of 99.99% in a melting furnace to form alloys at a melting temperature of 450°C. Take 300g of molten alloy and put it into the test mold to cool to room temperature, and then test it. After the content of each metal meets the conditions, pour the molten metal into a mold with a diameter of 70mm to make an alloy rod, and remove the surface oxidation of the cast alloy rod After the goods are vacuum packed.

[0031] Step 2: First clean the feeding cylinder, extrusion column, mold, etc. of the 350-ton extruder, then put the alloy rod into the extrusion cylinder for annealing, and close the outlet of the extruder with a solid mold, and the inside of the extruder The pressure was adjusted to 100MPa, the temperature was 200°C, and annealed for 4h. Roll out the alloy rod, remove the oxide on the surface of the alloy rod, and then vacuum pack the alloy rod.

[0032] Step 3, install a tin w...

Embodiment 2

[0034] Step 1: Put 0.08 tons of gold with a purity of 99.99% and 0.02 tons of tin with a purity of 99.99% in a melting furnace to form alloys at a melting temperature of 500°C. Take 300g of molten alloy and put it into the test mold to cool to room temperature, and then test it. After the content of each metal meets the conditions, pour the molten metal into a mold with a diameter of 70mm to make an alloy rod, and remove the surface oxidation of the cast alloy rod After the goods are vacuum packed.

[0035] Step 2: First clean the feeding cylinder, extrusion column, mold, etc. of the 350-ton extruder, then put the alloy rod into the extrusion cylinder for annealing, and close the outlet of the extruder with a solid mold, and the inside of the extruder The pressure was adjusted to 130MPa, the temperature was 250°C, and annealed for 4h. Roll out the alloy rod, use a peeling machine to remove the oxide on the surface of the alloy rod, and then vacuum pack the alloy rod.

[0036...

Embodiment 3

[0038] Step 1: Put 0.08 tons of gold with a purity of 99.99% and 0.02 tons of tin with a purity of 99.99% in a melting furnace to form alloys at a melting temperature of 500°C. Take 300g of molten alloy and put it into a test mold to cool to room temperature, and then test it. After the content of each metal meets the conditions, pour the molten metal into a mold with a diameter of 70mm to make an alloy rod. The cast alloy rod uses a peeling machine Vacuum packaging after removing surface oxides.

[0039] Step 2: First clean the feeding cylinder, extrusion column, mold, etc. of the 350-ton extruder, then put the alloy rod into the extrusion cylinder for annealing, and close the outlet of the extruder with a solid mold, and the inside of the extruder The pressure was adjusted to 150MPa, the temperature was 300°C, and annealed for 3h. Roll out the alloy rod, use a peeling machine to remove the oxide on the surface of the alloy rod, and then vacuum pack the alloy rod.

[0040] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com