Method for fabricating radiating pipes of water tank in car heat exchanger made from aluminum alloy, and dedicated device

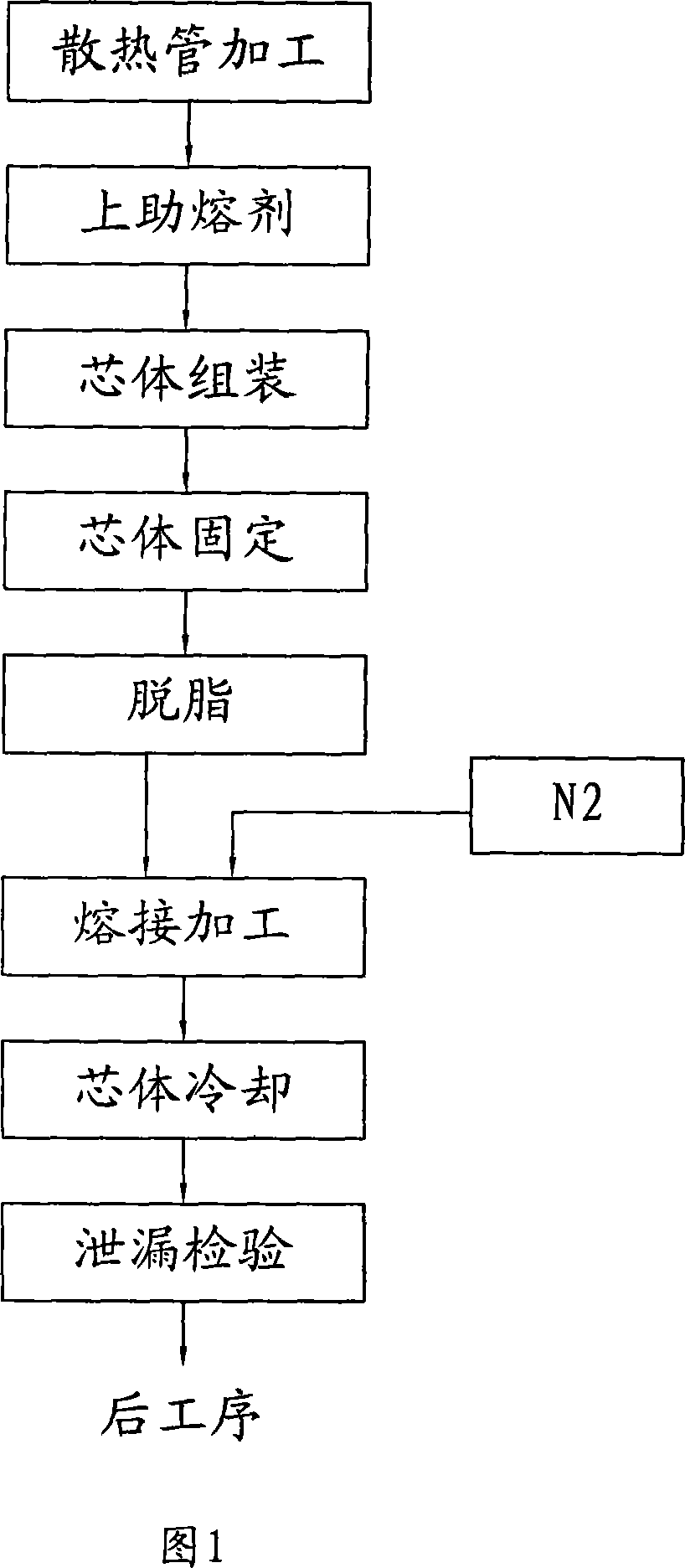

A technology of heat exchangers and processing methods, applied in heat exchange equipment, metal processing equipment, welding equipment, etc., can solve the problems of air and environmental pollution, inability to use flux, regular consumption of powder, etc., to reduce processing procedures, increase Observability, the effect of reducing waste of resources and energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described in detail below through the specific examples, the following examples are only descriptive, not restrictive, and cannot limit the protection scope of the present invention with this.

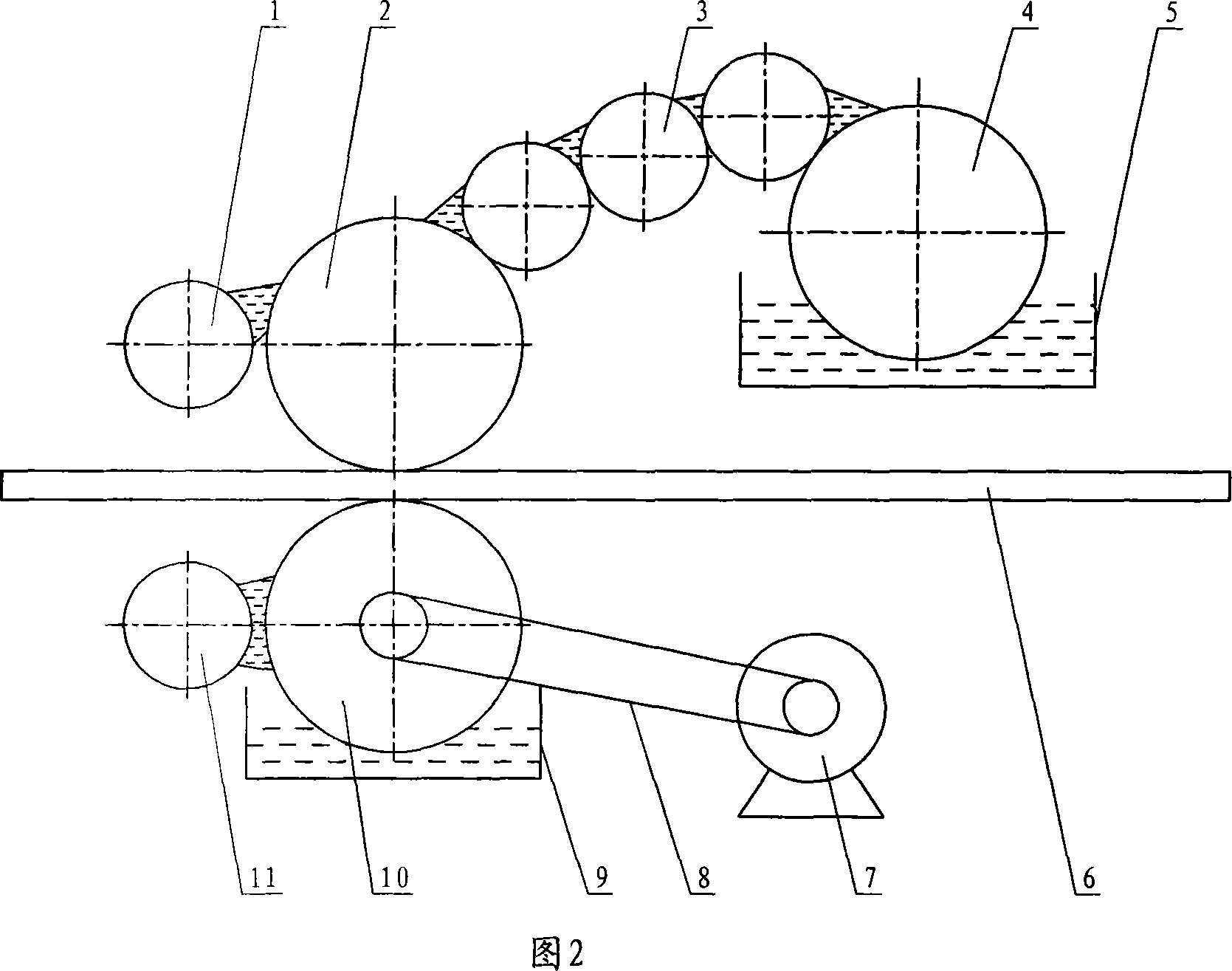

[0025] Since the printing method is a new flux coating technology, it is necessary to use a dedicated printing coating device. In order to be able to accurately and clearly describe the processing method of the present invention, firstly, the special equipment used for the cooling pipe of the water tank of the aluminum alloy heat exchanger of the automobile - the printing and coating device is described.

[0026] The structure of this printing and coating device is as follows: the heat dissipation pipe 6 to be processed is between the upper roller 2 and the lower roller 10 in the same radial direction, and the lower roller is driven by a motor 7 using a belt 8, and the lower part of the lower roller is dipped in a In the liquid storage tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com