Heavy-load pan-tilt camera with high camera quality stability

A PTZ camera and quality stability technology, applied in the field of PTZ cameras, can solve problems affecting camera focus, inconvenient maintenance, and affecting monitoring quality, etc., achieving high camera quality stability, saving production costs, and improving camera performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

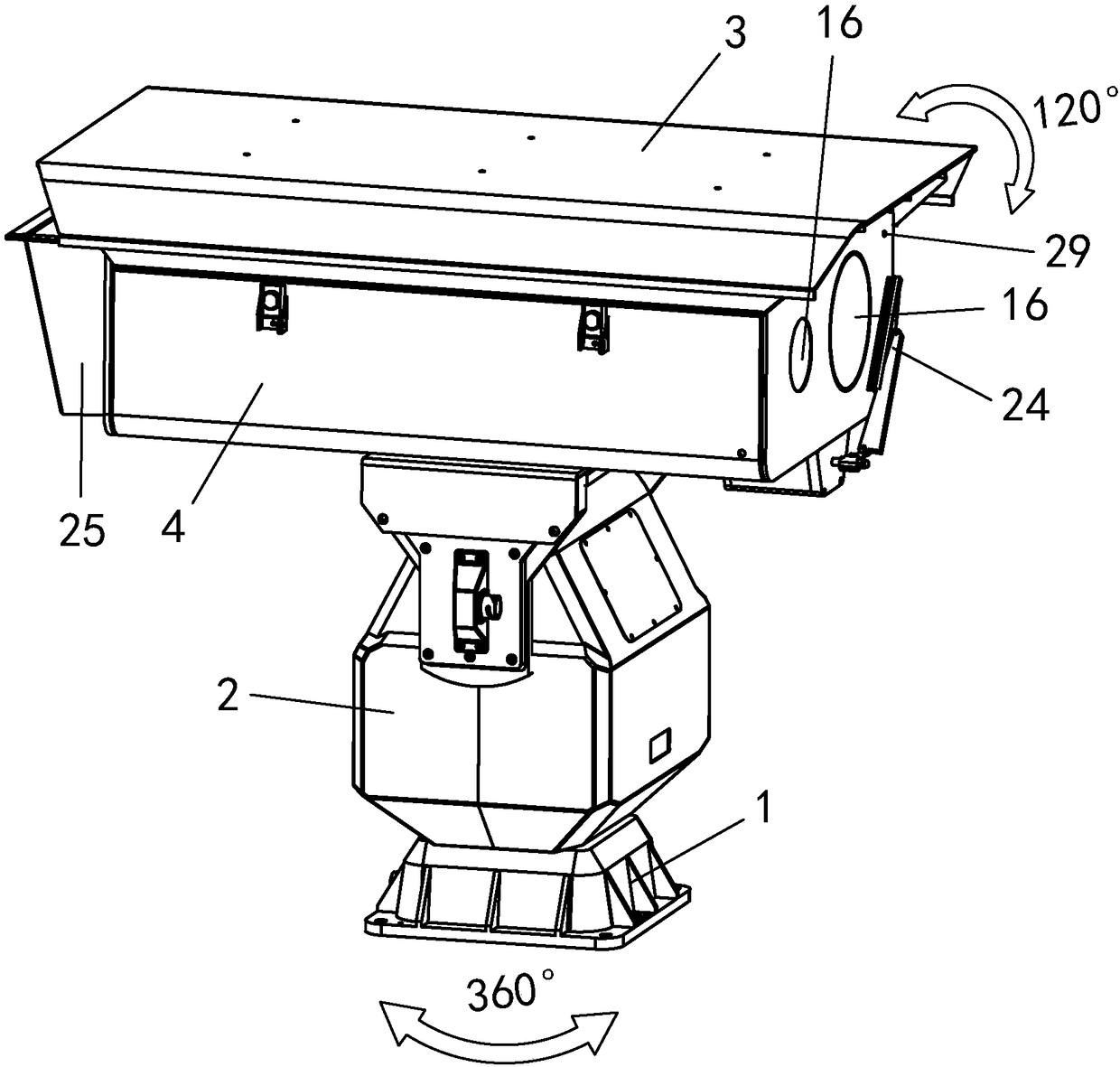

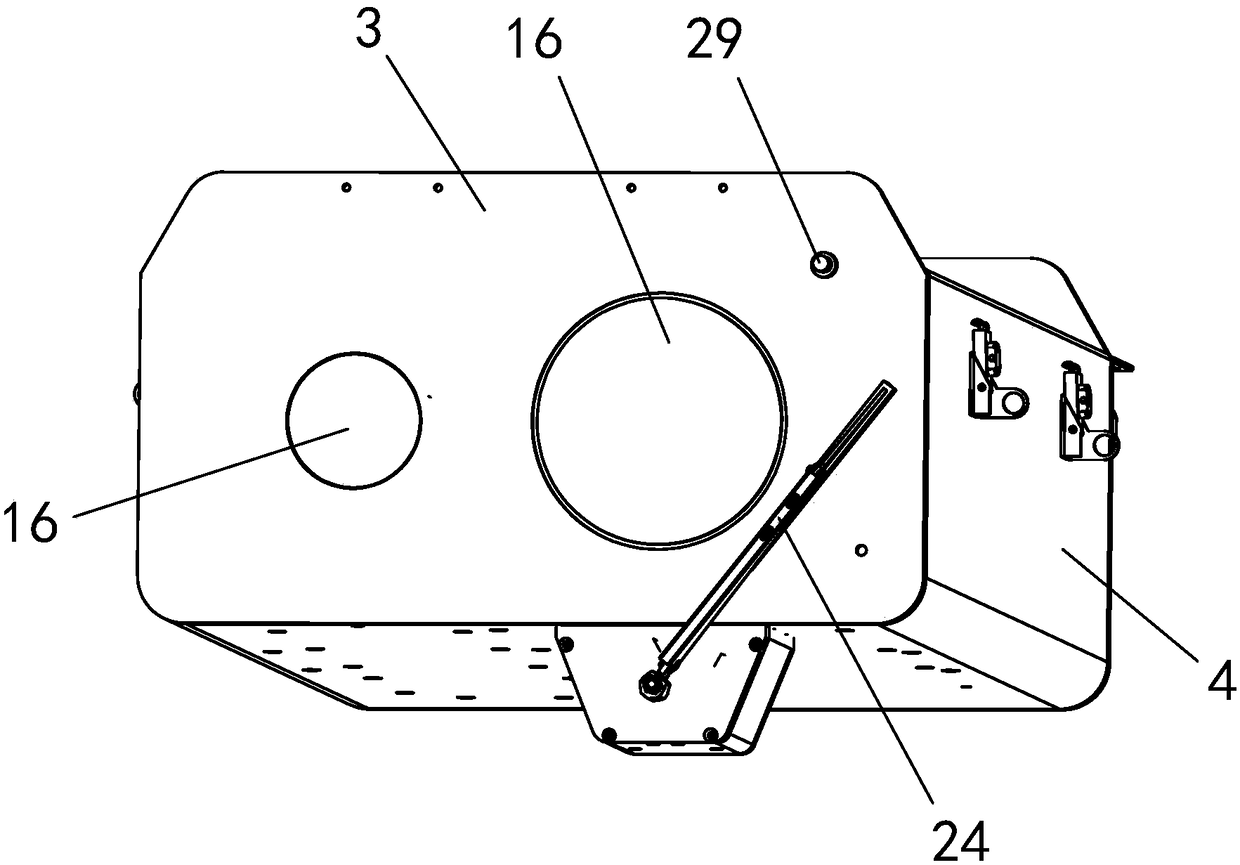

[0044] Example: see attached Figure 1-8 As shown, a heavy-duty pan-tilt camera with high camera quality and stability is an electrically adjustable laser-type heavy-duty pan-tilt camera, including a pan-tilt mount 1, a pan-tilt 2 and a camera 3; the pan-tilt 2 is rotatably connected to The top of the pan-tilt mount 1 rotates in the horizontal direction; the camera 3 is connected to the top of the pan-tilt 2 to rotate in the up-down direction; When turning, the gimbal 2 will rotate the 3 parts of the camera left and right, and the rotation angle is 360 degrees; at the same time, it can also control the 3 parts of the camera to rotate vertically in the up and down direction, and the rotation angle is at least 120 degrees; through the horizontal direction and the up and down direction Coordinated rotation, so that camera 3 can photograph the situation around the scene and up and down.

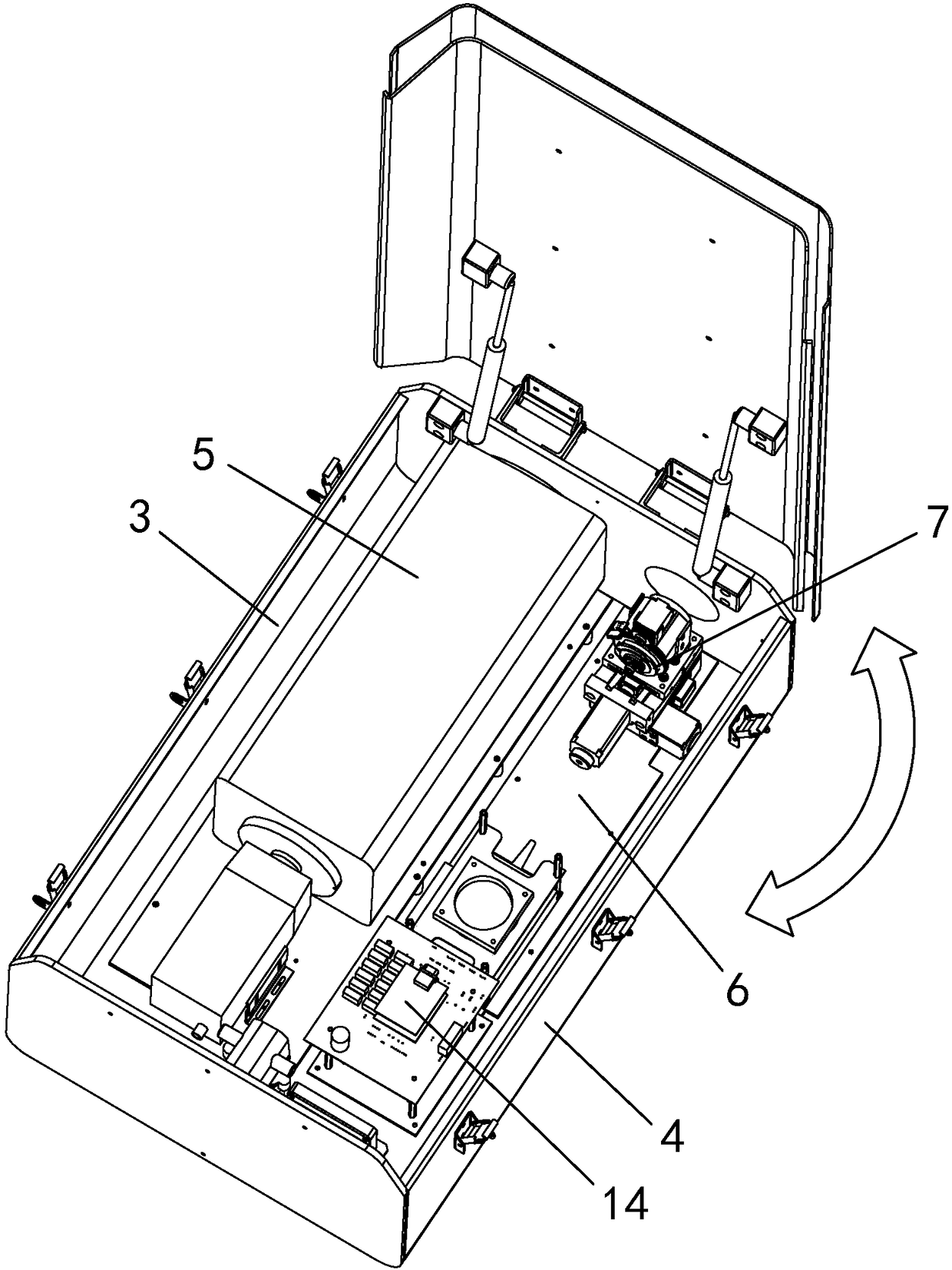

[0045] Wherein, the camera 3 includes a shield 4, which is internally provided with a camera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com