Method for producing colored bumpers

A production method and bumper technology, applied to bumpers, pre-treated surfaces, and devices for coating liquid on surfaces, can solve problems such as poor production safety, low degree of automation, and low production efficiency, and achieve stable dimensional accuracy, The effect of high degree of automation and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

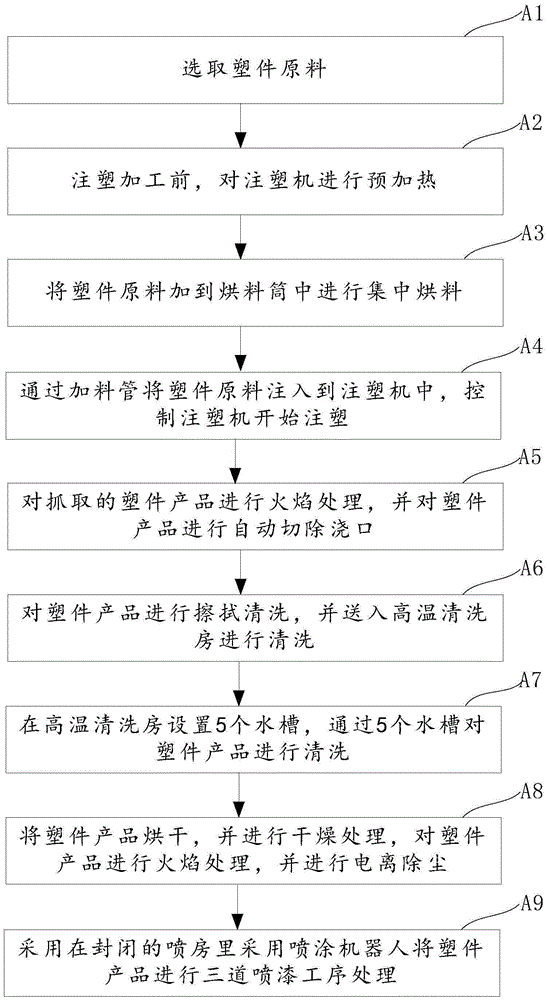

[0051] see figure 1 , a kind of color bumper production method that the embodiment of the present invention provides, it comprises:

[0052] Step A1, select raw materials for plastic parts; namely, by weight percentage, polypropylene 35-55%, heat stabilizer 3-4%, processing aid 3-5%, toughening agent 12-18%, compatibilizer 4-6% %, inorganic filler 12-22%, flame retardant 5-20%, dispersant 1-1.5% and antioxidant 1.5-2%.

[0053] Step A2, before the injection molding process, the injection molding machine is preheated, and the preheating time is 15 minutes.

[0054] Step A3: Put the raw material of the plastic part into the drying cylinder for concentrated drying, wherein the temperature of the cylinder is 180-235°C, the drying temperature of the raw material is 55-70°C, and the drying time is longer than 2 hours. This step can not only remove moisture, but also reduce the occurrence of defects in the injection molding process of the product, such as bubbles, silver wires and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com