Spin coating preparation method for dense diffusion barrier layer of limiting current type oxygen sensor

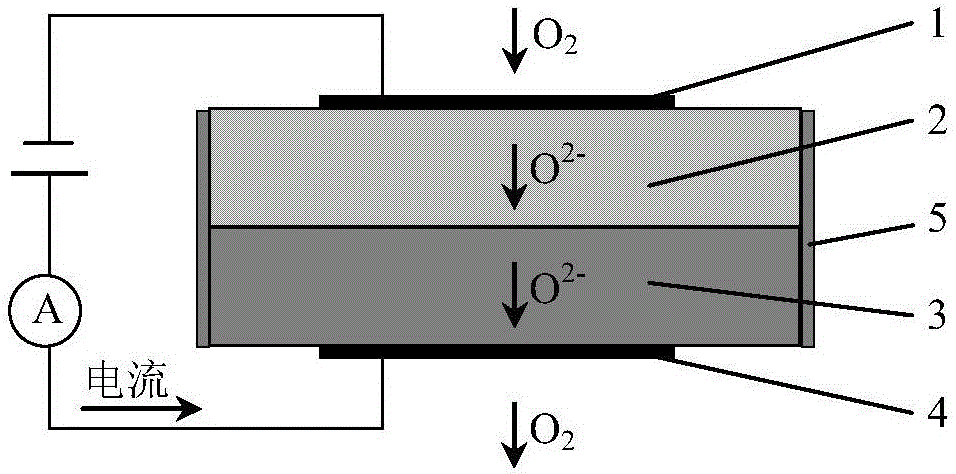

A limiting current type, spin coating technology, which is applied in the direction of instruments, scientific instruments, and material analysis by electromagnetic means, can solve problems such as unsatisfactory oxygen measurement performance, cumbersome preparation process, and cracking of sintered bodies, and achieve short manufacturing cycle , high bonding strength, heat-affected zone range and reduced deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] A method for preparing a dense diffusion barrier layer for a limiting current type oxygen sensor by spin coating, comprising the following steps:

[0057] Step 1, material preparation

[0058] (1) Mix ethyl cellulose and turpentine through alcohol, heat to 80°C in a water bath to dissolve, and after the dissolution is complete, an organic vehicle is obtained, and La 0.84 Sr 0.16 MnO 3 (LSM) is uniformly dispersed in the organic vehicle to prepare a dense diffusion barrier layer slurry La 0.84 Sr 0.16 MnO 3 ; Among them, according to the mass ratio, the dense diffusion barrier layer powder La 0.84 Sr 0.16 MnO 3 : turpentine through alcohol: ethyl cellulose=4: 7: 0.04;

[0059] Step 2, spin coating

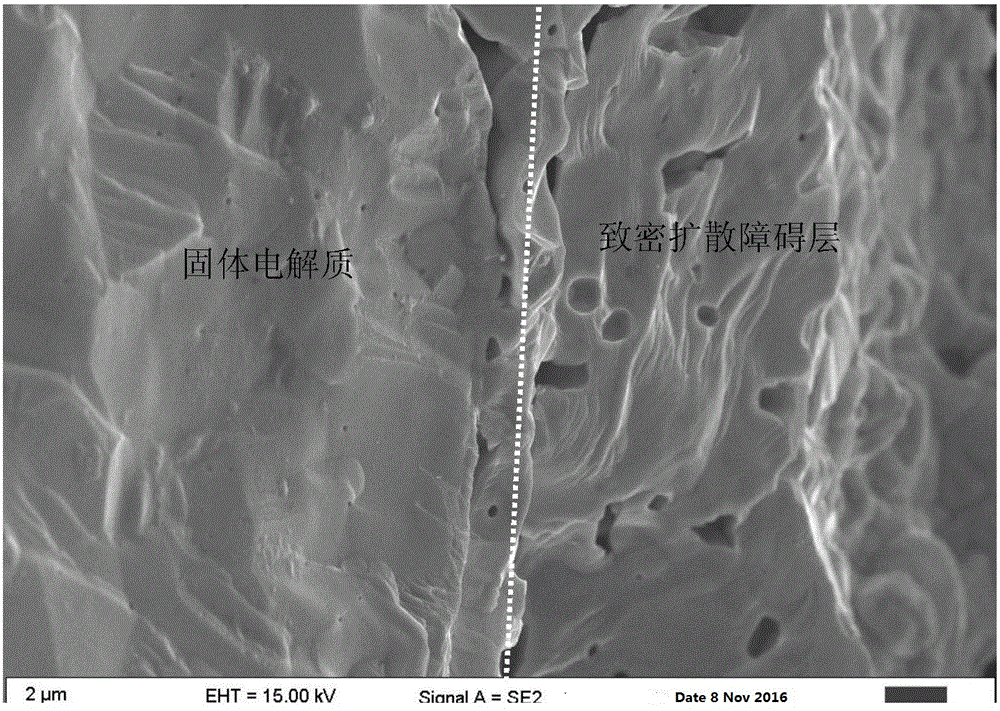

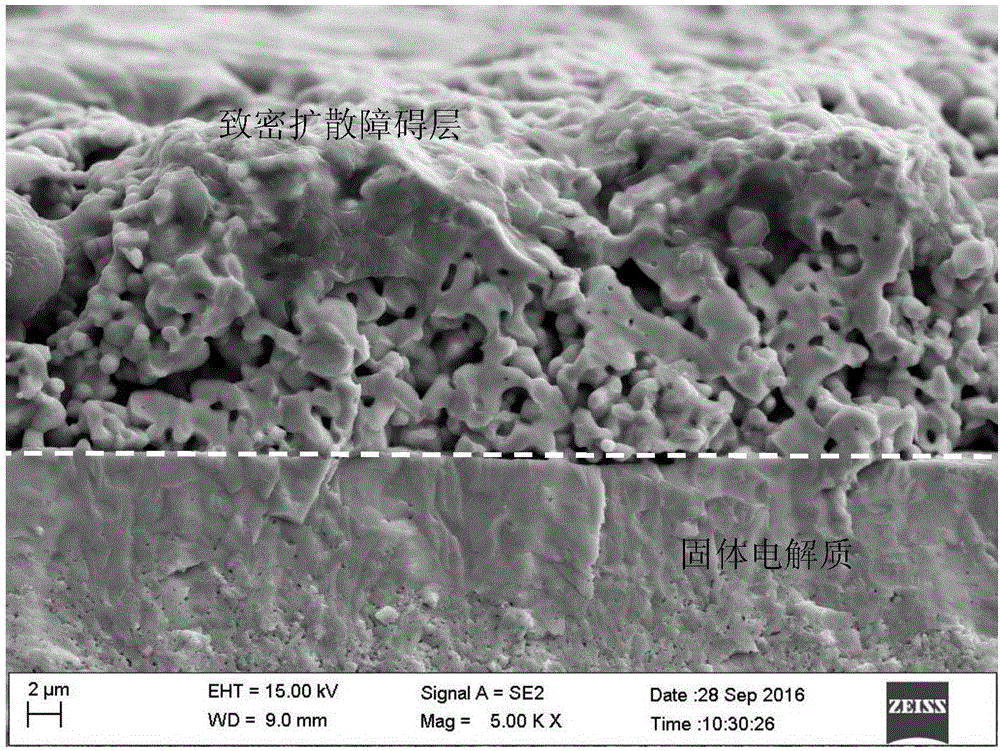

[0060] The dense diffusion barrier layer slurry was uniformly coated on the surface of the commercially available 8YSZ solid electrolyte with a spin coater to obtain a solid electrolyte with a dense diffusion barrier layer on the surface; wherein, the spin coating pr...

Embodiment 2

[0067] A method for preparing a dense diffusion barrier layer for a limiting current type oxygen sensor by spin coating, comprising the following steps:

[0068] Step 1, material preparation

[0069] (1) Mix ethyl cellulose and turpentine through alcohol, heat to 70°C in a water bath to dissolve, and after the dissolution is complete, an organic vehicle is obtained, and La 0.7 Sr 0.3 MnO 3 Uniformly dispersed in an organic vehicle to prepare a dense diffusion barrier layer slurry La 0.7 Sr 0.3 MnO 3 ; Among them, according to the mass ratio, the dense diffusion barrier layer powder La 0.7 Sr 0.3 MnO 3 : turpentine through alcohol: ethyl cellulose = 2: 5: 0.01;

[0070] Step 2, spin coating

[0071] The dense diffusion barrier layer slurry was uniformly coated on the surface of the commercially available 8YSZ solid electrolyte with a spin coater to obtain a solid electrolyte with a dense diffusion barrier layer on the surface; wherein, the spin coating process paramete...

Embodiment 3

[0078] A method for preparing a dense diffusion barrier layer for a limiting current type oxygen sensor by spin coating, comprising the following steps:

[0079] Step 1, material preparation

[0080] (1) Mix ethyl cellulose and ethylene glycol, and heat it in a water bath to 90°C for dissolution. After the dissolution is complete, an organic vehicle is obtained, and La 0.8 Sr 0.2 MnO 3 Uniformly dispersed in an organic vehicle to prepare a dense diffusion barrier layer slurry La 0.8 Sr 0.2 MnO 3 ; Among them, according to the mass ratio, the dense diffusion barrier layer powder La 0.8 Sr 0.2 MnO 3 : ethylene glycol: ethyl cellulose = 3: 6: 0.02;

[0081] Step 2, spin coating

[0082]The dense diffusion barrier layer slurry was uniformly coated on the surface of the commercially available 8YSZ solid electrolyte with a spin coater to obtain a solid electrolyte with a dense diffusion barrier layer on the surface; wherein, the spin coating process parameters of the spin c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com