Microwave thermogravimetric analysis system

A technology of reaction analysis and microwave heating chamber, applied in the direction of weighing by removing certain components, preparation of test samples, etc., can solve the problem of inability to directly measure the real-time change value of the weight of the reaction material and affect the in-depth analysis of the microwave pyrolysis reaction mechanism , parameter detection and control are not very accurate, etc., to achieve the effect of simple structure, low cost, and small temperature fluctuation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

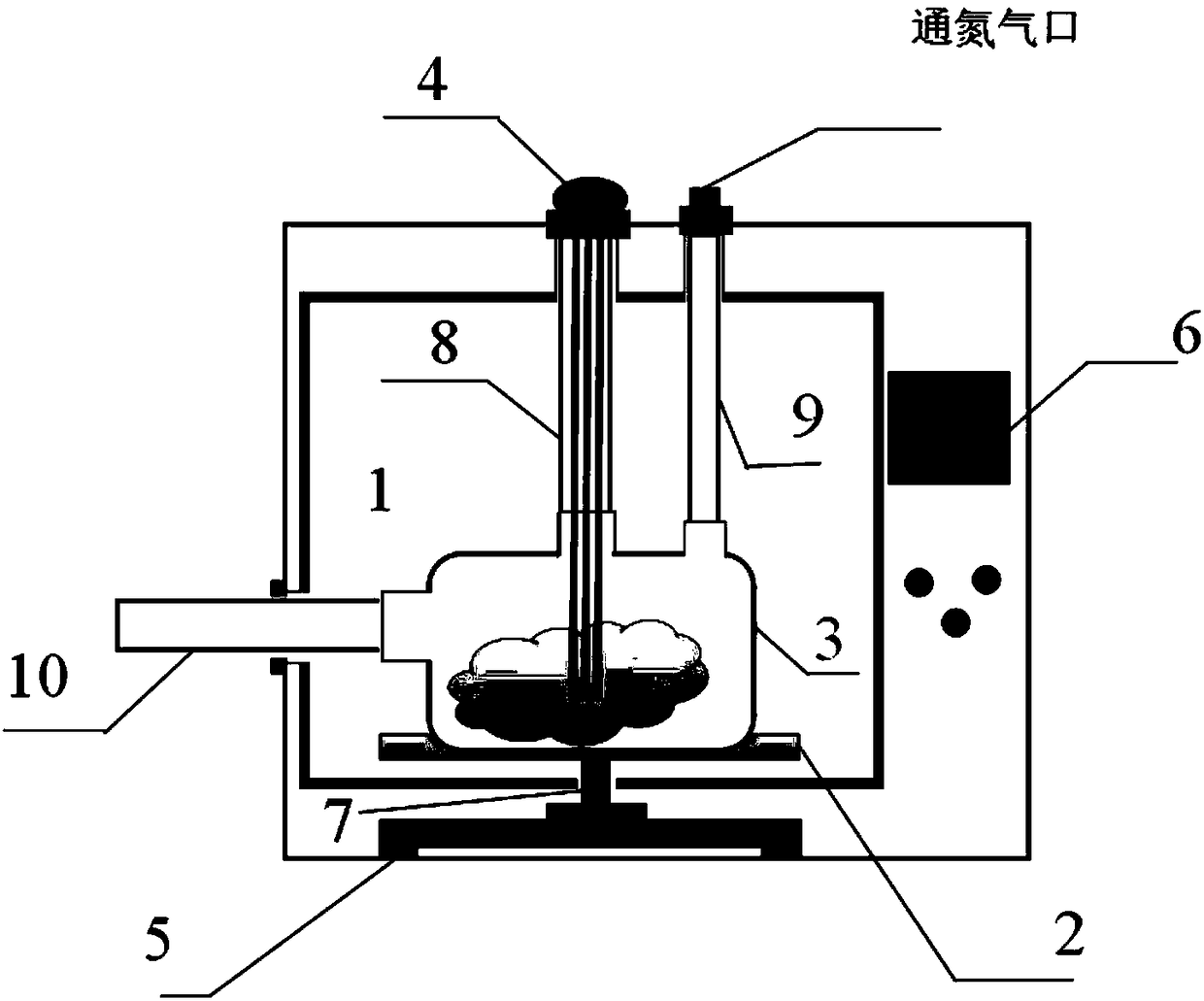

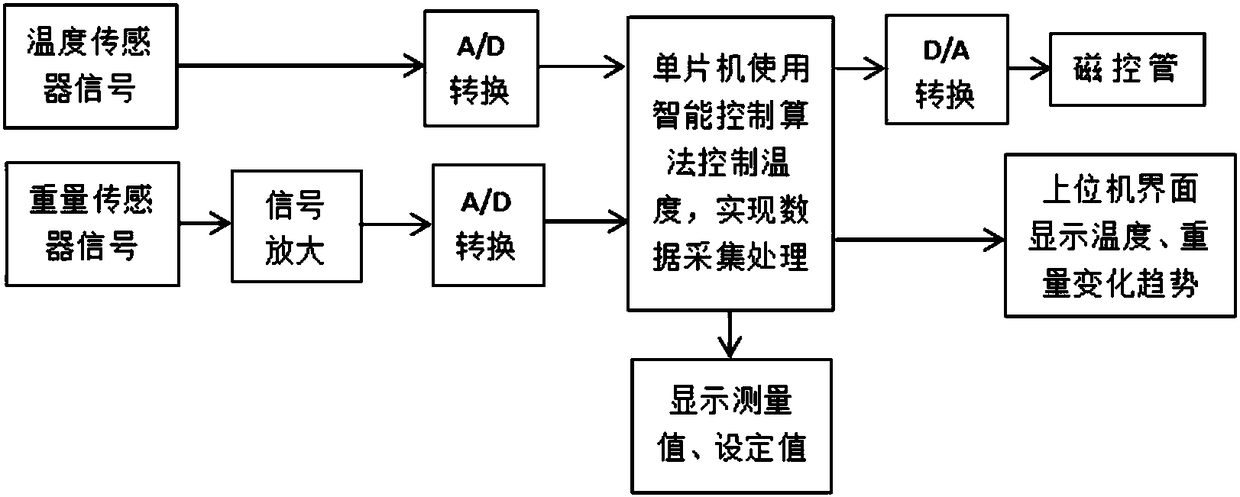

[0037] A microwave thermogravimetric reaction analysis system, the schematic diagram of which is shown in figure 1 , the schematic diagram of the reactor is shown in image 3 : The reaction analysis system is to open two holes in the middle of the upper wall of the heating chamber 1 of the microwave pyrolysis device. The oval openings are used to extend into the oval quartz tube 8 placed in the microwave heating chamber 1, and the oval quartz tubes The thermocouple temperature sensor 4 is inserted into the tube 8; the circular opening extends into the short cylindrical quartz tube 9, and the frosted outer interfaces of the oval quartz tube 8 and the cylindrical short quartz tube 9 are respectively placed on the circular tray 2 The two ports on the upper end of the quartz flask reactor 3 are connected. The opening of the left side wall of the microwave heating chamber 1 stretches into a cylindrical long quartz tube 10 and is connected with the quartz flask reactor 3 to ensure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com