Polysilicon channel type wool making and cooling device

A cooling device and polysilicon technology, applied in the direction of crystal growth, after treatment, chemical instruments and methods, etc., can solve the problems of non-directionality of polysilicon grains, inability to follow the production process of monocrystalline silicon, and cooling devices that cannot meet the requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

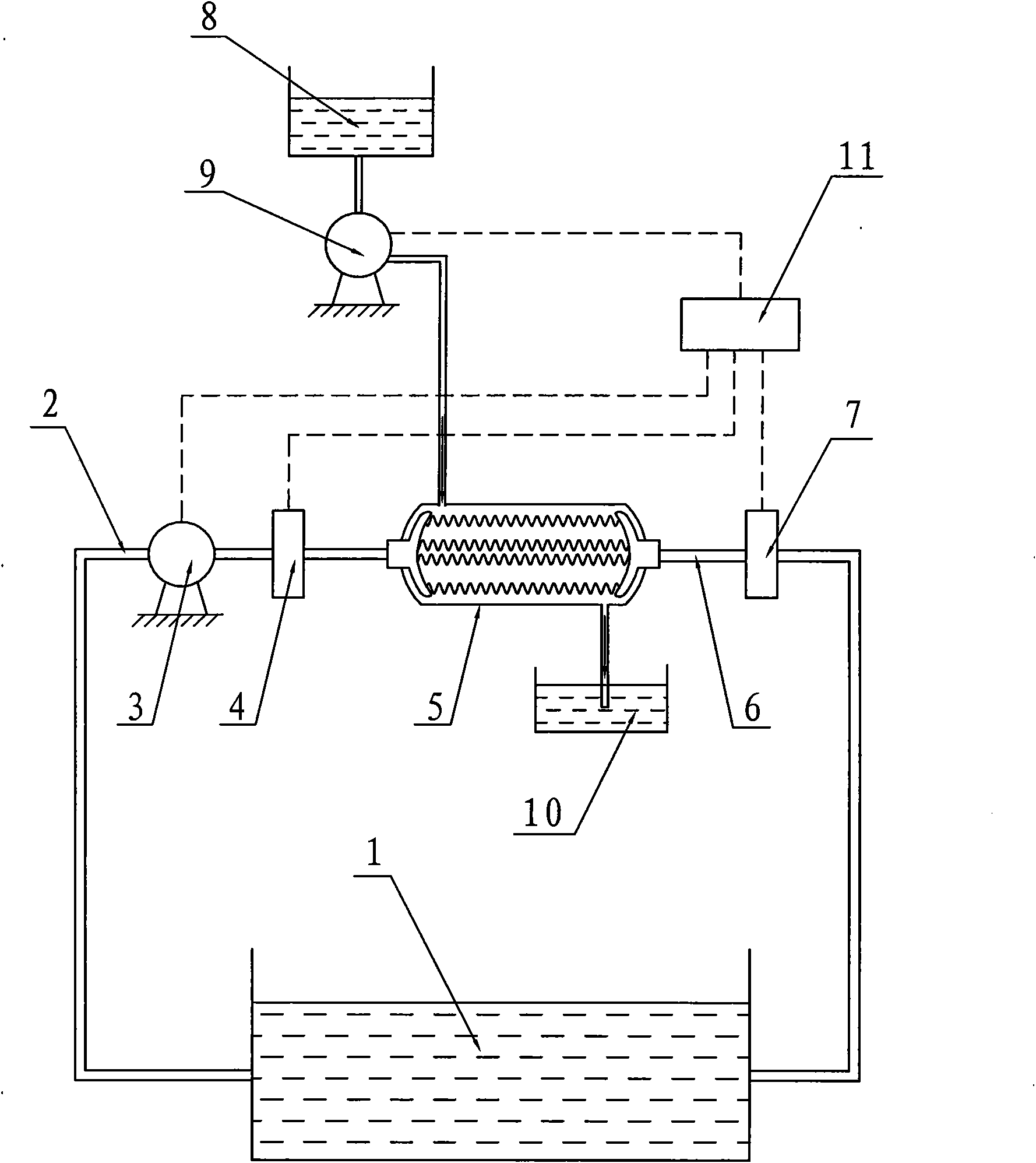

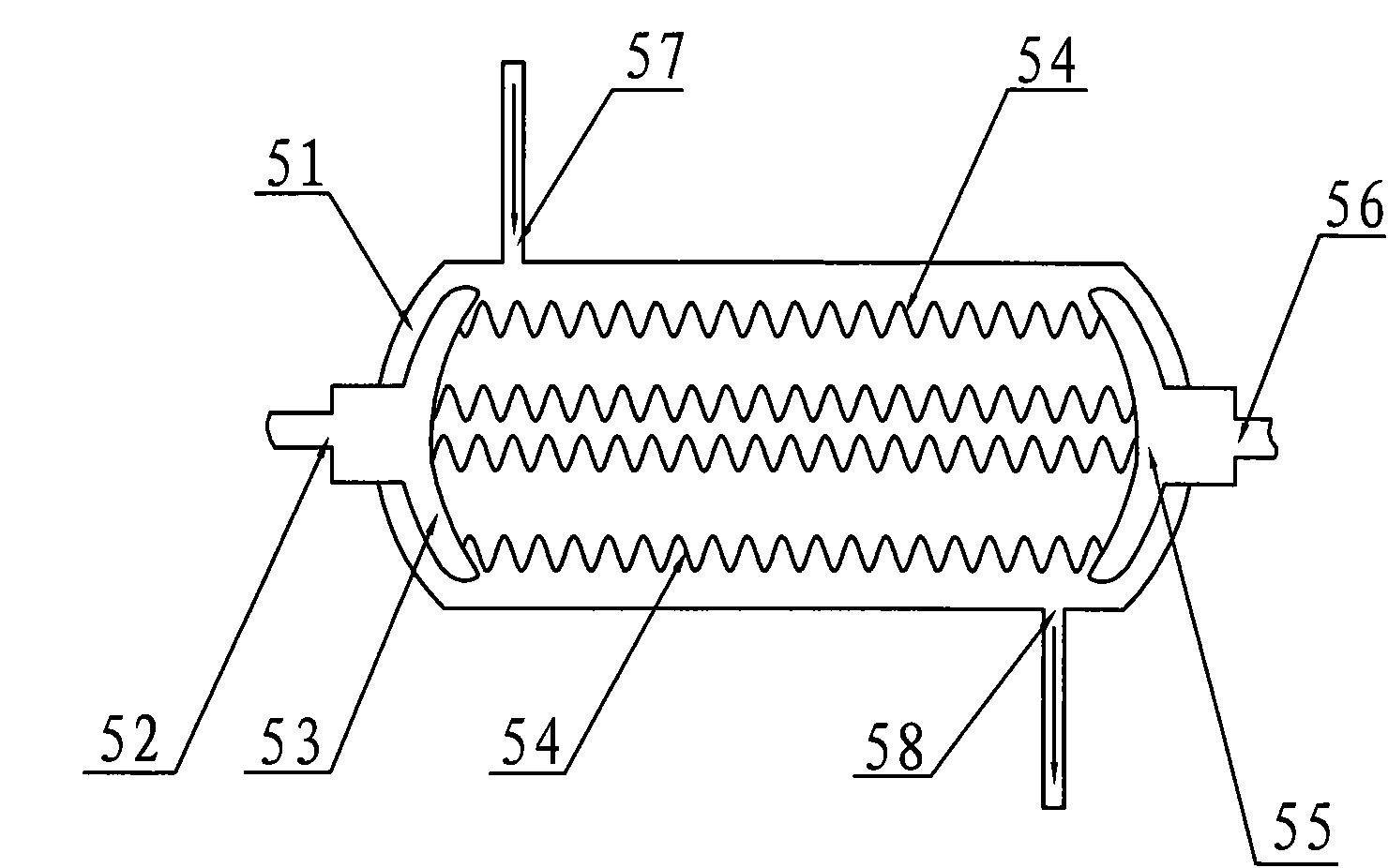

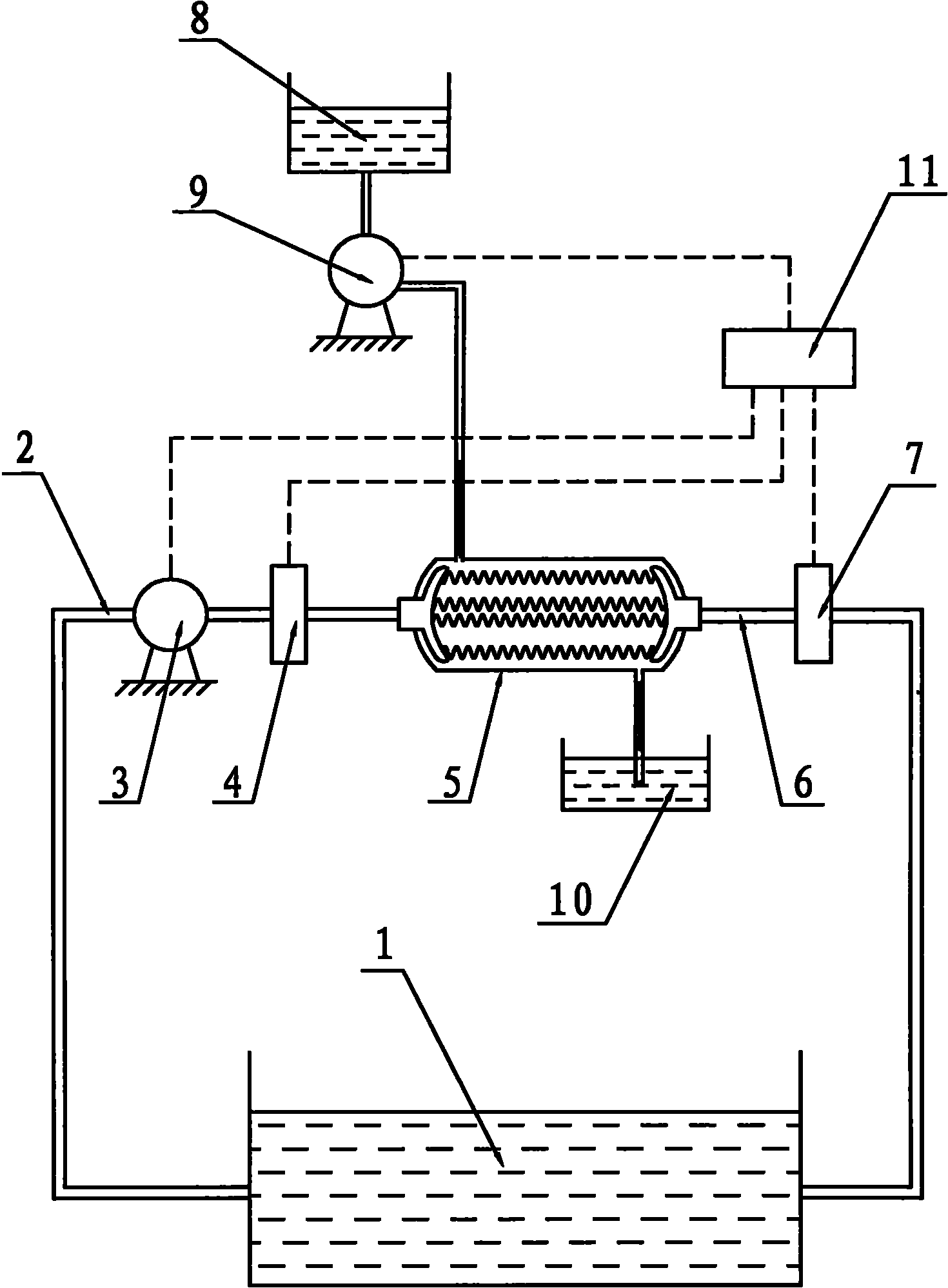

[0011] The polysilicon trough type texturing cooling device such as figure 1 , figure 2 As shown, it includes a velvet making tank 1, an corrosive liquid input pipe 2, a circulation pump 3, an inlet temperature sensor 4, a heat exchanger 5, an corrosive liquid output pipe 6, an outlet temperature sensor 7, a cooling liquid pool 8, a variable pump 9, The recovery pool 10 and the electric control unit 11, the heat exchanger 5 is composed of a cooling tank inner cavity 51, an corrosive liquid input port 52, a hot liquid chamber 53, a hot liquid branch pipe 54, a cold liquid chamber 55, an corrosive liquid output port 56, a cooling The liquid inlet 57 and the cooling liquid outlet 58, the corrosive liquid input port 52 is connected with the hot liquid chamber 53, the cold liquid chamber 55 is connected with the corrosive liquid output port 56, and all the hot liquid branch pipes 54 are connected with the hot liquid chamber 53 and the cold liquid chamber 55 are connected; the coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com