Plastic mold with mold heat conduction device

A plastic mold and heating technology, which is applied in the field of plastic molds, can solve the problems of slow heating, high cost, and unsafety, and achieve the effects of high heat transfer efficiency, good temperature change, and safe use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

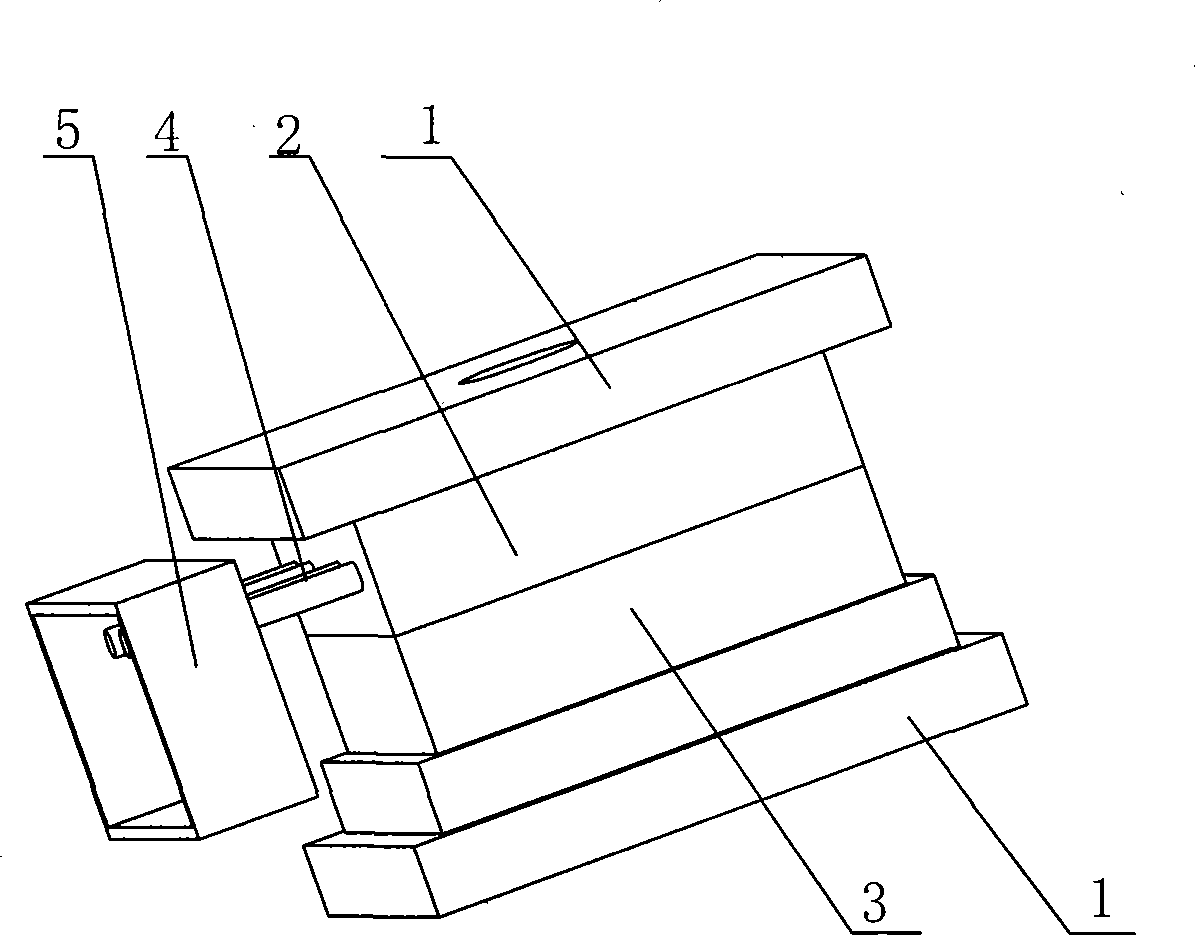

[0017] Such as figure 1 The mold temperature heat conduction plastic mold shown includes a mold base 1, a male mold core 2, and a female mold core 3; In the male mold core 2, the distance from the forming surface of the male mold core 2 is 1-5mm, and the other end of the heat conduction element 4 protrudes from the male mold core 2, and the heat conduction element 4 is a copper tubular heat conduction element. The heat conduction speed of the heat pipe is fast; a heating device 5 is provided at the protruding end of the heat conduction element 4 .

[0018] With this structure, since the copper heat pipe is set in the male mold core, and the distance from the forming surface of the male mold core is 1-5mm, the heat transfer speed of the copper heat pipe is fast, so that the male mold core can be better controlled. The temperature of the mold core changes, the heating efficiency is high, and the mold is safe during work.

no. 2 approach

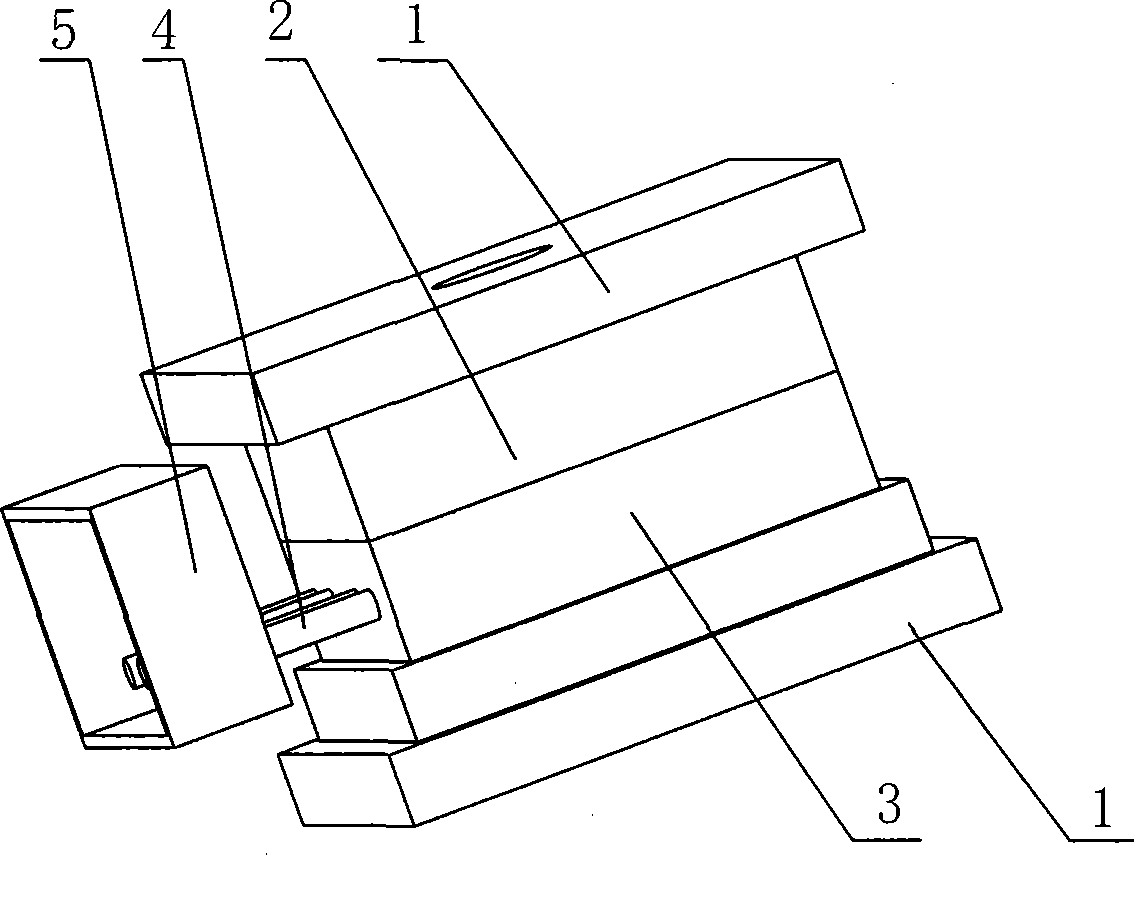

[0020] Such as figure 2 The mold temperature heat conduction plastic mold shown includes a mold base 1, a male mold core 2, and a female mold core 3; In the female mold core 3, the distance from the molding surface of the female mold core 3 is 1-8mm, and the other end of the heat conduction element 4 protrudes from the master mold core 3. The heat conduction element 4 is a heat conduction rod, and the heat conduction of the heat conduction rod is The speed is fast; a heating device 5 is provided at the protruding end of the heat conducting element 4 .

[0021] With this structure, since the heat conduction rod is set in the core of the master mold, and the distance from the forming surface of the core of the master mold is 1-8mm, the heat transfer speed of the heat conduction rod is fast, so that the temperature of the core of the master mold can be better controlled Changes, high heating efficiency, and the mold is safe during work.

no. 3 approach

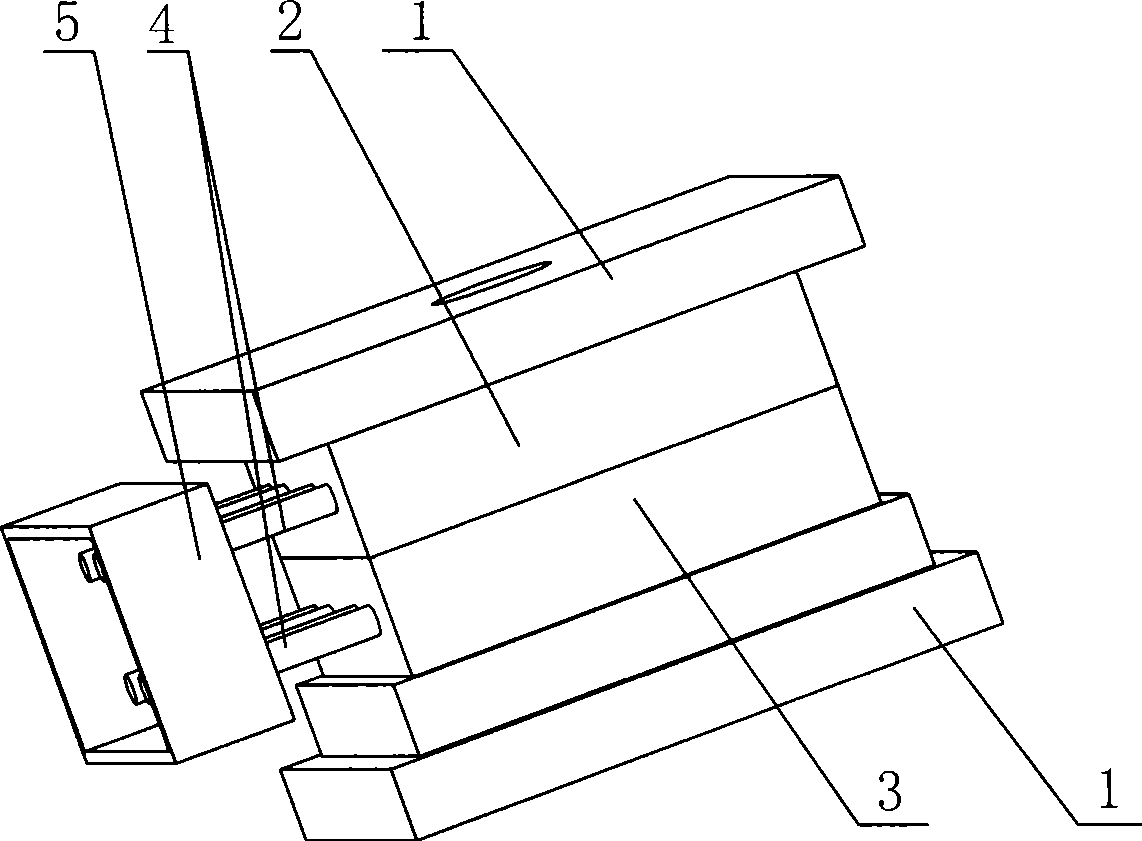

[0023] Such as image 3 The mold temperature and heat conduction plastic mold shown includes a mold base 1, a male mold core 2, and a female mold core 3; a heat-conducting member 4 made of a heat-conducting solid is installed in the male mold core 2 and the female mold core 3, and the heat-conducting One end of part 4 is installed in the male mold core 2 and the female mold core 3, the distance between the heat conducting part 4 and the forming surface of the male die core 2 is 1-5mm, and the distance from the forming surface of the female die core 3 is 1-8mm, and the heat conducting part The other end of 4 protrudes from the male mold core 2 and the female mold core 3, and the heat-conducting member 4 is heat-conducting plastic, which has a fast heat-conducting speed;

[0024] With this structure, since the heat-conducting plastic is set in the female mold core, and the distance from the forming surface of the male mold core is 1-5mm, and the distance from the forming surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com