LNG receiving station gasification device and power plant circulating water combined use system

A technology of circulating water system and gasification device, applied in pipeline system, gas/liquid distribution and storage, mechanical equipment, etc., can solve the problems of environmental protection temperature change limitation, economic and environmental benefit impact, large investment amount, etc. Guarantee the effect of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

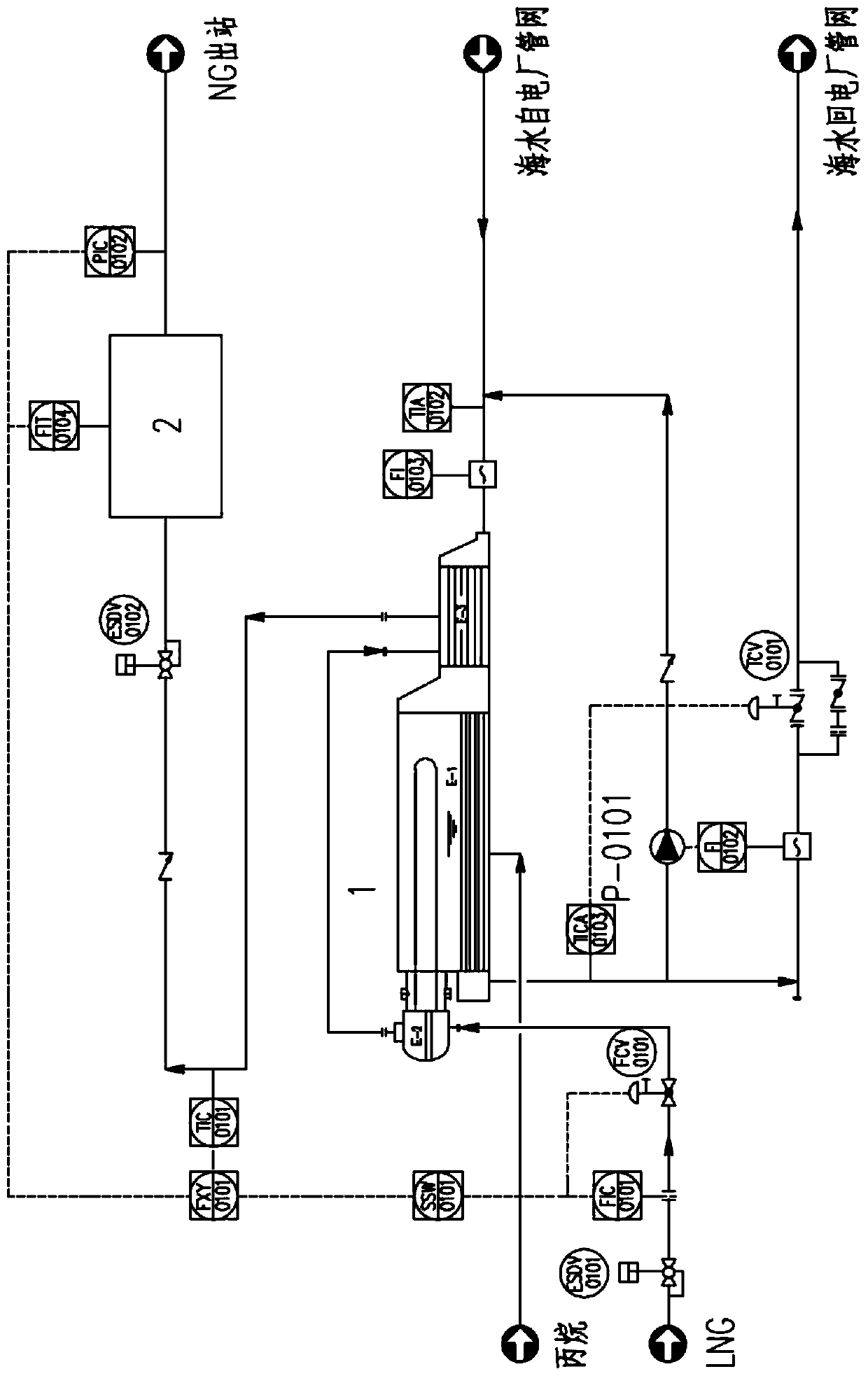

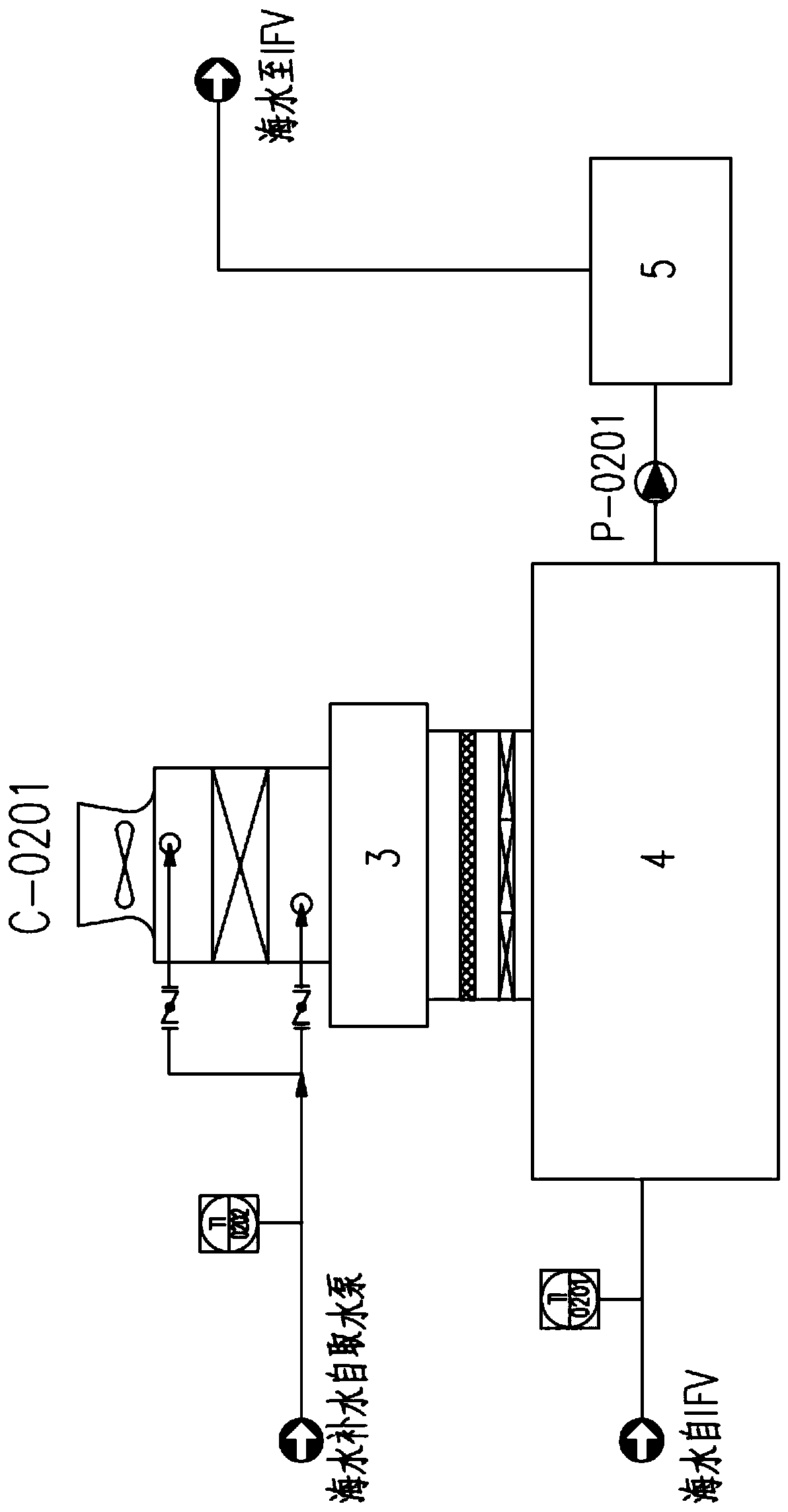

[0041] Below, the attached figure 1 , 2 This embodiment will be described in further detail.

[0042] like figure 1 As shown, a system for the joint utilization of a gasification device of a LNG receiving station of the present invention and power plant circulating water includes: IFV gasifier 1, seawater circulating pump P-0101, power plant circulating water system, and the power plant circulating water system includes circulating water cooling Tower C-0201, Tower Underwater Pool 3, Water Suction Pool 4, Water Intake Pump P-0201, Power Plant Cooling Water Equipment 5;

[0043] The natural gas inlet of the IFV gasifier is connected to the LNG feed pipe, and the natural gas outlet is connected to the NG discharge pipe. The seawater inlet of the IFV gasifier is connected to the seawater pipe network from the water equipment of the power plant. The seawater of the IFV gasifier The outlet end is connected to the water absorption pool of the power plant, and the water absorption...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com