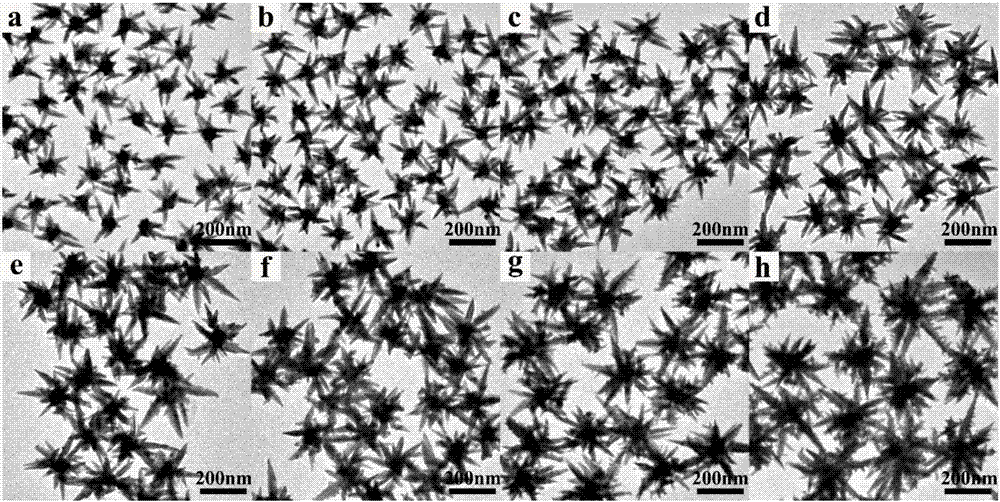

Synthetic method for monodisperse spinous gold nanoparticles

A gold nanoparticle, nanoparticle technology, applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of not being able to precisely control the number, length and width of thorns, and achieve high productivity High, reproducible results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Soak the glassware (50ml beaker and 10ml serum bottle) in aqua regia for 2 hours, rinse with saturated sodium nitrate solution and ultrapure water several times, and dry for later use.

[0020] (1) Use ultra-pure water to calibrate the first chloroauric acid solution with a molar concentration of 10 mmol / liter and the second chloroauric acid solution with a molar concentration of 15 mmol / liter by ultraviolet-visible spectroscopy. The required raw materials sodium borohydride, silver nitrate, glutathione and ascorbic acid are respectively configured into solutions with ultrapure water, wherein the molar concentration of the sodium borohydride solution is 10 mmol / liter, and the molar concentration of the first silver nitrate solution is 10 mmol / liter, the molar concentration of the second silver nitrate solution is 2 mmol / liter, the molar concentration of glutathione is 0.1 mole / liter, and the concentration of ascorbic acid solution is 0.1 mole / liter (there is only one kin...

Embodiment 2

[0031] The present embodiment is similar to Example 1, other fixed conditions are consistent with Example 1, and the preparation molar concentration is the second chloroauric acid solution of 20 mmol / liter, and the second chloroauric acid solution added in the overgrowth solution of adjustment step (3) The consumption of acid solution is 100 microliters, and the consumption of ascorbic acid solution is 120 microliters (the volume ratio of ascorbic acid solution and the second chloroauric acid solution is 1.2), makes cetyltrimethylammonium chloride solution and chloroauric acid The volume ratio of the solutions is 10, the volume ratio of the silver nitrate solution to the chloroauric acid solution is 0.3, and the volume ratio of the ascorbic acid solution to the chloroauric acid solution is 1.2. The total amount of overgrowth solution was 1.25 milliliters, and 4.71 milliliters of ultrapure water was added to adjust the concentration. The volume ratio of ultrapure water to overgr...

Embodiment 3

[0034] (1) Use ultrapure water to calibrate the first chloroauric acid solution with a molar concentration of 20 mmol / liter and the second chloroauric acid solution with a molar concentration of 25 mmol / liter with UV-visible spectroscopy. The required raw materials sodium borohydride, silver nitrate, glutathione and ascorbic acid are respectively configured into solutions with ultrapure water, wherein the molar concentration of the sodium borohydride solution is 10 mmol / liter, and the molar concentration of the first silver nitrate solution 5 mmol / L, the molar concentration of the second silver nitrate solution is 1.5 mmol / L, the molar concentration of glutathione is 0.05 mol / L, the concentration of the first ascorbic acid solution is 0.1 mol / L, and the second ascorbic acid The concentration is 0.2 mol / L.

[0035] Cetyltrimethylammonium bromide and cetyltrimethylammonium chloride were used as surfactants to stabilize gold nanoparticles, and cetyltrimethylammonium bromide with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com