Nodular cast iron laser hardening technology

A nodular cast iron and laser strengthening technology, which is applied in the field of laser heat treatment, can solve the problems of electrodynamic action in the melting layer, difficult to change thermal mode, and low energy density, and achieve the effects of small deformation, short process cycle, and low surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

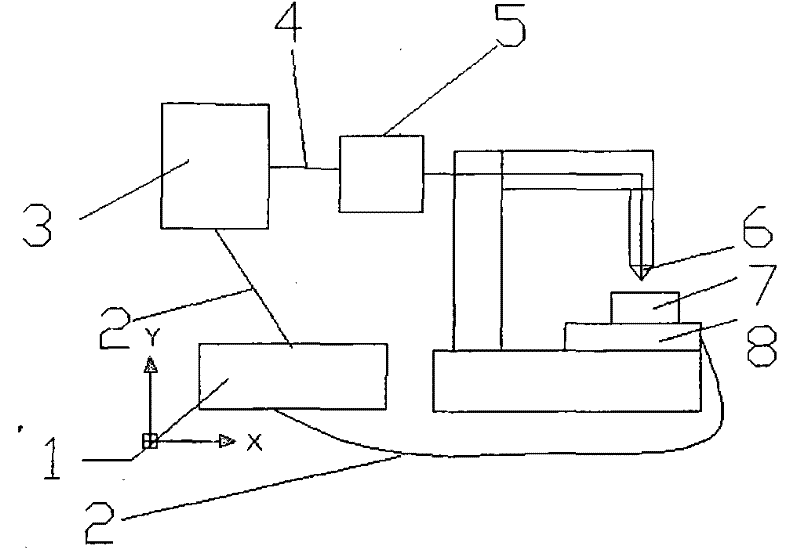

[0008] 1) Determine the parts to be strengthened on the surface of the workpiece according to the working conditions and conditions of the workpiece;

[0009] 2) Planning the scanning path of the quenching work head;

[0010] 3) The scanning path programming and process parameter design of the quenching working head;

[0011] 4) According to the planned path, the displacement stage is manipulated so that the quenching head scans the surface of the workpiece to complete the surface quenching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com