Black pepper peel degumming strain and use thereof

A technology of degumming bacteria and pepper, which is applied in the field of microorganisms, can solve the problems of large water consumption, microbial pollution, and large floor space, and achieve the effect of short process cycle and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

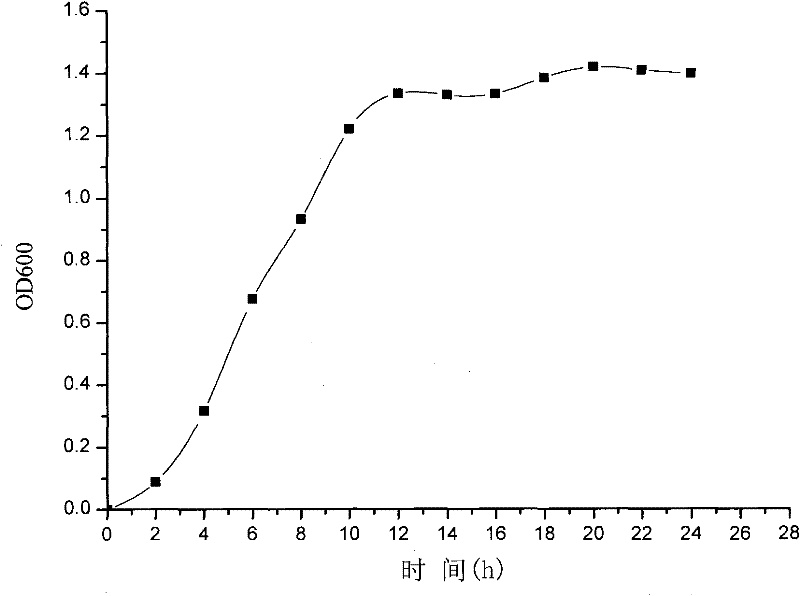

[0022] Embodiment 1: Separation and purification of bacterial strains

[0023] Collect soil samples and pepper macerate samples from pepper planting areas in Wenchang, Qionghai, Haikou, Wanning and other places in Hainan, weigh 20g or draw 20mL samples, put them in a 500mL triangular flask containing 100mL sterile water, and put them at 30 Shake at 100r / min in a shaker at ℃ for 1d; take 1mL of the supernatant or mixed solution and transfer it to 50mL enrichment medium for enrichment and culture for 1d, take 1mL of the mixed solution and add it to a 25mL test tube filled with 9ml sterile water and mix well to prepare into a dilution of 10 -1 , 10 -2 , 10 -3 , 10 -4 、10 -5 、10 -6 suspension; then for 10 -4 、10 -5 、10 -6 Take 0.1mL peptone plates coated with beef extract for each of the three gradients, make 3 plates for each dilution, and incubate at 30°C for 3 days. Pick colonies with different shapes on the plate, streak and purify on the beef extract peptone plate; t...

Embodiment 2

[0025] Example 2: Primary Screening of Bacterial Strains

[0026] The colonies isolated in Example 1 were spot-planted on the isolation medium, and the bacterial strains that produced larger yellow color-changing circles on the isolation medium were selected. Since 1.6% bromocresol purple ethanol solution was added to the separation medium as a pH indicator, the pectinase-producing bacteria degrade the pectin in the medium to produce D-galacturonic acid, and the medium changed from the original purple to yellow , resulting in a color change circle. After preliminary screening, a total of 20 strains were screened out.

[0027] Described separation medium preparation method: each component content (g / L): (NH 4 ) 2 SO 4 6.0, KH 2 PO 4 4.5,K 2 HPO 4 10.5, yeast powder 1.5, pectin 2.0, agar 20.0, dilute to 1000 mL with distilled water, adjust the pH to 7.0, add 3 mL of 1.6% bromocresol purple ethanol solution, and sterilize at 121 °C for 20 min.

Embodiment 3

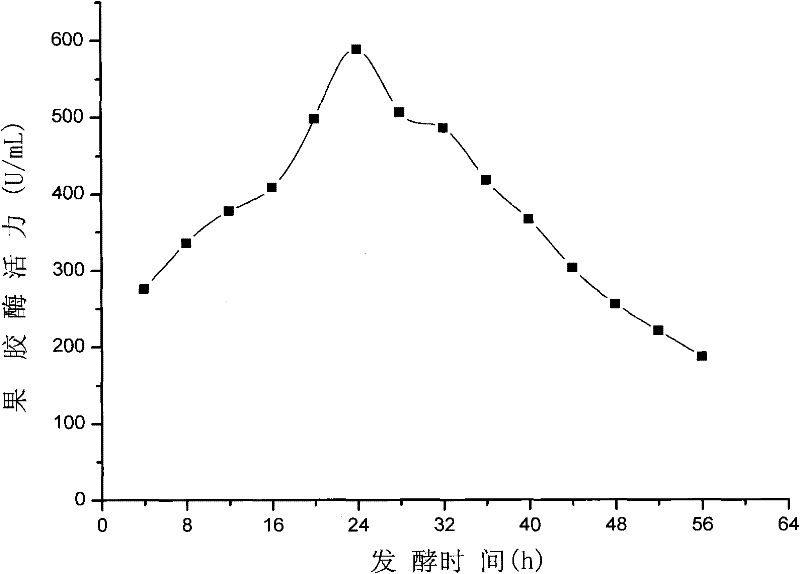

[0028] Embodiment 3: Re-screening of bacterial strains

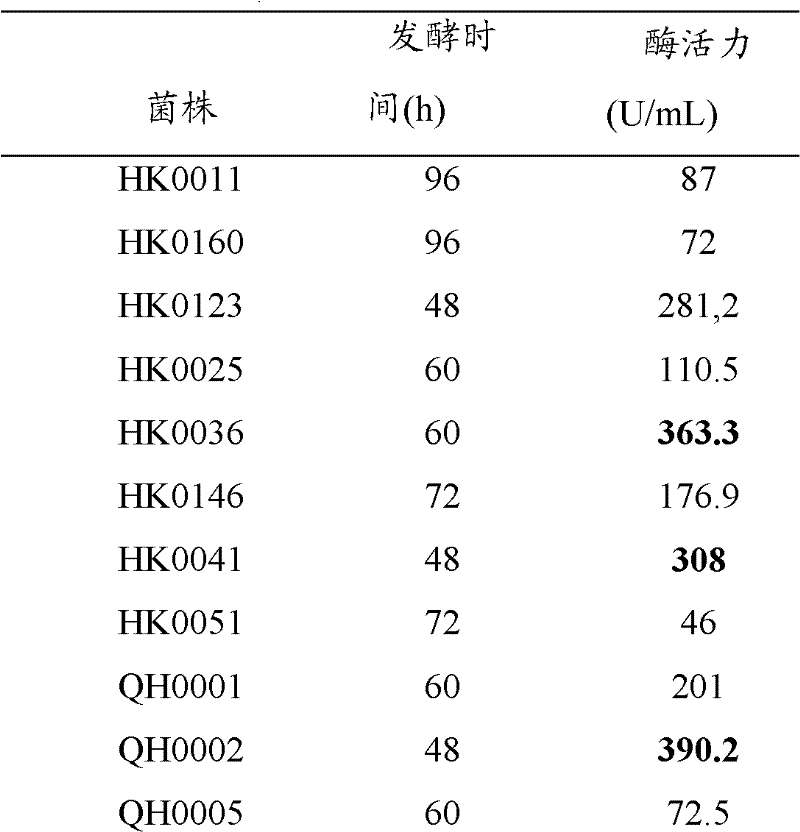

[0029] The 20 strains screened in Example 2 were inoculated in the seed medium, cultivated at 30°C for 18h, then inoculated in the fermentation medium at an amount of 3%, and cultivated at 30°C and 200r / min for 2-3d, then 15000r / min Centrifuge for 5 minutes, take the supernatant, and measure the activity of pectinase. The results are shown in Table 1.

[0030] Table 1 strain rescreening enzyme activity assay results

[0031]

[0032]

[0033] It can be seen from Table 1 that the five strains with strong pectinase activity are QH0017, WCZC0110, HK0041, QH0002 and HK0036, among which the pectinase activity produced by strain WCZC0110 is the strongest, reaching 466.3U / mL.

[0034]Seed culture medium is well-known beef extract peptone medium in the art; The assay method of pectinase activity is to utilize known method in this area (referring to Wang Xiaomin, Wu Wenlong, Lu Lianfei, etc. Spectrophotometer method is mea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com