Method for preparing gold electrolyte through gold electrolysis anode mud

An anode slime and electrolyte technology, which is applied in the electrolysis process, electrolysis components, photography process, etc., can solve problems such as increasing capital occupation, and achieve the effect of reducing volatilization loss, reducing the amount of raw materials, and reducing the risk of introducing impurity carbon.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

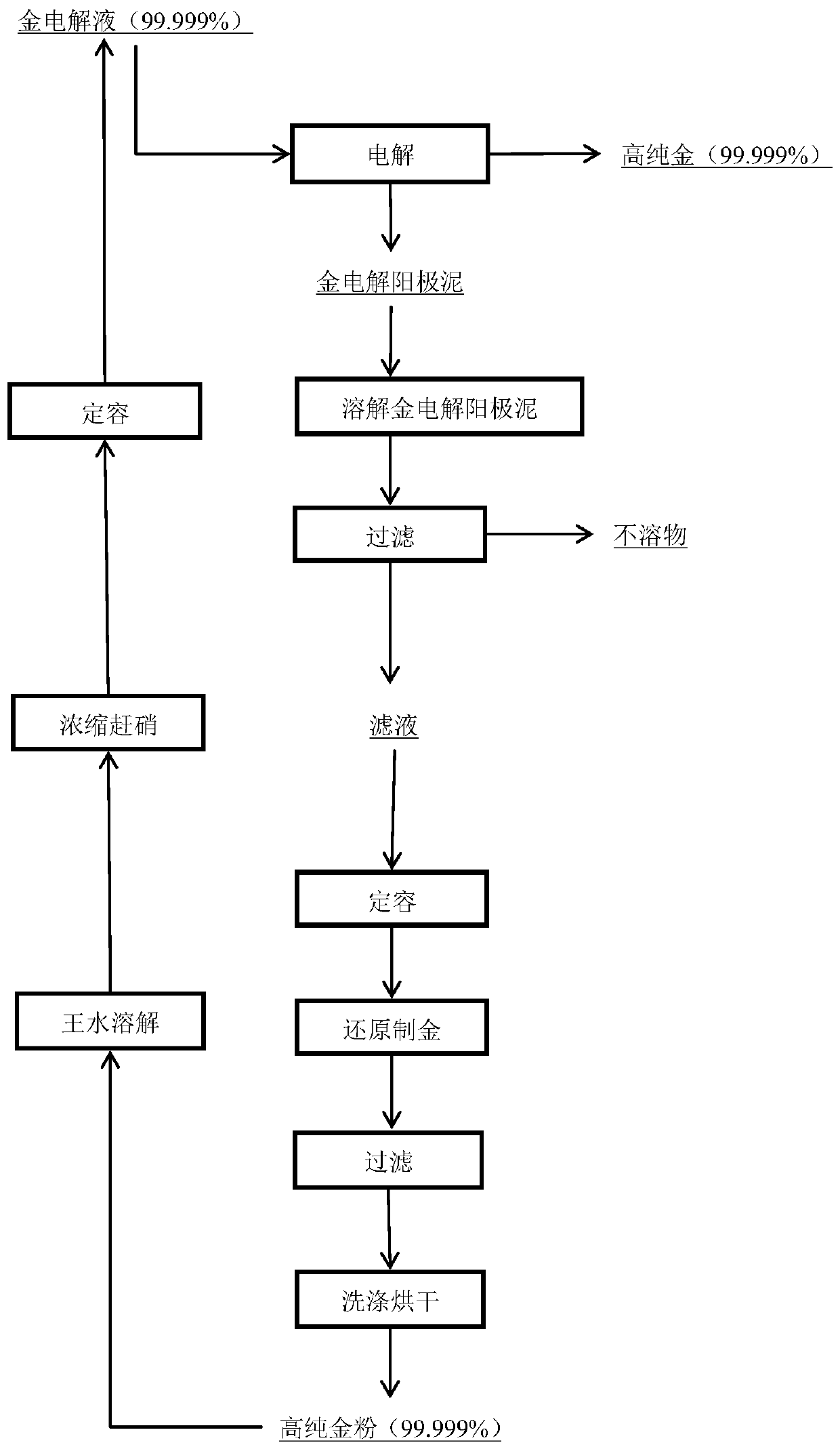

Method used

Image

Examples

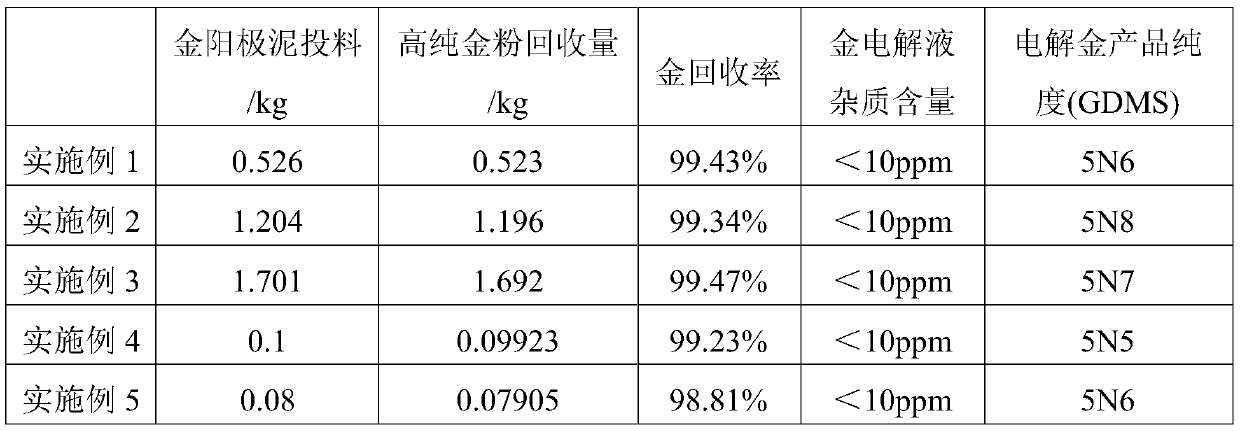

Embodiment 1

[0058] Utilize gold electrolysis anode slime to prepare gold electrolyte according to the following method:

[0059] (1) Aqua regia dissolution: take 0.747kg of anode bag containing gold electrolytic anode slime (0.526kg of gold electrolytic anode slime) and place it in a crucible, first add 1.5L concentrated hydrochloric acid, then add 0.5L concentrated nitric acid, and heat to 50 ℃ and continue to stir until the anode slime is completely dissolved to obtain a red gold solution; take out and wash and dry the anode bag for subsequent use. The resulting gold solution was filtered to obtain a filtrate and insoluble matter. Collect the insolubles, and recover the precious metals after a certain amount.

[0060] (2) Concentrate hydrogen peroxide to catch nitrate: heat the filtrate obtained in step (1) to a boiling state, add hydrogen peroxide in batches to catch nitrate, keep stirring during the process of nitrate catch, until no yellow smoke is produced after adding hydrogen per...

Embodiment 2

[0065] Utilize gold electrolysis anode slime to prepare gold electrolyte according to the following method:

[0066] (1) Dissolving in aqua regia: take 1.628 kg of anode bag containing gold electrolytic anode slime (1.204 kg of gold electrolytic anode slime) and place it in a crucible, first add 3 L of concentrated hydrochloric acid, then add 1 L of concentrated nitric acid, heat to 60 ° C and Stir continuously until the anode slime is completely dissolved to obtain a red gold solution; take out and wash and dry the anode bag for subsequent use. The solution was filtered to obtain a filtrate and insoluble matter. Collect the insolubles, and recover the precious metals after a certain amount.

[0067] (2) concentration of hydrogen peroxide to catch up with nitrate: the filtrate obtained in step (1) is heated to boiling, hydrogen peroxide is added in batches to catch up with nitrate, and stirring is continued during the process of catching up with nitrate, until no yellow smoke...

Embodiment 3

[0072] Utilize gold electrolysis anode slime to prepare gold electrolyte according to the following method:

[0073] (1) Dissolving in aqua regia: take 2.365 kg of anode bags containing gold electrolytic anode slime (1.701 kg of gold electrolytic anode slime) and put them in a crucible, first add 4.5 L of concentrated hydrochloric acid, then add 1.5 L of concentrated nitric acid, and heat to 70 ℃ and continue to stir until the anode slime is completely dissolved to obtain a red gold solution; take out and wash and dry the anode bag for subsequent use. The solution was filtered to obtain a filtrate and insoluble matter. Collect the insolubles, and recover the precious metals after a certain amount.

[0074] (2) concentration of hydrogen peroxide to catch up with nitrate: the filtrate obtained in step (1) is heated to boiling, hydrogen peroxide is added in batches to catch up with nitrate, and stirring is continued during the process of catching up with nitrate, until no yellow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com