All-single-walled carbon nanotube field effect transistor and preparation method thereof

A single-walled carbon nanotube and field-effect transistor technology, which is applied in the field of all-single-walled carbon nanotube field-effect transistors and their preparation, can solve the problem that the performance stability of the device needs to be improved, the processing process is time-consuming and inefficient, and it is unfavorable for the direct preparation of the device. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

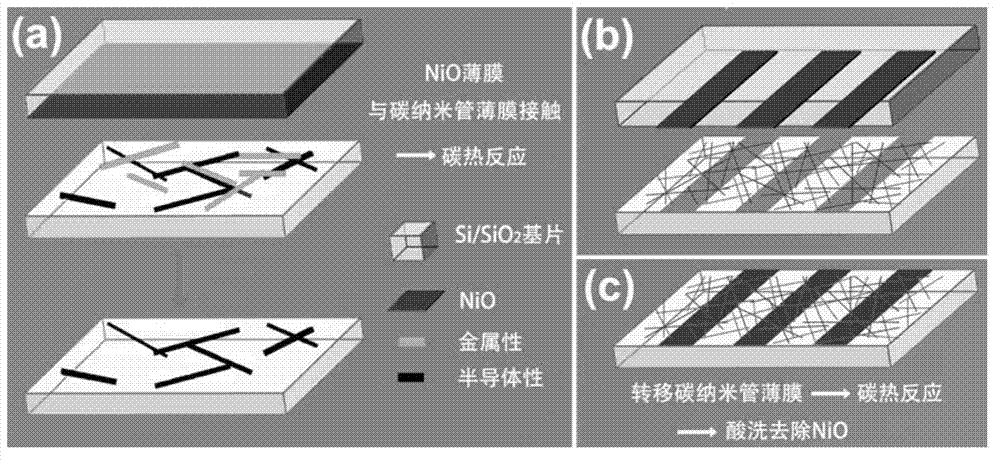

[0037] The invention provides a design and preparation method of a full single-wall carbon nanotube field effect transistor, which is prepared by low-temperature carbon-thermal reaction of metal oxides and photolithography technology, including the following steps:

[0038] (1) Using ion beam assisted deposition (IBAD) on Si / SiO 2 Substrate (Si substrate surface covered with a layer of amorphous SiO 2 , SiO 2 layer thickness of 100-500nm) SiO 2 Deposit 0.02-2nm thick catalyst (such as: Fe, Ni or Co, etc.) on the surface. The substrate after the deposition of the metal film is at 800-1000°C under Ar / H 2 (Ar, H 2 Mixed gas in any proportion. Preferably, by volume ratio, H 2 85~95%, Ar5~15%) pretreatment in the mixed atmosphere for 2-20min to form metal nanoparticles, and then use Ar to load hydrocarbon organic matter as a carbon source to trigger the growth of single-walled carbon nanotubes. Single-walled carbon nanotubes are The sample grows on the surface and exists in th...

Embodiment 1

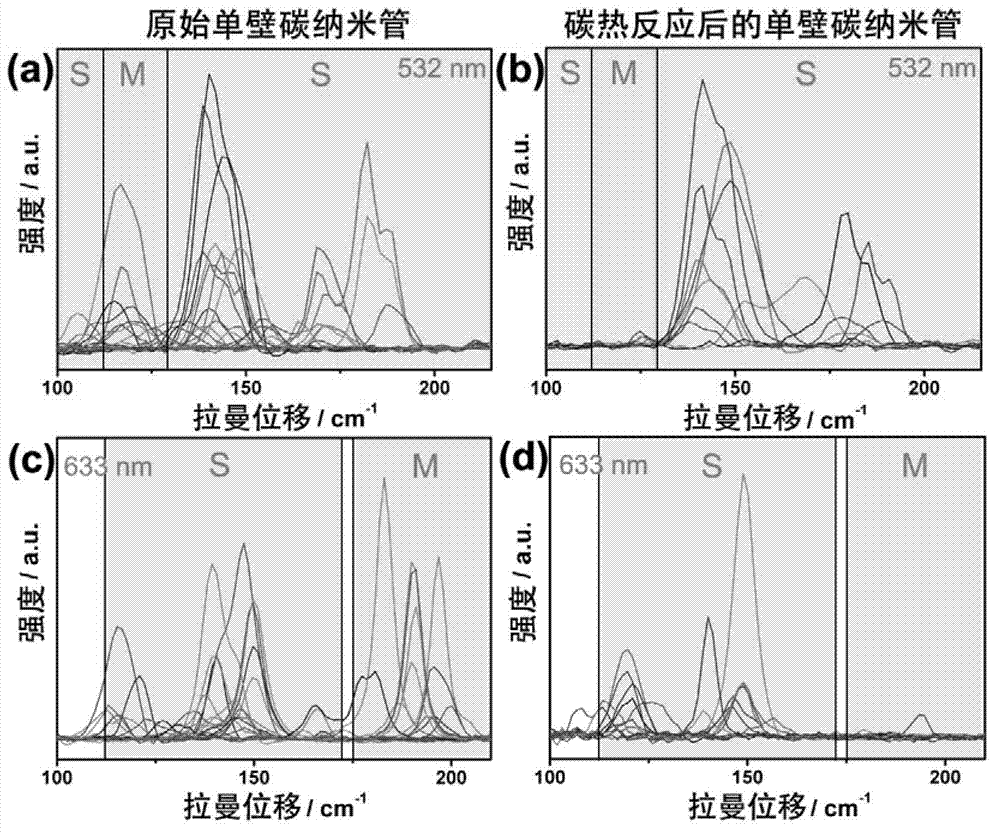

[0046] Si / SiO by ion beam assisted deposition 2 A 0.02 nm thick Co film was deposited on the substrate as a catalyst. The matrix is at 950°C and Ar / H 2 (by volume ratio, H 2 90%, Ar 10%) in a mixed atmosphere for 5 minutes to form Co nanoparticles with a particle size of 1-5nm, and then use Ar to load C 2 h 5 OH was used as a carbon source to grow single-walled carbon nanotubes. Raman spectra of as-grown single-walled carbon nanotubes, such as figure 2 (a) and figure 2 (c) shown. Raman spectrum characterization shows that the obtained is a mixture of metallic and semiconducting carbon nanotubes.

[0047] On Si / SiO 2 A 100nm Ni film was deposited on the substrate and oxidized at 600°C. The substrate with NiO film and the substrate with single-walled carbon nanotube film are stacked against each other, and pressure is applied to ensure the tight fit between the two. After 30 minutes of carbon thermal reaction in an air atmosphere at 350°C, the two Separated, pickle...

Embodiment 2

[0049] Si / SiO by ion beam assisted deposition 2 A 0.1 nm thick Co film was deposited on the substrate as a catalyst. matrix at 900°C and Ar / H 2 (by volume ratio, H 2 50%, Ar 50%) in a mixed atmosphere for 10 minutes to form Co nanoparticles with a particle size of 1-5nm, and then use Ar to load C 2 h 5 OH was used as a carbon source to grow single-walled carbon nanotubes.

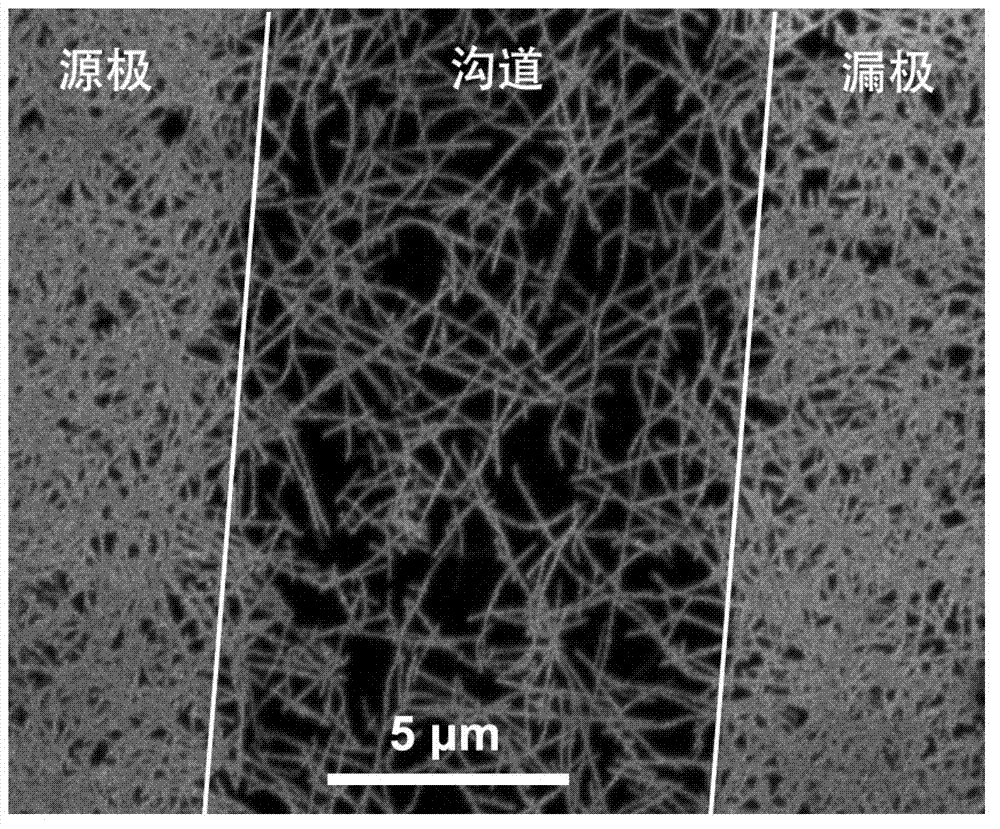

[0050] Si / SiO by photolithography 2 Ni lines are deposited on the substrate, the thickness of the Ni lines is about 100 nm, the width of the Ni lines is 10 μm, and the interval is 200 μm. The Ni lines were pre-oxidized to form NiO in an air atmosphere at 600 °C. After 30 minutes of carbon thermal reaction in an air atmosphere at 350°C, the two were separated, and the residual NiO was removed by pickling, and the NiO was washed and removed with 1M (mol / L) HCl solution, and the substrate was washed and dried with deionized water. , the preparation process is as figure 1 (c) shown. Only semiconducting...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com