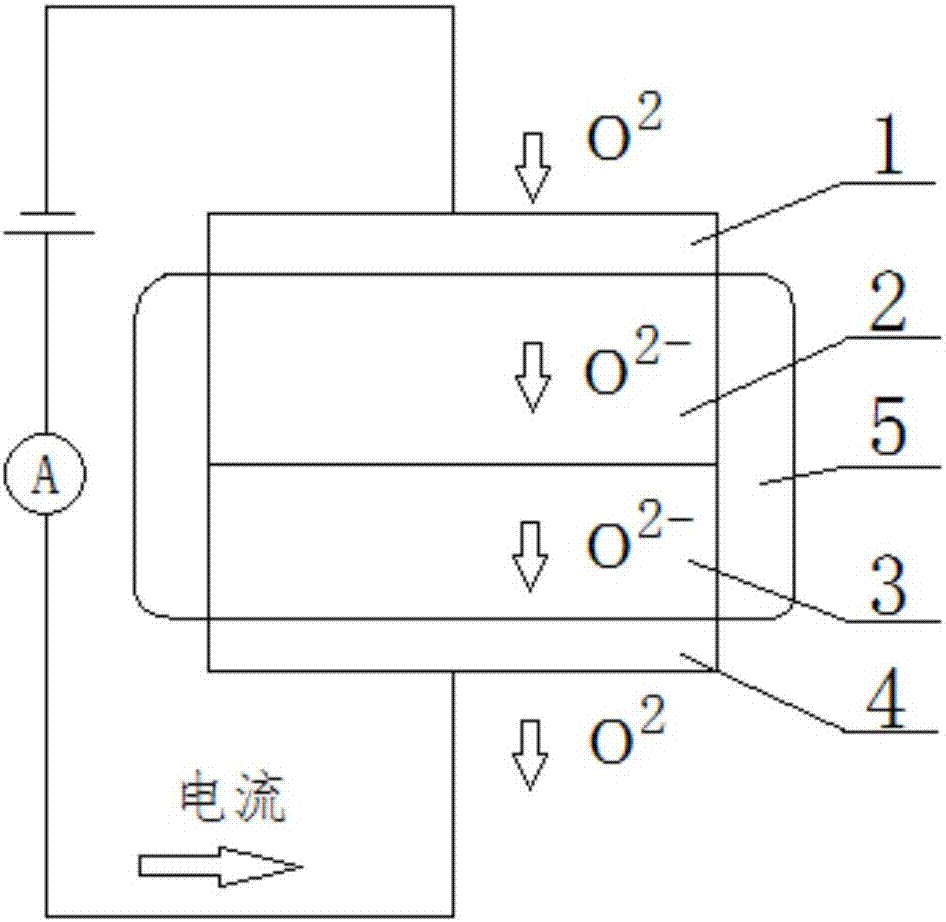

Manufacturing method of double-layer structure of electrolyte layer and compact diffusion layer for oxygen sensor

A technology of electrolyte layer and double-layer structure, which is applied in the direction of instruments, scientific instruments, and material analysis through electromagnetic means. It can solve the problems of dense diffusion layer with many pores, cracks in sintered body, and unfavorable mass production, etc., and achieve 3D printing. The effect of saving speed, reducing pores, and shortening the production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

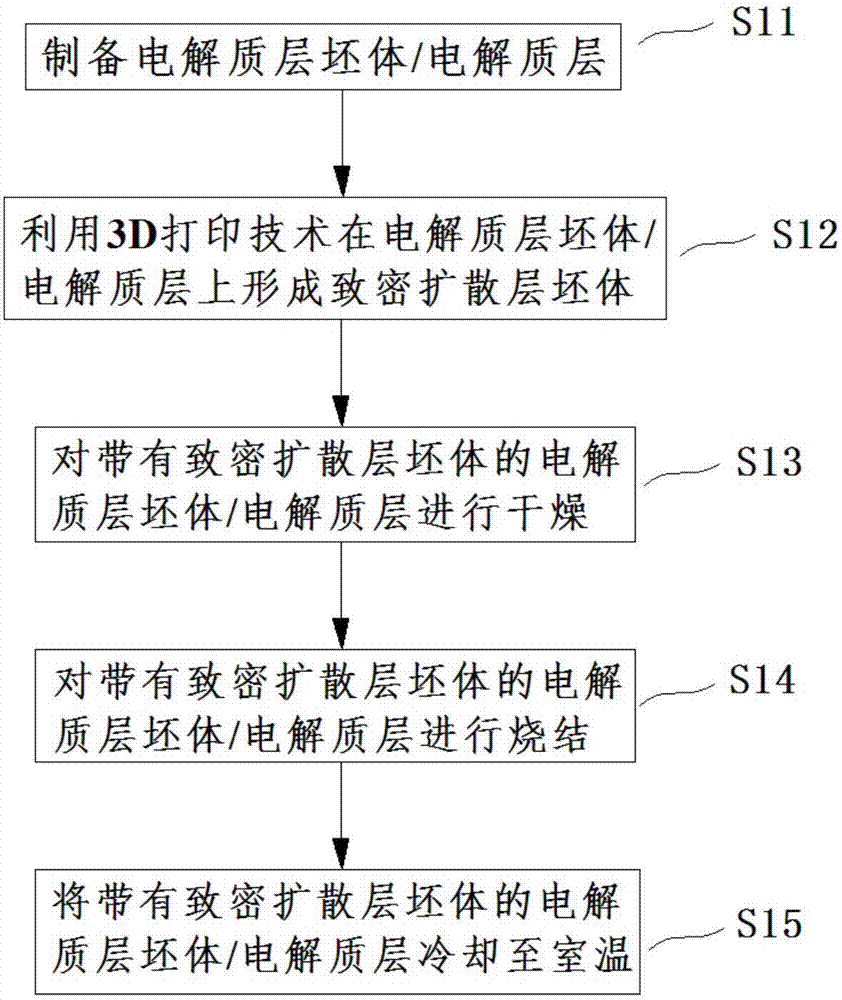

[0032] refer to figure 2 , this embodiment provides a method for manufacturing a double-layer structure of an electrolyte layer and a dense diffusion layer for an oxygen sensor, which specifically includes the following steps:

[0033] S11. Prepare the electrolyte layer green body. The electrolyte layer green body is a non-compact layered object, which has not become a dense body, and requires sintering and cooling after sintering to form the electrolyte layer. The main component in the electrolyte layer body that forms the corresponding electrochemical properties is YSZ (Y 2 o 3 -stabilized-ZrO 2 ), wherein the electrolyte layer green body is a cylinder.

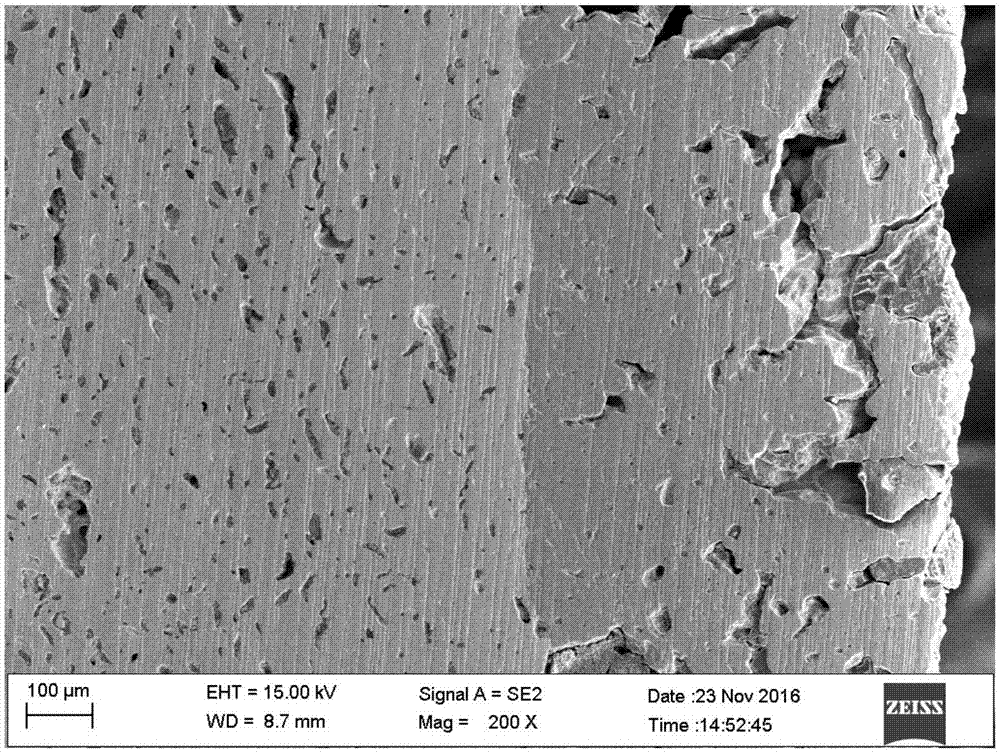

[0034] S12. Use 3D printing technology to form a dense diffusion layer green body on the electrolyte layer green body. The dense diffusion layer green body is a layered object that is not tightly connected and has not become a dense body. It also needs sintering and cooling after sintering. A dense diffuse layer is for...

Embodiment 2

[0067] The difference between the manufacturing method of the double-layer structure of the electrolyte layer and the dense diffusion layer provided in this embodiment and the embodiment 1 is that:

[0068] In step S15, the thickness of the electrolyte layer 3 is 2.5 mm, and the thickness of the dense diffusion layer 2 is 1.8 mm.

[0069] The double-layer structure formed in this embodiment was made into an oxygen sensor. After testing, the range of oxygen measurement was 0-29.7vol%.

Embodiment 3

[0071] The difference between the manufacturing method of the double-layer structure of the electrolyte layer and the dense diffusion layer provided in this embodiment and the embodiment 1 is that:

[0072] In step S15, the thickness of the electrolyte layer 3 is 2 mm, and the thickness of the dense diffusion layer 2 is 1.6 mm.

[0073] The double-layer structure formed in this embodiment was made into an oxygen sensor. After testing, the range of oxygen measurement was 0-30vol%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com