Liquid drop generation device and liquid drop generation system

A droplet generation and droplet technology, applied in chemical instruments and methods, laboratory utensils, laboratory containers, etc., can solve the problems of difficult control of droplet generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

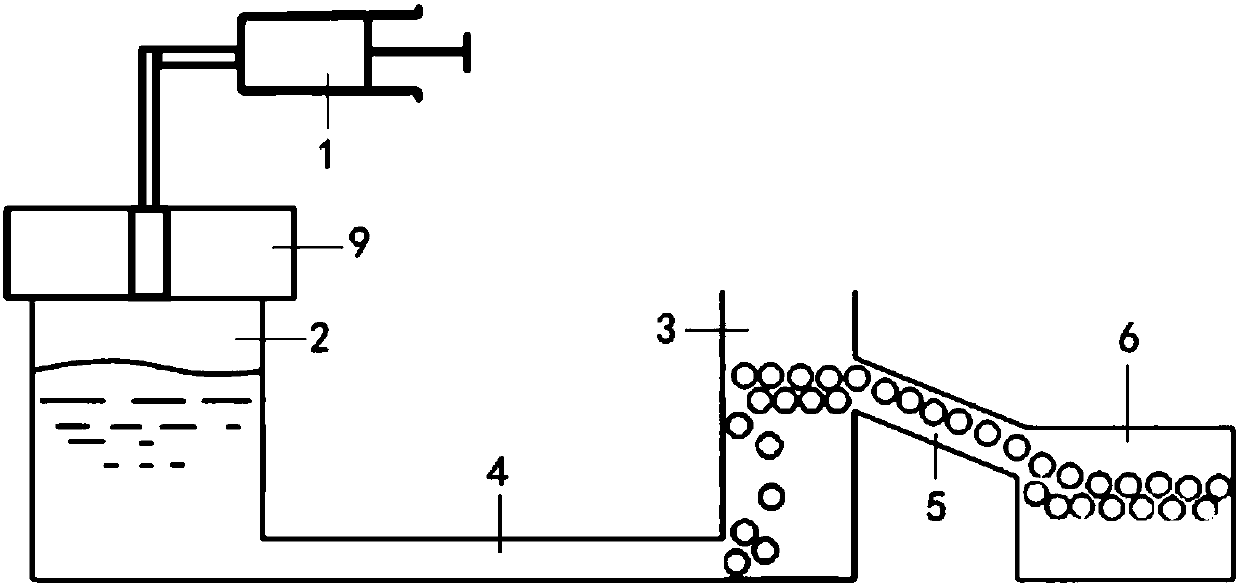

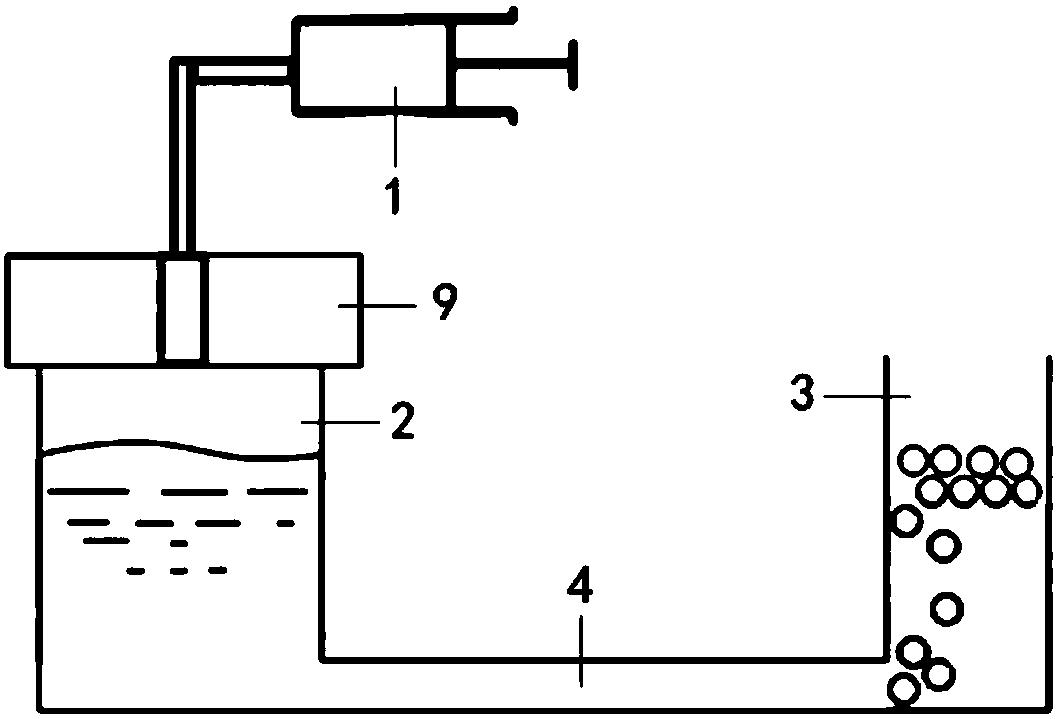

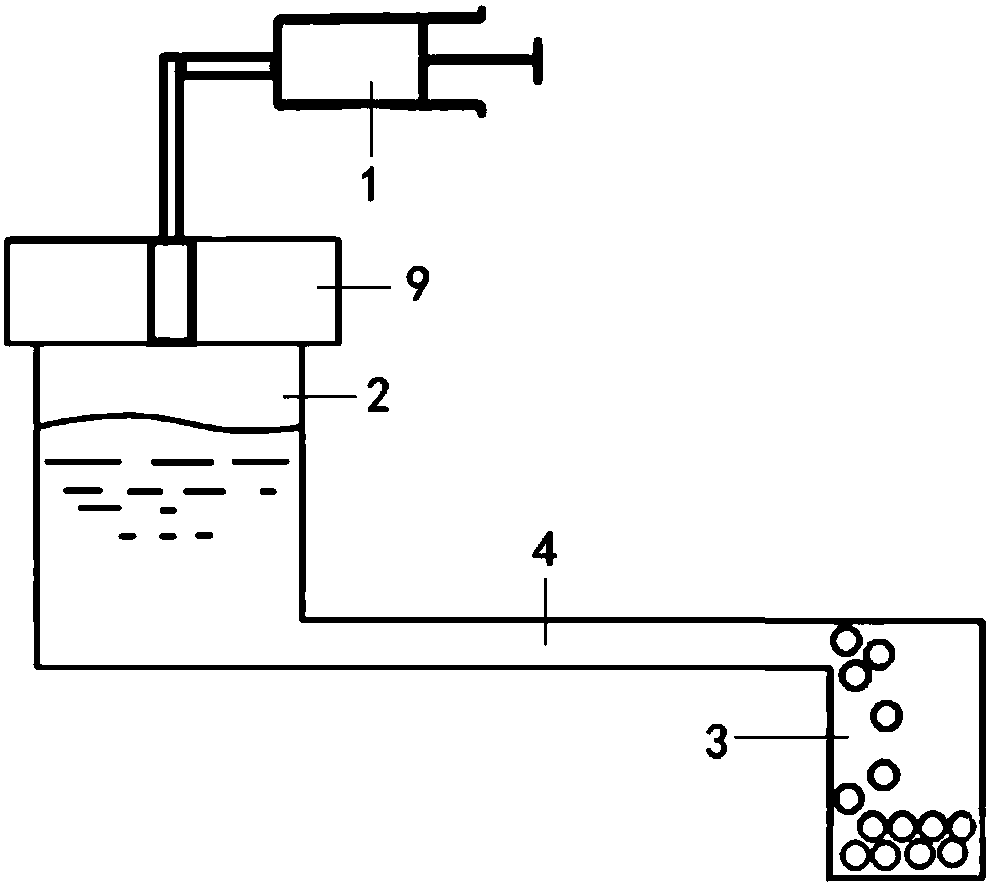

[0031] From Figures 1 to 8 It can be seen that the droplet generation device described in the embodiment of the present invention includes an injection mechanism 1, a dispersed phase reservoir 2, a continuous phase reservoir 3 and a microchannel 4, and the output end of the injection mechanism 1 is connected to the dispersed phase The inside of the liquid storage tank 2 is conducted, and one end of the microchannel 4 is conducted with the inside of the dispersed phase liquid storage tank 2, and the other end of the microchannel 4 is conducted with the inside of the continuous phase liquid storage tank 3. Generally, the width of the microchannel 4 is different from the depth of the microchannel 4, and the size of the microchannel 4 is smaller than the size of the continuous ph...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com