Vertical cutting-off machine of fine dried noodles

A cutting machine and noodle technology, applied in the field of mechanical equipment, to achieve the effect of strong grabbing ability, precise operation control, and easy mechanized recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

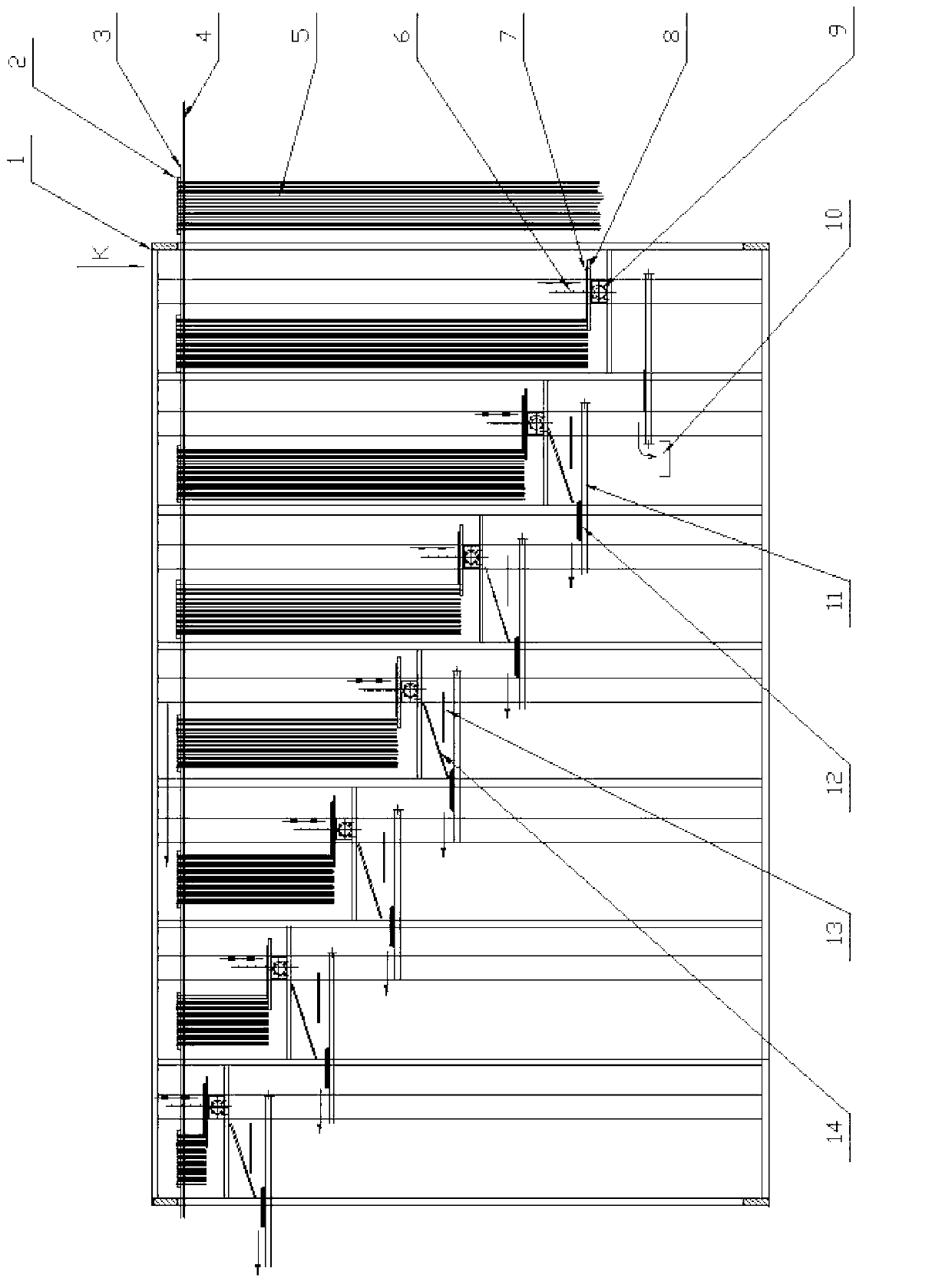

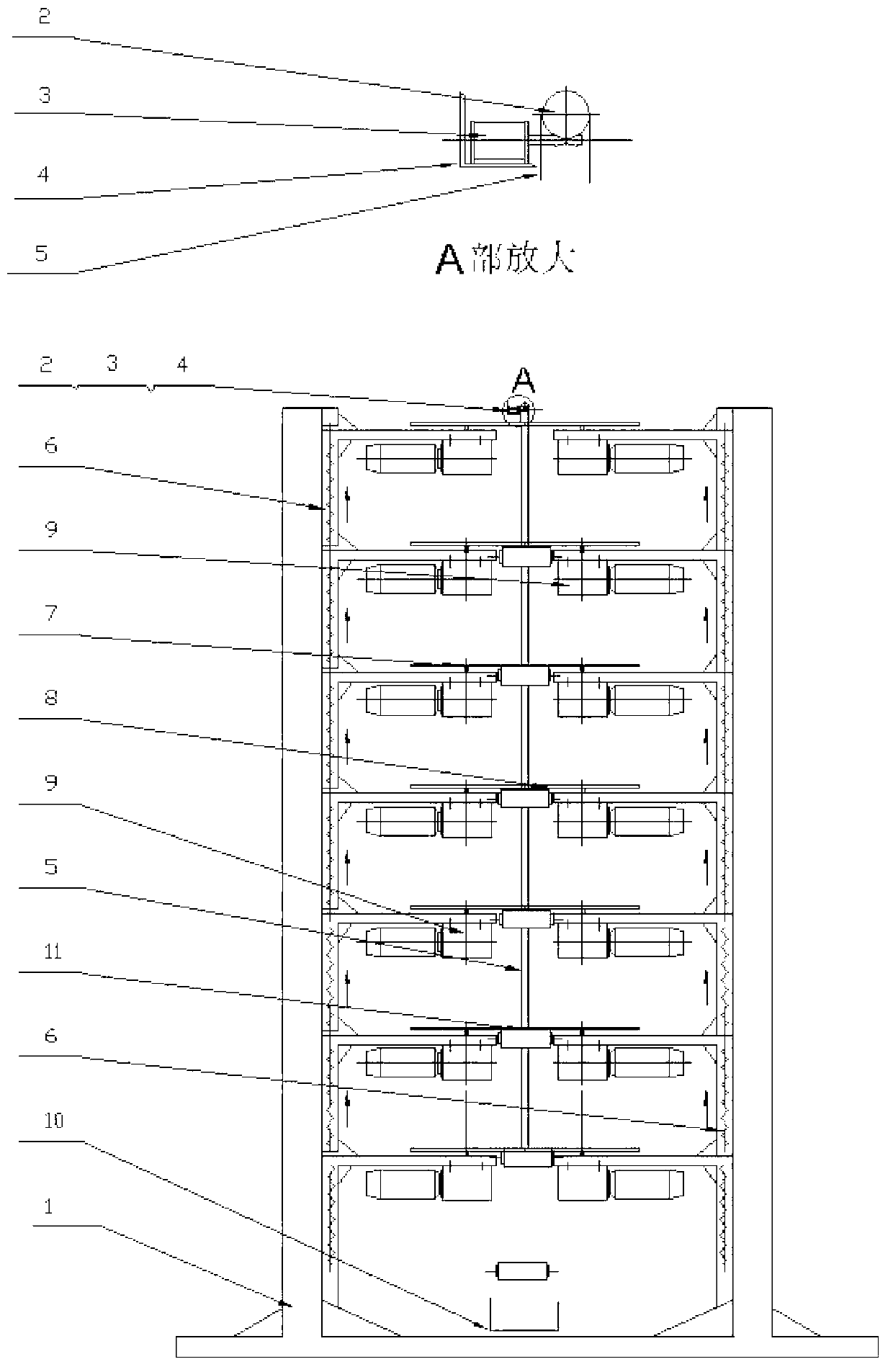

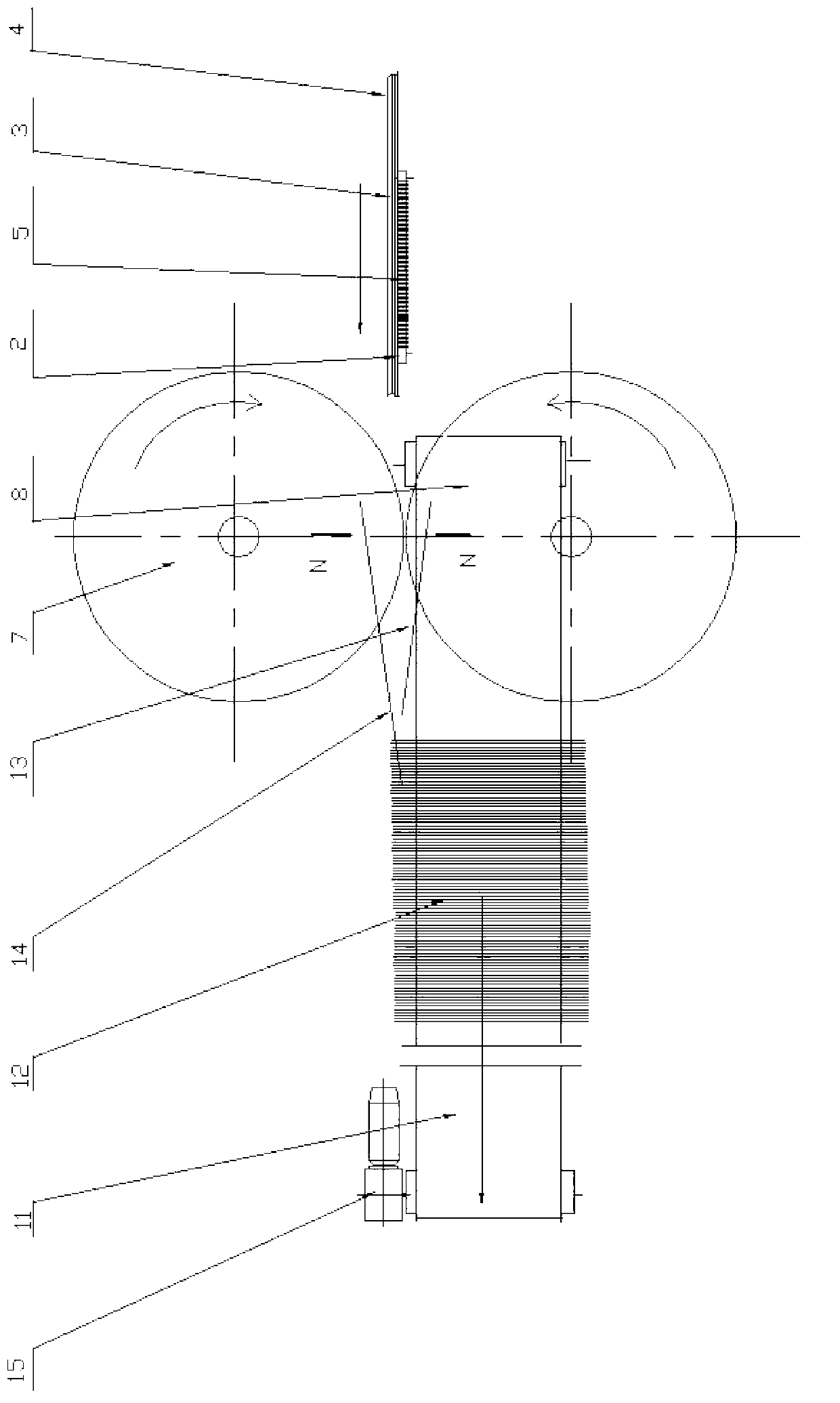

[0027] Embodiments of the vertical noodle cutting machine of the present invention will be further described below in conjunction with the accompanying drawings.

[0028] Such as Figure 1 to Figure 6 Shown, a kind of vermicelli vertical cutting machine of the present invention comprises frame 1, is located at the vermicelli cutting device on frame 1, is cut into vermicelli conveyer belt 11 and noodle bar conveying mechanism guide rail 4, is installed on frame-shaped frame 1 There are more than two sets of dried noodle cutting devices comprising left rotary cutter 7, right rotary cutter 8 and rotary cutter driving mechanism 9, each group of left rotary cutter 7 and right rotary cutter 8 cooperate to form a pair of dried noodle cutters, Each group of noodle cutting devices is horizontally installed on the longitudinal frame of the frame 1, and the cutting points of each pair of noodle cutters are all in the same vertical plane. The corresponding height positions are installed,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com