Patents

Literature

32results about How to "Strong grabbing ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

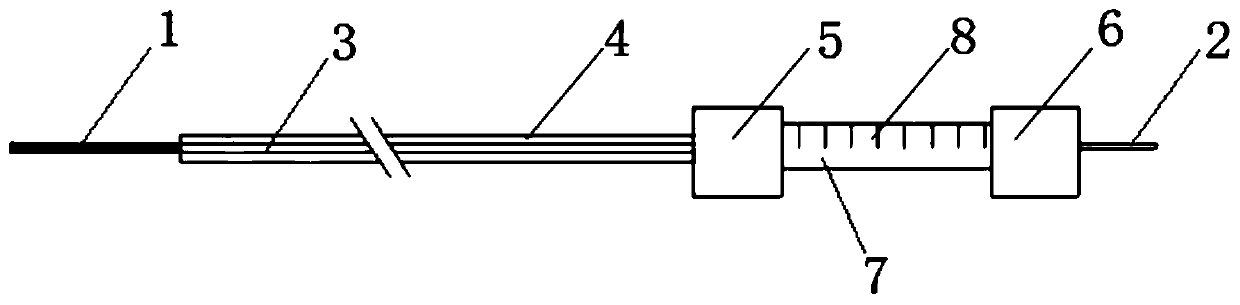

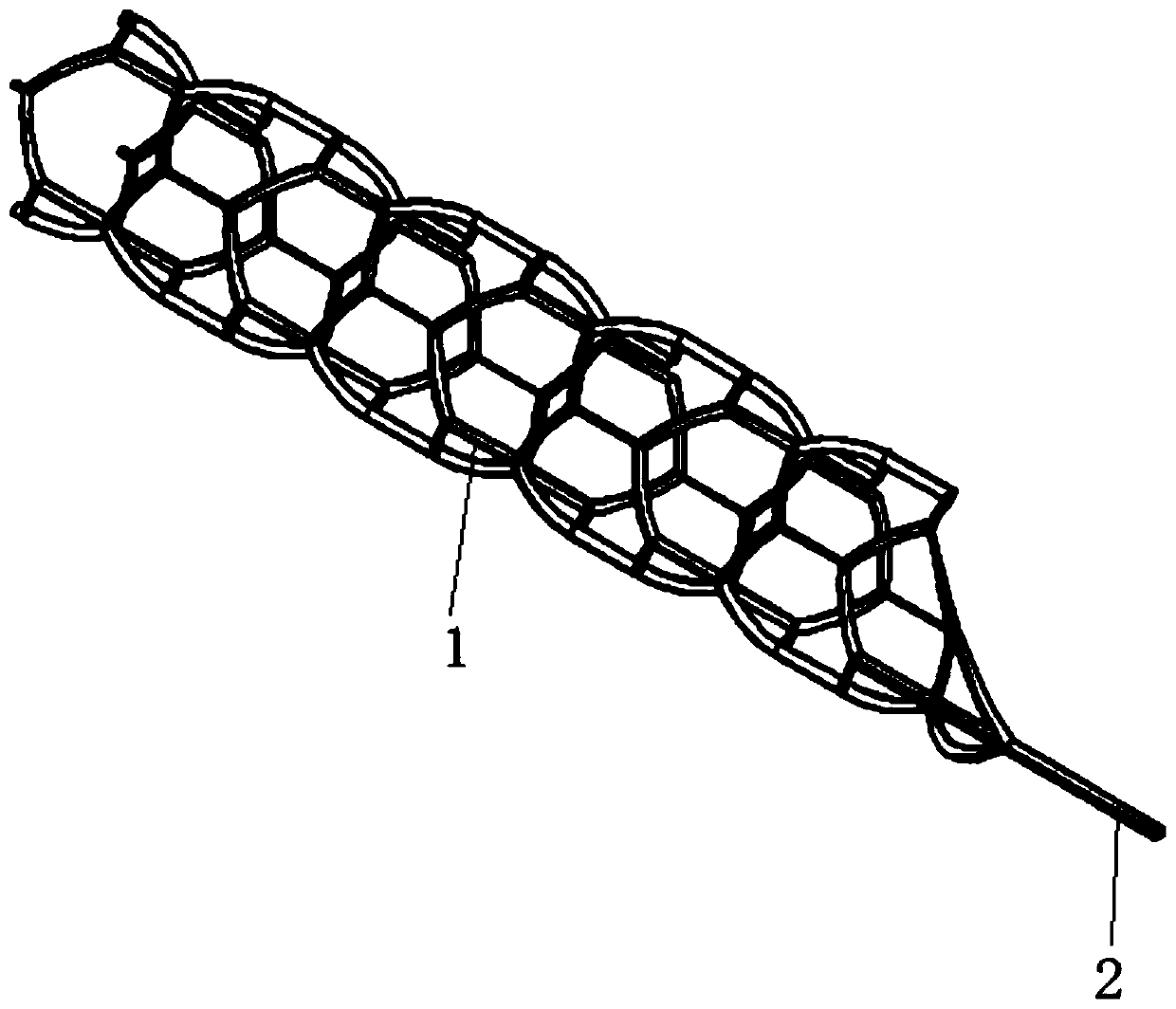

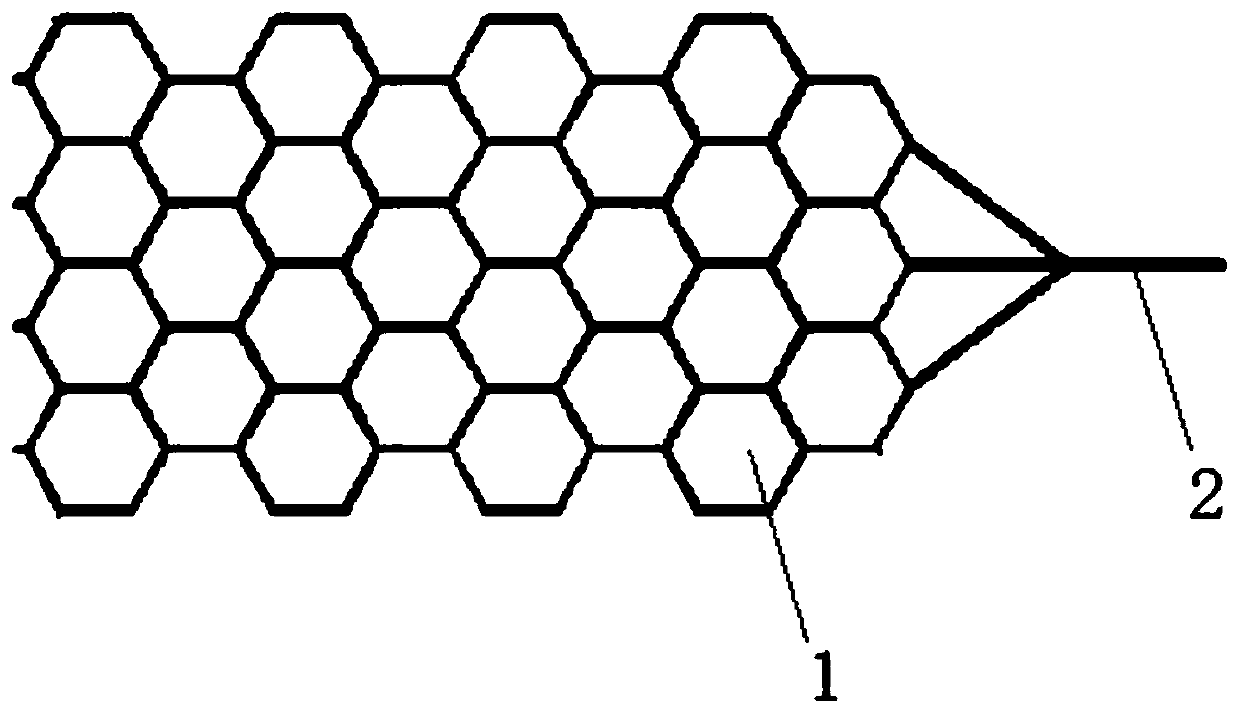

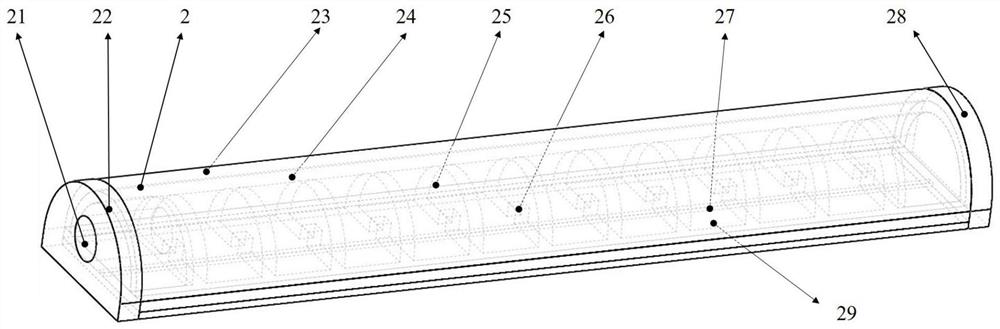

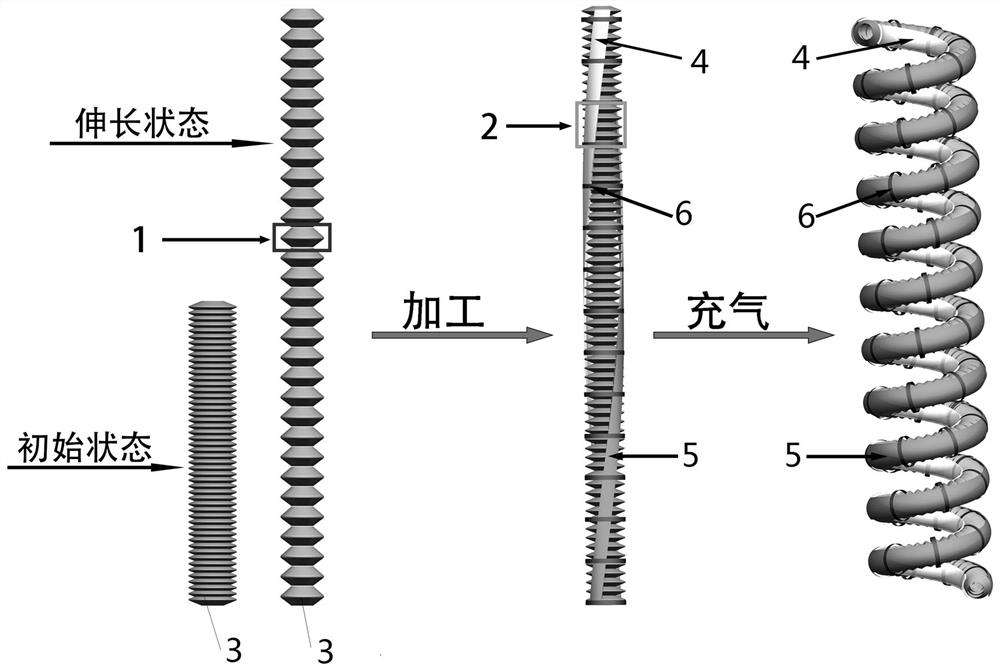

Snakelike wound software actuator

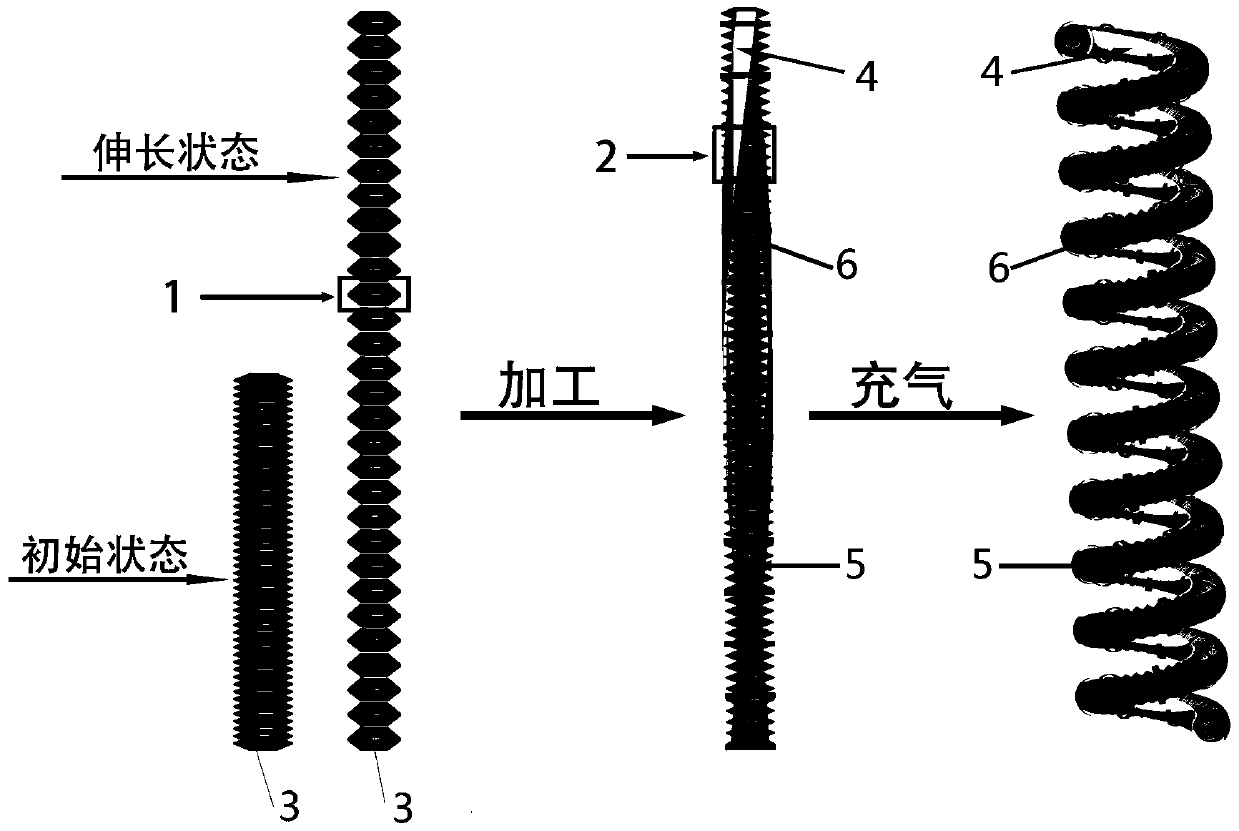

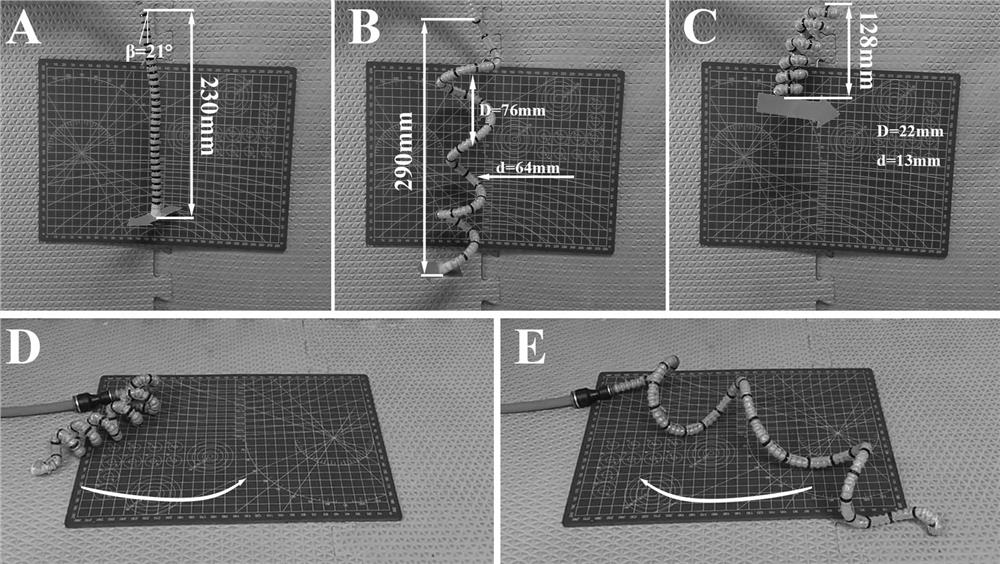

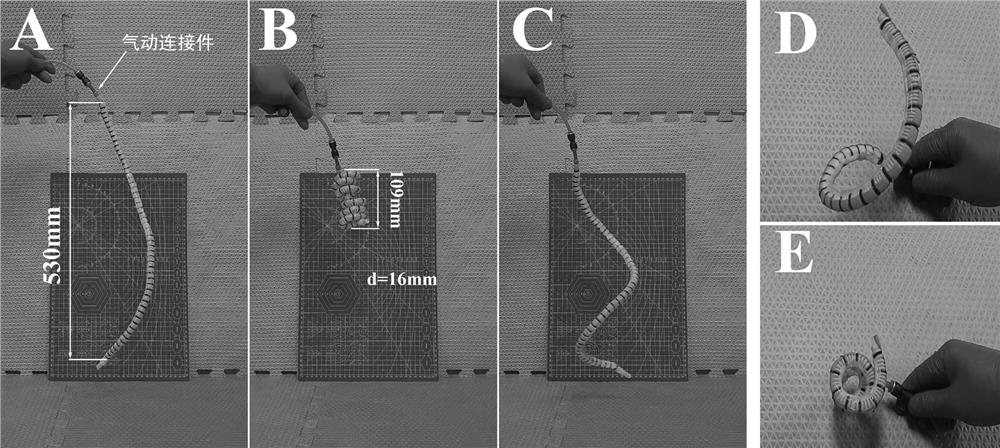

The invention provides a snakelike wound software actuator, which is aimed at solving the problem that a software robot is still in a research stage and needs to be further expanded. The snakelike wound software actuator comprises an elastic corrugated pipe, a strain limiting layer, an elastically stretchable layer, a fixed connecting piece, and an air passage pipe for connection with an air source. The novel snakelike wound actuator provided by the invention covers a wound actuator with the strain limiting layer and a wound actuator without the strain limiting layer. The winding performance of the snakelike wound actuator with the strain limiting layer is determined by depending on the strain limiting layer and the elastically stretchable layer; the snakelike wound actuator with the strain limiting layer can wind a long and thin rod rapidly and efficiently; and with the increase of inflation pressure, the snakelike wound actuator winds an object more tightly and can lift a 1.3kg object. The wound actuator without the strain limiting layer is relatively light and soft; the winding manner of the actuator is determined only by depending on the fixed orientation of the elastically stretchable layer; and the wound actuator without the strain limiting layer can also wind and lift the object.

Owner:SOUTHWEAT UNIV OF SCI & TECH

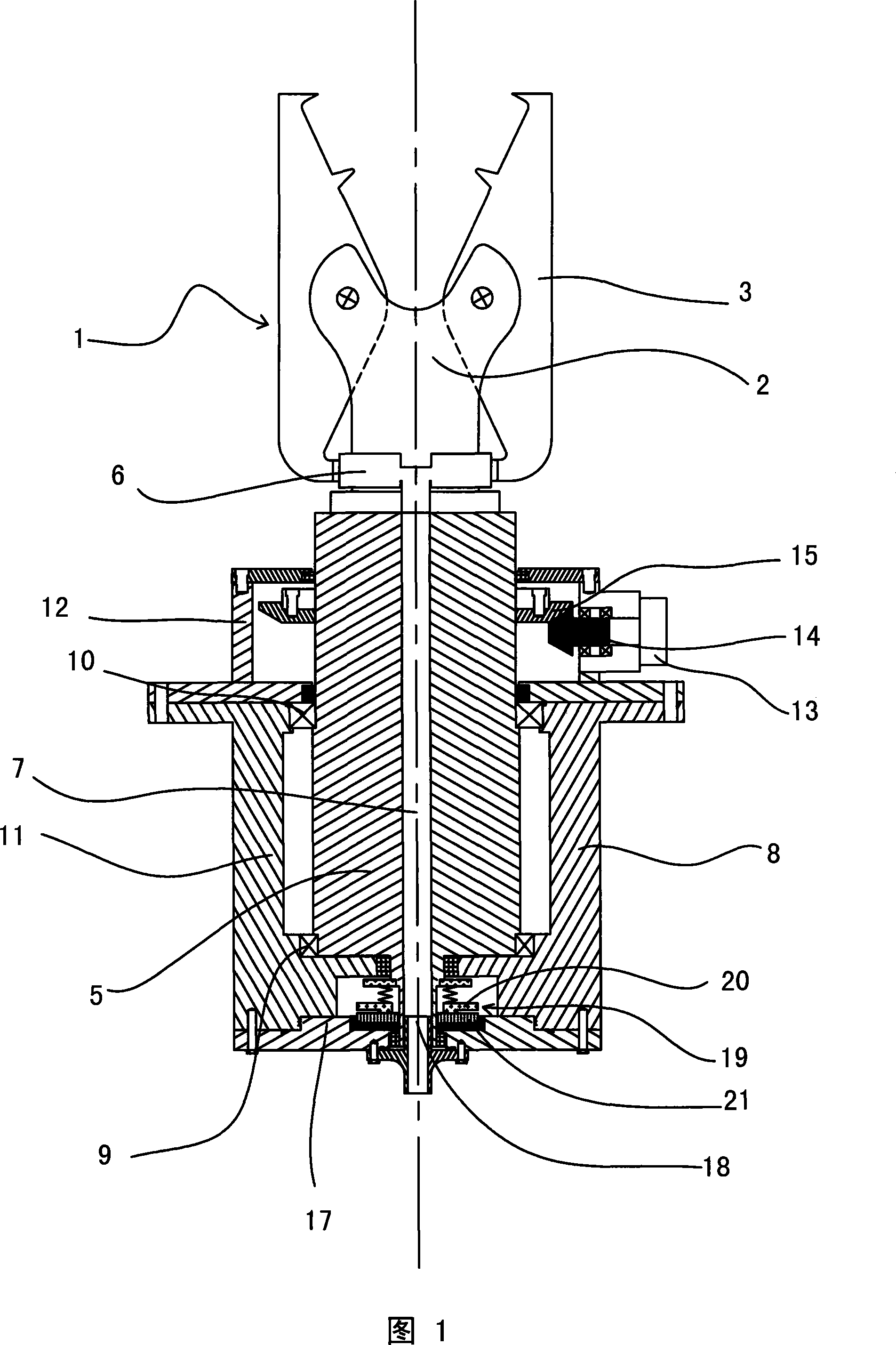

Mechanical arm

InactiveCN101104263AThe operator is flexibleEasy to grabGripping headsHydraulic cylinderHydraulic motor

Disclosed is a manipulator, which is characterized in that the invention comprises three parts: a jaw, a shaft and a beam-barrel. The jaw comprises a bracket and at least two claws. The middle parts of the two claws are hinged on the bracket whose back end is connected with the shaft. A hydraulic cylinder is respectively arranged at the rear end of the two claws. Pistons of the two hydraulic cylinders are connected with corresponding rear ends of the claws. The center of the shaft is provided with oil supplying holes which are respectively connected with the two hydraulic cylinders so as to form a lever-type grasping mechanism. The shaft is rotationally supported inside the beam-barrel. A first umbrella-shaped gear arranged on the output shaft of a hydraulic motor meshes with a second umbrella-shaped gear which is correspondingly connected on the shaft so that a rotating mechanism where the jaw can rotate around the shaft by 360 degrees is formed. The manipulator has characteristics of reasonable design, high performance price ratio, simple structure, convenient using, high work efficiency and good reliability.

Owner:钱成

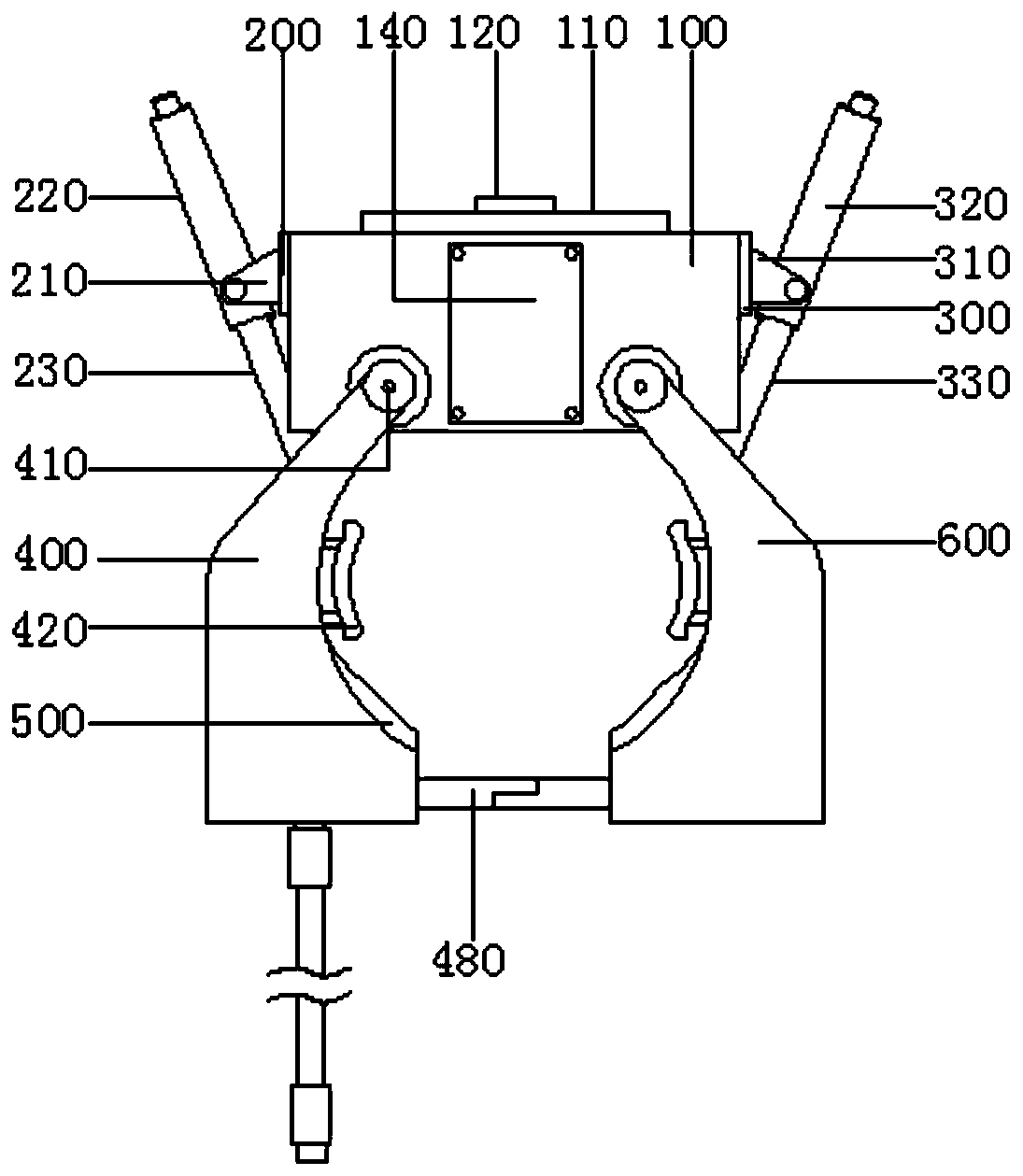

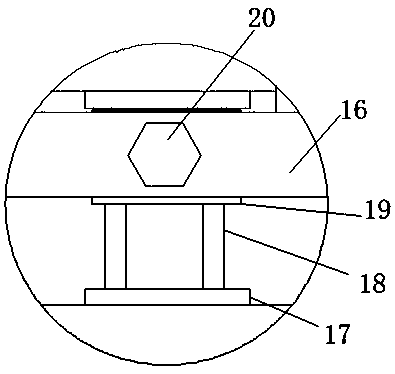

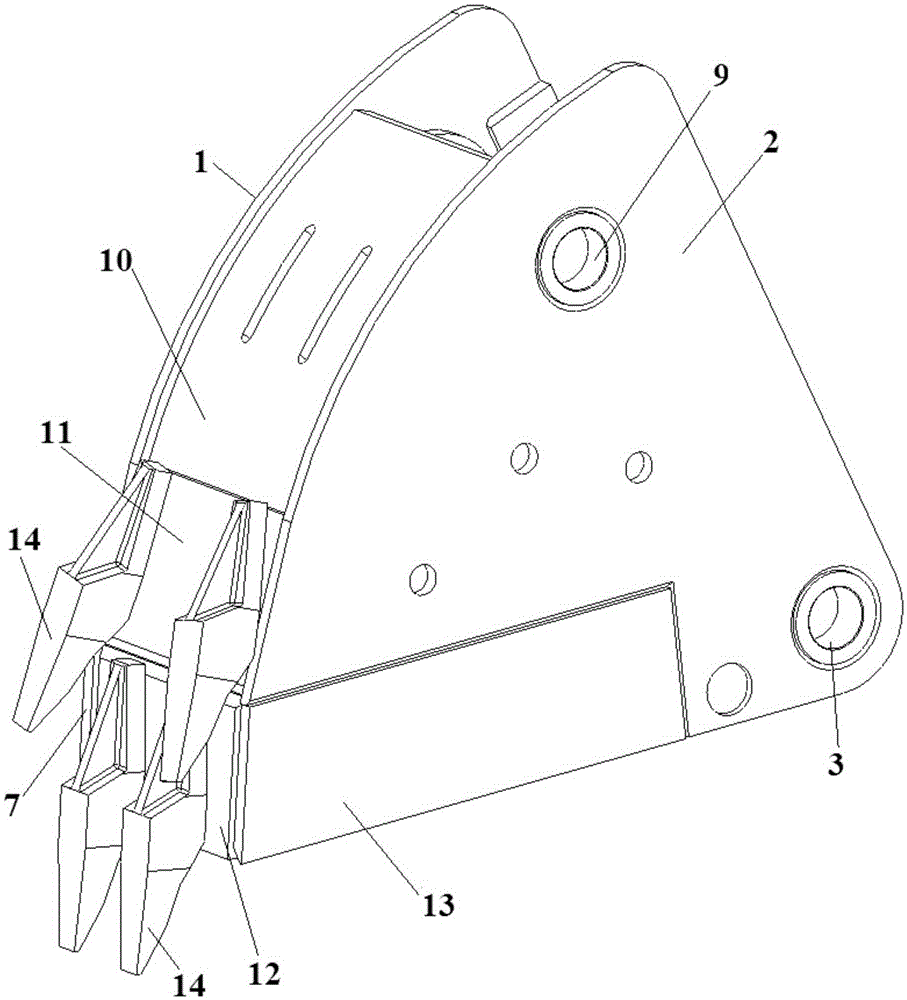

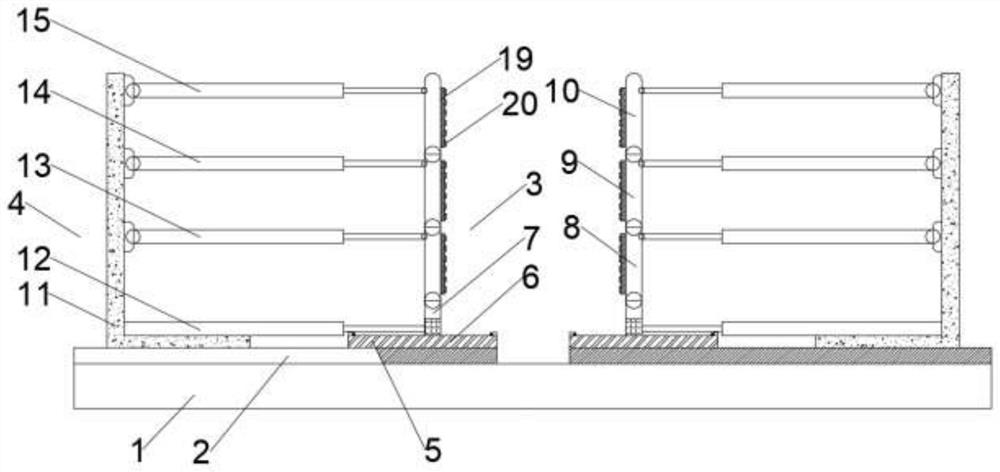

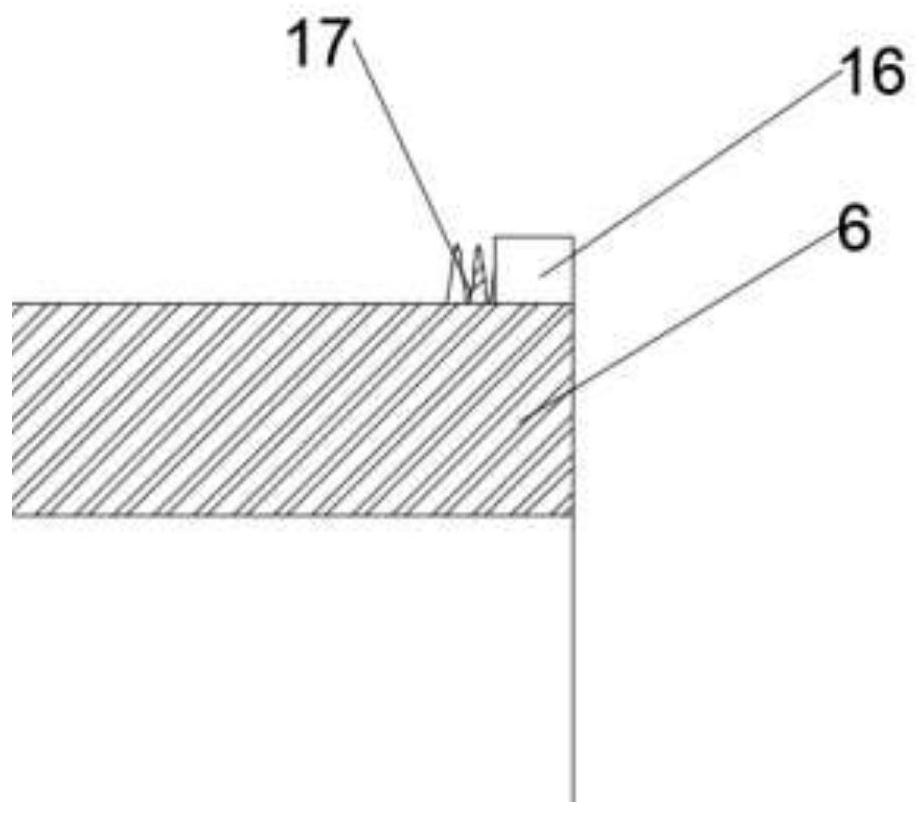

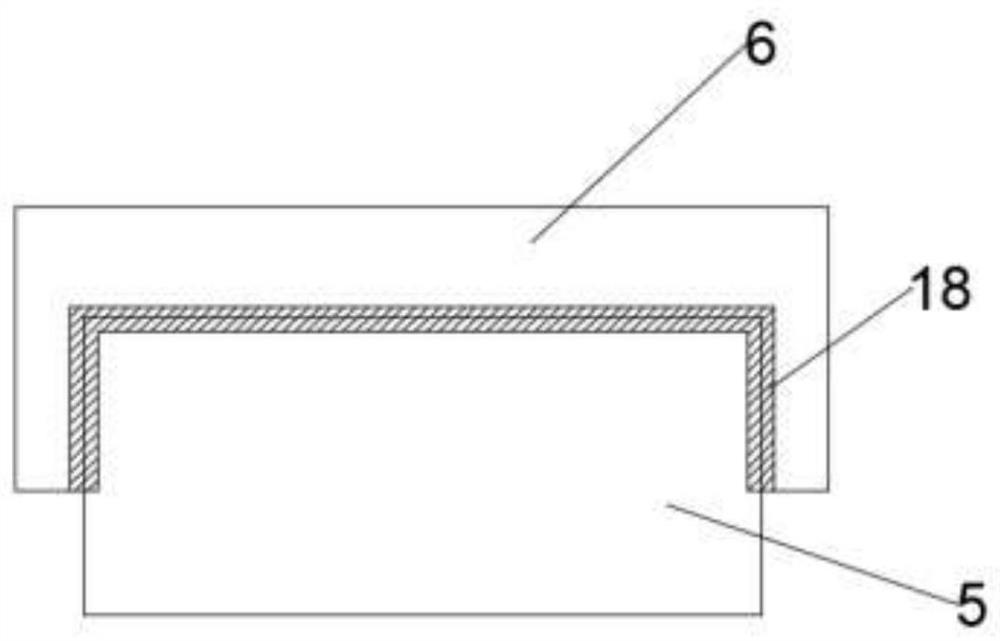

Clamp structure for grabbing mechanical equipment

ActiveCN110549356AStrong grabbing abilityImprove the anti-drop effectGripping headsConveyor partsFriction effectEngineering

The invention belongs to the technical field of mechanical equipment accessories, and particularly relates to a clamp structure for grabbing mechanical equipment. The clamp structure for the grabbingmechanical equipment comprises a top shell, a main lug, an auxiliary lug, a main frame, bearings, bottom pads, an auxiliary frame and a fixed bolt; and the left side wall and the right side wall of the top shell are fixedly connected with the main lug and the auxiliary lug through screws. The clamp structure for the grabbing mechanical equipment can control a main push rod device and an auxiliarypush rod device to push a telescopic rod, after the telescopic rod influences the main frame and the auxiliary frame, logs of same specification can be clamped, after being matched with the bottom pads, the contact area is large, the friction effect is strong, the sliding probability is reduced, after being clamped, the circumferential outer walls of the logs of the same specification are contacted with side pads, the side pads are stressed to be matched with springs to retract, cross rods synchronously move to trigger trigger switches on contact plates, so that miniature electric push rods push connecting rods, the bottom protection effect is achieved, the falling prevention performance is good, the double-safety effect can be achieved, the transfer of the logs of the same specification has safety and stability, and the transfer efficiency of the logs of the same specification is improved.

Owner:CHANGSHA CITY WANZHENG LORRY CARRIAGE

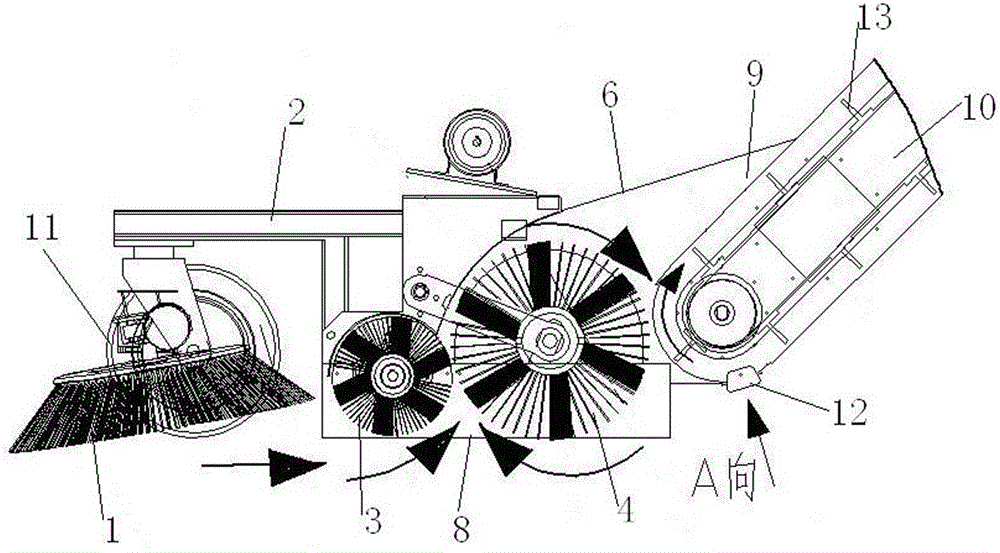

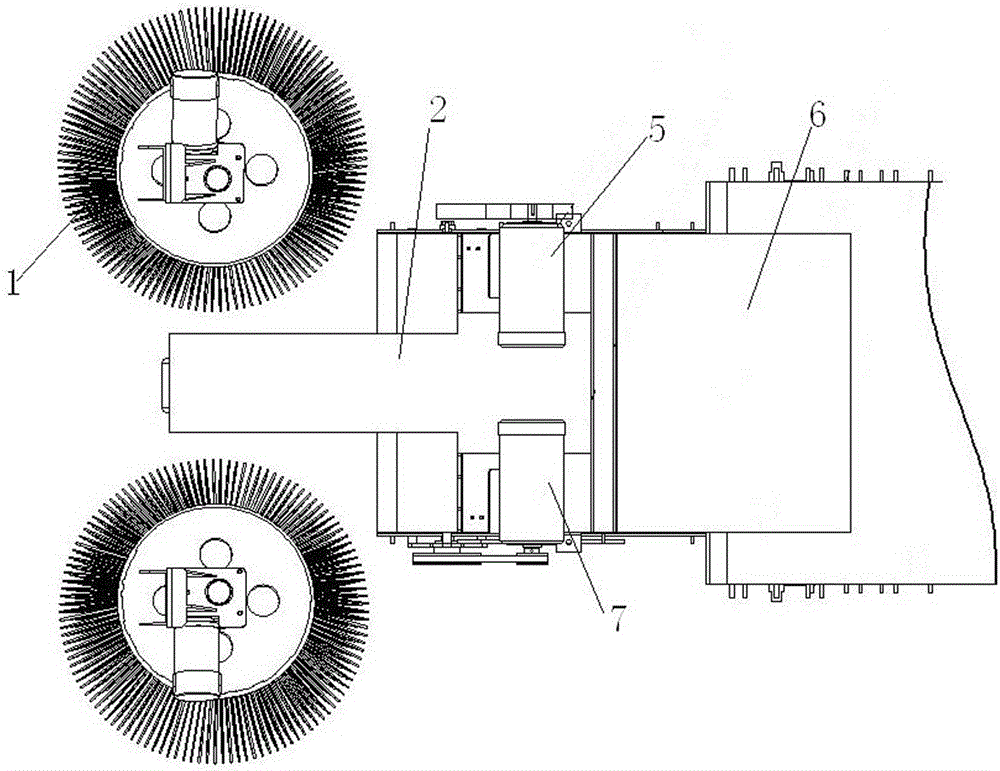

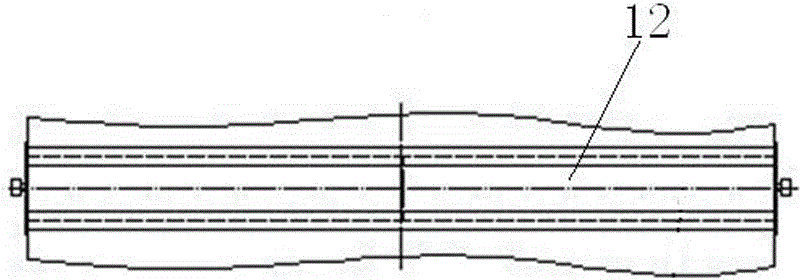

Paired-roller roll-sweeping brush superstrong garbage grabbing mechanism based sweeper

InactiveCN106087819AStrong grabbing abilityImprove gripRoad cleaningEngineeringMechanical engineering

The invention provides a paired-roller roll-sweeping brush superstrong garbage grabbing mechanism based sweeper. The sweeper comprises a frame, a garbage sweeping assembly which is connected with the frame and a motor component, the garbage sweeping assembly is provided with a side brush, an auxiliary roll brush and a main roll brush, the auxiliary roll brush and the main roll brush are opposite in rotating direction, and the auxiliary roll brush is parallel to the main roll brush. The paired-roller roll-sweeping brush superstrong garbage grabbing mechanism based sweeper has the advantages that garbage grabbing capability is further improved, and garbage sweeping effect of equipment is strengthened.

Owner:JIANGSU MORAL ENVIRONMENTAL PROTECTION TECH CO LTD

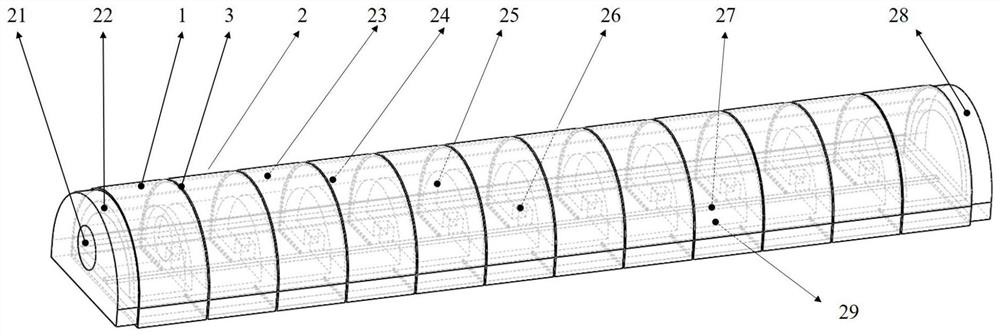

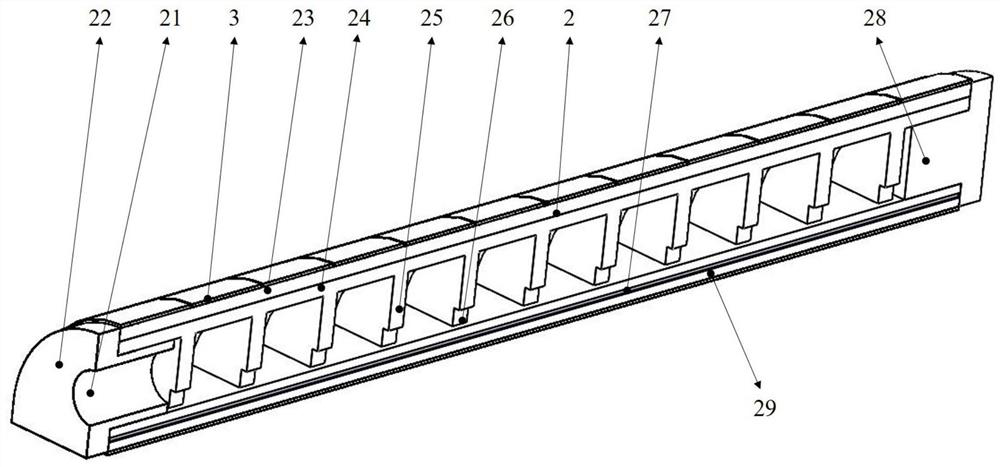

Thrombus taking stent, preparation method of thrombus taking stent and thrombus taking device

ActiveCN111437006AStrong grabbing abilityReduce the impact of damageStentsSurgeryBlood vessel wallsBiomedical engineering

The invention relates to medical instruments, in particular to a thrombus taking stent, a preparation method of the thrombus taking stent and a thrombus taking device. The thrombus taking stent mainlycomprises a stent body produced with a shape memory alloy as a raw material, a hydrophilic layer is arranged on the outer surface of the stent body, and a micro-nano porous structure layer is arranged on the inner surface of the stent body. Under the structure that the diameter of the stent body is smaller than 2 mm, the effects of optimizing the grabbing capacity of the stent body and minimizingthe damage effects on blood vessel walls can be achieved, the operation performing difficulty and time can be reduced and shortened to a great extent during an operation, and the operation efficiencycan be effectively improved.

Owner:XUANWU HOSPITAL OF CAPITAL UNIV OF MEDICAL SCI +1

Soft driver

ActiveCN113172640ALarge bending forceLarge bending deformationGripping headsEngineeringElastic plastic

The invention provides a soft driver. The soft driver comprises a driver body and a binding layer wrapping the periphery of the soft driver body; the soft driver body comprises a plurality of elastic layers which are sequentially stacked from inside to outside, a front end cover and a rear end cover, wherein the front end cover and the rear end cover block the two ends of the elastic layers; the hardness of the outermost elastic layer is the highest, the hardness of the other elastic layers is gradually increased or equal in sequence from inside to outside, and a cavity used for containing fluid is formed in the innermost elastic layer; the rear end cover is a closed end cover, and a first through hole for introducing fluid into the cavity is formed in the front end cover; and the binding layer wraps part of the outer side wall of the outermost elastic layer and is a stretchable thin sheet formed by cutting a plurality of notches distributed at intervals in a thin sheet made of a non-stretchable elastic material or an elastic plastic material, and bending deformation of the soft driver body is achieved while expansion of the soft driver body is limited. The soft driver is large in output force, large in bending deformation and high in response frequency, and can be used in the fields of industry and clinical medicine.

Owner:TSINGHUA UNIV

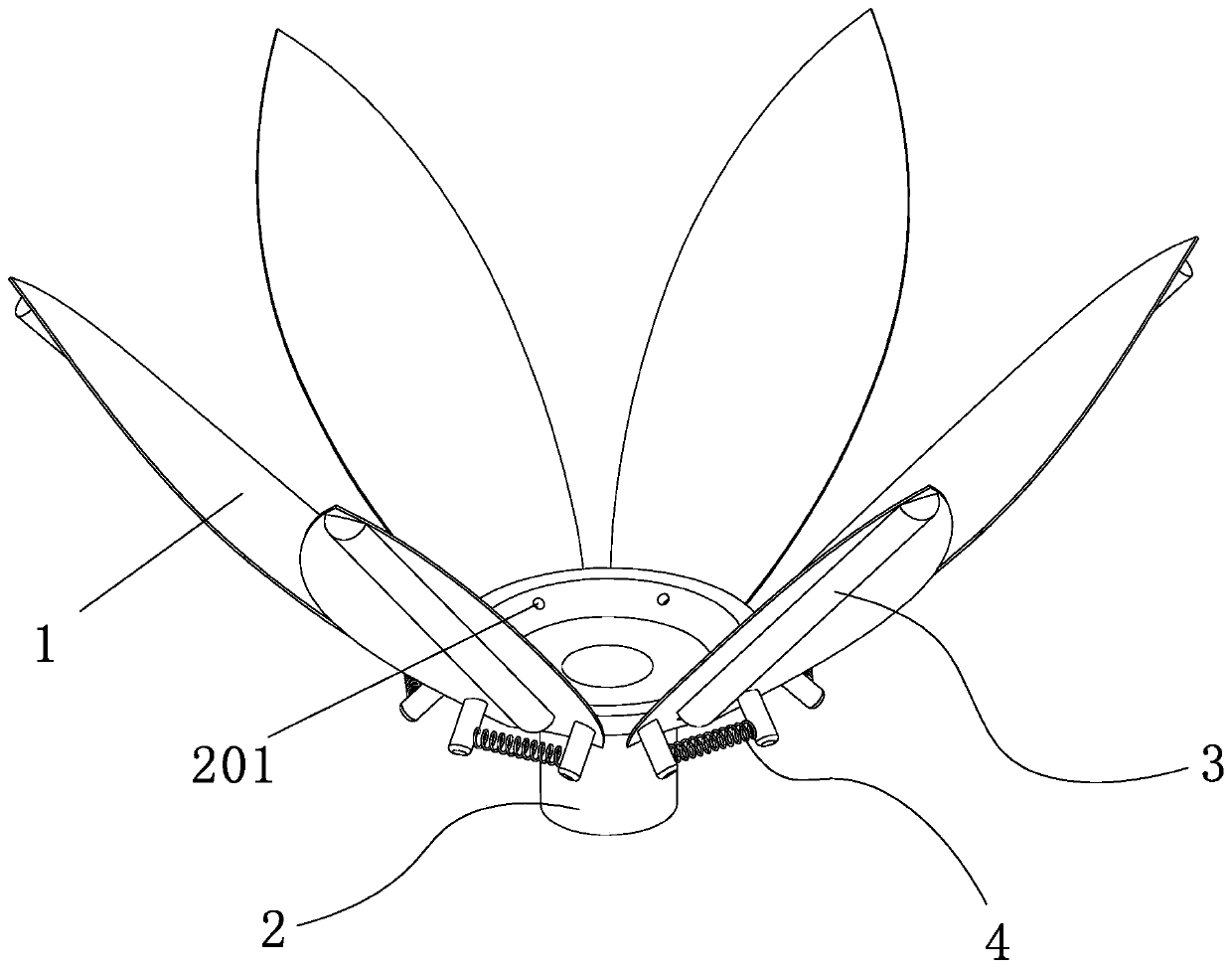

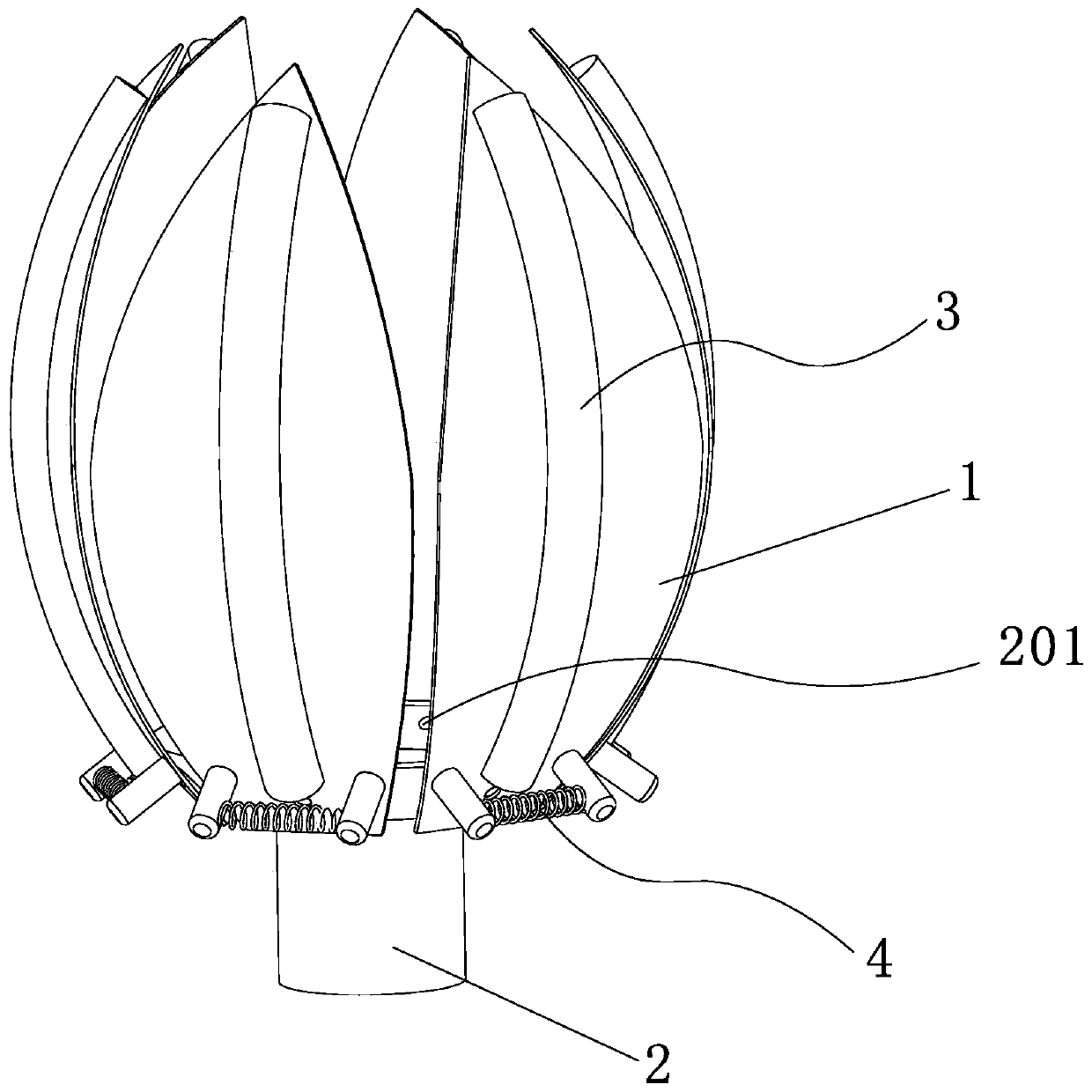

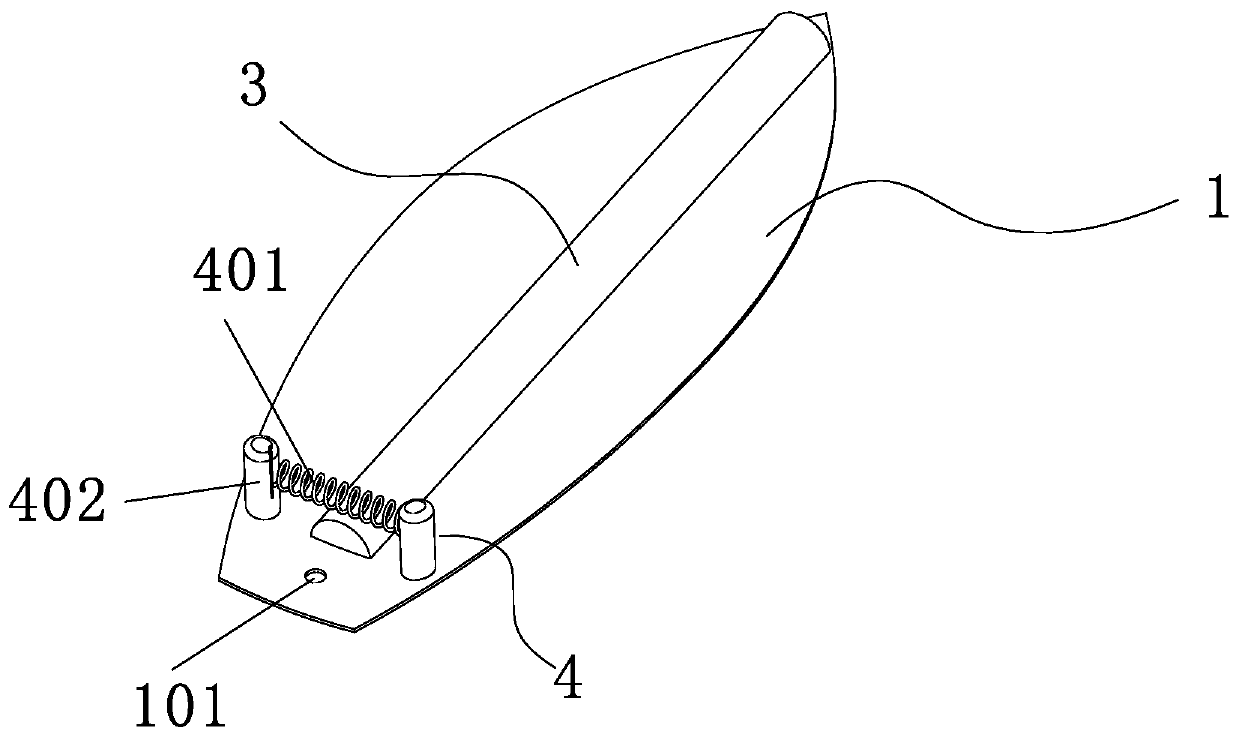

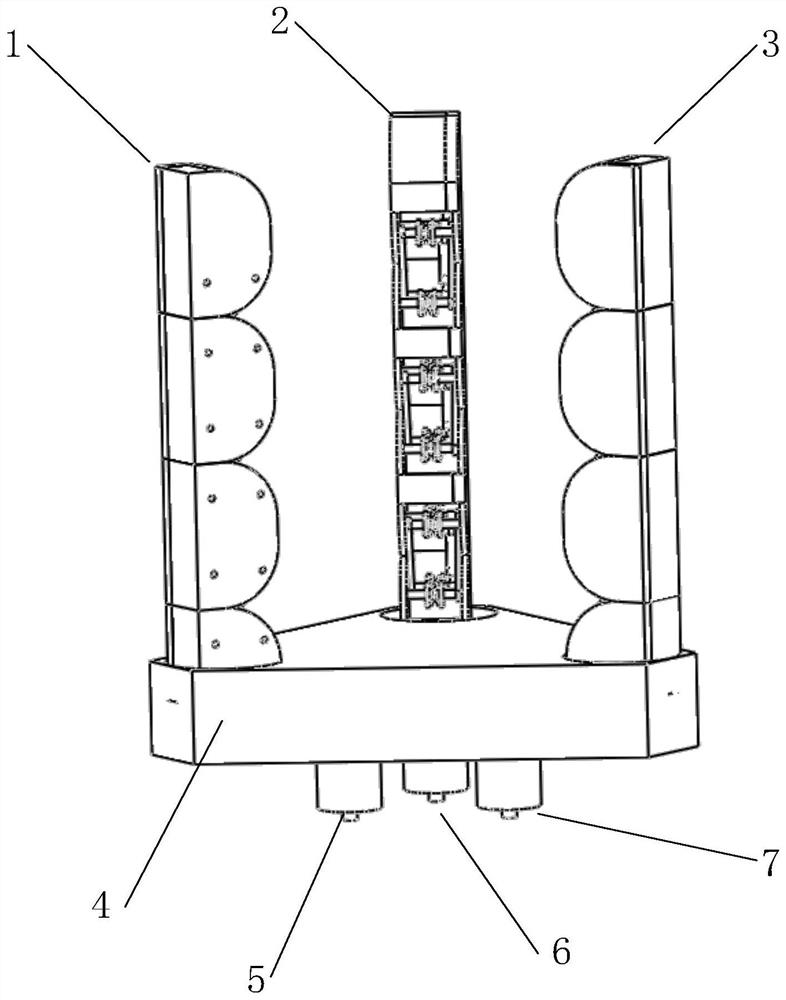

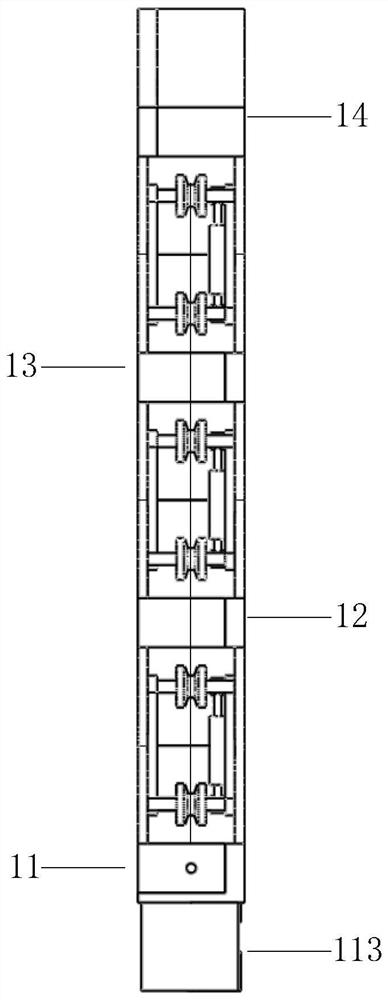

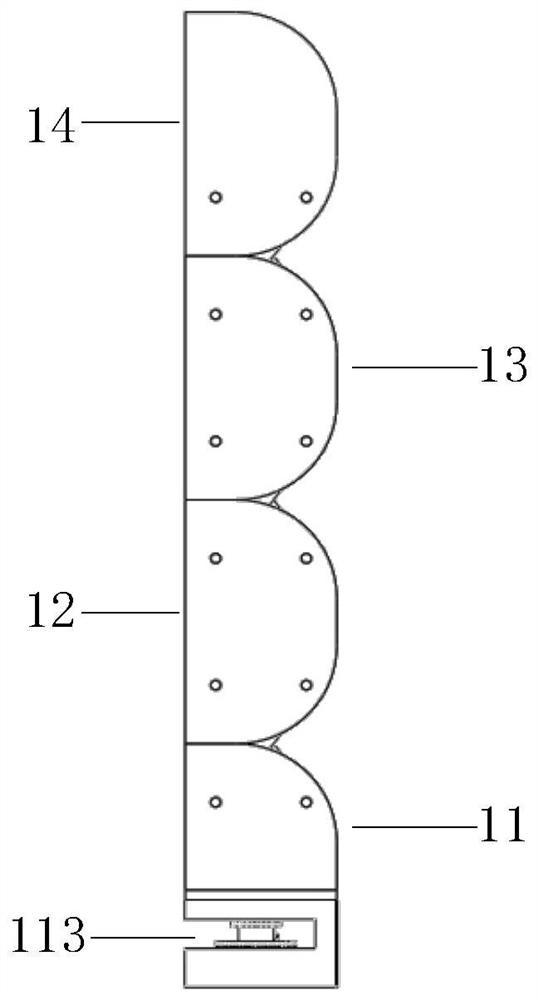

Bistable flexible machine gripper provided with bionic petal structure and manufacturing method of bistable flexible machine gripper

The invention discloses a bistable flexible machine gripper provided with a bionic petal structure and a manufacturing method of the bistable flexible machine gripper. The bistable flexible machine gripper provided with the bionic petal structure comprises a pedestal and grab units with bistable characteristics, wherein the grab units are arranged to be of the bionic petal structure, the grab units are fixed to the periphery of the pedestal, a driving unit is fixed to each grab unit, and each driving unit comprises a grab driving unit used for driving the corresponding grab unit to deform close to the center of the gripper and a release driving unit used for driving the corresponding grab unit to deform away from the center of the gripper. According to the bistable flexible machine gripperprovided with the bionic petal structure and the manufacturing method of the bistable flexible machine gripper, grab capability is strong, response speed is high, the structure is simple, invisibility is high, manufacturing is convenient, the grab capability can be maintained without the action of external force, energy consumption is low, smoothness is good, and the gripper can adapt to complicated, irregular and variable objects.

Owner:ZHEJIANG UNIV OF TECH

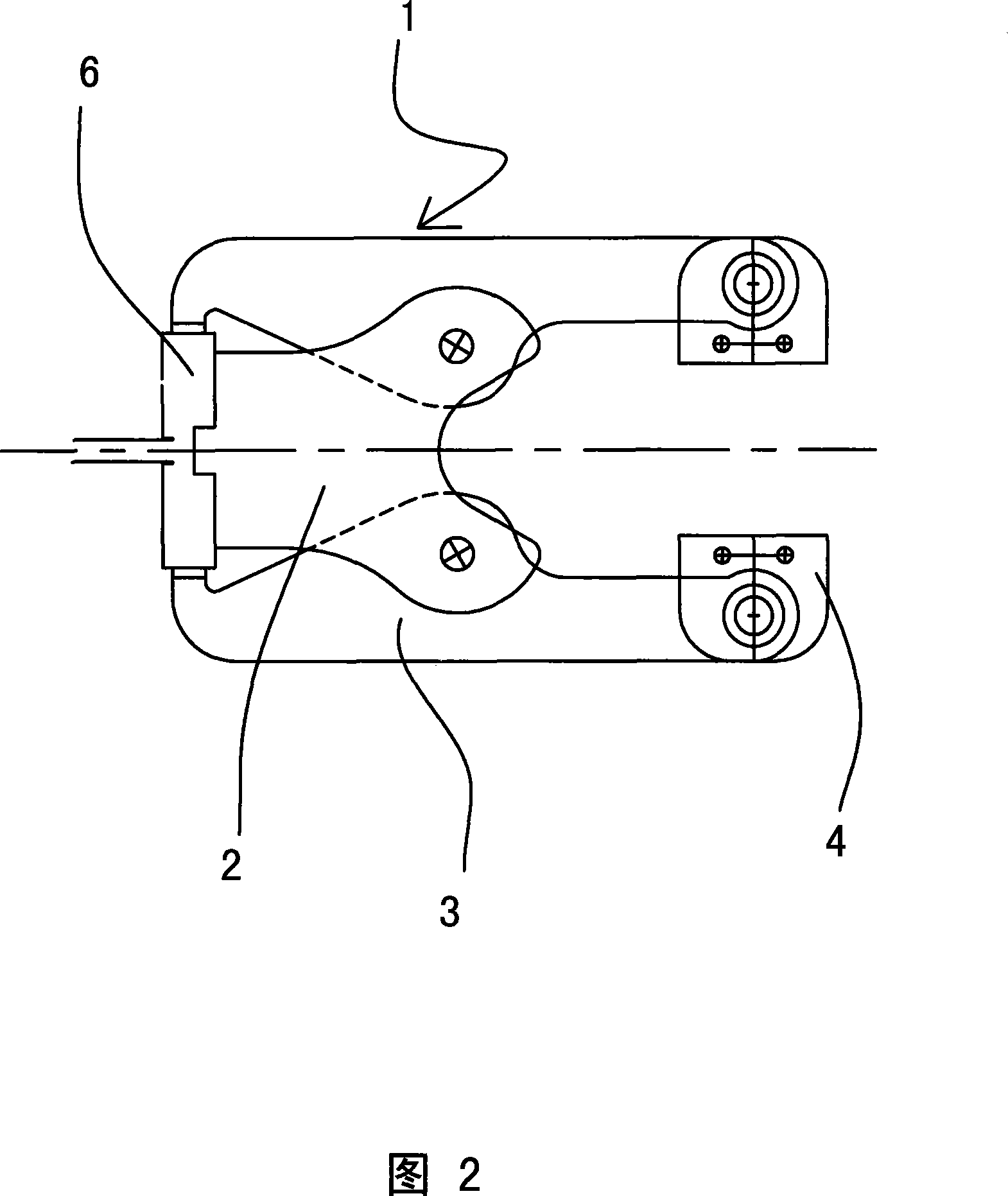

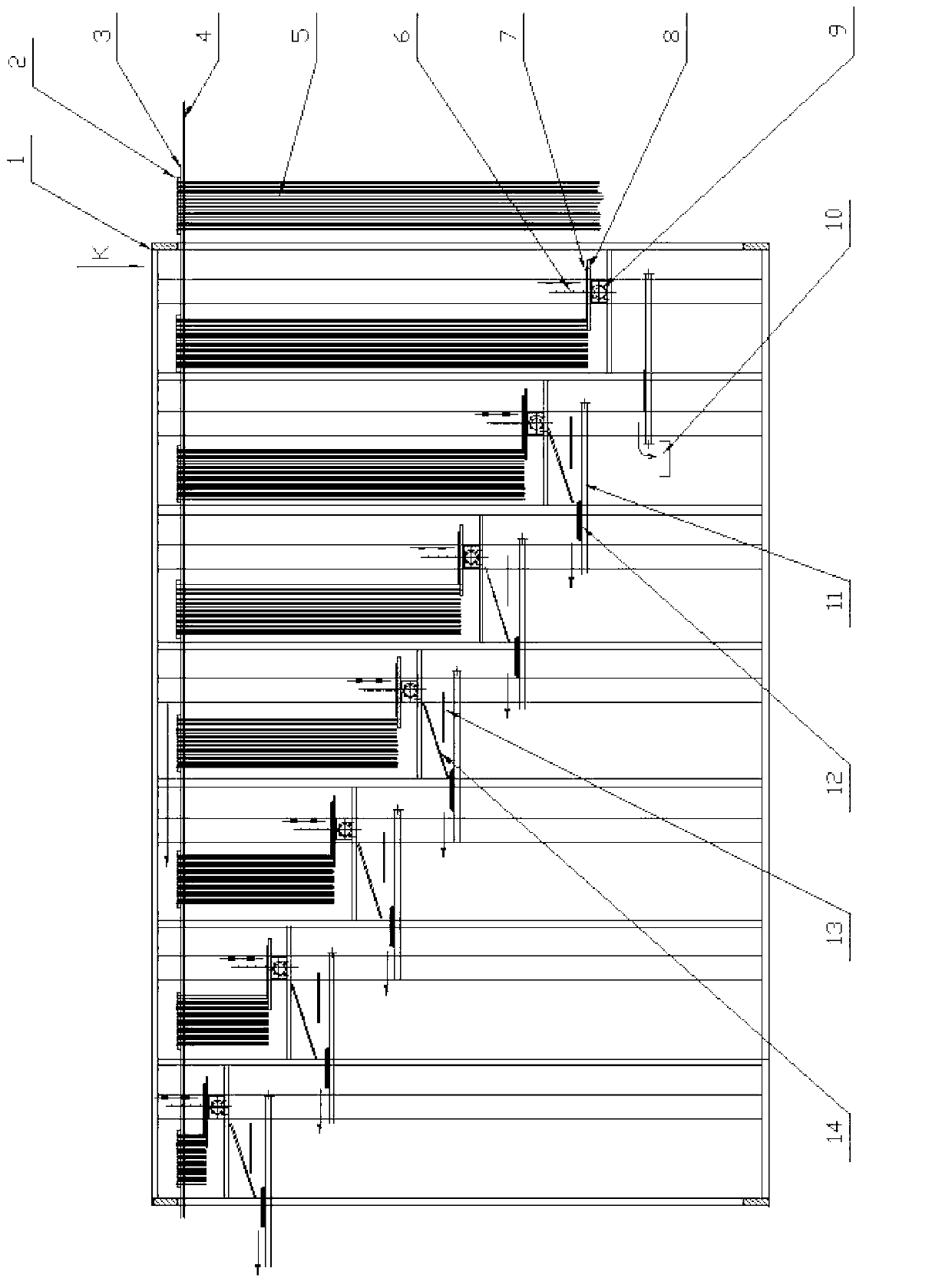

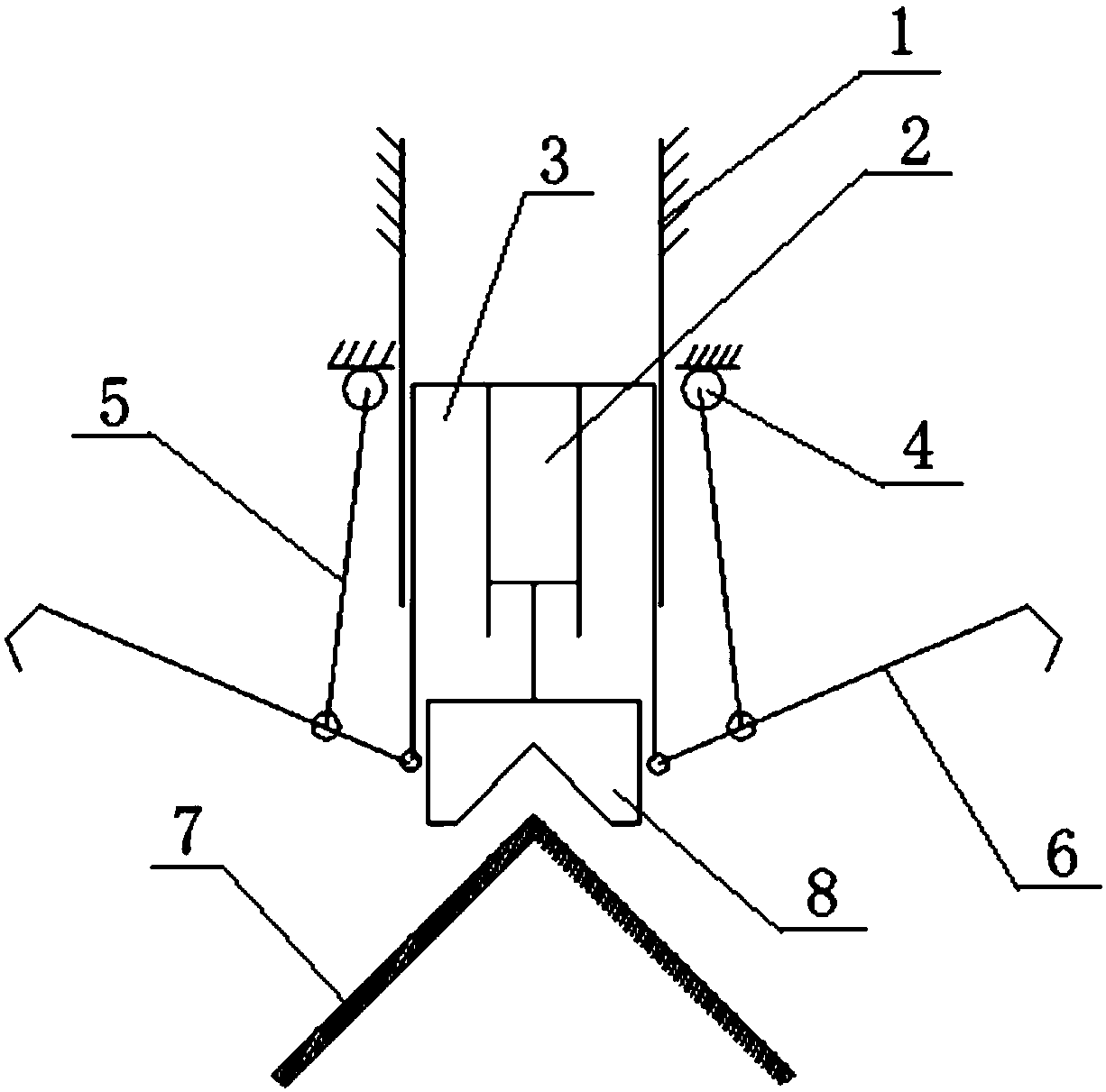

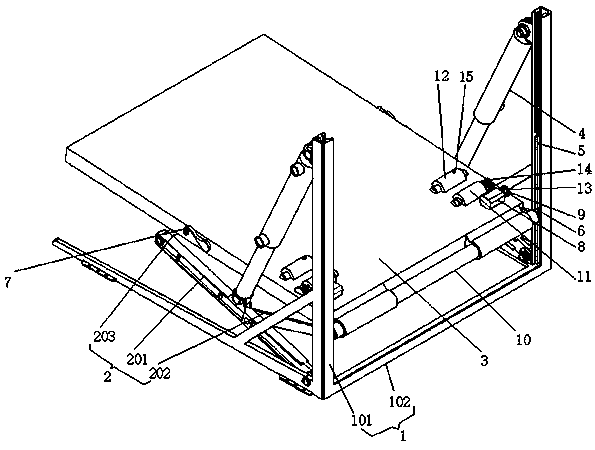

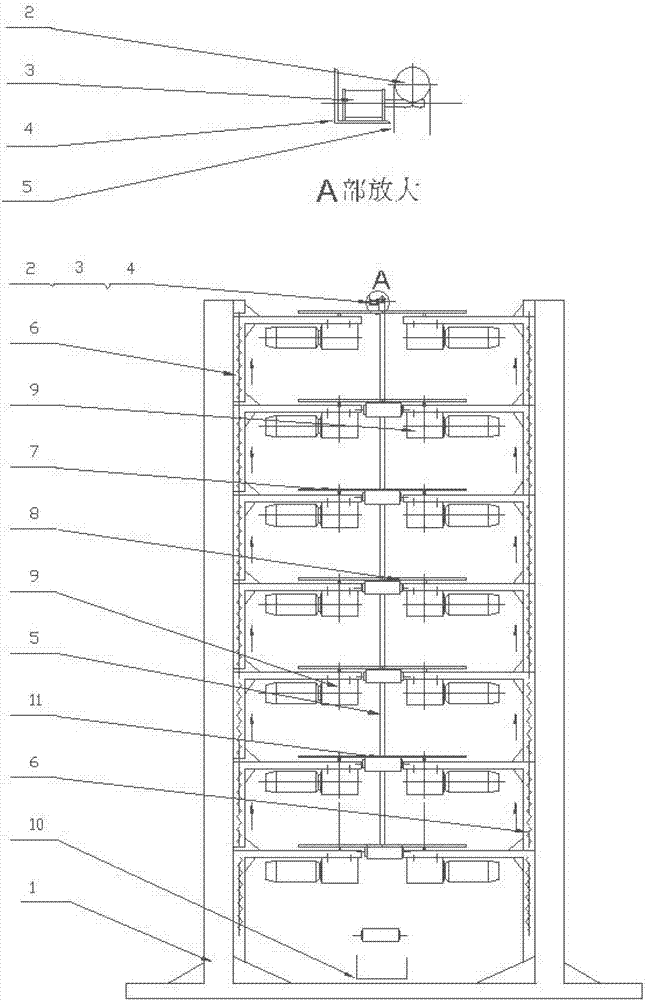

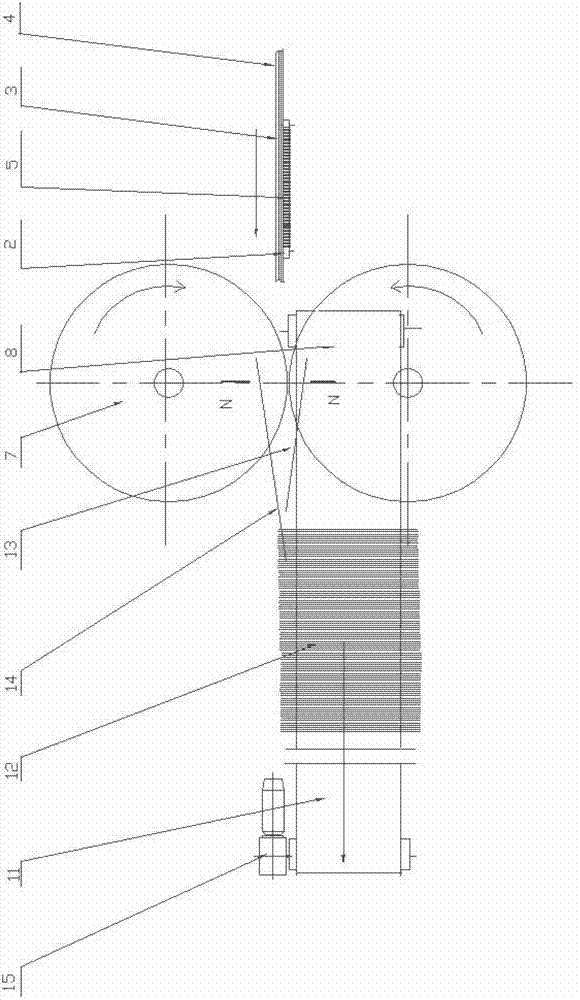

Vertical cutting-off machine of fine dried noodles

The invention discloses a vertical cutting-off machine of fine dried noodles, relating to a fine dried noodle machine, and in particular relates to a mechanical device for cutting dried fine dried noodles into fine dried noodle sections with required certain length in a production process of the fine dried noodles. The machine comprises a stand, fine dried noodle cutting-off devices arranged on the stand, cut fine dried noodle conveying belts and a fine dried noodle rod conveying mechanism guide rail, wherein more than two groups of fine dried noodle cutting-off devices comprising left rotating cutters, right rotating cutters and rotating cutter drive mechanisms are arranged on the frame-shaped stand, each group of left rotating cutter and right rotary cutter is matched to form a pair of fine dried noodle cutter consists of a left rotating cutter and a right rotary cutter which are matched with each other, all groups of fine dried noodle cutting-off devices are arranged at different heights on the stand according to the demand, the cut fine dried noodle conveying belt is arranged below each group of fine dried noodle cutting-off device, the fine dried noodle rod conveying mechanism guide rail is arranged on the top of the stand, fine dried noodles to be cut off enter the vertical cutting-off machine in a vertical state to be cut off. The rotating speed of the rotary cutters is 30-60 rpm. The machine has the advantages that the cut fine dried noodles are uniform, the length of the cut fine dried noodle sections is regulated flexibly and conveniently, and the cut fine dried noodles directly enters a fine dried noodle metering device and fine dried noodle rods completing the cutting off can be directly sent to a fine dried noodle rod bin of a fine dried noodle cutting unit of a fine dried noodle production line; after applied to the fine dried production line, the machine can improve the mechanization and automation level of the fine dried noodle production line.

Owner:山东江泷机械有限公司

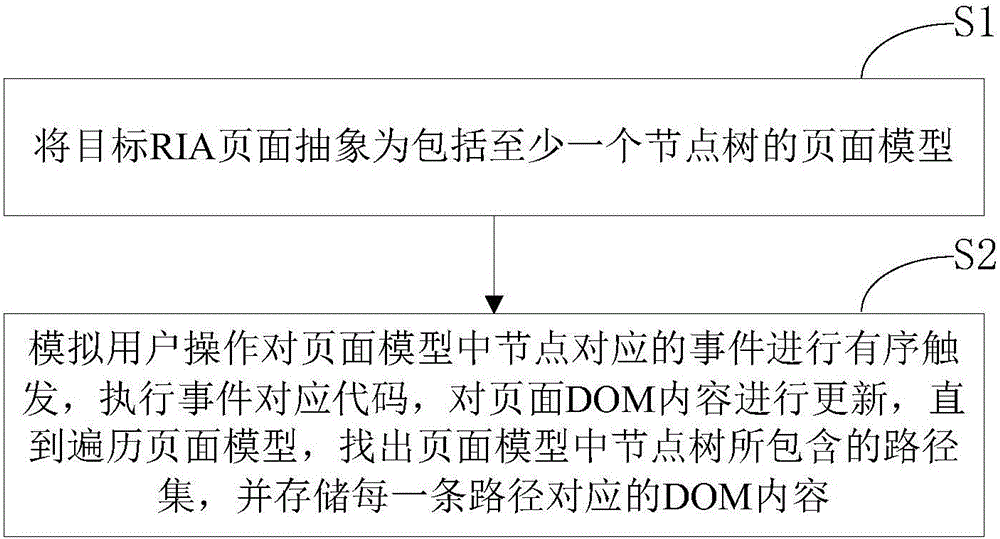

Method for capturing cloud calculating data from RIA (Rich Internet Application) page

InactiveCN106055714AAchieve crawlingReduce occupancyWeb data indexingSpecial data processing applicationsDocument Object ModelDatabase

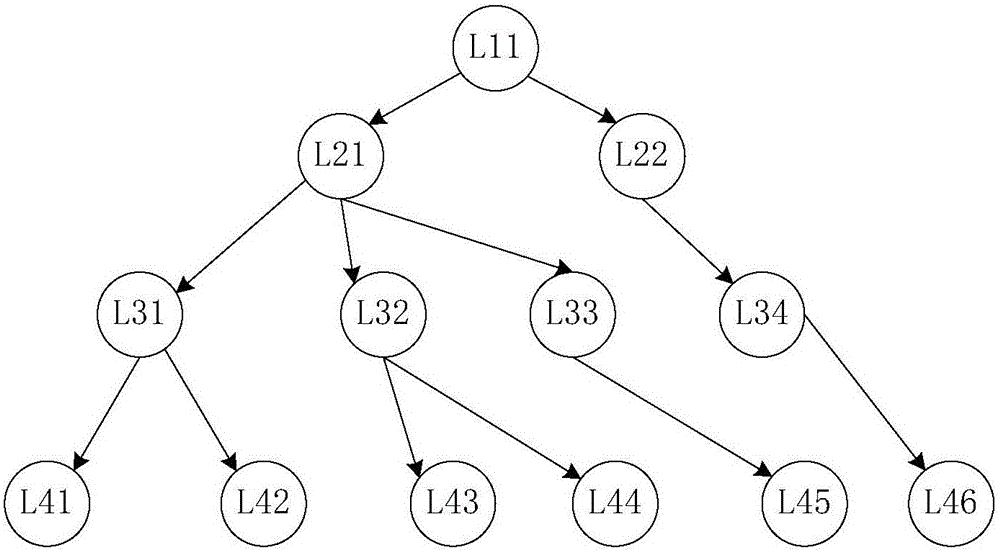

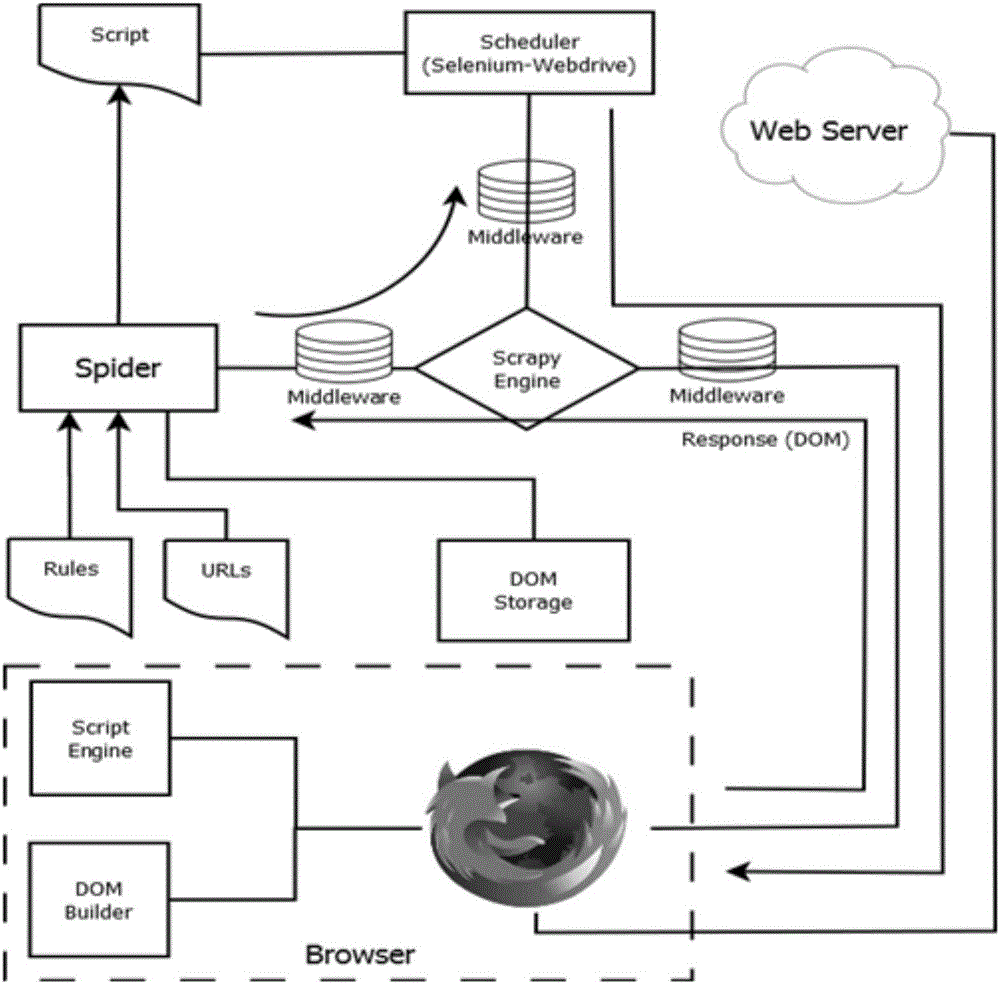

The invention discloses a method for capturing cloud calculating data from an RIA (Rich Internet Application) page. The method comprises the steps of: abstracting a target RIA page into a page model including at least one node tree; and then simulating a user operation to carry out ordered triggering on an event corresponding to a node in the page model, executing a corresponding code of the event, updating a DOM (Document Object Model) content of a page until the page model is traversed, finding out a path set included by the node tree in the page model, and storing the DOM content corresponding to each path. According to the method, through automatically triggering the event corresponding to the node and executing the corresponding code of the event, the DOM contents of the page are updated and nodes of a next layer are dynamically extended, the cloud calculating data from the RIA page are captured, and the method is high in capturing capability, low in occupation for system resources and good in application prospect.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

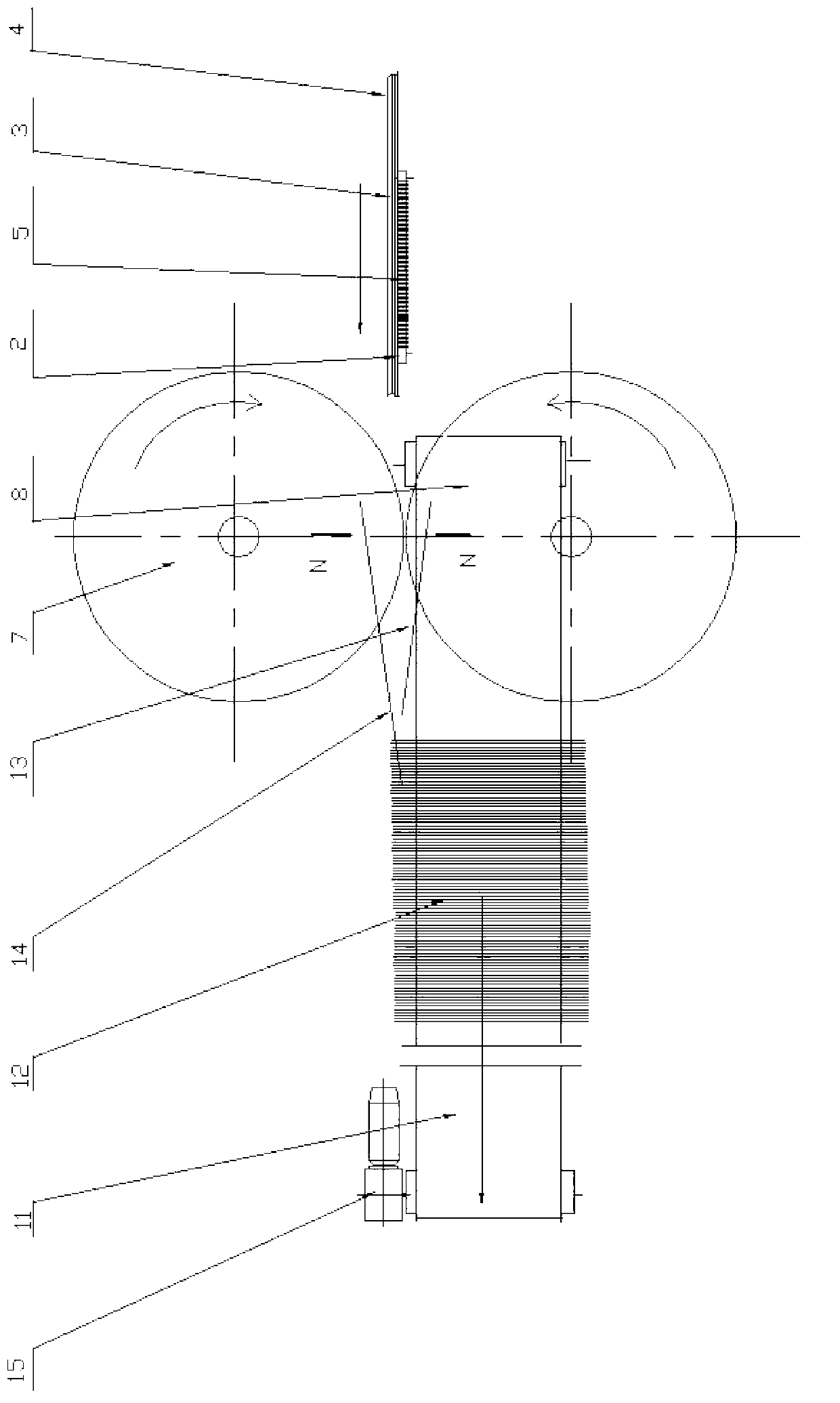

Straw briquetting mechanism with vertical shaft, flat die and straight roller

The invention provides a straw briquetting mechanism with a vertical shaft, a flat die and a straight roller, and belongs to the technical field of agricultural machinery. The straw briquetting mechanism mainly comprises a base, a transmission system, a collection hopper, a support, the main shaft, the flat die, a pressing roller frame, the pressing roller and a sleeve. The main shaft is vertically installed at the center position of the base and the center position of the support. The flat die is horizontally installed on the support. A pressing roller frame sleeve is vertically installed on the main shaft and fixed on the support. The pressing roller is horizontally installed at the radial shaft end of a pressing roller frame sleeve. The flat die is sleeved with the sleeve. The collection hopper is installed at the lower end of the flat die and fixed to the support. The flat die is provided with a plurality of square through holes within the circumference, and the center line of each hole coincides with the rotation center line of each pressing roller tooth, so that it is ensured that straws can be successfully pressed into the holes of the die. The pressing roller is in a straight gear shape, rotates along with the shaft under the driving of the pressing roller frame, and meanwhile rotates around the axis of the pressing roller to press the straws into the holes of the die continuously, so that straw blocks with the regular shape and high intensity are formed, and the production rate and the ratio of briquetting are high. The straw briquetting mechanism is simple and compact in structure, the holes of the flat die are not prone to being blocked, and working continuity is good.

Owner:HEILONGJIANG INST OF PASTURAGE MECHANISATION

Humanoid dexterous robotic hand with passive rotating joint and operation method thereof

ActiveCN109591038ASafe and secure gripTypical underdriven structureGripping headsRotational freedomRobot hand

The invention relates to the technical field of dexterous robot hands, and discloses a humanoid dexterous robotic hand with passive rotating joints and an operation method thereof. The humanoid dexterous robotic hand with the passive rotating joints comprises a first finger, a second finger, a third finger, a palm, a first driving motor, a second driving motor and a third driving motor. The humanoid dexterous robotic hand with the passive rotating joints solves the problems that a coupling transmission mechanism of an existing humanoid dexterous robotic hand is complex in structure, poor in reliability and the like, and meanwhile, a degree of rotational freedom is additionally provided for the fingers of the dexterous robotic hand. The humanoid fingers of the humanoid dexterous robotic hand can rotate around the central axes of the humanoid fingers by utilizing the rotating joints, and can be transformed automatically into a plurality of grabbing postures according to objects in different shapes, so that the adaptability of the dexterous robotic hand is enhanced; and the length of driven ropes and the length of driving ropes are adjusted, so that the initial pose of the dexterous robotic hand can be adjusted and re-calibrated. The novel humanoid dexterous robotic hand can achieve the envelope grabbing without a complicated control system and a transmission system, and has a passive degree of rotational freedom and the relatively high adaptability to the objects in different shapes.

Owner:BEIJING UNIV OF POSTS & TELECOMM

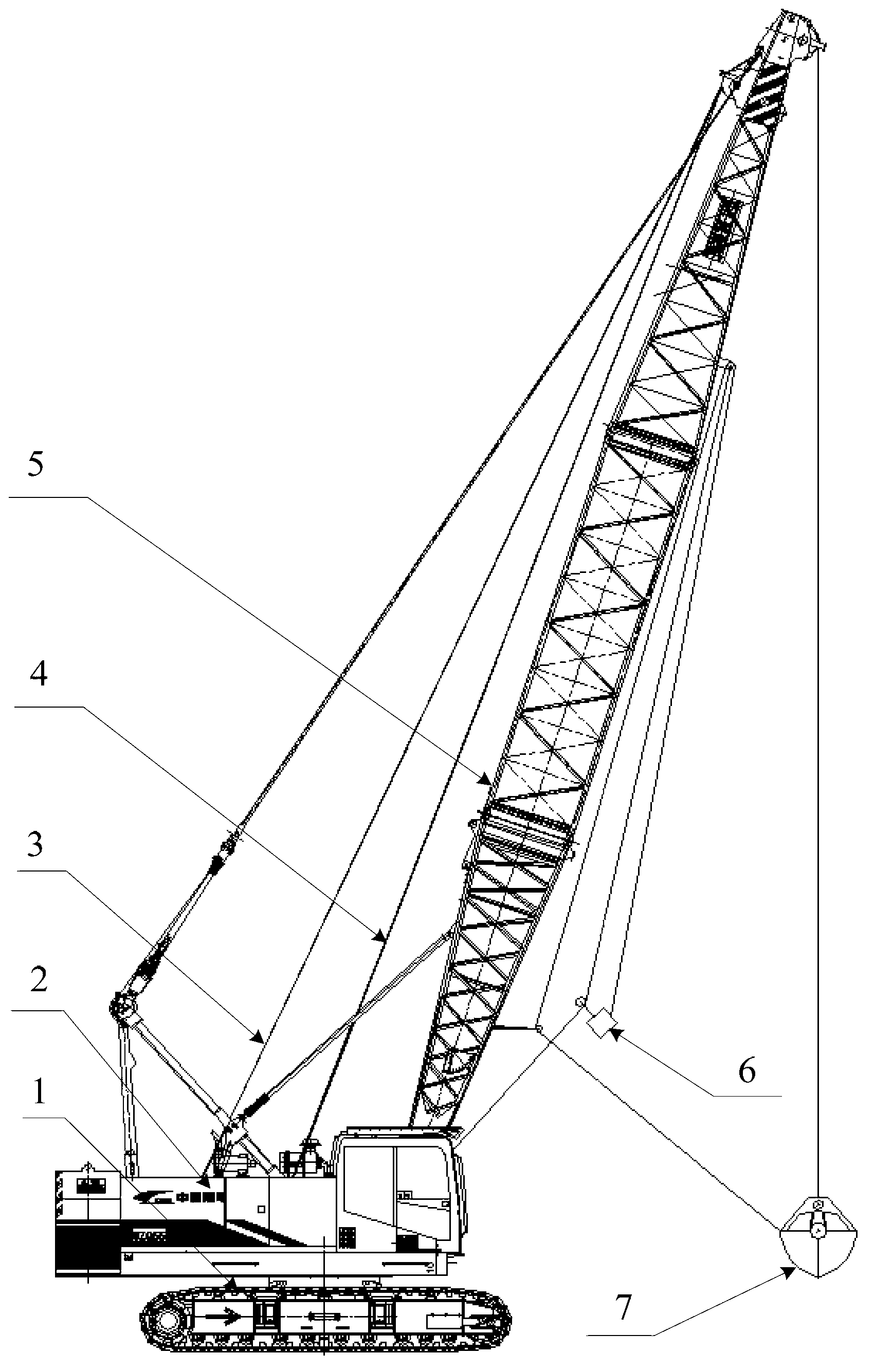

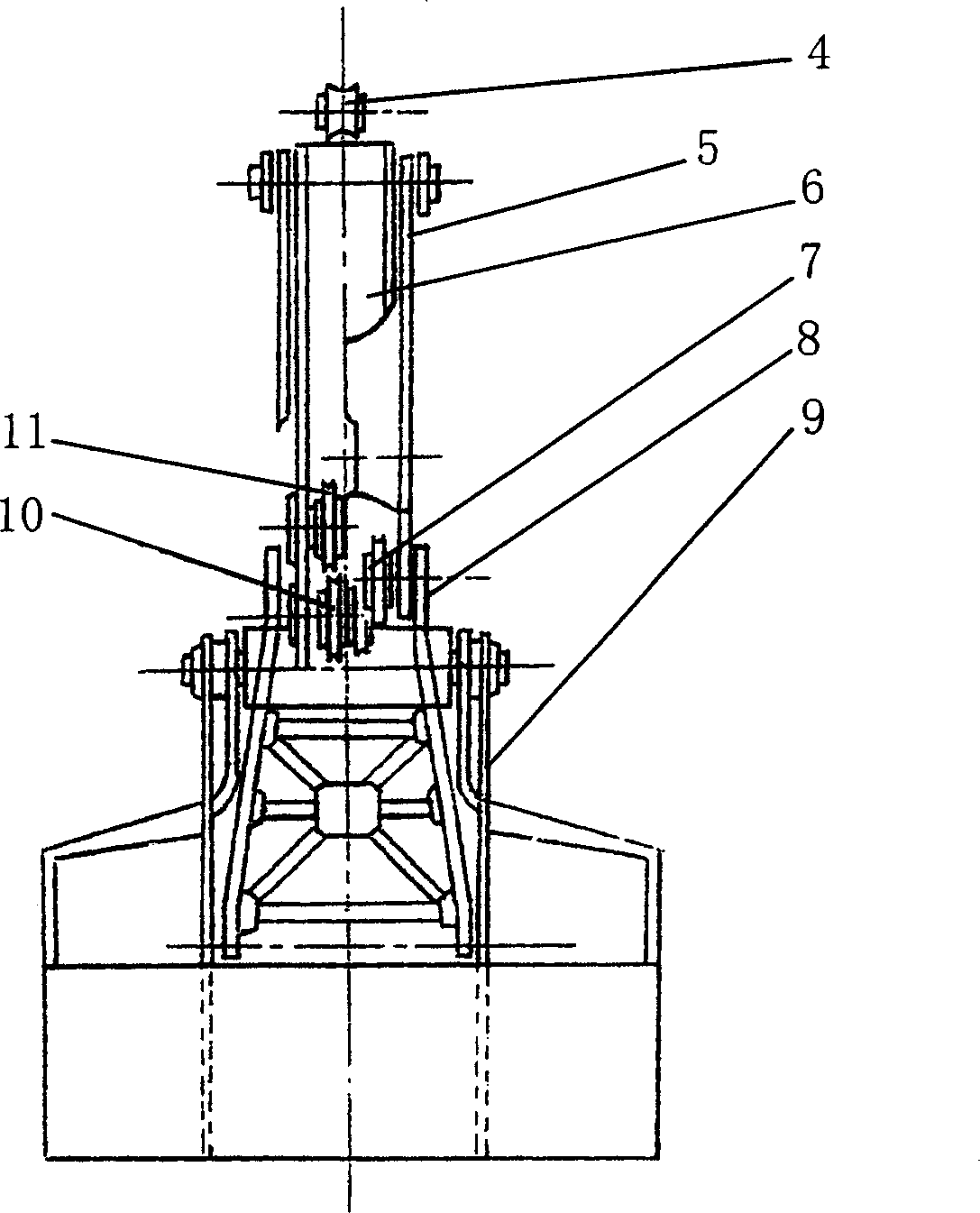

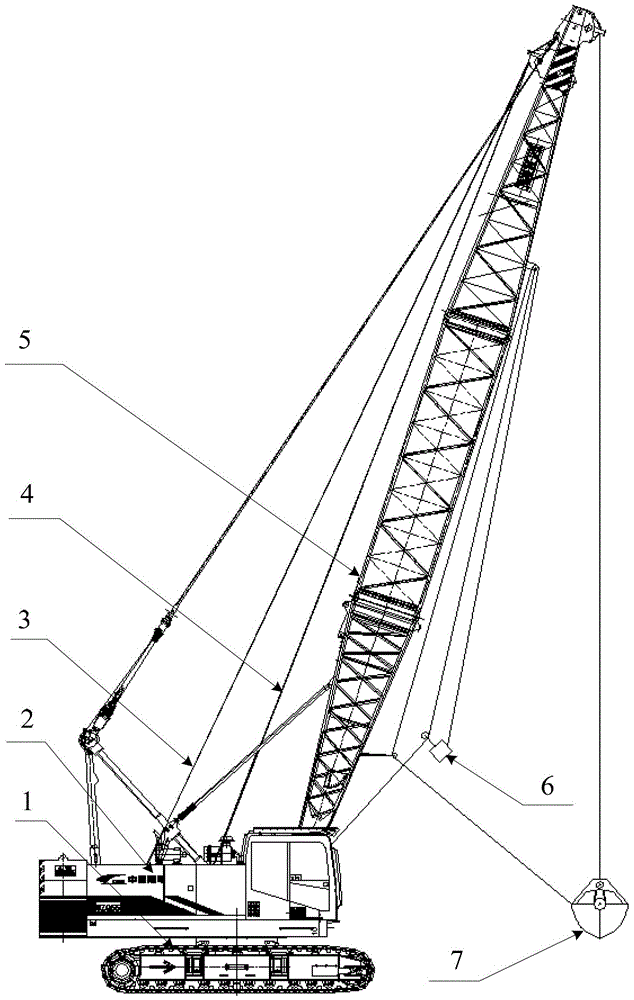

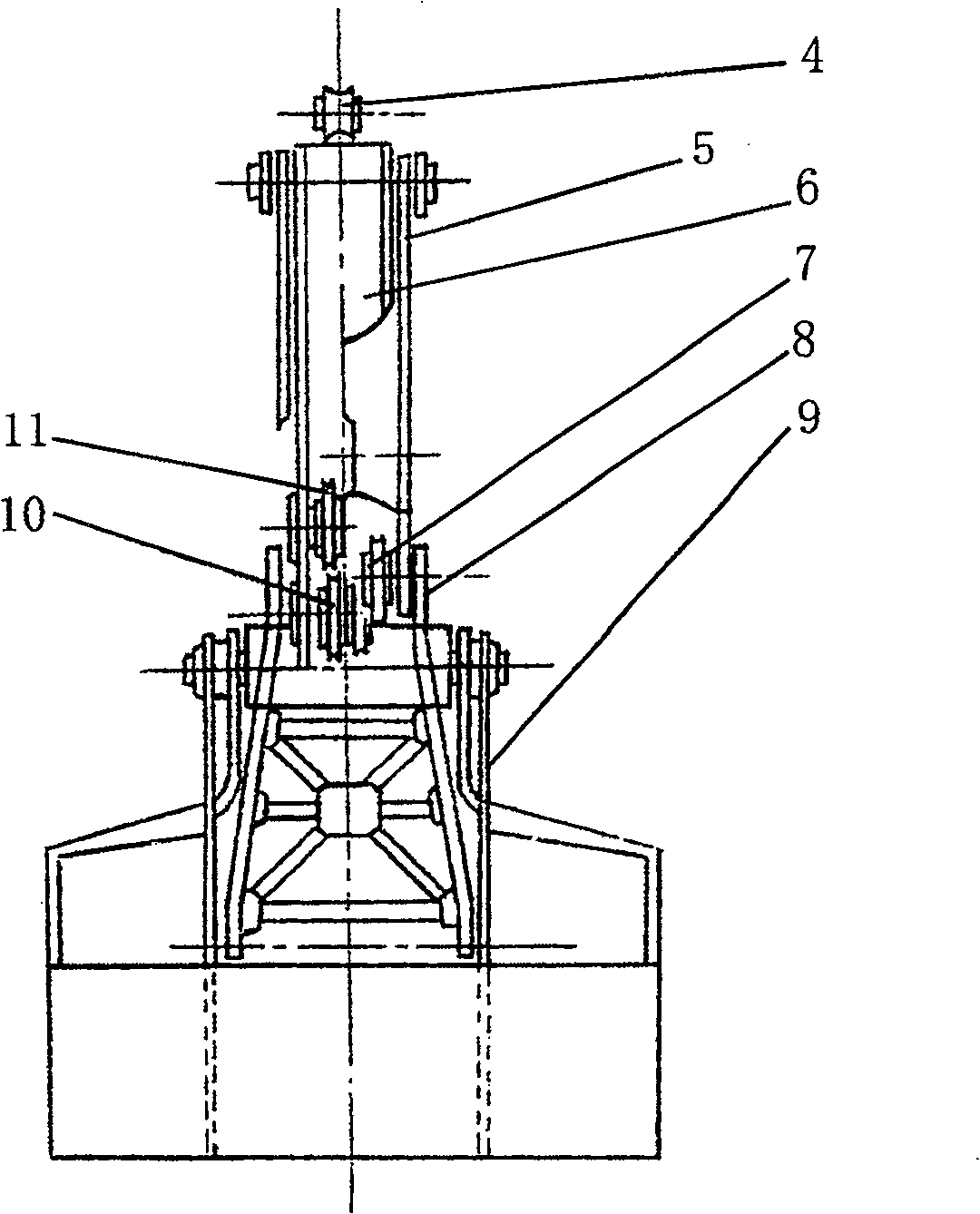

Deep-foundation grab crane

The invention discloses a deep-foundation grab crane. An entire truck adopts crawler hydraulic crane remounting design; the ground pressure is small; the stability is high; main winching and auxiliary winching are controlled by parallel-variable double-pump total power; main and auxiliary winching motors are controlled respectively, so that double winching synchronization is achieved; a grab bucket is lifted by the main winching; the auxiliary winching provides a bucket closing tension force; single-rope tension forces of the main winching and the auxiliary winching can reach 10T, so that the main winching and the auxiliary winching have the super high lifting capacity; a closing bucket adopts 4-multiplying-power pulley block design, thus a bucket closing force can reach 40T, so that the main winching and the auxiliary winching have the super high grabbing capacity; the grab bucket adopts a sliding block pulley block stabilizing device; and the deep-foundation grab crane is simple, practical and good in stability.

Owner:BEIJING CSR TIMES LOCOMOTIVE & ROLLING STOCK MECHANICS

Mechanical gripper

PendingCN108098806APrecise positioningGuaranteed stabilityGripping headsMechanical engineeringEngineering

Owner:CHANGAN UNIV

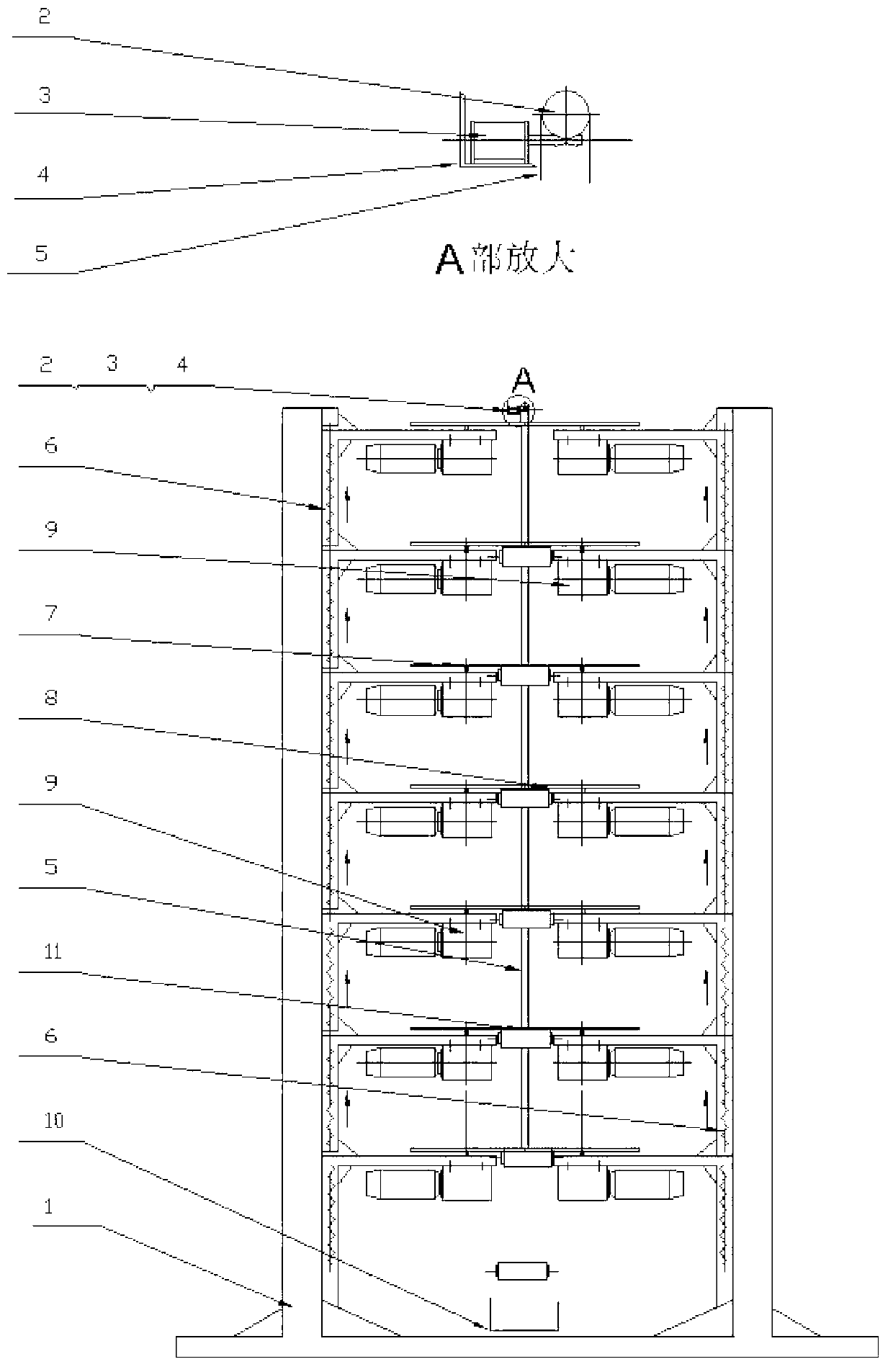

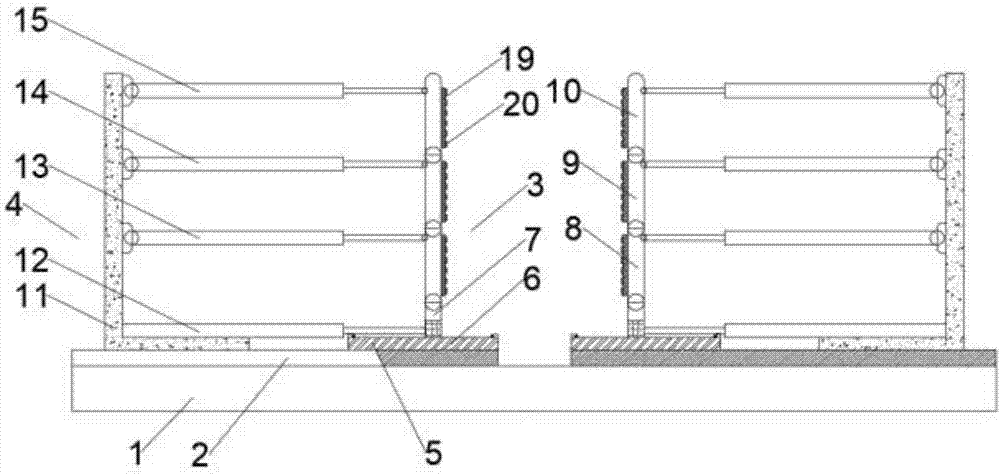

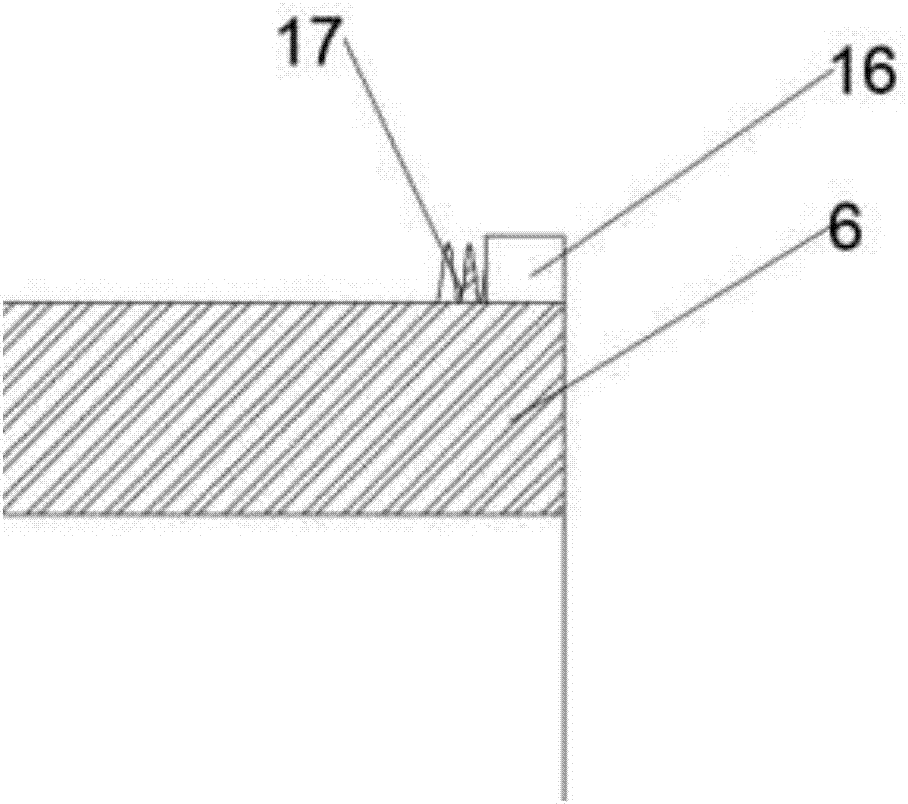

Self-generating household parking device

The invention discloses a self-generating household parking device, comprising a vertical pile, wherein the vertical pile comprises a fixed base, and the front and rear sides of the fixed base are provided with fixed piles; the opposite sides of the two fixed piles are provided with sliding slots, a sliding block is connected between the two sides of the inner surface of each sliding slot, and a rotating rod is fixedly connected between the opposite sides of the two sliding blocks. The invention relates to the technical field of parking devices and equipment. The household parking device occupies a small space, and two vehicles can be parked on one parking space, which greatly saves space, the voltage is low due to a self-generating system, and the control mode is simple and efficient; thedevice structure is simple, the cost is low, and re-planning circuit design is avoided, which brings convenience to a user; high safety, low failure rate and good social benefits are realized. Therefore, the self-generating household parking device is easy to promote among families, and is very suitable for application in underground garages with height limitation to ensure the safety of the surrounding environment during parking and meets safety requirements.

Owner:SHANDONG TRANSPORT VOCATIONAL COLLEGE

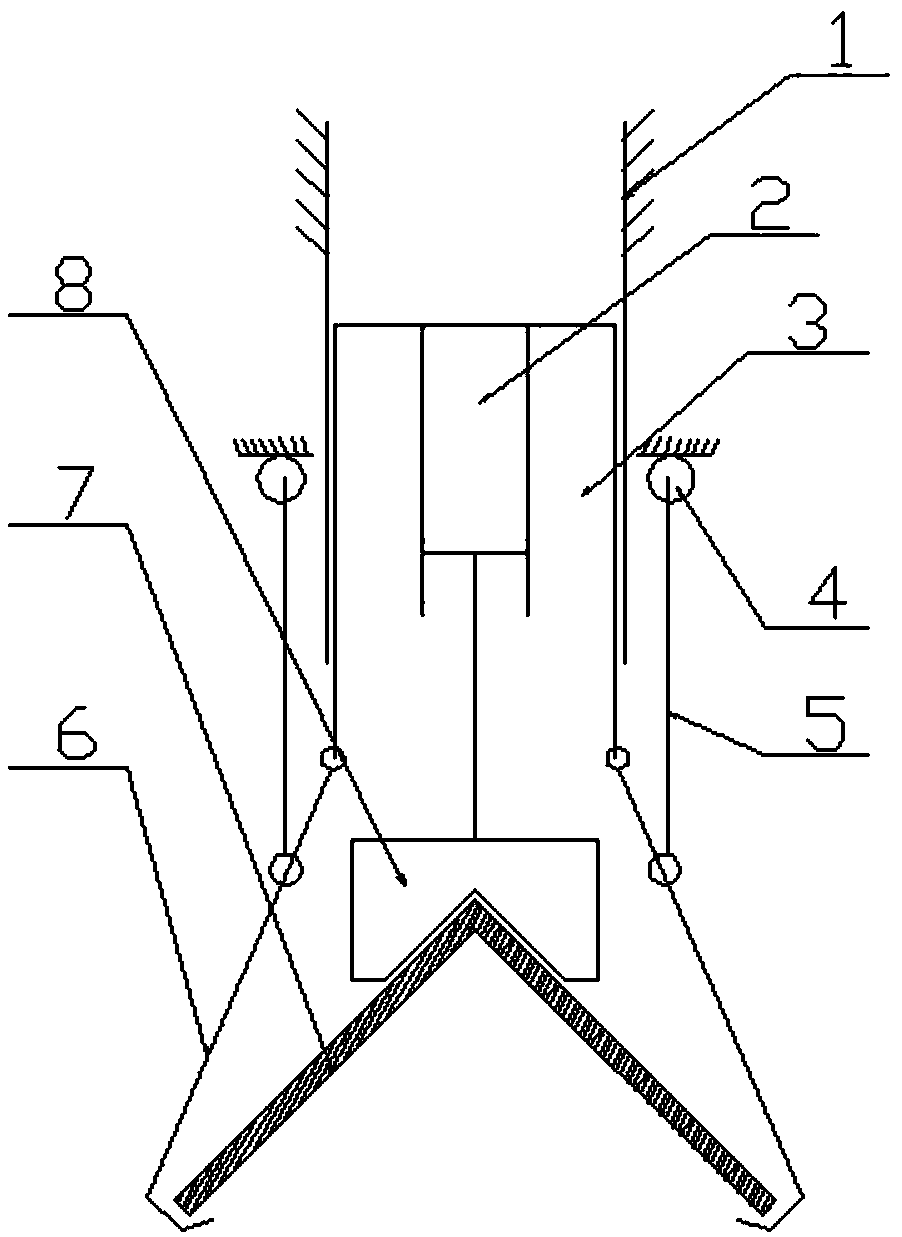

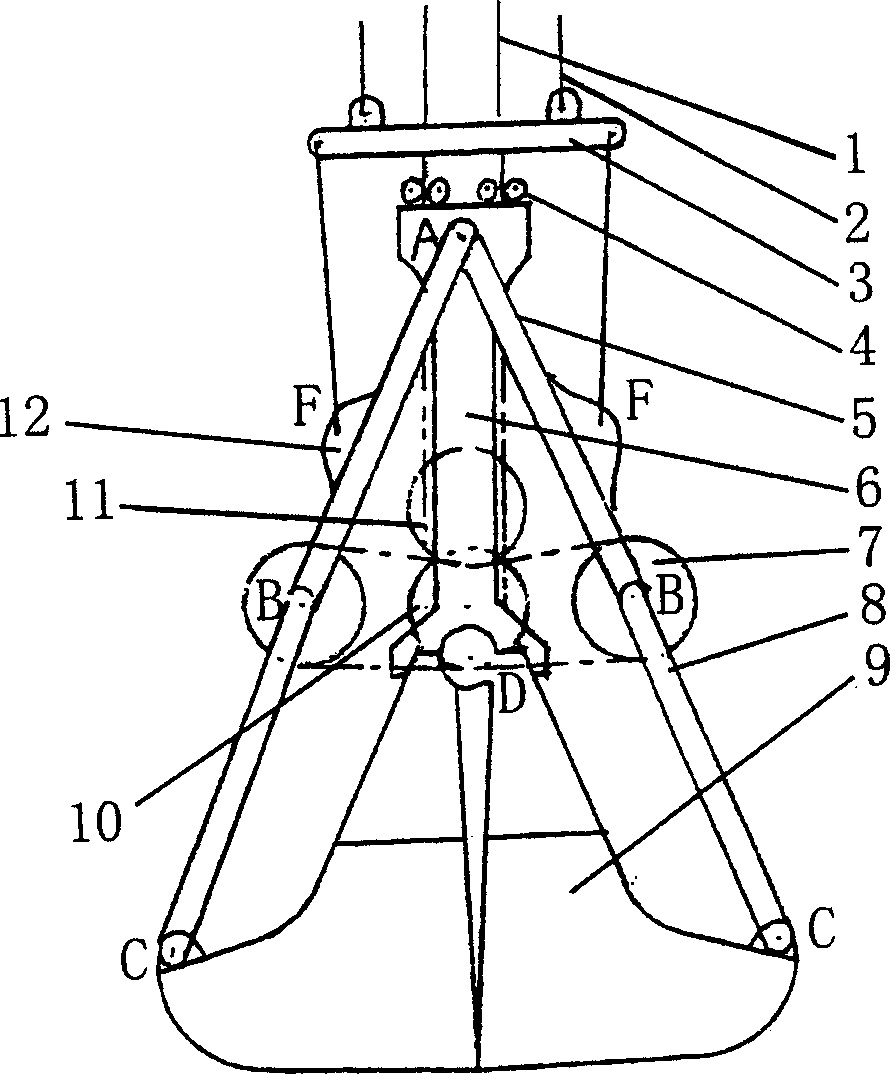

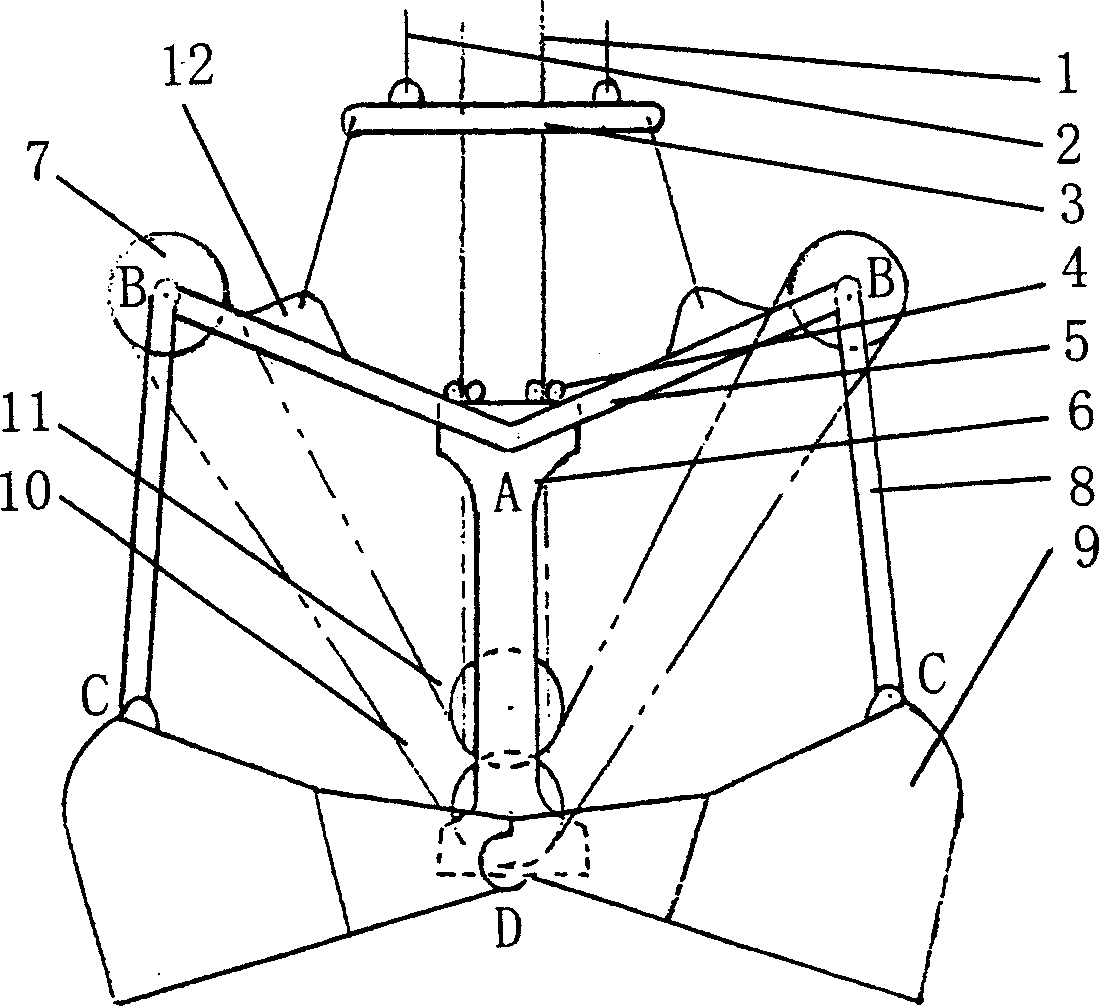

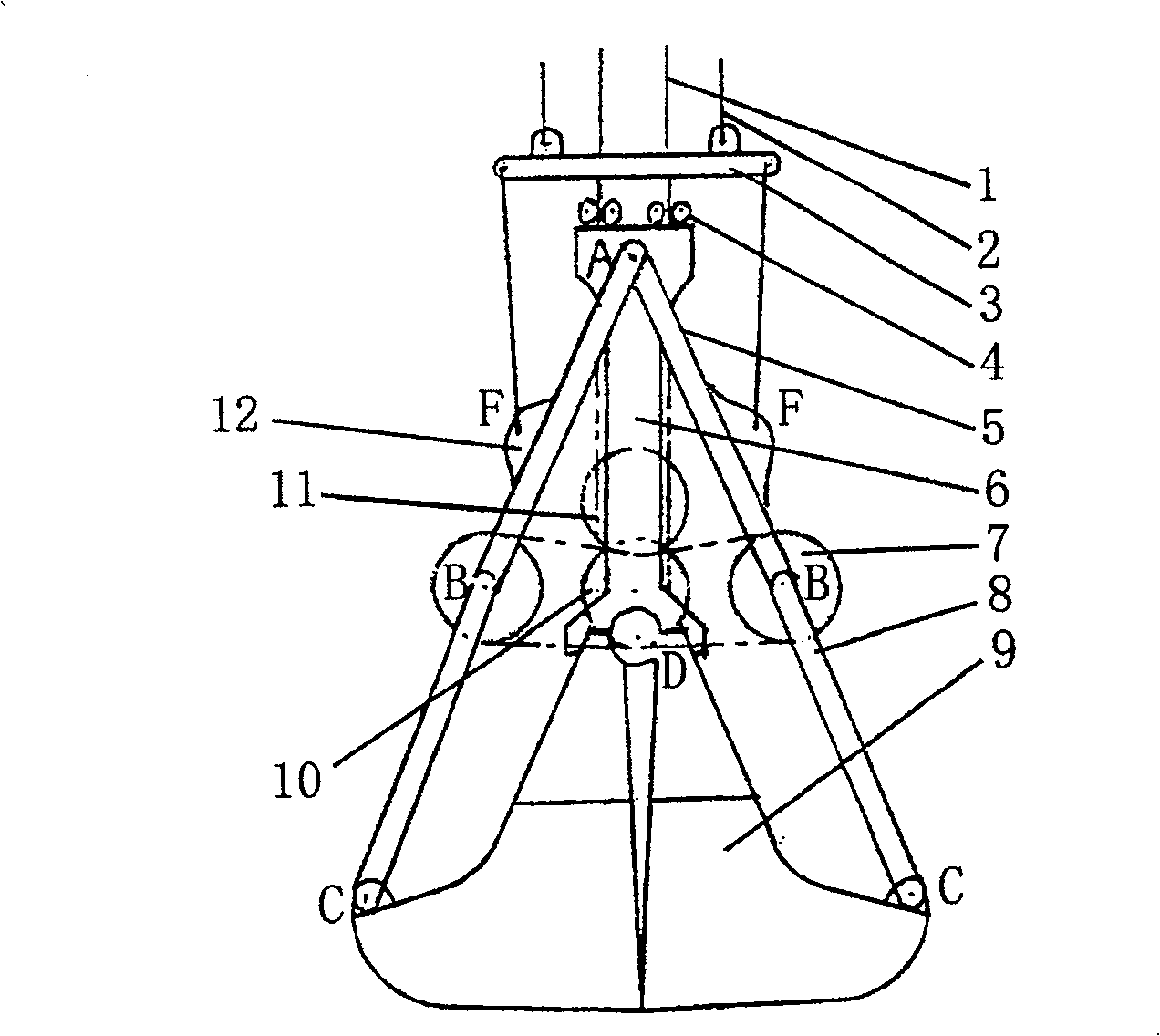

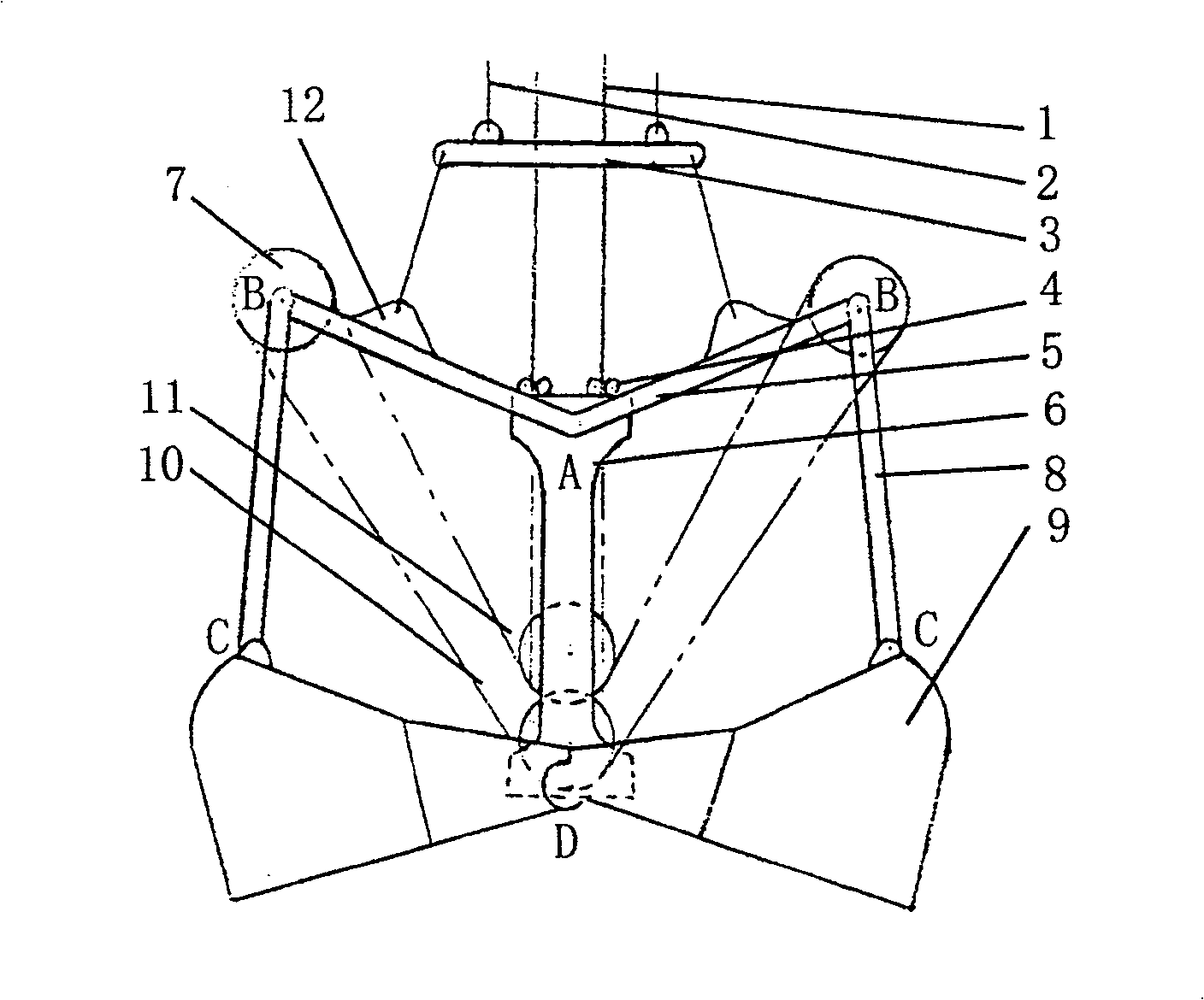

Short arm-tie type grab bucket

InactiveCN1850573ARealize opening and closingImprove gripLoad-engaging elementsStart stopEngineering

The invention is about a short brace grab bucket which includes the start-stop rope, the supporting rope, the supporting rope frame, the block rope wheel group, the bucket jaw plate, the centre sill hinged with the jaw plate and the two connected devices. The centre sill pulley block is set in the hinged point of the centre sill which is installed the centre sill guide wheel group. The up end of the left-right up supporting bars is hinged to the centre sill and the down end is connected to the left-right down supporting bars. The invention can change the grab ability by changing the times of the group pulley block, so it has the high grab ability but simple structure and long life.

Owner:胡开宸

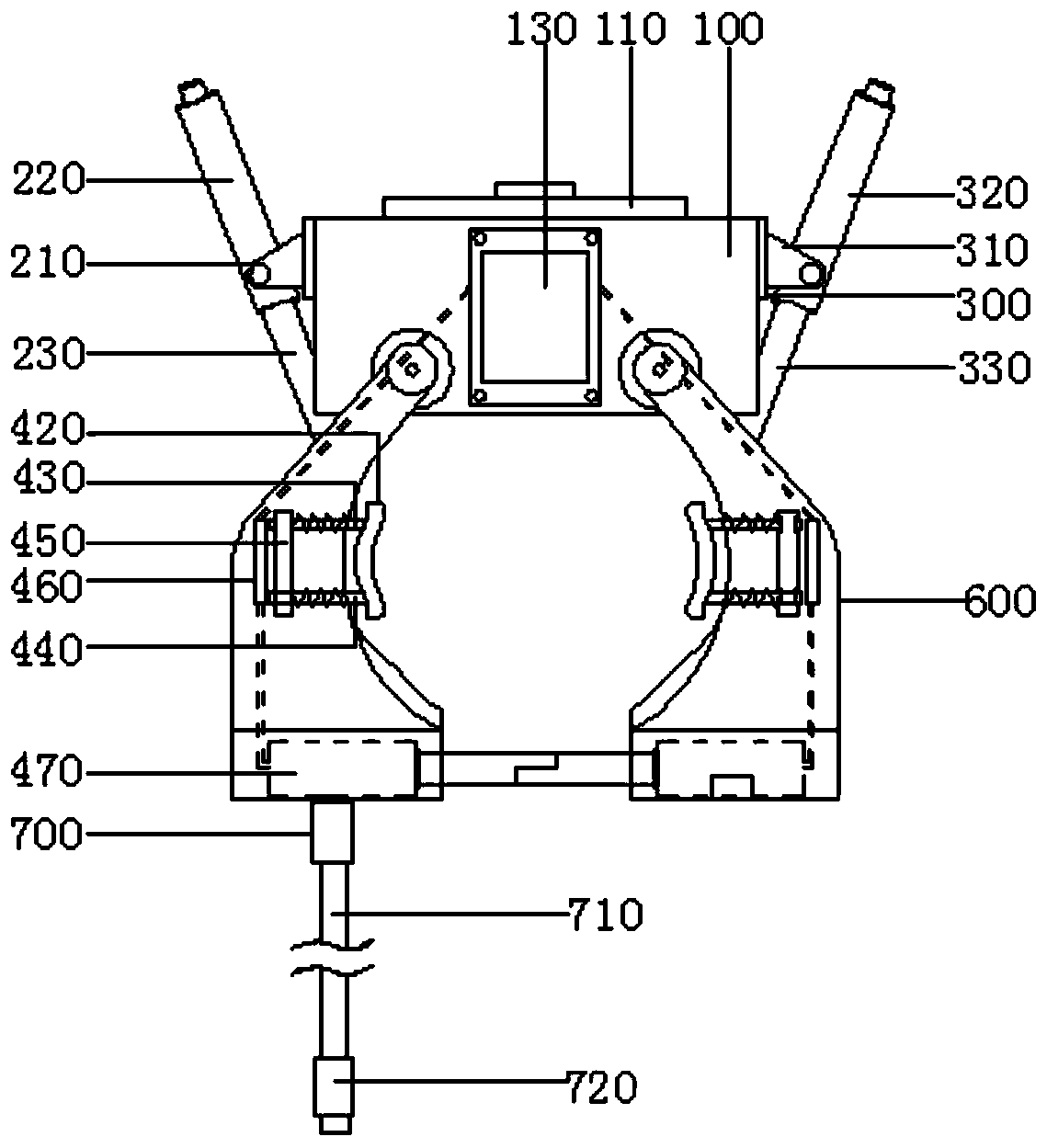

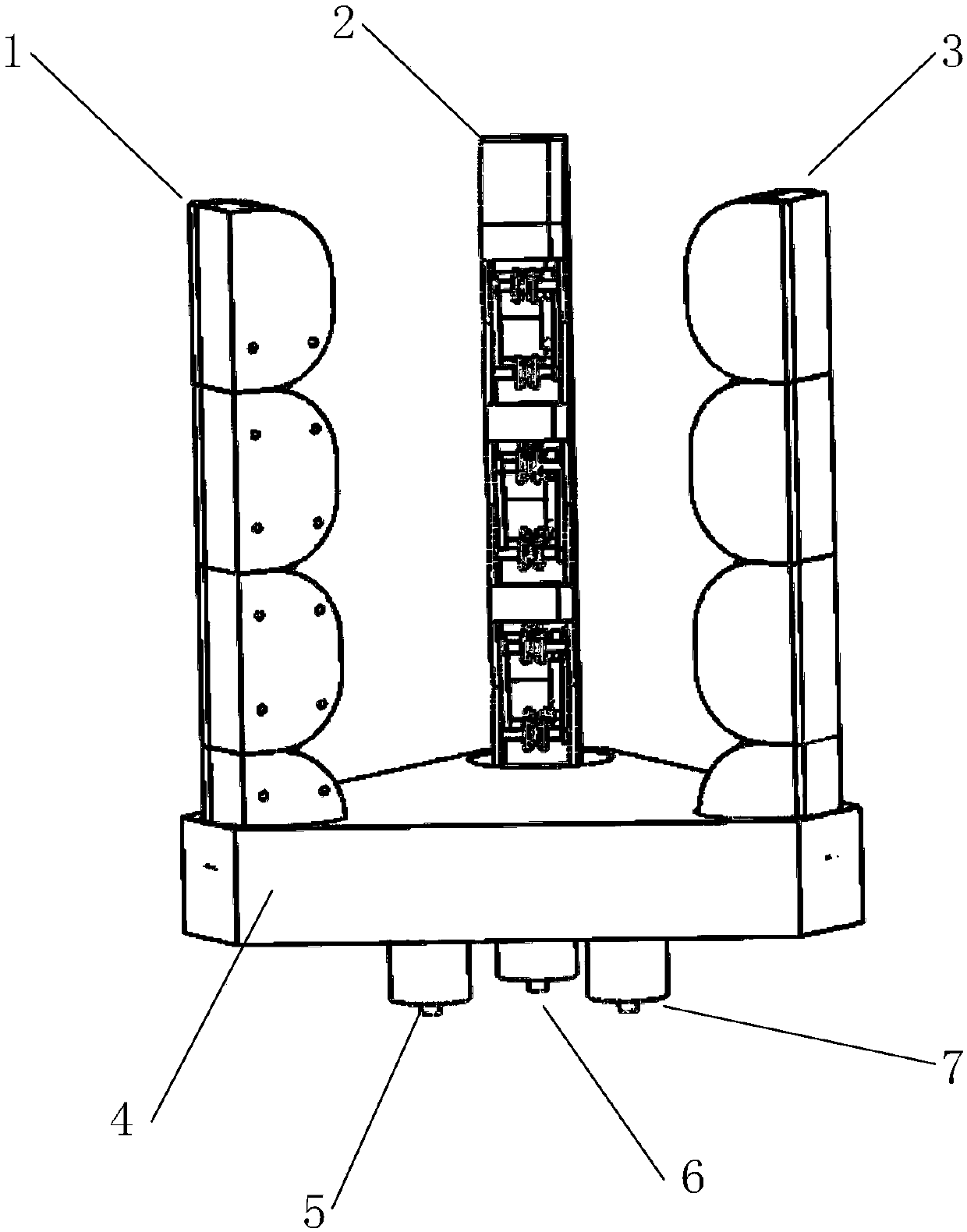

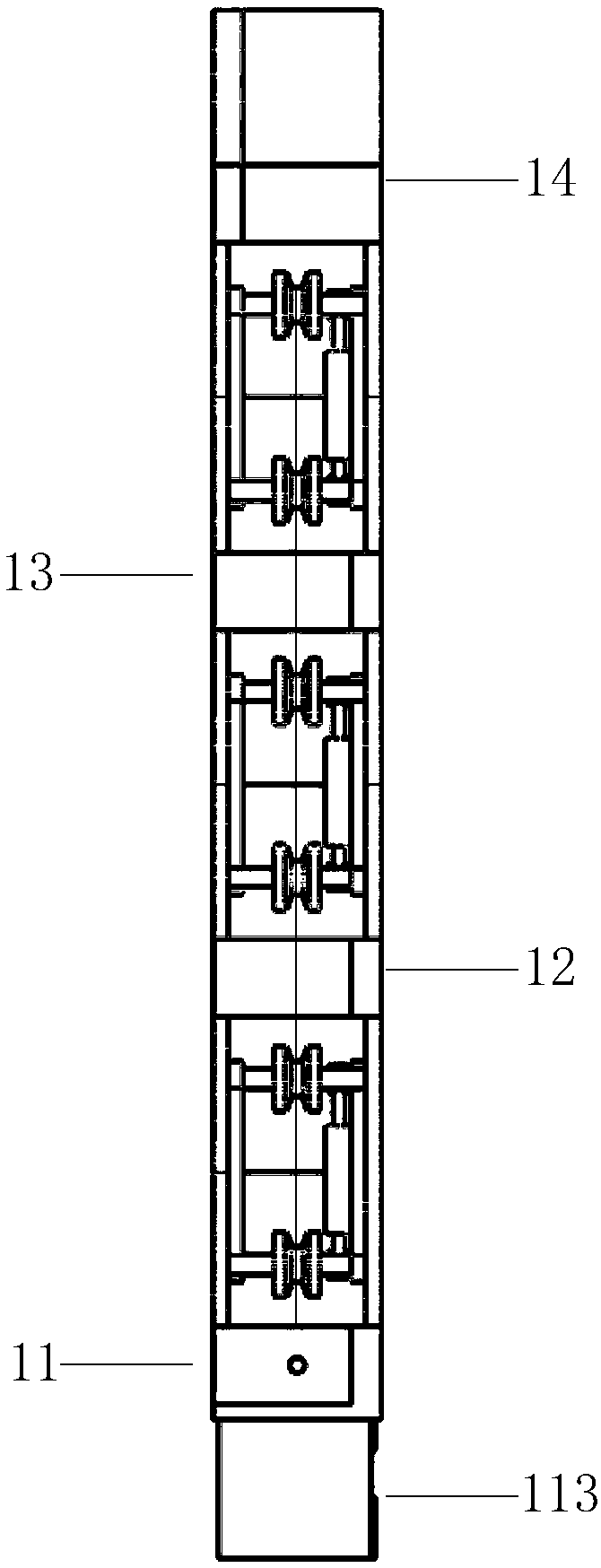

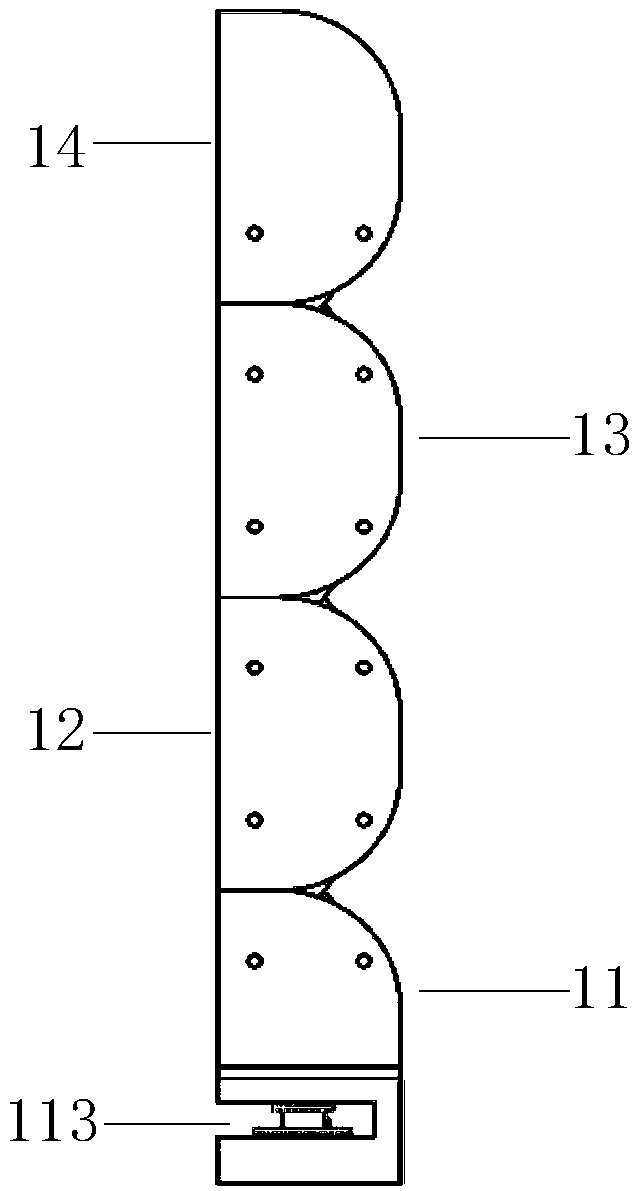

Mechanical claw for climbing tower and using method thereof

The invention discloses a mechanical claw for climbing a tower and a using method thereof. The mechanical claw comprises an upper rack, a lower rack, a thread lead screw and a deceleration motor capable of forwards and backwards rotating; the deceleration motor is fixed to the lower rack, one end of the thread lead screw is connected with the deceleration motor through a coupling, and the other end of the thread lead screw penetrates out of the upper rack; the mechanical claw further comprises a third connecting rod and a claw connecting rod; the claw connecting rod comprises a first claw connecting rod body and a second claw connecting rod body, the first claw connecting rod body is connected with the second claw connecting rod body in a hinged mode, and the upper end portion of the first claw connecting rod body is connected with the lower rack; the upper end portion of the third connecting rod is connected with the upper rack, and the lower end portion of the third connecting rod is connected with the hinged portion of the first claw connecting rod body and the second claw connecting rod body; and a hydraulic push rod and a jacking block are connected with the lower portion of the lower rack in sequence, and the hydraulic push rod is connected with a push rod motor. The problem that in the prior art, the mechanical claw for tower climbing operation is weak in grasping ability and poor in adaptability is solved. According to the mechanical claw for climbing the tower, multi-angle angle steel grasping is achieved, and adaptability is strong.

Owner:CHANGAN UNIV

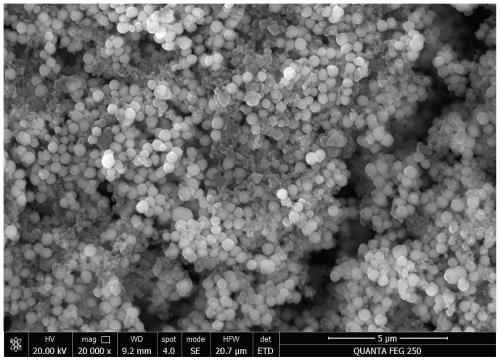

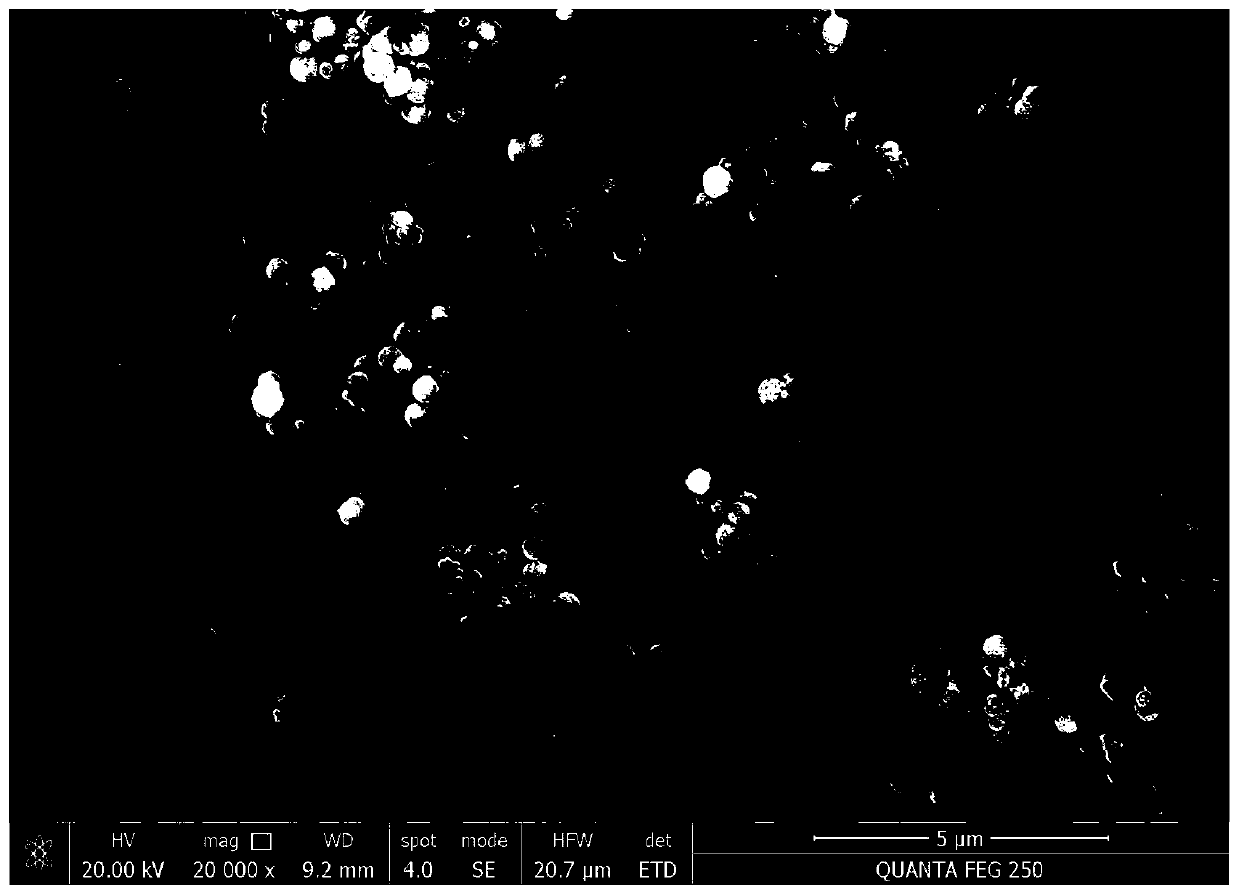

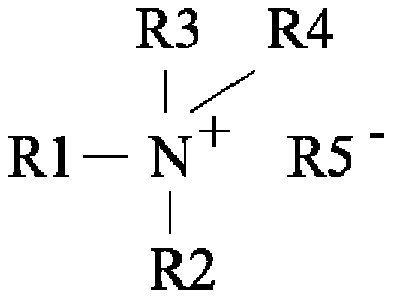

Preparation method of polyquaternium magnetic microsphere with core-shell structure

InactiveCN111116851AStrong grabbing abilityRealize continuous productionOther chemical processesAlkali metal oxides/hydroxidesMicrospherePhysical chemistry

The invention relates to a preparation method of polyquaternium magnetic microspheres with a core-shell structure, and the method comprises the following steps: dispersing seed microspheres in an organic solvent, adding a silane coupling agent under the condition of mechanical stirring, regulating the pH value to make the solution alkaline, and reacting to obtain double-bond-modified magnetic microspheres; dispersing the double-bond modified magnetic microspheres into an organic solvent, then adding a quaternary ammonium salt monomer, an initiator and a cross-linking agent, heating to 40-90 DEG C in a water bath, and reacting for 1-24 hours to obtain the quaternary ammonium salt modified magnetic microspheres. The quaternary ammonium salt has very strong adsorption capacity on biomacromolecules, and can be used for quickly separating the biomacromolecules, and the yield is more than 90%; the surface of the polyquaternium magnetic microspheres is rich in quaternary ammonium salt, so that the polyquaternium magnetic microspheres have strong adsorption capacity to biomacromolecules and are high in separation yield. The prepared microspheres are especially suitable for automatic separation and extraction of the biomacromolecules.

Owner:SUZHOU WEIDU BIOTECH CO LTD

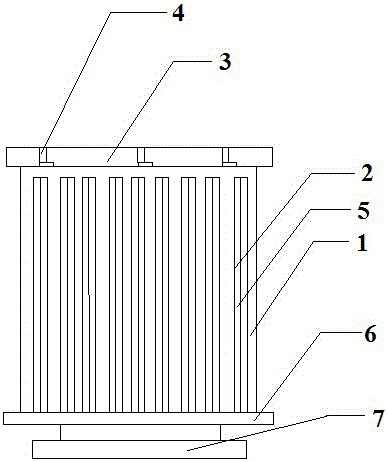

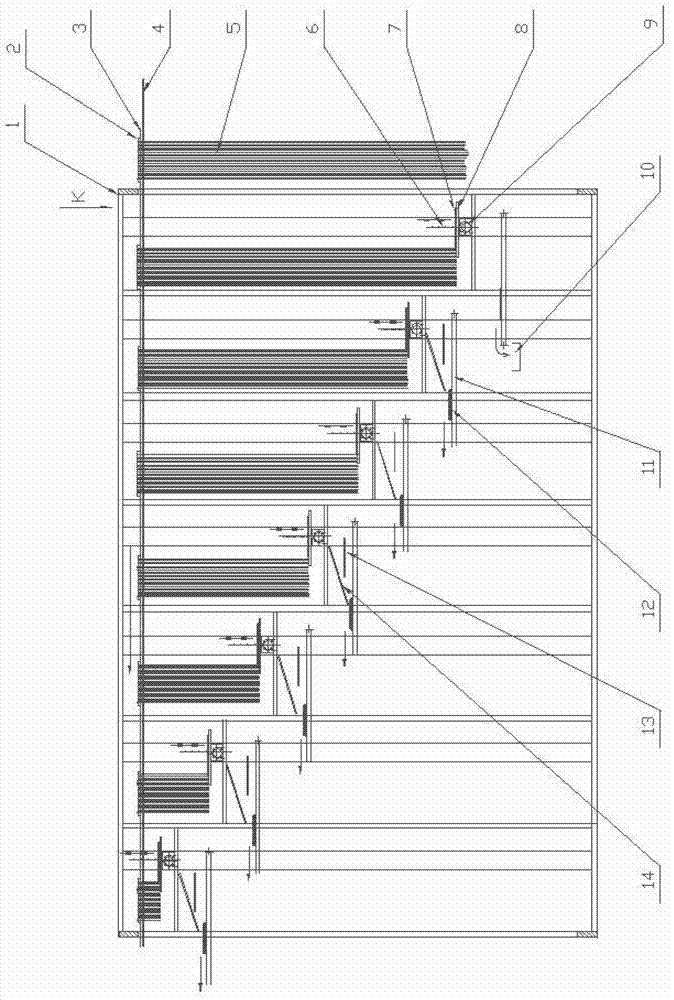

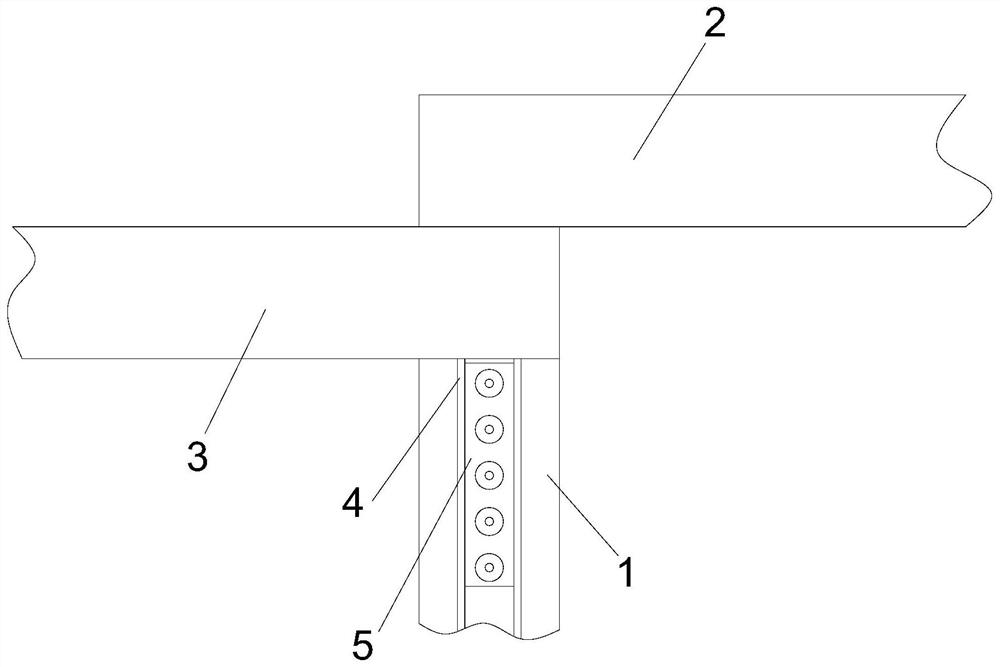

Totally-enclosed transformer fuel tank shell

InactiveCN106024313AStrong grabbing abilityImprove gripTransformers/inductances coolingTransformers/inductances casingsTransformerFuel tank

The invention discloses a totally-enclosed transformer fuel tank shell, and relates to the technical field of power supply equipment. The totally-enclosed transformer fuel tank shell comprises a body (1), a rotary valve (2), a connecting rod (3), a spray head (4), a material placing plate (5), a baffle plate (6), a water outlet hole (7), an upper cabinet door (8), an upper handle (9), a control cabinet (10), a water outlet (11), a lifting frame (12), a controller (13) and a lower handle (14). The totally-enclosed transformer fuel tank shell provided by the invention overcomes many drawbacks of the conventionalfuel tank shell formed by welding a steel plate; and the grasping capability of an L-shaped hanging hook is higher and more stable.

Owner:常熟市东方特种金属材料厂

Vertical cutting-off machine of fine dried noodles

InactiveCN102986764BEasy to adjustHigh degree of automationDough shapingProduction lineMechanization

The invention discloses a vertical cutting-off machine of fine dried noodles, relating to a fine dried noodle machine, and in particular relates to a mechanical device for cutting dried fine dried noodles into fine dried noodle sections with required certain length in a production process of the fine dried noodles. The machine comprises a stand, fine dried noodle cutting-off devices arranged on the stand, cut fine dried noodle conveying belts and a fine dried noodle rod conveying mechanism guide rail, wherein more than two groups of fine dried noodle cutting-off devices comprising left rotating cutters, right rotating cutters and rotating cutter drive mechanisms are arranged on the frame-shaped stand, each group of left rotating cutter and right rotary cutter is matched to form a pair of fine dried noodle cutter consists of a left rotating cutter and a right rotary cutter which are matched with each other, all groups of fine dried noodle cutting-off devices are arranged at different heights on the stand according to the demand, the cut fine dried noodle conveying belt is arranged below each group of fine dried noodle cutting-off device, the fine dried noodle rod conveying mechanism guide rail is arranged on the top of the stand, fine dried noodles to be cut off enter the vertical cutting-off machine in a vertical state to be cut off. The rotating speed of the rotary cutters is 30-60 rpm. The machine has the advantages that the cut fine dried noodles are uniform, the length of the cut fine dried noodle sections is regulated flexibly and conveniently, and the cut fine dried noodles directly enters a fine dried noodle metering device and fine dried noodle rods completing the cutting off can be directly sent to a fine dried noodle rod bin of a fine dried noodle cutting unit of a fine dried noodle production line; after applied to the fine dried production line, the machine can improve the mechanization and automation level of the fine dried noodle production line.

Owner:山东江泷机械有限公司

Grab Body and Diaphragm Wall Hydraulic Grab

ActiveCN103422523BProtection from being brokenAdd depthSoil-shifting machines/dredgersEngineeringCivil engineering

Owner:XCMG CONSTR MACHINERY

A Deep Foundation Grab Crane

The invention discloses a deep-foundation grab crane. An entire truck adopts crawler hydraulic crane remounting design; the ground pressure is small; the stability is high; main winching and auxiliary winching are controlled by parallel-variable double-pump total power; main and auxiliary winching motors are controlled respectively, so that double winching synchronization is achieved; a grab bucket is lifted by the main winching; the auxiliary winching provides a bucket closing tension force; single-rope tension forces of the main winching and the auxiliary winching can reach 10T, so that the main winching and the auxiliary winching have the super high lifting capacity; a closing bucket adopts 4-multiplying-power pulley block design, thus a bucket closing force can reach 40T, so that the main winching and the auxiliary winching have the super high grabbing capacity; the grab bucket adopts a sliding block pulley block stabilizing device; and the deep-foundation grab crane is simple, practical and good in stability.

Owner:BEIJING CSR TIMES LOCOMOTIVE & ROLLING STOCK MECHANICS

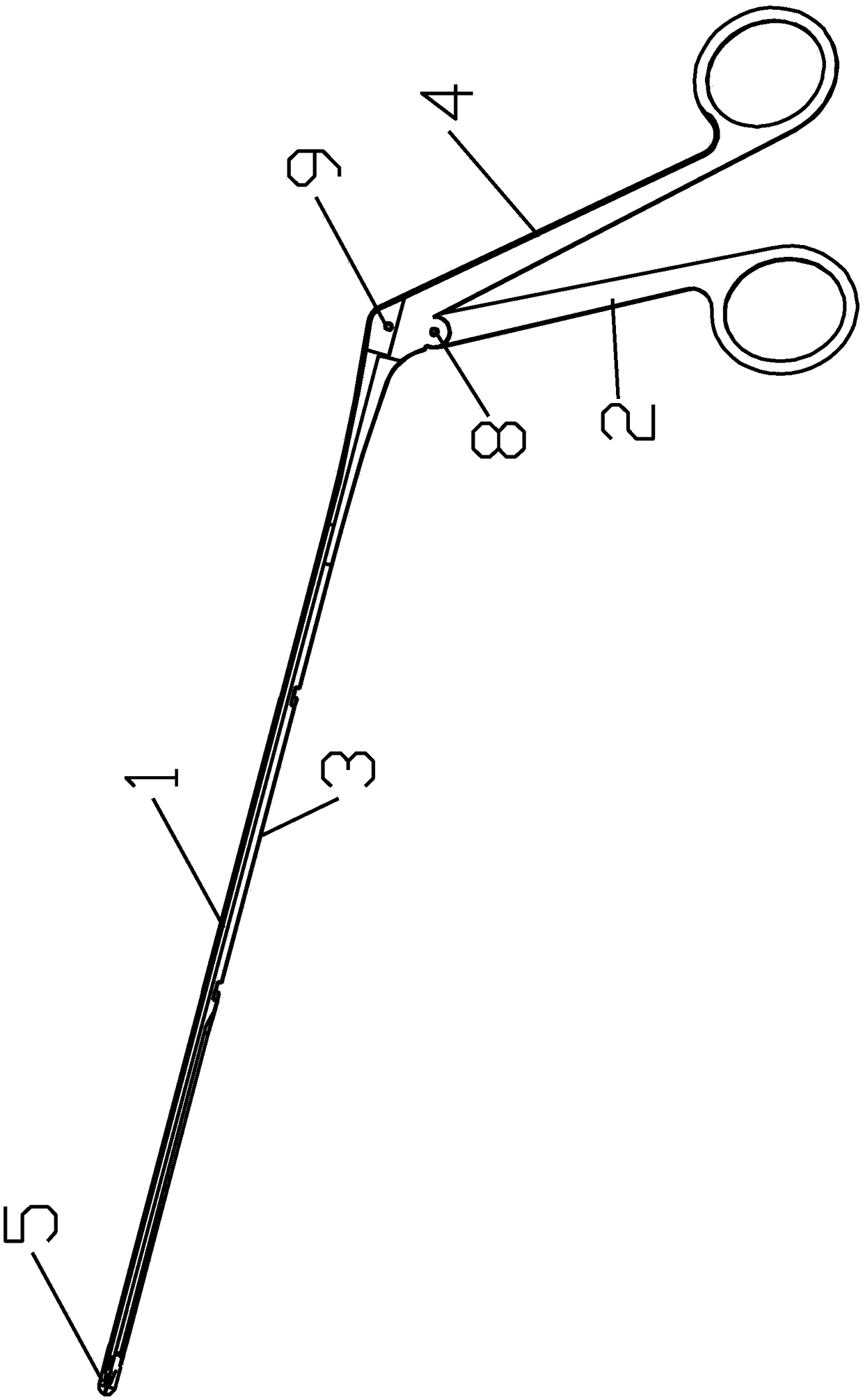

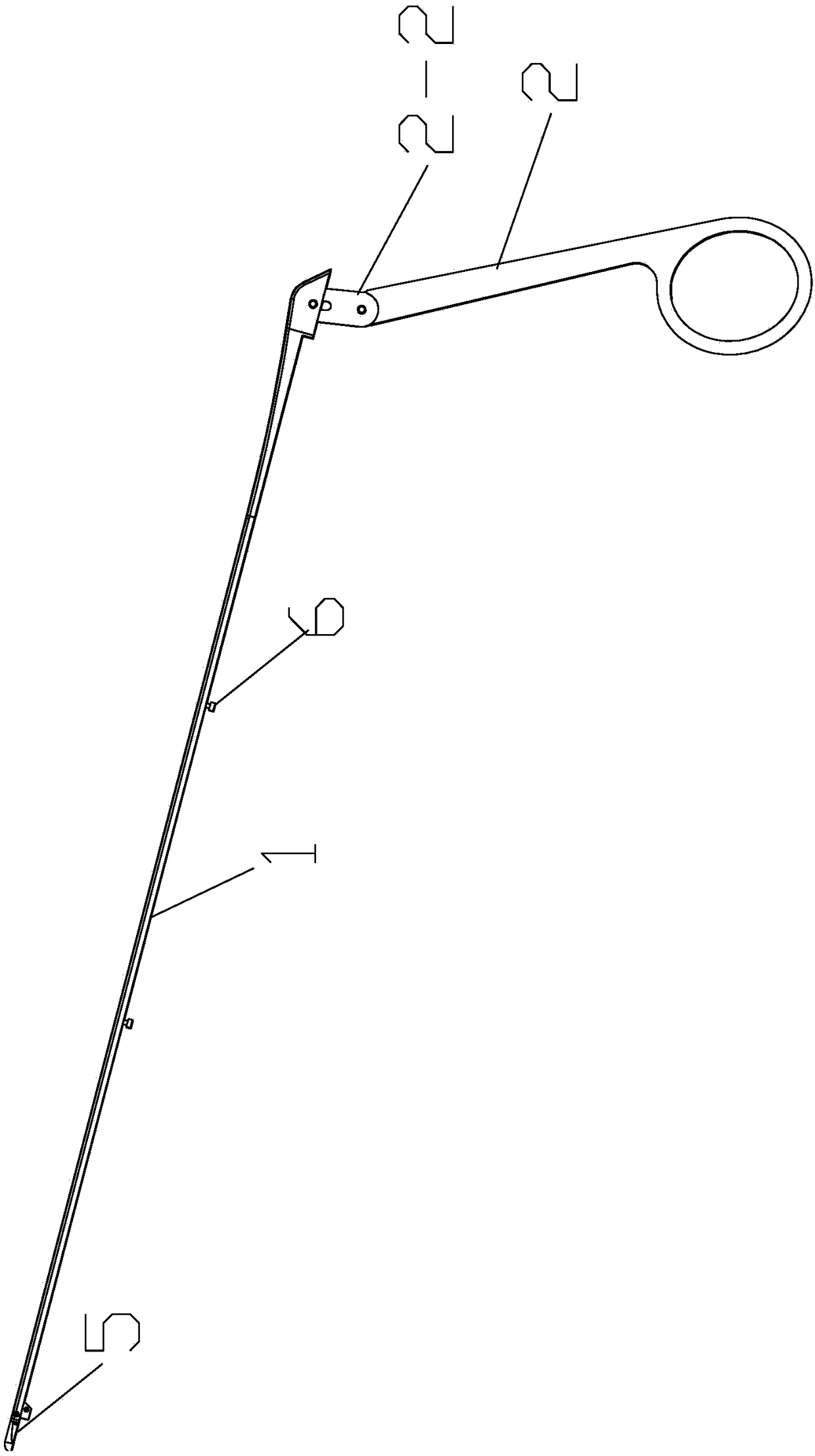

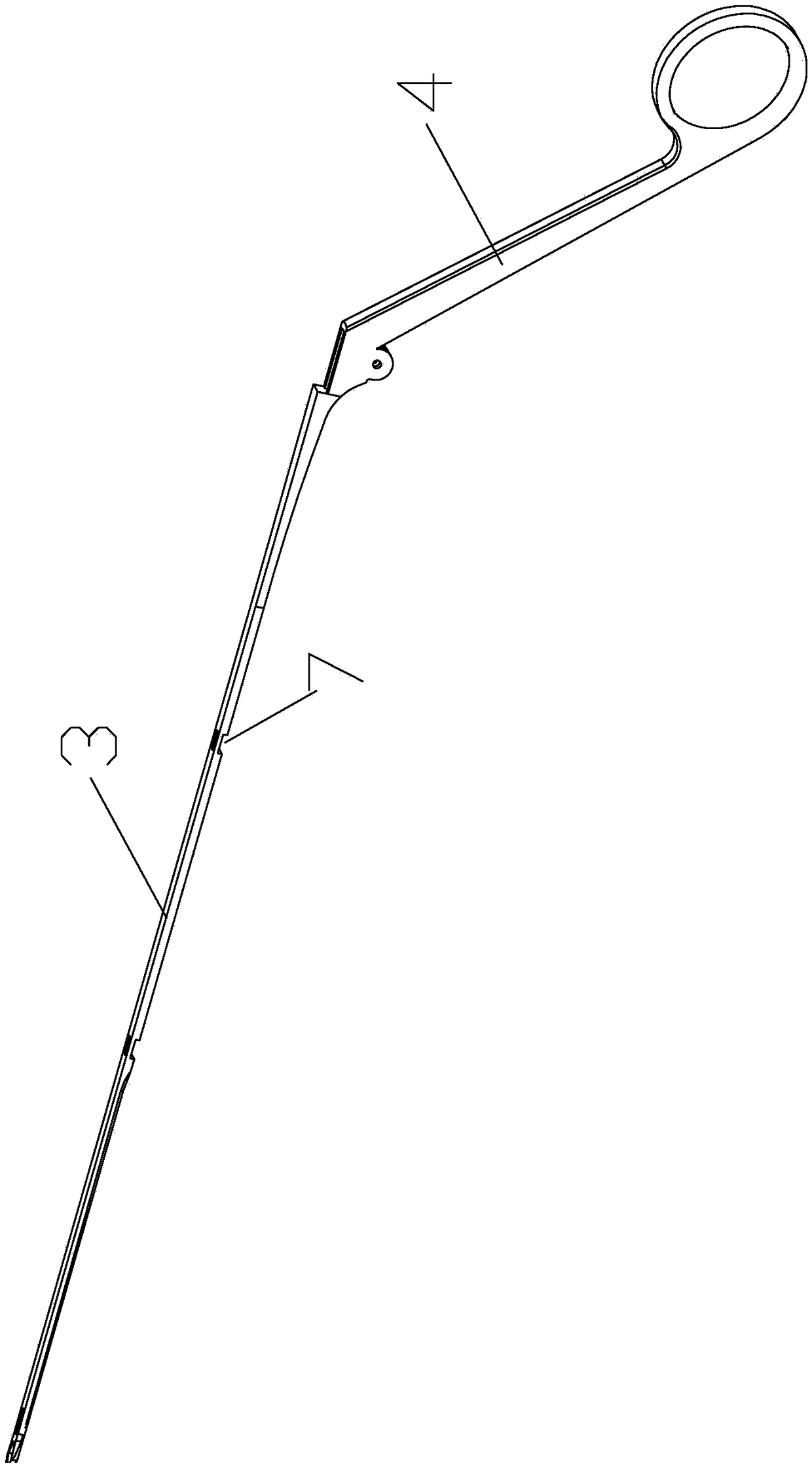

Gun-shaped sampling tongs

PendingCN108245201AStrong grabbing abilityLarge sampling volumeSurgeryVaccination/ovulation diagnosticsEngineering

The invention belongs to the technical field of medical apparatuses, and particularly relates to gun-shaped sampling tongs. The gun-shaped sampling tongs comprise a gun-shaped movable part and a gun-shaped fixed part, the movable part comprises a first tongs rod and a first handle, the fixed part comprises a second tongs rod and a second handle, the first handle penetrates through the second handle to be pivoted to the first tongs rod, the first handle and the second handle form an angle, the first tongs rod is parallel to the second tongs rod, the end of the first tongs rod is a sampling end,a jaw sheet is arranged at the sampling end and is pivoted to the first tongs rod and the second tongs rod separately, and when the angle between the first handle and the second handle is adjusted, the first handle pulls the first tongs rod, and then the pivoting part of the jaw sheet and the second tongs rod achieves shaft rotation to open the sampling end. The gun-shaped sampling tongs are highin grasping capability and flexible to use.

Owner:TRAUSON CHINA MEDICAL INSTR COMPANY

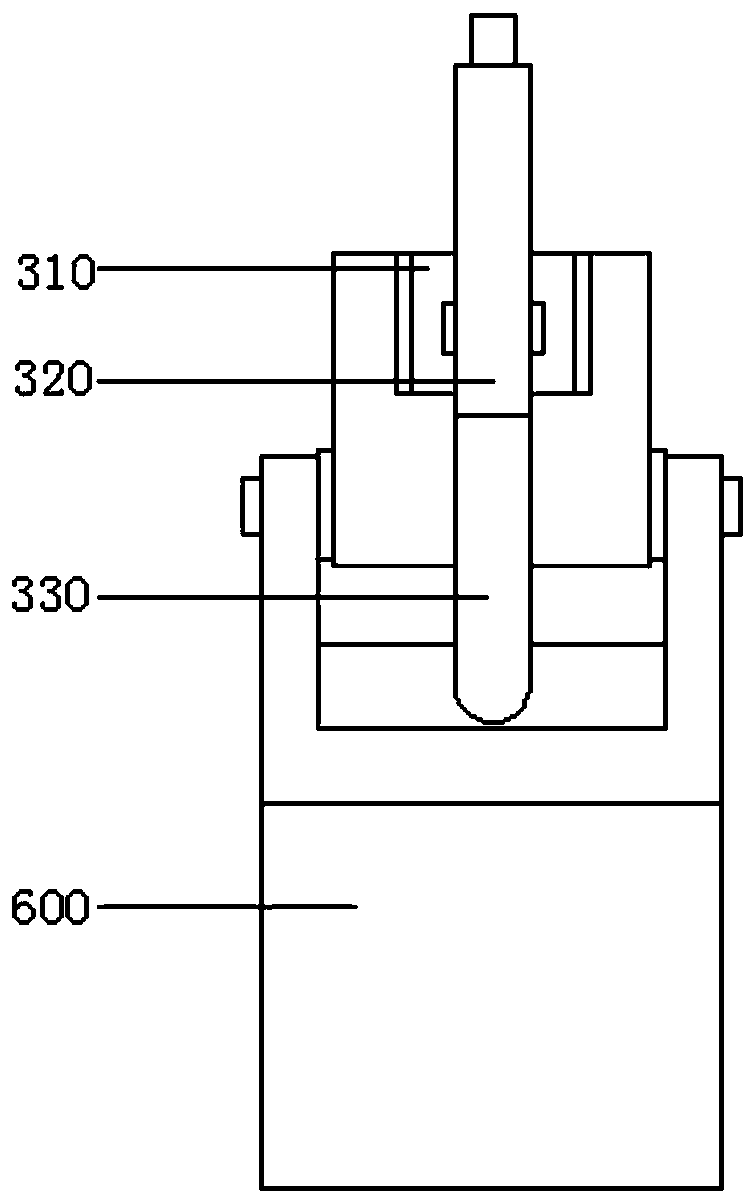

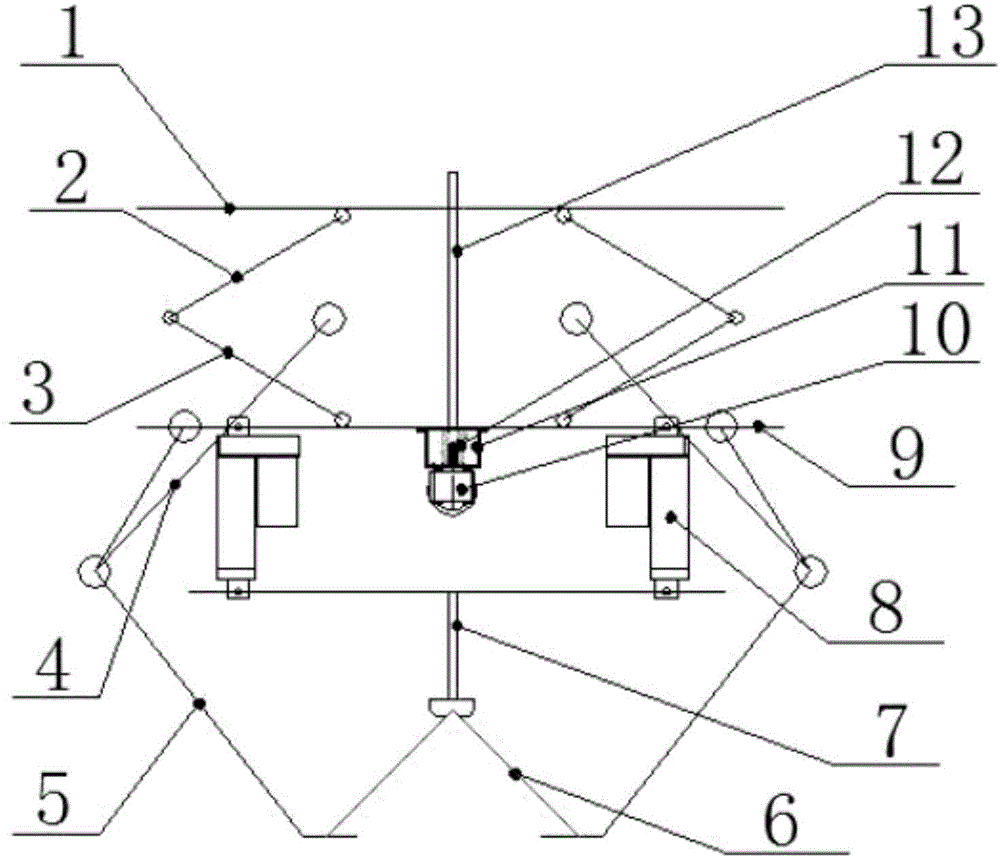

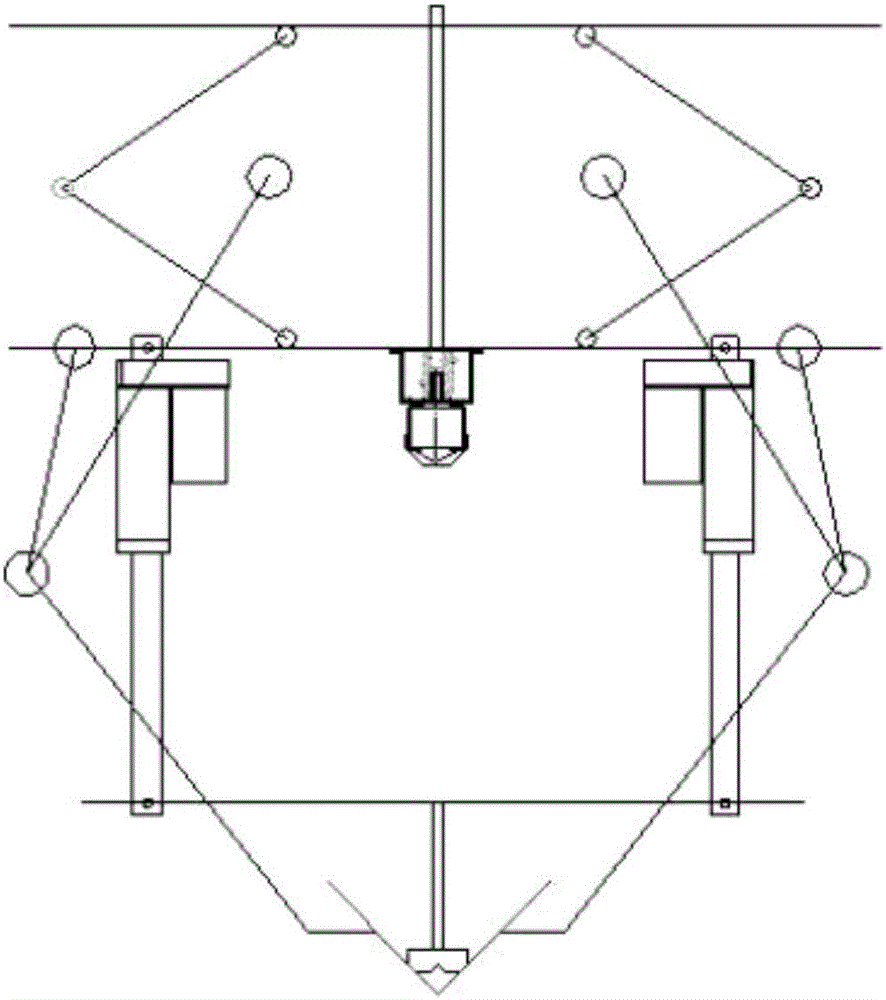

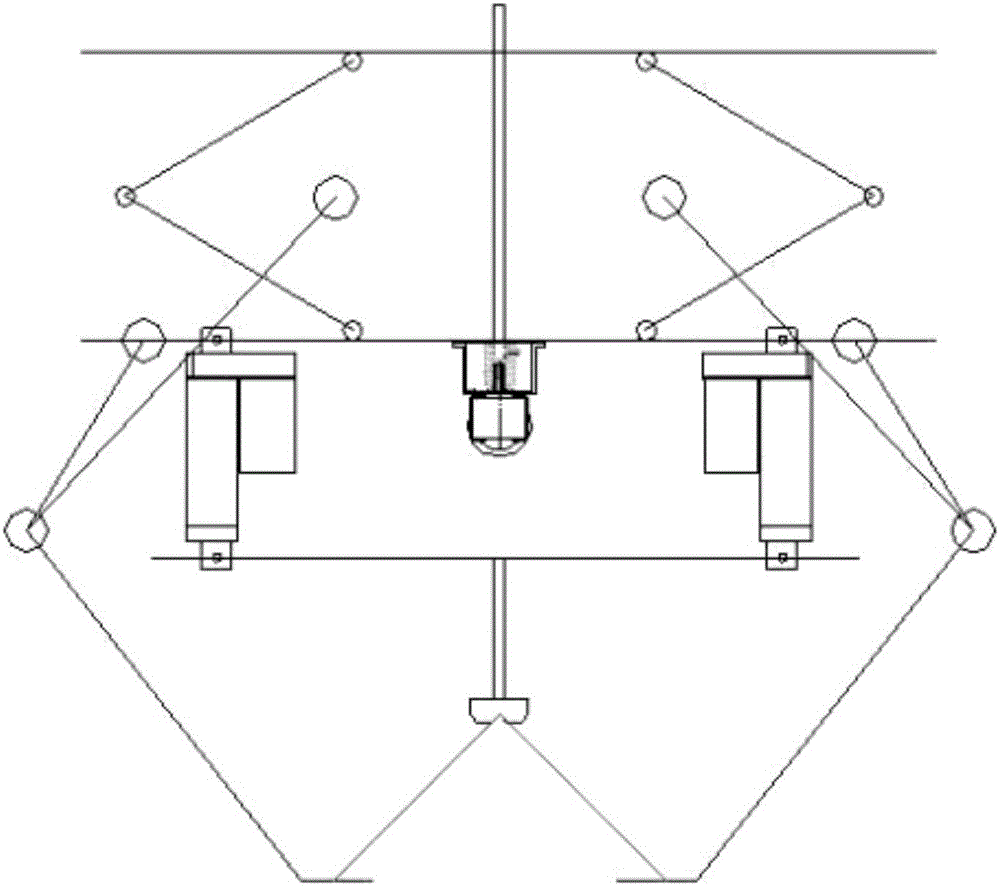

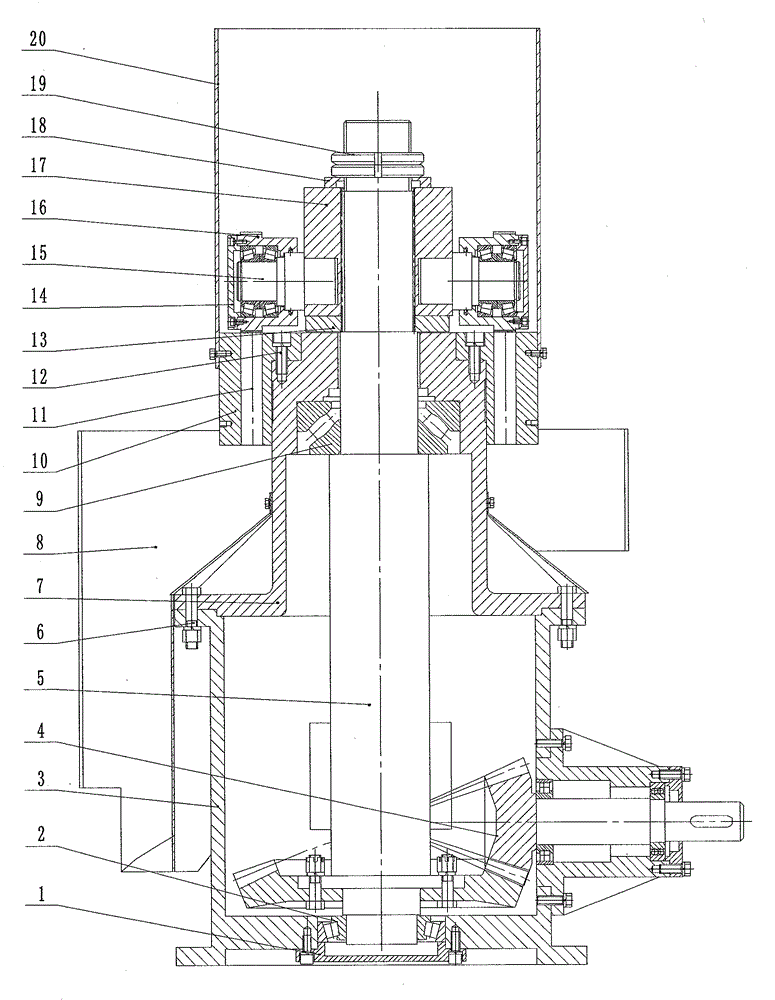

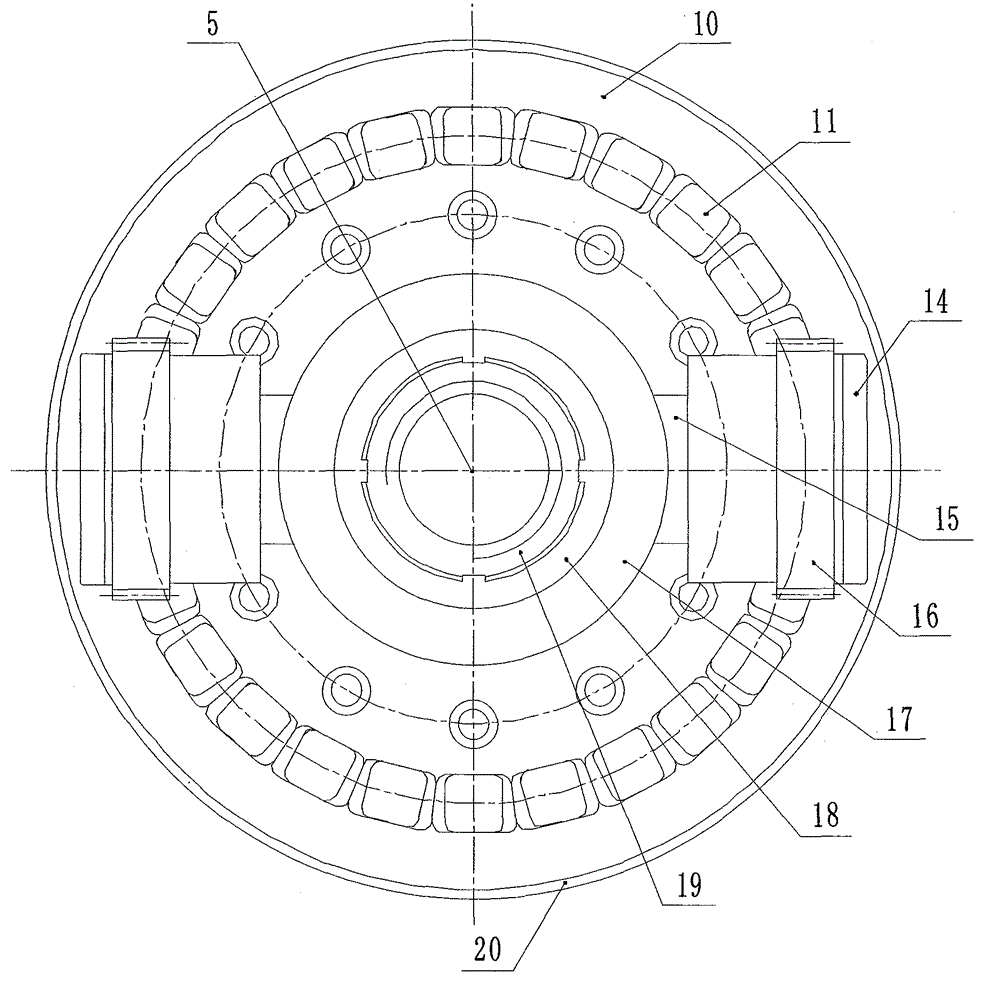

A robot's high-precision grasping mechanism

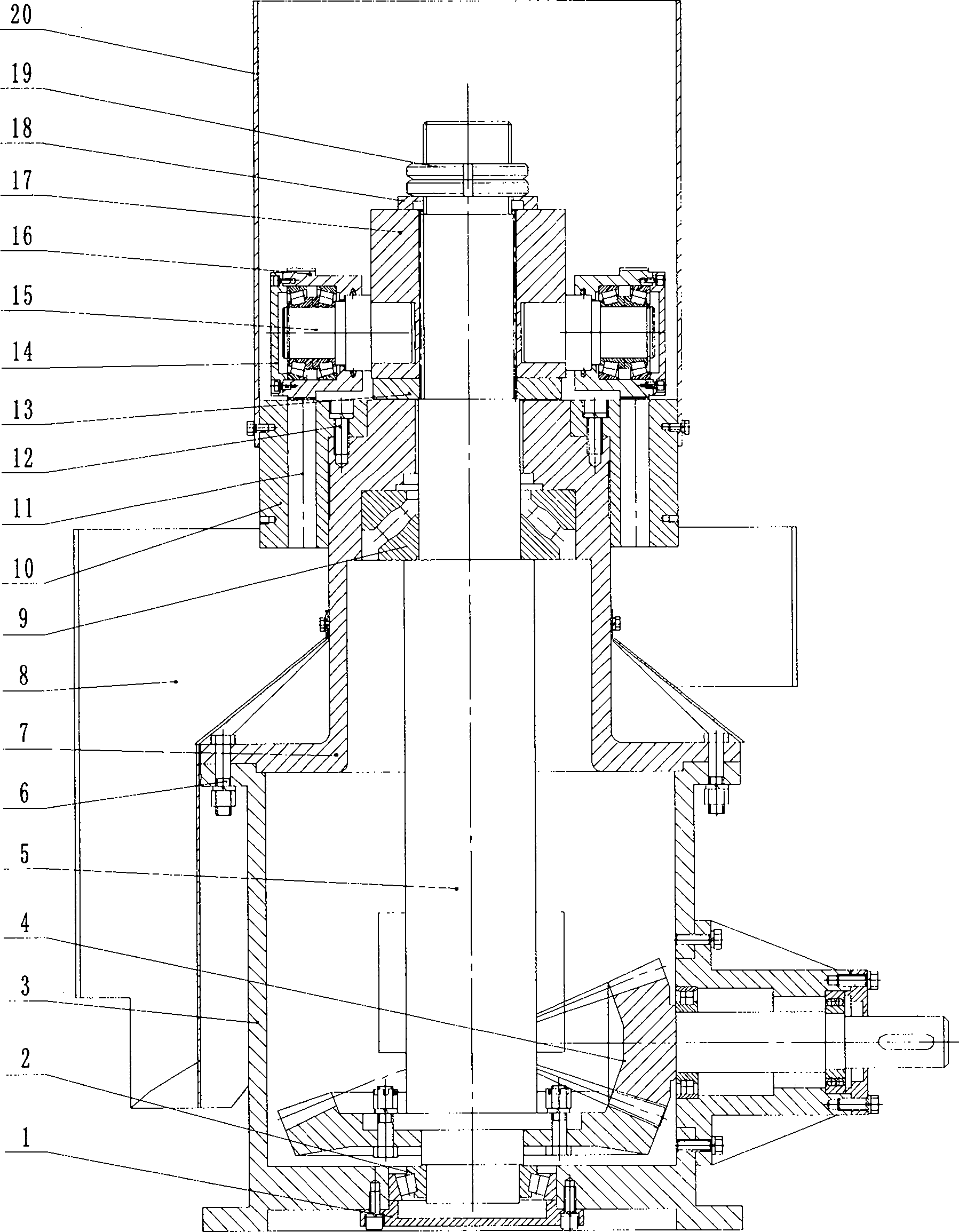

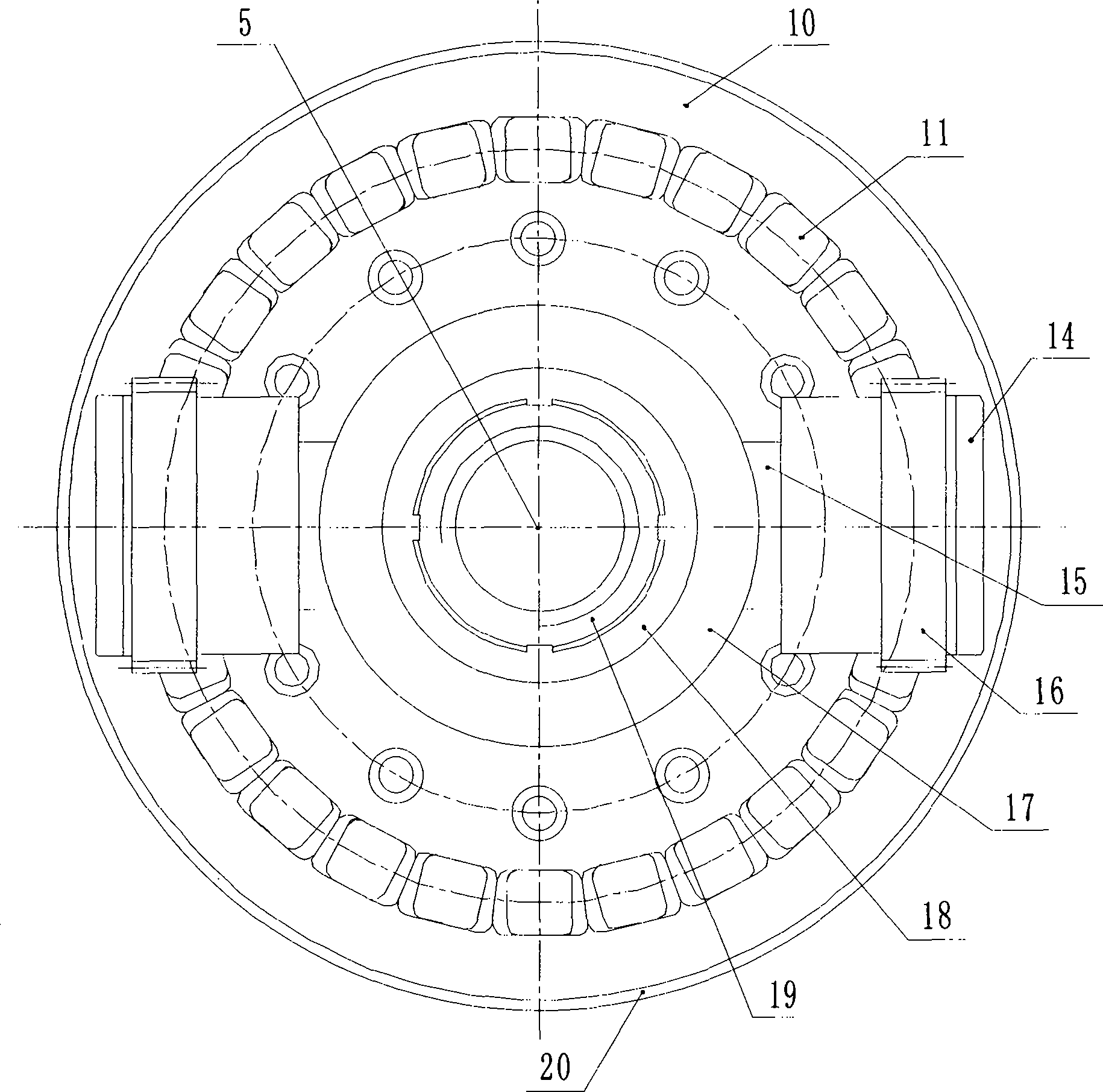

ActiveCN107322619BStrong grabbing abilityGood grabbing effectGripping headsControl engineeringStructural engineering

The invention discloses a high-precision grasping mechanism of a robot, which includes a grasping base, the grasping base is a circular structure, and at least three sub-bases are arranged on the grasping base, and the The sub-bases are arranged at equal intervals around the center of the grabbing base, and the sub-bases are arranged along the axial direction of the grabbing base. The sub-bases are provided with a clamping device and a driving device. The clamping device It includes a guide rail, the guide rail is fixed on the sub-base, and the guide rail is provided with a sliding seat, the slide seat is provided with a clamping seat, and the clamping seat is hinged with a first clamping arm through a hinge, The first clamping arm is hinged to a second clamping arm, and the second clamping arm is hinged to a third clamping arm, which has strong versatility and good gripping effect, and can grasp workpieces with flat surfaces. It has a strong grasping ability, and has a strong grasping ability for workpieces with curved surfaces, and can grasp workpieces with different surfaces.

Owner:ANHUI POLYTECHNIC UNIV

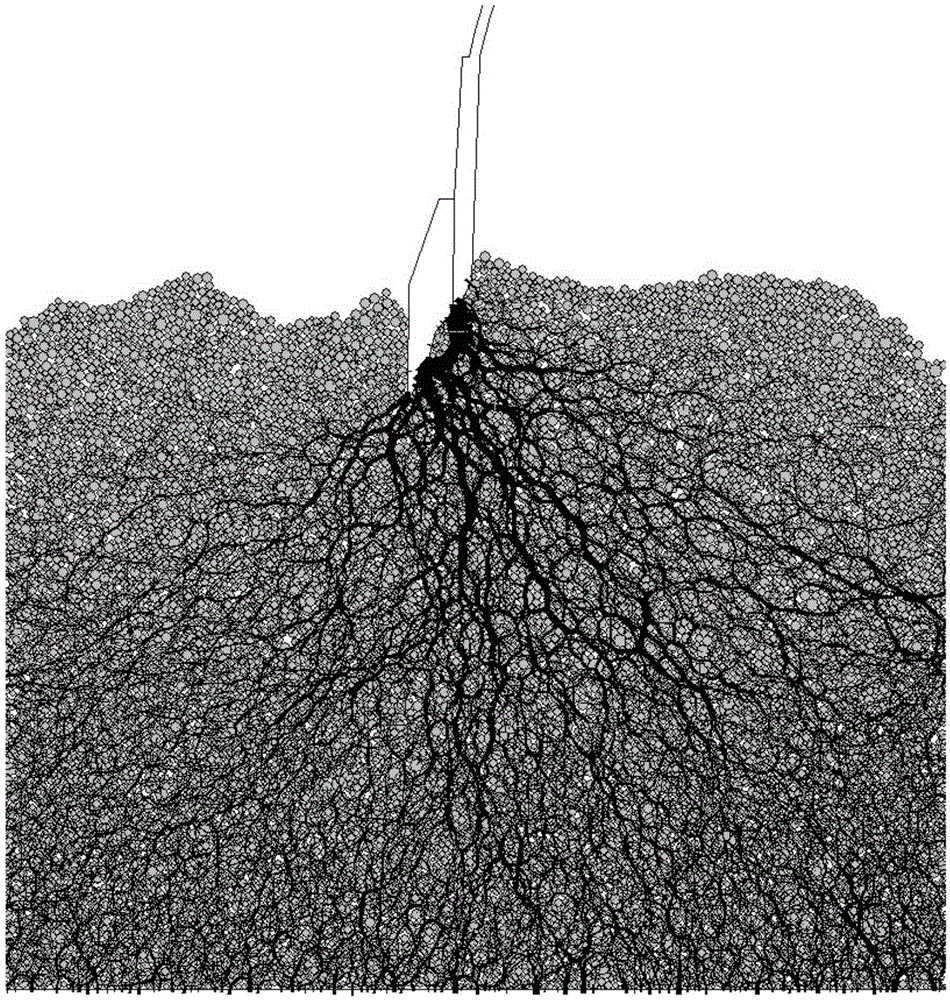

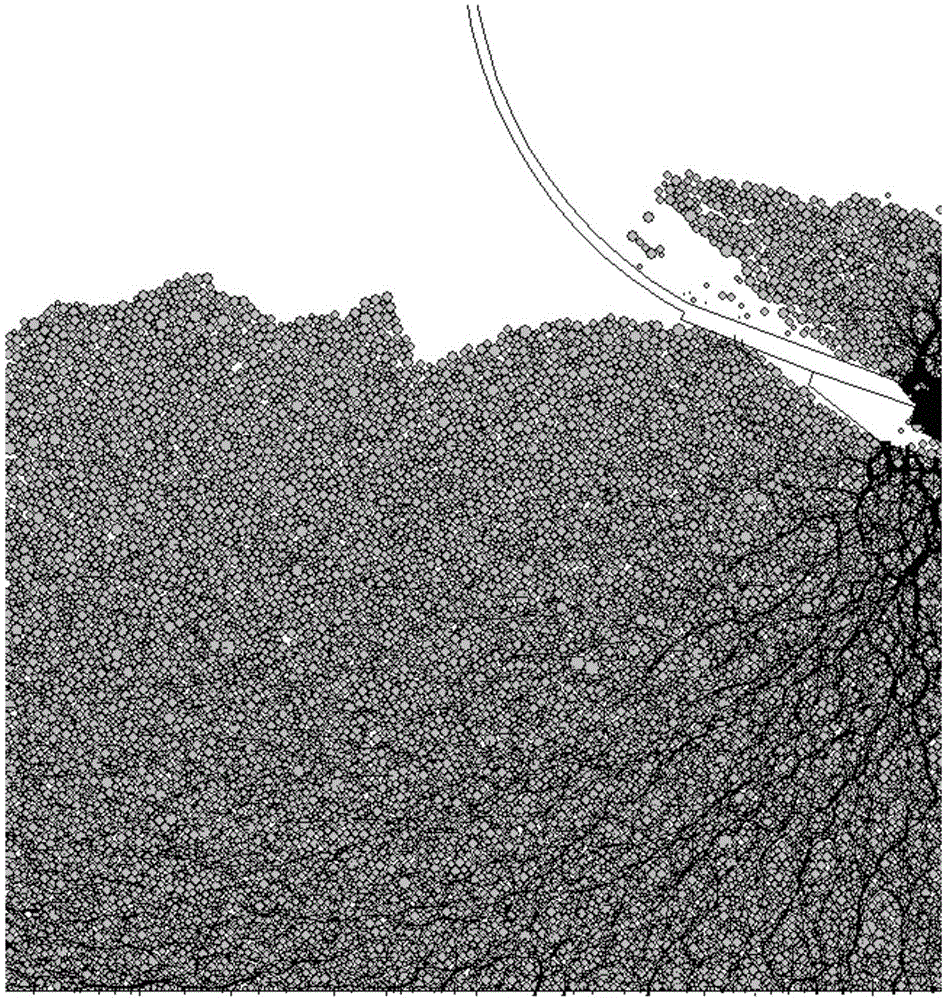

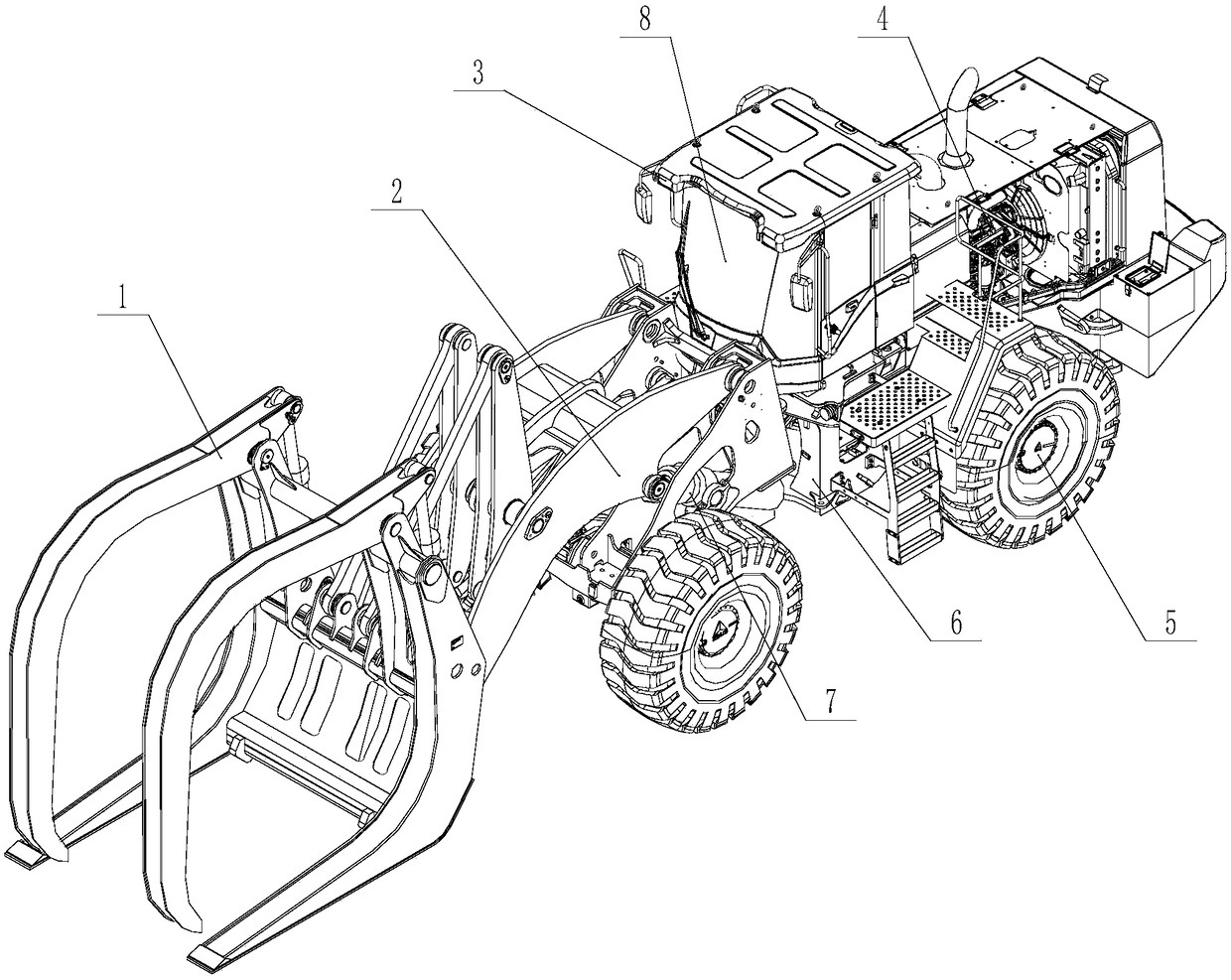

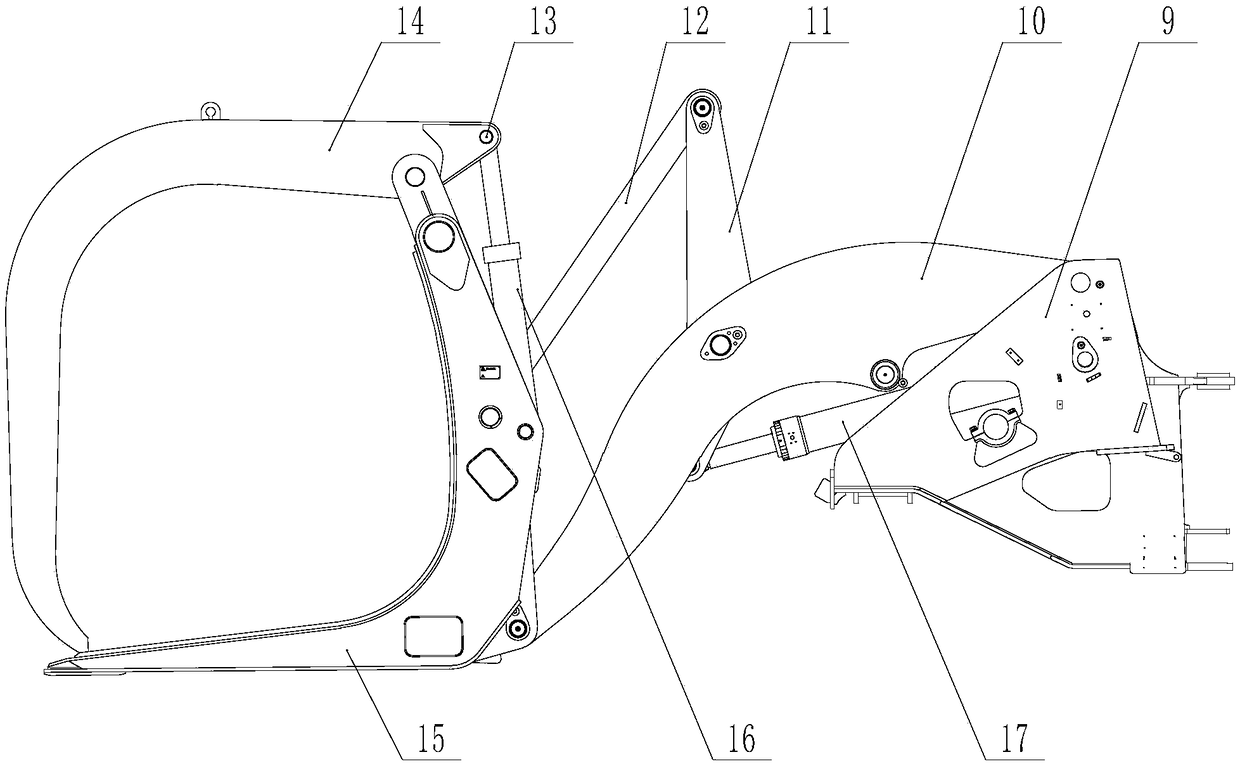

Large-sized wood grabbing loading machine

InactiveCN108116993ALarge power ratioSmall change in angleLoad-engaging elementsCranesSix-bar linkageMachine tool

The invention discloses a large-sized wood grabbing loading machine and belongs to an engineering mechanical wheel type loading machine. The large-sized wood grabbing loading machine mainly comprisesa large-sized loading machine; a forward rotation six-connecting-rod mechanism is arranged at the front end of the large-sized loading machine; a large-sized wood grabbing machine tool is arranged atthe front end of the forward rotation six-connecting-rod mechanism; the forward rotation six-connecting-rod mechanism comprises a machine frame, a rotating bucket oil cylinder, a movable arm, a rocking arm and a pull rod; the machine frame is connected with the large-sized loading machine; the front end of the movable arm is hinged with the large-sized wood grabbing machine tool; the back end of the movable arm is hinged with the upper part of the machine frame; the stretching end of the rotating bucket oil cylinder is hinged with the lower end of the rocking arm; the other end of the rotatingbucket oil cylinder is hinged with the machine frame; the middle part of the rocking arm is hinged with the middle part of the movable arm; the upper end of the rocking arm is in splicing connectionwith one end of the pull rod; and the other end of the pull rod is hinged with the large-sized wood grabbing machine tool. The large-sized wood grabbing loading machine is strong in power, reasonablein matching, large in tractive force and high in grabbing ability, and can meet the requirement of the overload condition. The large-sized wood grabbing loading machine is mainly applied to wood loading and unloading.

Owner:SHANDONG LINGONG CONSTR MACHINERY

Vertical shaft flat die straight roller straw briquetting mechanism

The invention provides a vertical shaft flat die straight roller straw briquetting mechanism, which belongs to the technical field of agricultural machinery. It mainly includes the base, transmission system, collecting hopper, support, main shaft, flat die, pressure roller frame, pressure roller, sleeve, the main shaft is installed vertically at the center of the base and the support, the flat die is installed horizontally on the support, and the press The roller frame sleeve is installed vertically on the main shaft and fixed on the support. The pressure roller is installed horizontally on the radial shaft end of the pressure roller frame sleeve. The sleeve is set outside the flat die. seat. The flat die has several square through holes in the circumference range, the center line of the hole coincides with the rotation center line of the pressure roller teeth to ensure that the material is smoothly pressed into the die hole, the pressure roller is in the shape of a spur gear, driven by the pressure roller bracket The shaft rotates and rotates around its own axis at the same time, continuously pressing the material into the die hole to form regular-shaped, high-density straw blocks with high productivity and molding rate. The structure is simple and compact, the die hole is not easy to be blocked, and the working continuity is good.

Owner:HEILONGJIANG INST OF PASTURAGE MECHANISATION

A humanoid dexterous hand with passive rotating joints and its operating method

ActiveCN109591038BTypical underdriven structureImprove adaptabilityGripping headsPhysical medicine and rehabilitationRotational freedom

The invention relates to the technical field of robotic dexterous hands, and discloses a humanoid dexterous hand with passive rotary joints and an operation method thereof, including a first finger, a second finger, a third finger, a palm, a first drive motor, a second a driving motor and a third driving motor. The device solves the problems of complex structure, poor reliability and the like existing in the coupling transmission mechanism of the existing humanoid dexterous hand, and at the same time adds an additional rotational degree of freedom to the fingers of the dexterous hand. The humanoid finger of the device can rotate around its own central axis by using the rotating joint, and can independently change various grasping postures for objects of different shapes, which enhances the adaptability of the dexterous hand; by adjusting the length of the passive rope and the active rope, it can adjust and recalibrate the initial pose of the dexterous hand. The novel humanoid dexterous hand designed by the invention can realize envelope grasping without complex control system and transmission system, has passive rotation degree of freedom, and has high self-adaptive ability to objects of different shapes.

Owner:BEIJING UNIV OF POSTS & TELECOMM

Snake-like winding soft actuator

This application provides a snake-like winding soft actuator, which aims to solve the problem that the soft robot is still in the research stage and needs to be further expanded. It includes an elastic bellows, a strain-limiting layer, an elastic expansion layer, a fixed connector, and an air pipe for connecting with an air source. The present application provides a novel serpentine winding actuator, which includes two types: a winding actuator with a strain-limiting layer and a winding actuator without a strain-limiting layer. The serpentine winding actuator with strain-limiting layer relies on the strain-limiting layer and the elastic stretch layer to determine the winding performance, and can quickly and efficiently wind the slender rod tightly. As the inflation pressure increases, the serpentine winding actuator will wind tighter and can lift 1.3kg objects. The winding actuator without the strain-limiting layer is lighter and softer, and only depends on the fixed direction of the elastic stretching layer to determine the winding method of the actuator, which can also wind and lift objects.

Owner:SOUTHWEAT UNIV OF SCI & TECH

High-precision grabbing mechanism of robot

ActiveCN107322619AStrong grabbing abilityGood grabbing effectGripping headsMechanical engineeringRobot

The invention discloses a high-precision grabbing mechanism of a robot. The high-precision grabbing mechanism comprises a grabbing base which is of a circular structure, the grabbing base is provided with at least three sub-bases, and the sub-bases are arranged around the circle center of the grabbing base at equal interval and arranged in the axial direction of the grabbing base; each sub-base is provided with a clamping device and a driving device, each clamping device comprises a guide rail, each guide rail is fixed to the corresponding sub-base and provided with a sliding base, each sliding base is provided with a clamping base, a first clamping arm is hinged to each clamping base through a hinge, a second clamping arm is hinged to each first clamping arm through a hinge, and a third clamping arm is hinged to each second clamping arm through a hinge. According to the high-precision grabbing mechanism of the robot, the universality is high, the grabbing effect is good, not only is the grabbing capability on a workpiece with the flat surface high, but also the grabbing capability on a workpiece with the curved surface is high, and workpieces with different surfaces can be grabbed.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

Short arm-tie type grab bucket

InactiveCN100534889CRealize opening and closingImprove gripLoad-engaging elementsCouplingEngineering

The present invention aims to design a kind of short strut type grab, comprising opening and closing rope, supporting rope, supporting rope rack, retaining rope wheel group, bucket body jaw plate, middle beam hinged with the bucket body jaw plate, and Two connecting devices, wherein, the jaw plate of the bucket body is hinged to the middle beam and has a hinge point, a middle beam pulley block is arranged on the hinge point, and a center beam guide wheel set is arranged on the middle beam, short The strut-type grab is symmetrically arranged left and right, and its feature is that it also includes: two upper struts on the left and right, the upper ends of which are hinged with the middle beam; two lower struts on the left and right, respectively hinged with the lower ends of the two upper struts on the left and right The left and right two strut pulleys are respectively installed at the hinge points of the left and right upper struts and the lower struts. The invention can adjust the grasping capacity by changing the magnification of the rope pulley group to adapt to different materials, and has the characteristics of strong grasping capacity, simple structure, convenient maintenance, reliable performance and long service life.

Owner:胡开宸

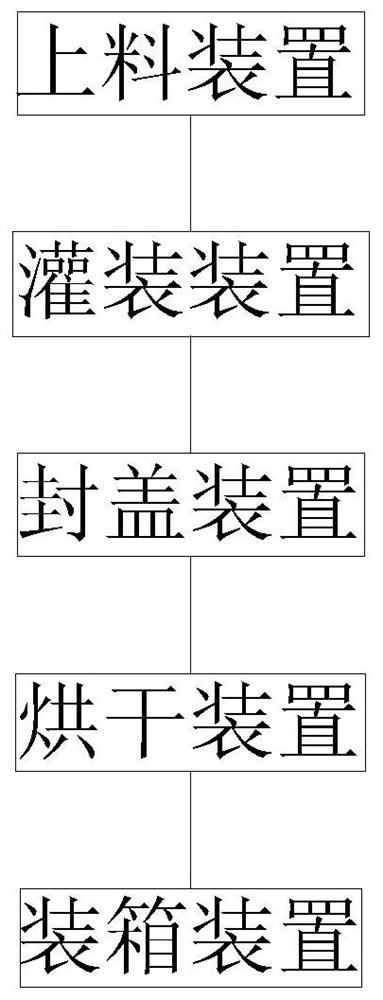

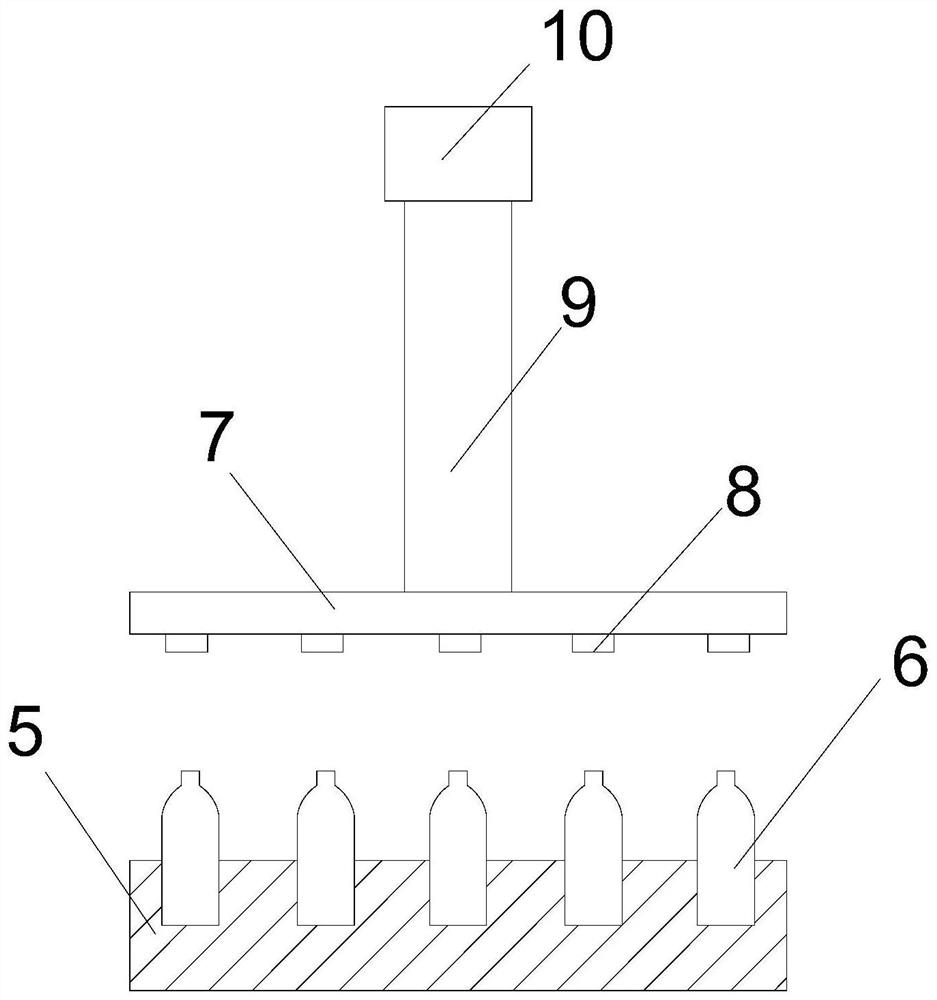

Liquor packaging production line

InactiveCN112028001AStrong grabbing abilityReasonable use of spaceLiquid fillingPackaging automatic controlProduction lineSingle chip

The invention discloses a liquor packaging production line, and belongs to the technical field of liquor production. The production line comprises a single-chip microcomputer, a feeding conveyer belt,a packaging conveyer belt, a recycling conveyer belt, a storage device, a feeding device, a filling device, a cap sealing device and a drying device. The feeding device, the filling device, the cap sealing device and the drying device are sequentially arranged in the conveying direction of the packaging conveyer belt. The feeding device is located at the starting end of the packaging conveyer belt. The feeding conveyer belt is perpendicular to the packaging conveyer belt. The tail end of the feeding conveyer belt is close to the starting end of the packaging conveyer belt. A discharging opening is formed between the tail end of the feeding conveyer belt and the starting end of the packaging conveyer belt. The production line can fill liquor efficiently and automatically.

Owner:广西丹泉酒业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com