Mechanical arm

A technology of manipulators and rotating shafts, applied in the direction of manipulators, chucks, manufacturing tools, etc., can solve the problems of inability to complete free rotation around the arm shaft and inaccurate positioning, and achieve convenient and fast grasping operations, simple structure, and high work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

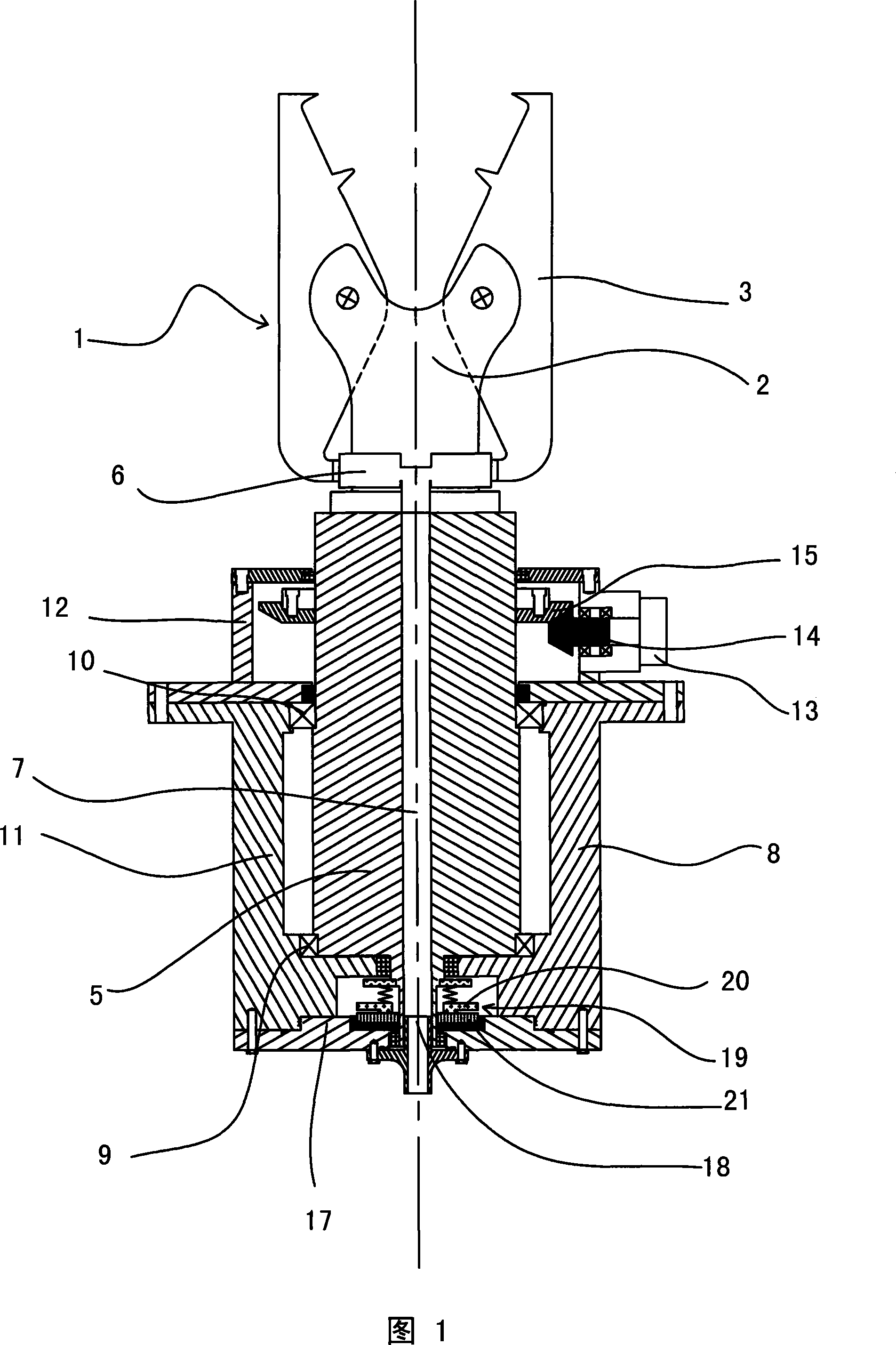

[0025] Embodiment: Referring to the accompanying drawing 1, a manipulator includes three parts: a claw 1 , a rotating shaft 5 and a shaft cylinder 8 .

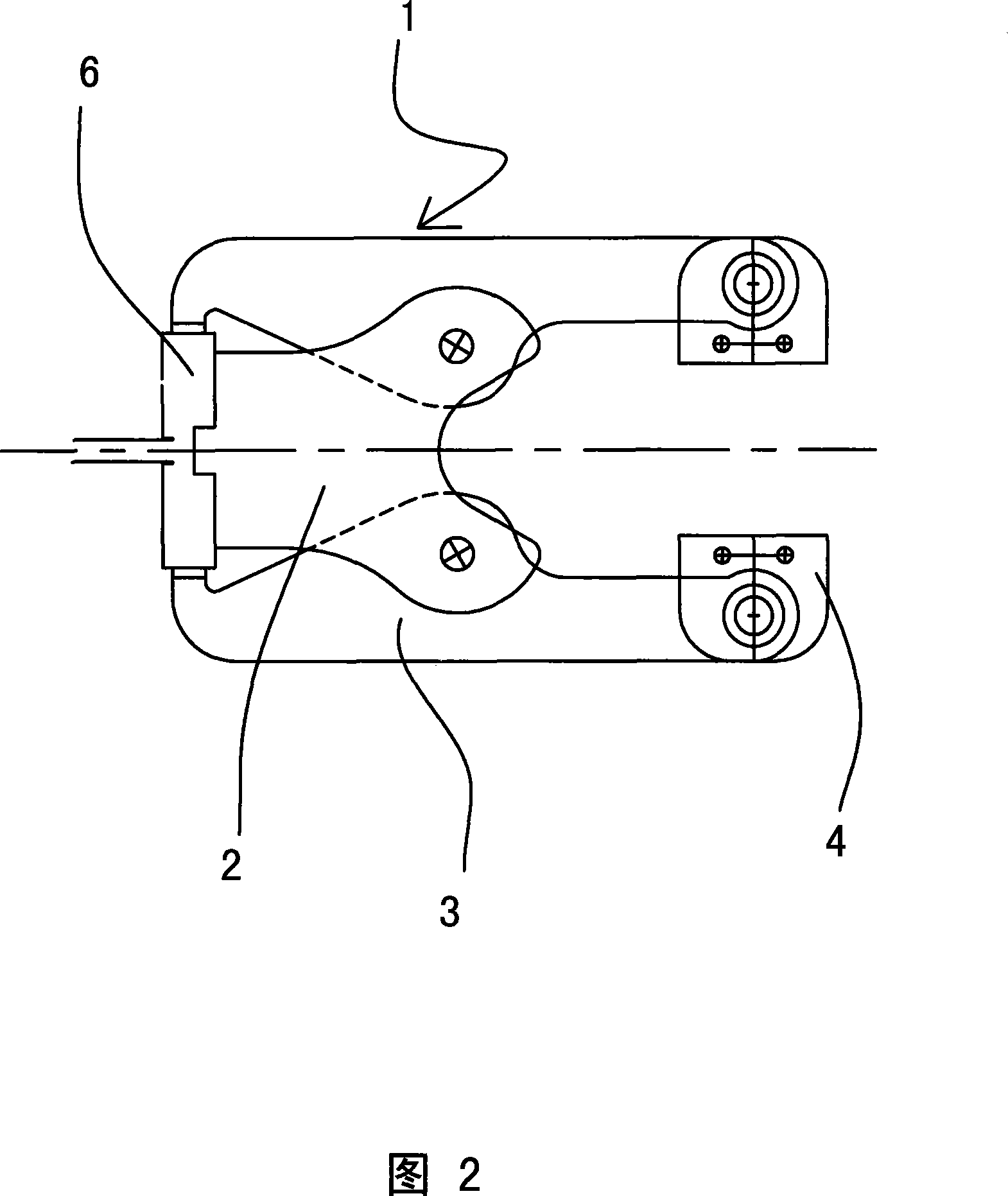

[0026] Referring to the accompanying drawing 1, the claw portion 1 is composed of a bracket 2 and two claws 3, the inner sides of the two claws 3 are provided with sharp teeth (as shown in Figure 1), and the claws 3 can also be hinged at the front end Claw surface is the claw head 4 (referring to accompanying drawing 2) of the curved surface of the suitable blank shape of band anti-skid tooth. Two finger claws 3 are symmetrical to the central axis of support 2 and are hinged on the protruding part of support 2 with the middle part, and the rear end of support 2 is connected to the rotating shaft 5 with the center of the axis, and the rear part of support 2 or the front part of rotating shaft 5 correspond to two The tail ends of the finger claws 3 are fixedly connected to a hydraulic cylinder 6 respectively, and the pistons of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com