Deep-foundation grab crane

A crane and deep foundation technology, applied in cranes and other directions, can solve the problems of low efficiency, limited excavation depth, slow excavation speed, etc., and achieve the effects of convenient operation, low cost and large bucket capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

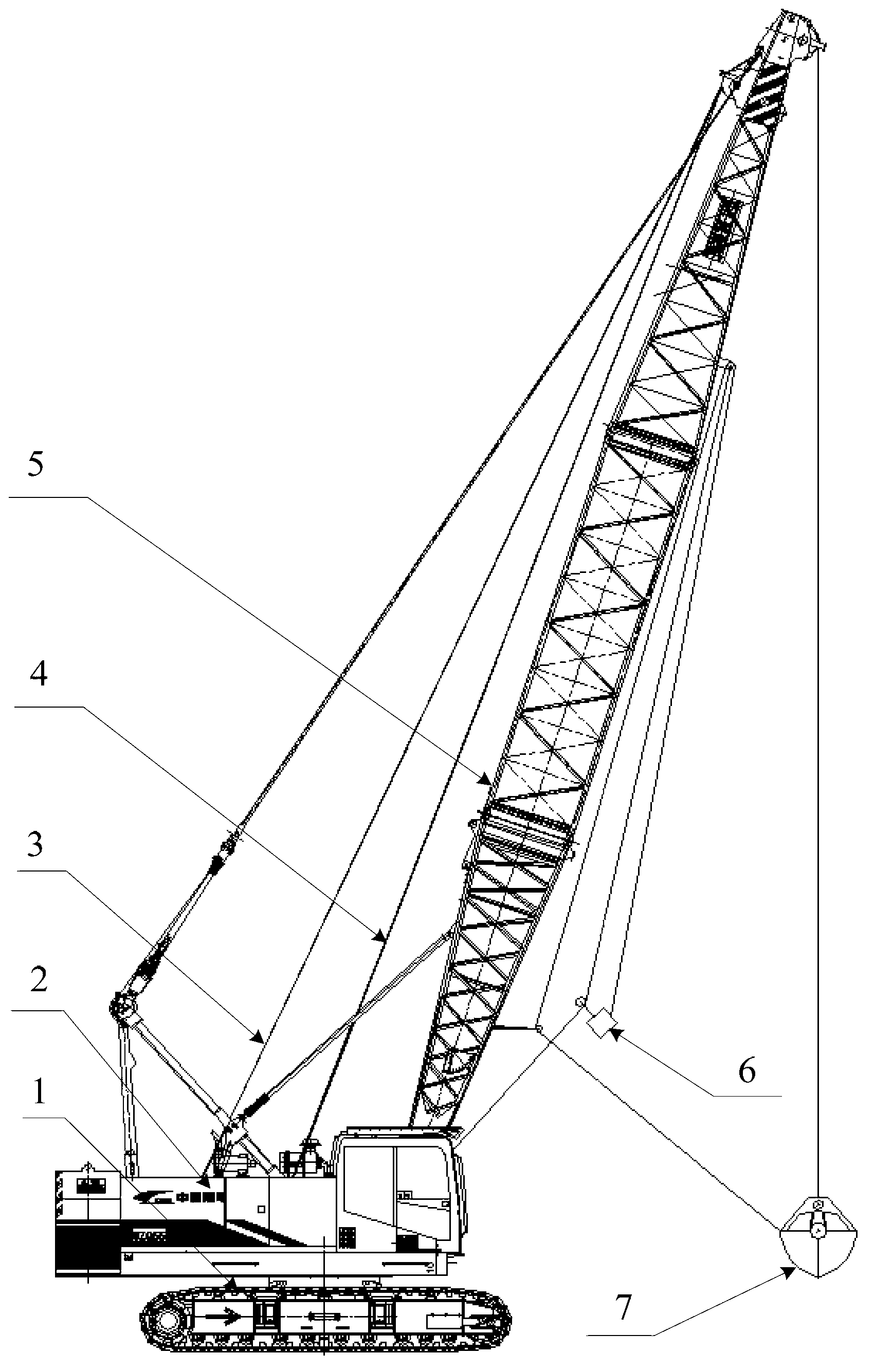

[0017] The invention discloses a deep foundation grab crane, which is professional equipment designed for grabbing and fetching soil during deep foundation construction. It is not limited by the construction depth and has the characteristics of high excavation efficiency.

[0018] For ease of understanding, the technical terms involved in the scheme of the present invention are now explained as follows:

[0019] Deep foundation: The deep foundation has a large buried depth, and the lower solid soil layer or rock layer is used as the foundation of the bearing layer. Diffusion and distribution of the borne load to the shallow layer of the foundation through the bottom surface of the foundation. Therefore, when the shallow soil quality of the construction site cannot meet the requirements of the building for the bearing capacity and deformation of the foundation, and it is not suitable to adopt foundation treatment measures, it is necessary to consider adopting a deep foundation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com