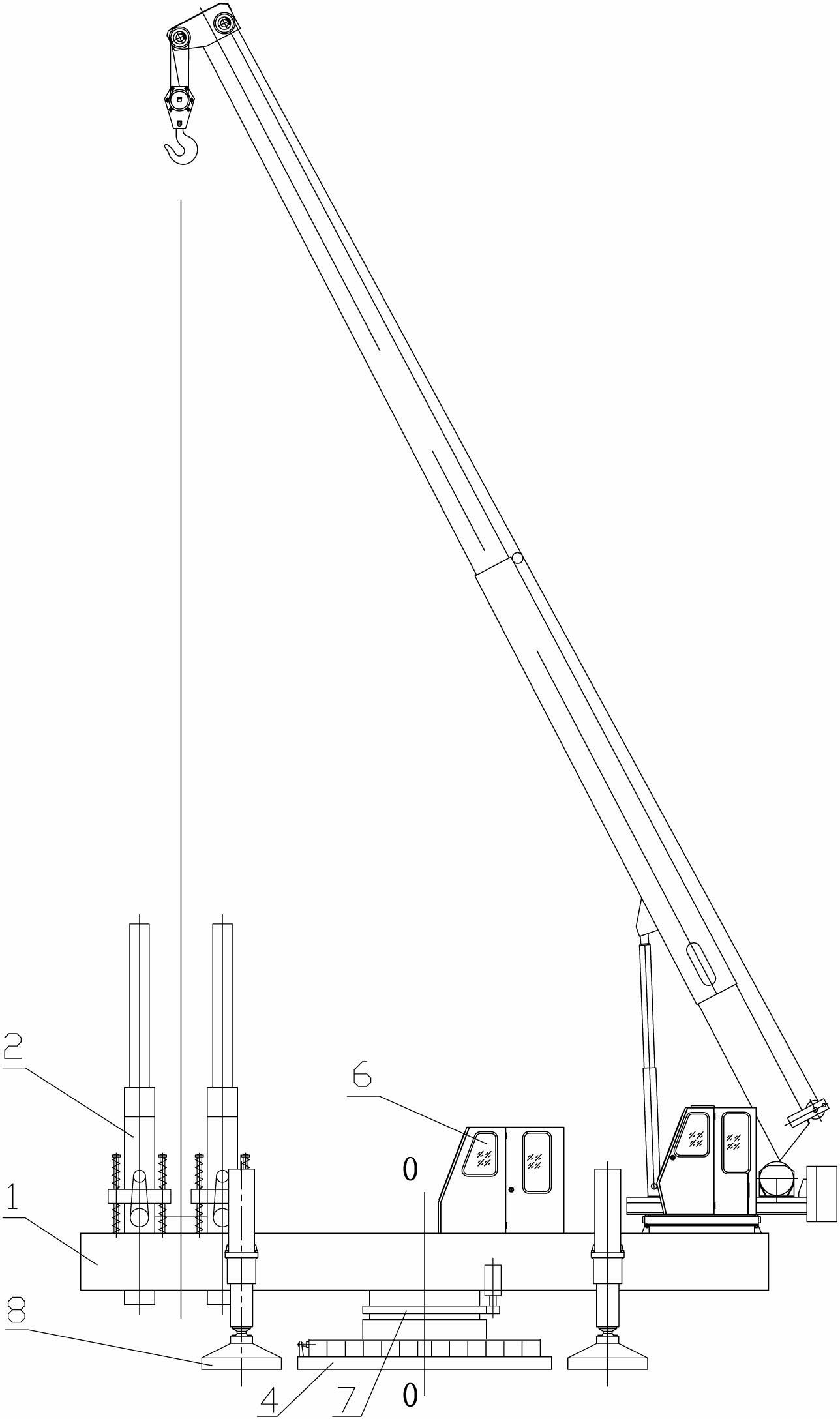

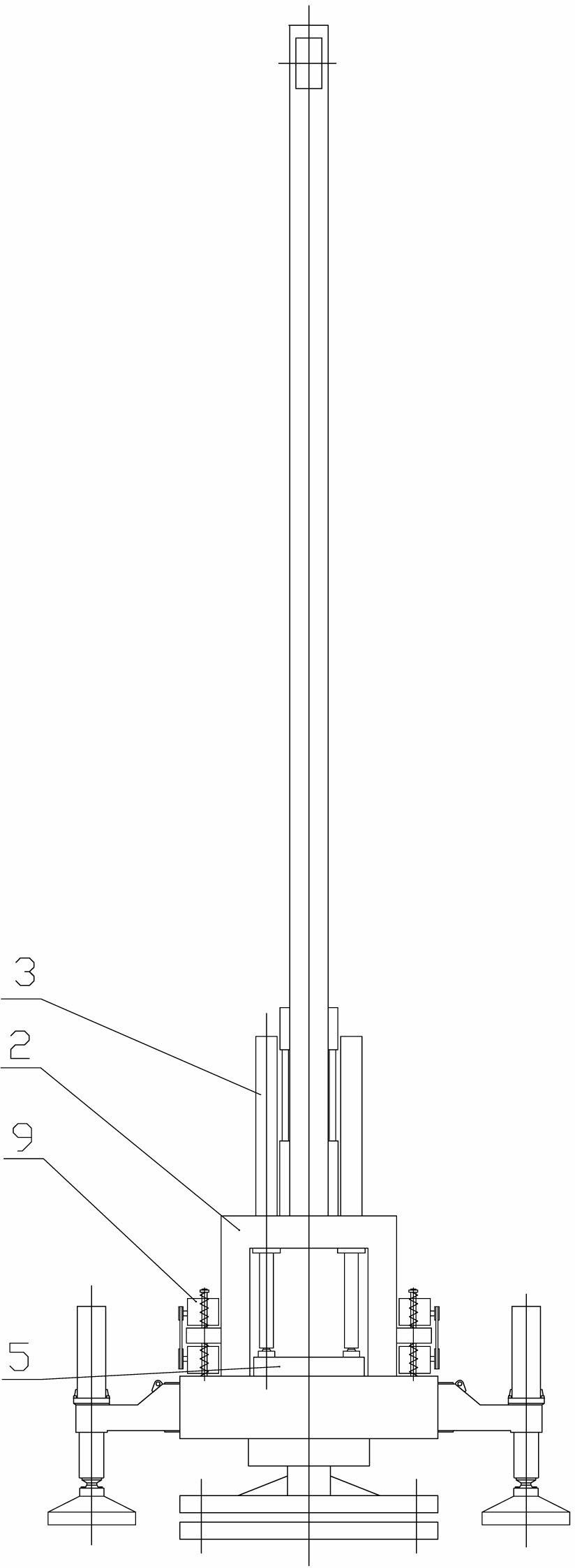

Hydraulic dynamic and static cooperation pile pressing machine

A hydraulic power, pile driver technology, applied in the direction of sheet pile wall, building, foundation structure engineering, etc., can solve problems such as failure to work normally, shortened working life, seal ring wear, etc., to achieve light weight, cost reduction, grounding ratio The effect of pressure reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

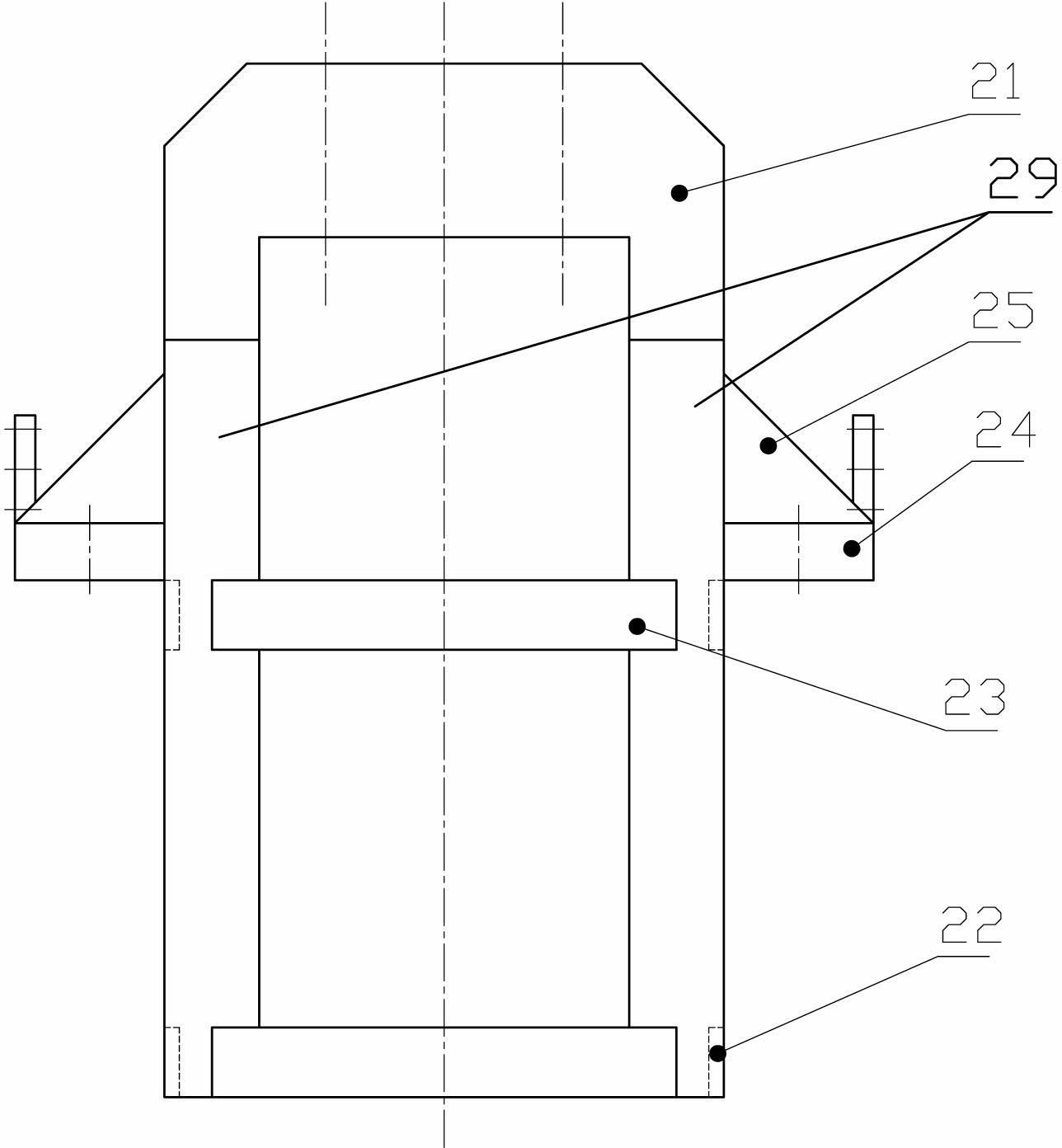

[0033] The hydraulic, dynamic and static cooperative pile driver of the present invention is a new pile driver formed by synergy on the basis of the hydraulic hammer pile driver and the hydraulic static pile driver, and by synthesizing their respective characteristics. The hammer body of the existing hydraulic hammer is lifted by a two-way linear motion oil cylinder, and falls with an acceleration of 1.6g (g is the acceleration of gravity), hitting on the pile head, and the striking power is determined by changing the stroke and changing the hammer body. adjusted by weight. And the present invention has done following improvement: the power source of drive power is changed into the oil motor of rotary motion, DC motor or AC motor drive by the oil cylinder of two-way linear motion; It is the power brought by the tangential acceleration of the eccentric wheel acting downward, acting on the parallel gantry installed with the pile-pressing cylinder, and then transmitted to the pil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com