Large-sized wood grabbing loading machine

A loader, a large-scale technology, applied in the direction of cranes, transportation and packaging, load suspension components, etc., can solve the problems of small lifting force and digging force, cannot meet the requirements of grabbing wood, and the rocker arm is easy to touch wood, etc., to achieve The effect of large containment area, small change in force transmission ratio, and large force transmission ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing:

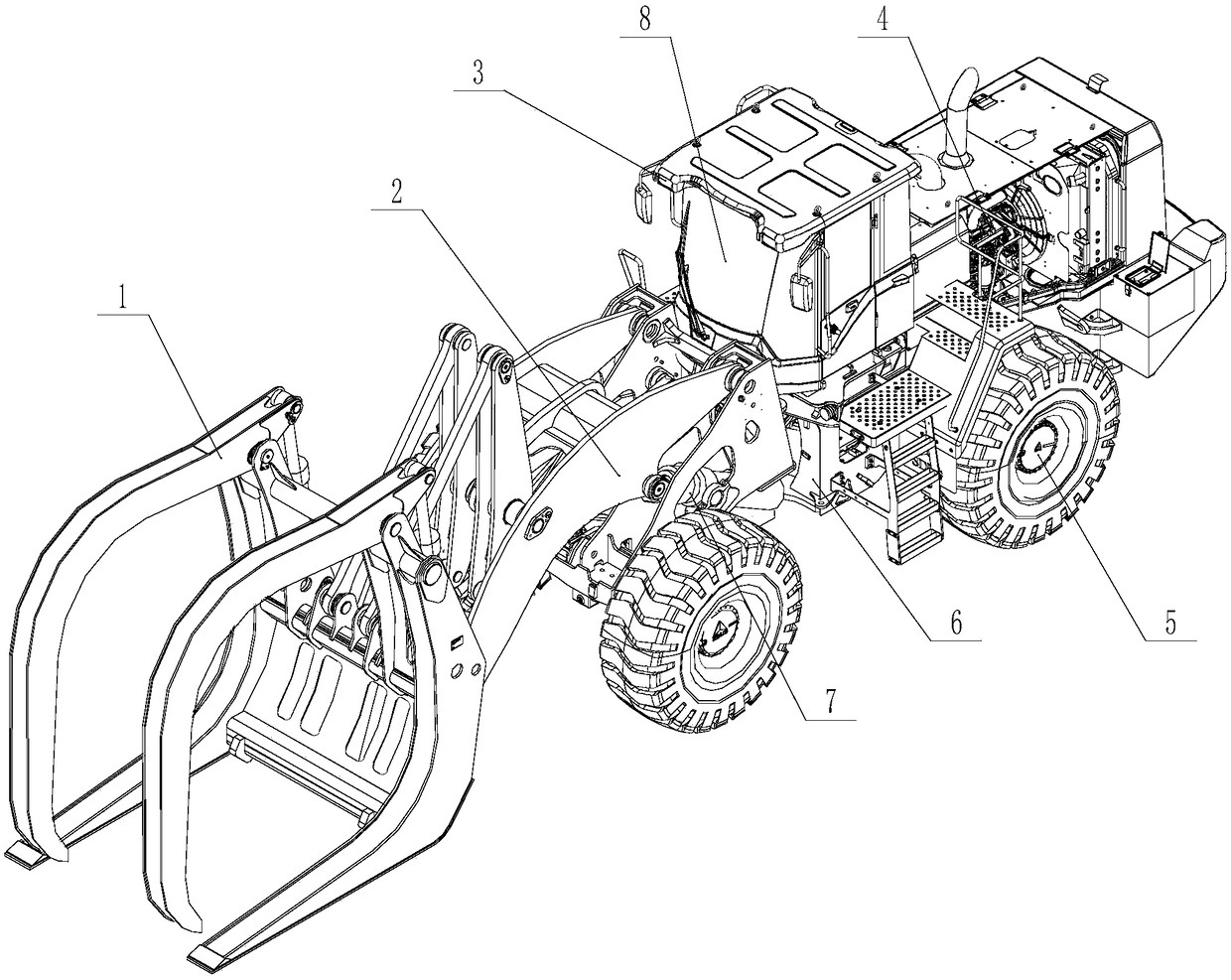

[0020] Such as figure 1 As shown, the large-scale log loader includes a large-scale loader. The front end of the large-scale loader is provided with a forward-rotating six-bar linkage mechanism 2. Cab 8, electrical system 3, power system 4, transmission system 5, structural parts 6 and hydraulic system 7.

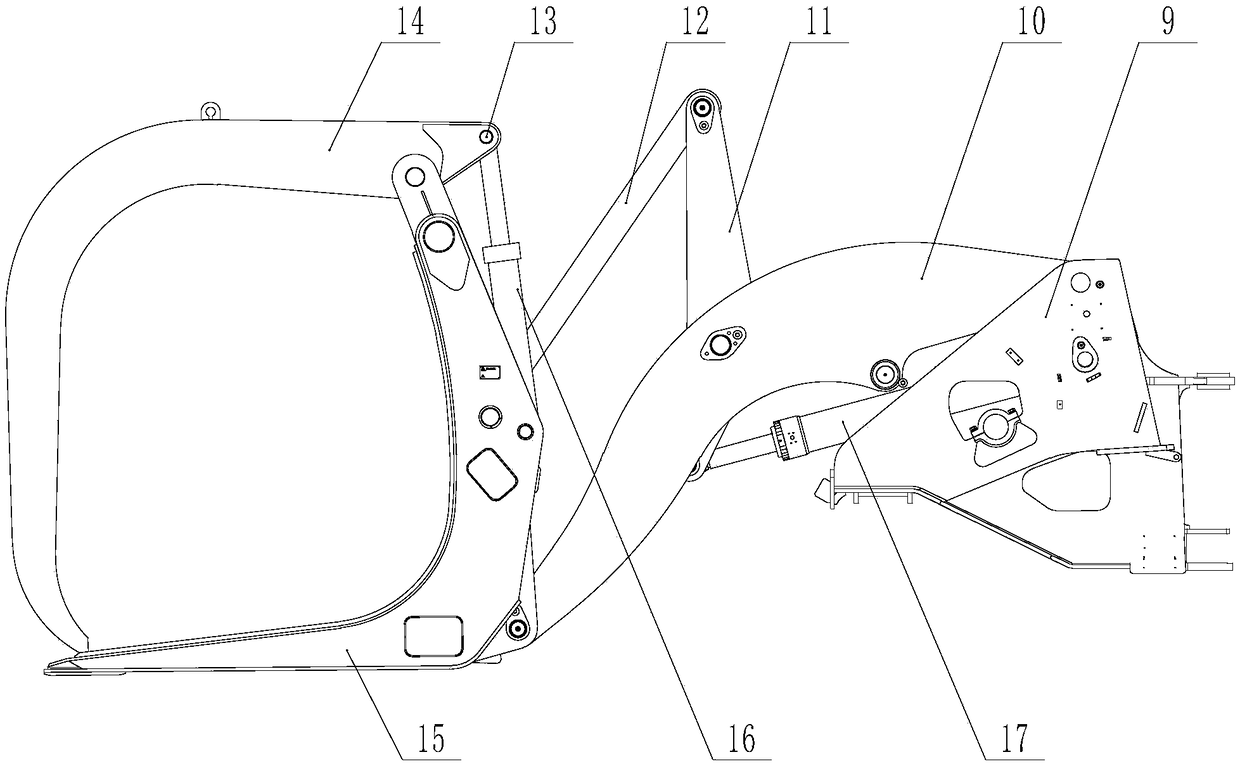

[0021] Such as figure 2 As shown, the forward rotating six-bar linkage mechanism 2 includes a frame 9, a bucket cylinder 17, a boom 10, a rocker arm 11 and a pull rod 12, the bucket cylinder 17 is connected with the hydraulic system 7, the bucket cylinder 17, the rocker 11 and pull rod 12 are respectively two parts, symmetrically arranged between the frame 9 and the large-scale wood-grabbing machine 1; It is hinged with the upper part of the frame 9, the extended end of the bucket cylinder 17 is hinged with the lower end of the rocker arm 11, the other end of the buc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com