A robot's high-precision grasping mechanism

A grasping mechanism and high-precision technology, applied in the direction of manipulators, manufacturing tools, chucks, etc., can solve the problems of poor versatility, poor workpiece grasping ability, and poor grasping ability of workpieces with different surfaces, etc., to achieve the grasping effect Good, strong grasping ability and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

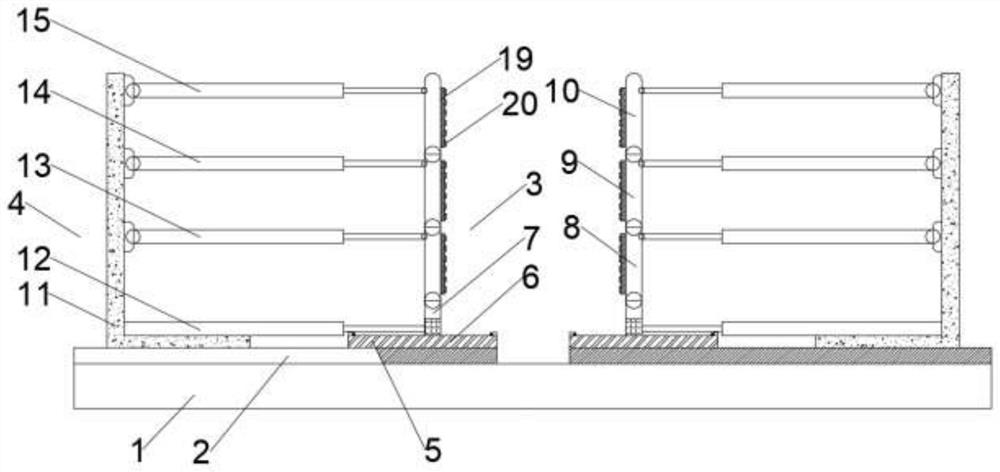

[0024] like figure 1 , Figure 4 and Figure 5 As shown, a high-precision grabbing mechanism of a robot provided by the present invention includes a grabbing base 1, the grabbing base 1 is a circular structure, and at least three points are arranged on the grabbing base 1. The base 2, the sub-base 2 is arranged at equal intervals around the center of the grabbing base 1, the sub-base 2 is arranged along the axial direction of the grabbing base 1, and the sub-base 2 is provided with The clamping device 3 and the driving device 4, the centers of the clamping device 3, the driving device 4 and the grasping base 1 are on a straight line, and the driving device 4 is located on the outside of the grasping base 1;

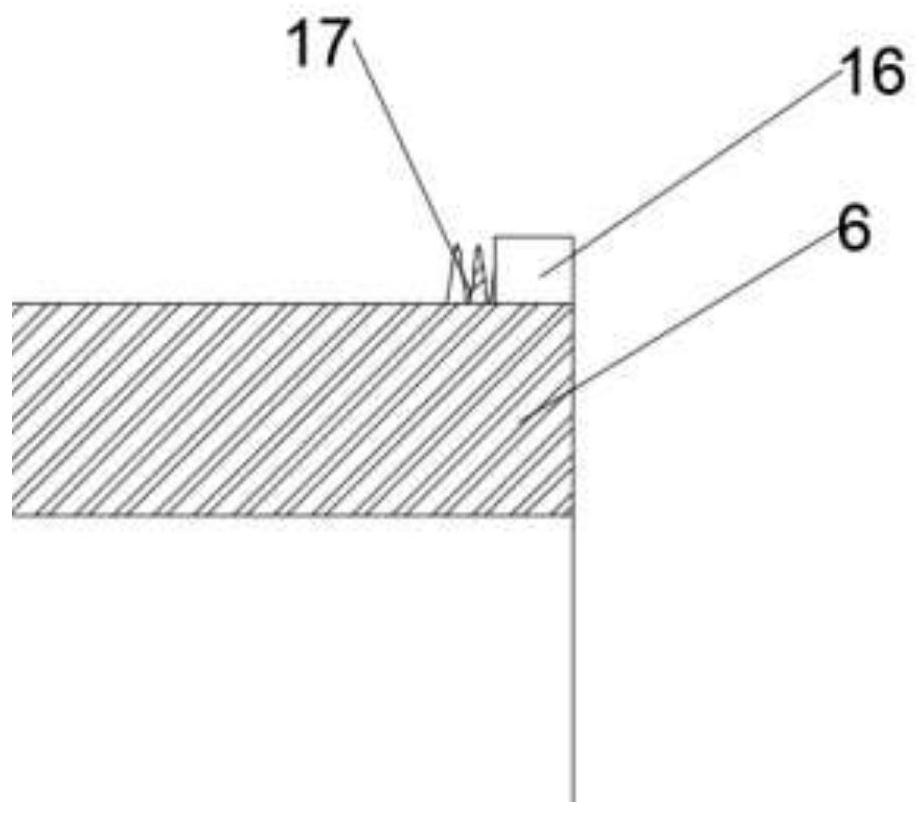

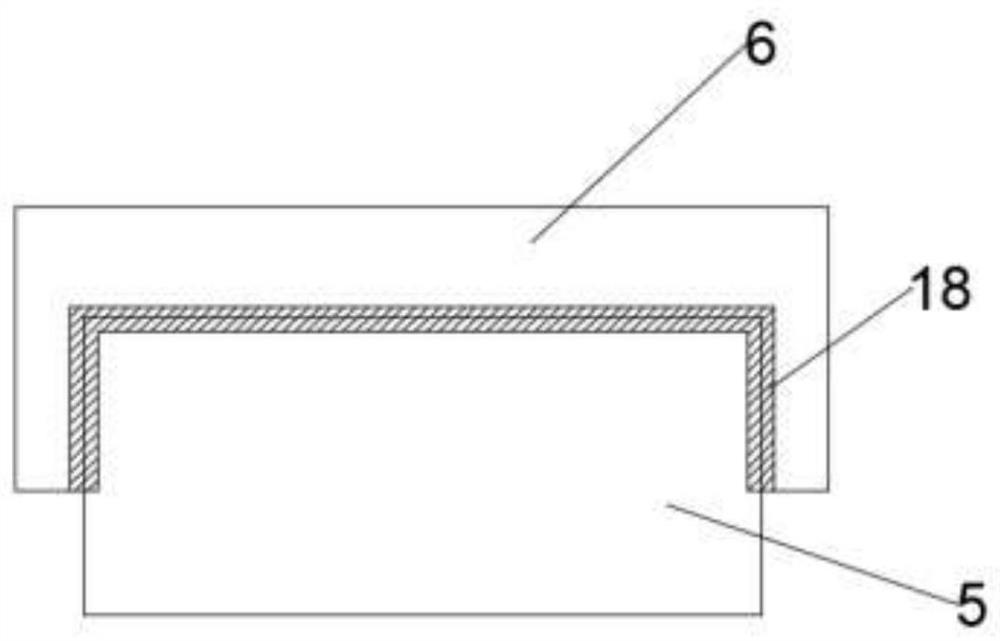

[0025] like figure 1 , Figure 4 and Figure 5 As shown, the clamping device 3 includes a guide rail 5, the guide rail 5 is fixed on the sub-base 2, and the guide rail 5 is provided with a slide seat 6, and the slide seat 6 is provided with a clamping seat 7, The cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com