Preparation method of polyquaternium magnetic microsphere with core-shell structure

A technology of magnetic microspheres and polyquaternary ammonium salts, which can be applied in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., can solve the problems of low nucleic acid amount, limited saturation magnetization, low saturation magnetization, etc. The effect of strong grasping ability, increased production capacity and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The invention provides a method for preparing magnetic microspheres with high saturation magnetization, high binding efficiency, simple process flow, and applicable to automation, capable of rapid biological macromolecules. The initiator, the crosslinking agent and the quaternary ammonium salt monomer are coated with the quaternary ammonium salt group on the surface of the seed microsphere through free radical polymerization.

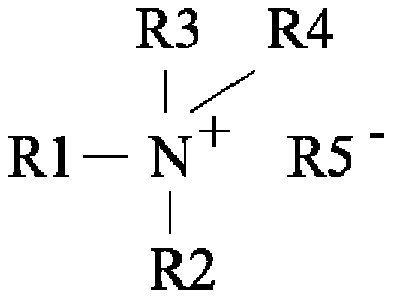

[0029] The structural formula of the quaternary ammonium salt monomer is:

[0030]

[0031] In the formula, R1 has a carbon-carbon double bond, R2, R3, and R4 are the same or different hydrocarbon groups with a carbon chain length of 1 to 10 atoms arranged in a straight or branched chain, and R5 is a halogenated element, sulfonate or Sulfate A negatively charged group.

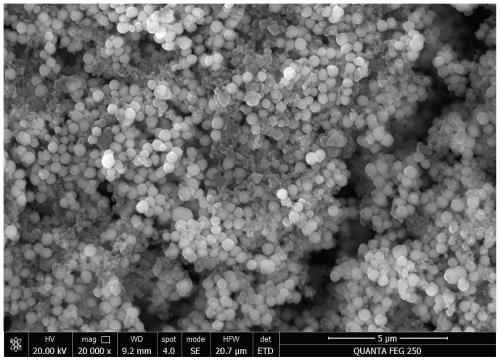

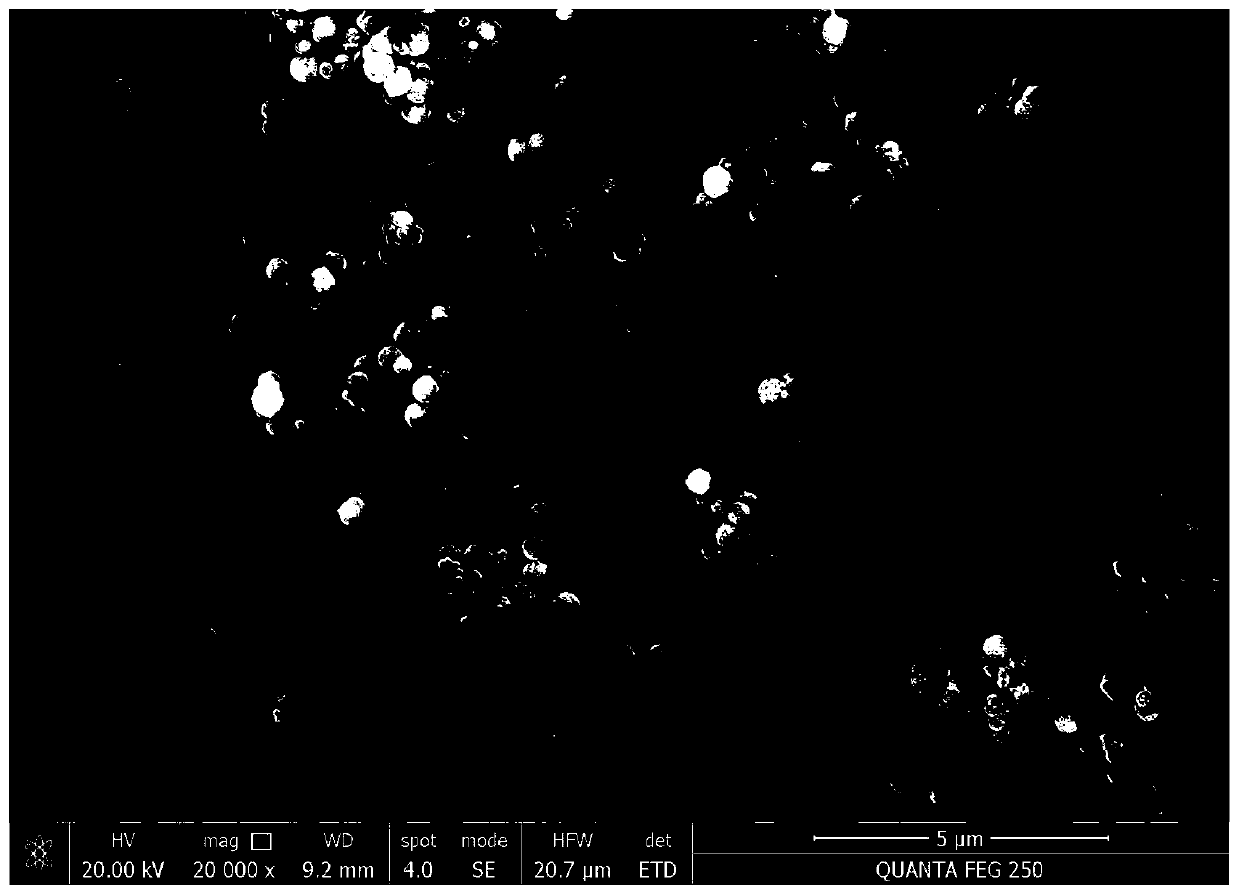

[0032] First, disperse the seed microspheres with a particle size of 10 nm to 5 μm in an organic solvent, and add a silane coupling agent under the condition of mechanical st...

Embodiment 1

[0039] Weigh 10g of ferroferric oxide magnetic microspheres (average particle diameter 100nm) and disperse them in the ethanol solution of 200ml, add 1g of gamma-methacryloxypropyltrimethoxysilane while stirring, then add 10g of Sodium hydroxide solution (0.5g / ml) was reacted at 40°C for 15 hours to obtain magnetic microspheres modified with double bonds on the surface, which were stored for future use.

Embodiment 2

[0041] Weigh 10g of ferroferric oxide magnetic microspheres (average particle diameter 500nm) and disperse them in the ethanol solution of 200ml, add 1g of gamma-methacryloxypropyltrimethoxysilane while stirring, then add 10g of Sodium hydroxide solution (0.5g / ml) was reacted at 70°C for 3 hours to obtain magnetic microspheres modified with double bonds on the surface, which were stored for future use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com