Preparation method and device of micro-fluidic dual-aqueous-phase monodisperse calcium alginate microspheres

A calcium alginate, two-phase technology, which is applied to non-active ingredients in medical preparations, chemical instruments and methods, pharmaceutical formulations, etc., can solve problems such as inability to directly encapsulate cells, uneven size, and uneven size of microspheres. , to achieve the effect of simple and fast generation method, simple and fast preparation method, and good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

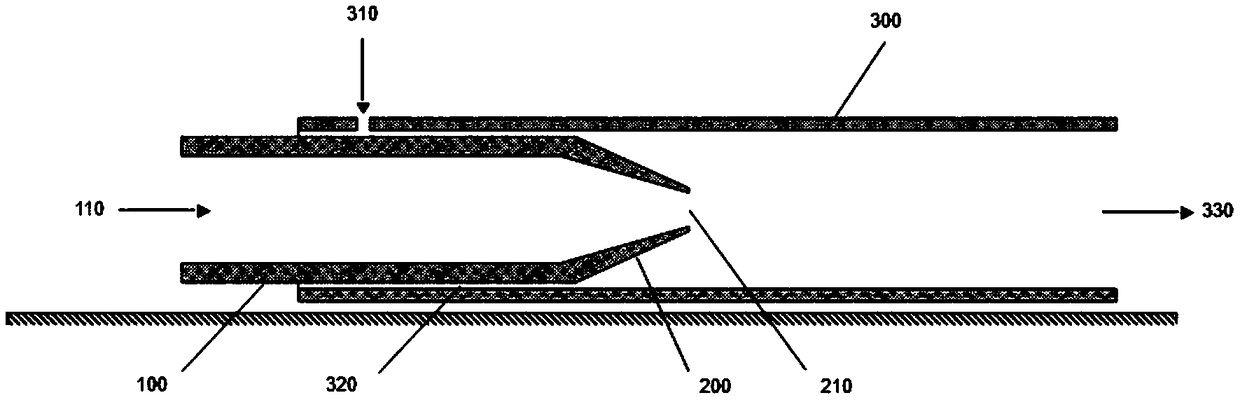

[0036] A method for preparing microfluidic two-phase monodisperse calcium alginate microspheres, comprising the following steps:

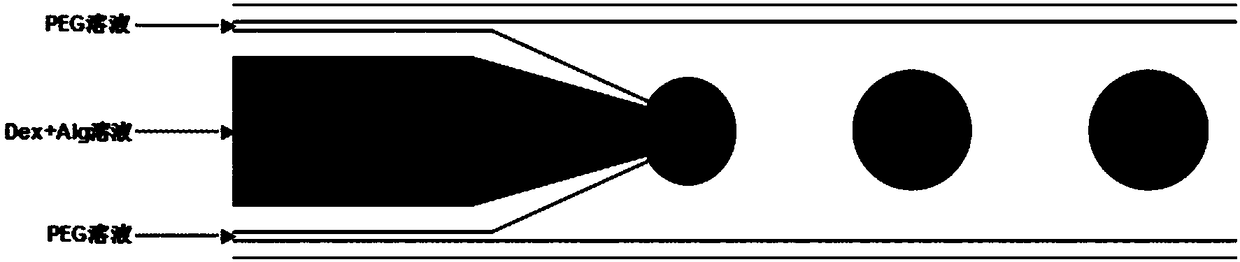

[0037] The polyethylene glycol aqueous solution is used as the outer water phase, and the dextran + sodium alginate aqueous solution is used as the inner water phase; a two-phase sodium alginate droplet is generated at the tip of the cone through a coaxial capillary device; the outer water phase is continuous Sampling, the inner aqueous phase is periodic intermittent sampling;

[0038] The two-phase sodium alginate droplet is passed into the calcium chloride aqueous solution to form the required monodisperse calcium alginate microspheres.

[0039] Further, the preparation process of the polyethylene glycol, dextran and sodium alginate aqueous solution is as follows:

[0040] Separately prepare polyethylene glycol aqueous solution and 8% (w / w) dextran aqueous solution with a mass fraction of 8% (w / w); after being fully mixed by a rotary incubator, ...

Embodiment 1

[0048] (1) The preparation of solution, preparation 50mL mass fraction respectively is the polyethylene glycol (PEG) aqueous solution of 8% (w / w) and the dextran (Dex) aqueous solution of 8% (w / w); After fully mixing After standing for 6 hours, the phases were separated; the upper phase was PEG solution, and the lower phase was Dex solution; the upper and lower phases were extracted respectively in two beakers for later use; sodium alginate was added to the extracted Dex solution to prepare the quality of sodium alginate Dextran + sodium alginate solution with a fraction of 0.5% (w / w), mixed evenly, and placed in a beaker for use; prepare 10% (w / w) CaCl with deionized water 2 solution.

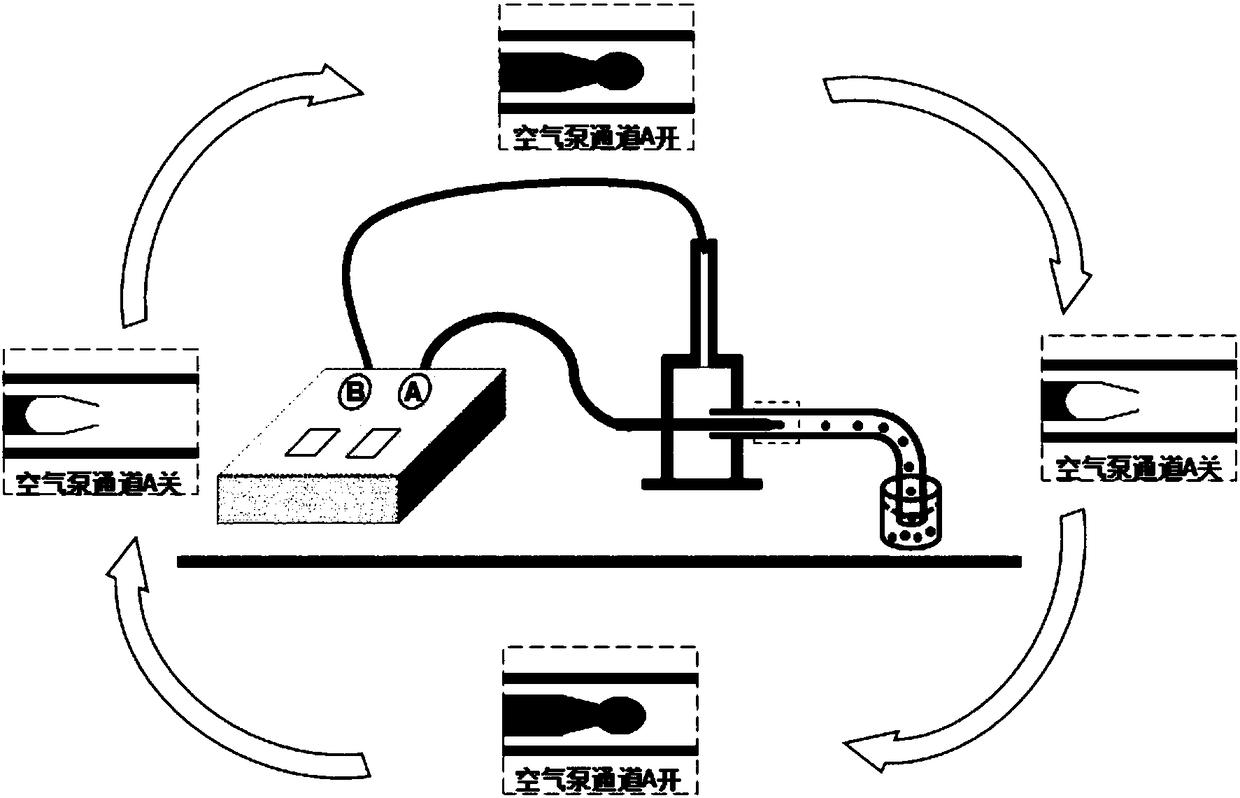

[0049] (2) For the preparation of two-phase calcium alginate microspheres, take dextran + sodium alginate solution and PEG solution respectively and place them in air pump vials A and B; The time is 0.2s, and the closing time is 1.5s; the external phase adopts continuous input; set the pressu...

Embodiment 2

[0052] (1) The preparation of solution, preparation 50mL mass fraction respectively is the polyethylene glycol (PEG) aqueous solution of 8% (w / w) and the dextran (Dex) aqueous solution of 8% (w / w); After fully mixing After standing for 6 hours, the phases were separated; the upper phase was PEG solution, and the lower phase was Dex solution; the upper and lower phases were extracted respectively in two beakers for later use; sodium alginate was added to the extracted Dex solution to prepare the quality of sodium alginate Dextran + sodium alginate solution with a fraction of 0.5% (w / w), mixed evenly, and placed in a beaker for use; prepare 10% (w / w) CaCl with deionized water 2 solution.

[0053] (2) For the preparation of two-phase calcium alginate microspheres, take dextran + sodium alginate solution and PEG solution respectively and place them in air pump vials A and B; The time is 0.2s, and the closing time is 1.5s; the external phase adopts continuous input; set the pressu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com