Hot melt adhesive

A polyamide hot-melt adhesive and diamine technology, applied in adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of polyamide hot-melt adhesive process complexity and pollution, and achieve green raw materials Environmental protection, easy and simple production, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

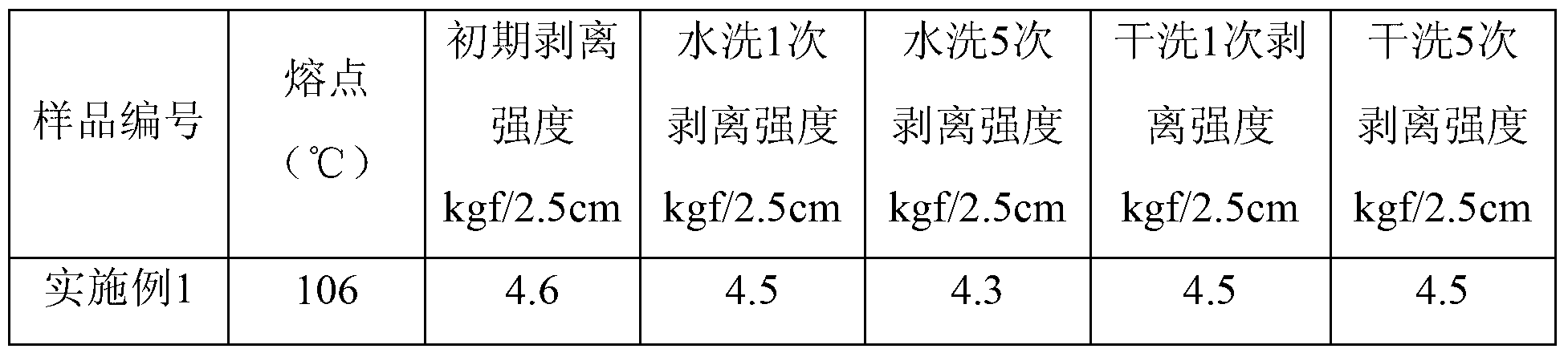

Embodiment 1

[0042] Polymerization: 1.0kg of adipic acid, 1.8kg of suberic acid, 2.7kg of tetradecanedioic acid, 5.2kg of dimer acid, 0.3kg of acetic acid, 3.8kg of pentamethylenediamine, 6.3kg of caprolactam, and 3.3kg of laurolactam , 80g of phosphorous acid, 1.1kg of water and 60g of polyethylene wax were put into a 100-liter polymerization kettle (K / SY166-2007 type), vacuumized and filled with nitrogen for 3 times, and the air in the kettle was replaced, and the temperature of the oil bath was gradually raised to 260~ 265°C, when the pressure in the kettle rises to 1.2MPa, slowly open the vent valve on the kettle to keep the pressure at 1.2MPa, and when the temperature in the kettle reaches 225°C, slowly open the large vent valve to keep the pressure in the kettle at 2 hours uniformly drop from 1.2MPa to normal pressure, maintain the normal pressure for 1 hour, vacuumize to -0.05Mpa (gauge pressure), keep the vacuum for 2min, fill the polymerization kettle with nitrogen to the pressure ...

Embodiment 2

[0045] Polymerization: 1.0kg of adipic acid, 5.2kg of undecanedibasic acid, 4.3kg of dimer acid, 0.3kg of butyric acid, 1.5kg of pentamethylenediamine, 3.5kg of octyldiamine, 4.1kg of 8-capryllactam, 12 - Put 5.3kg of aminododecanoic acid, 60g of sodium hypophosphite, 0.5kg of water and 60g of polyethylene wax into a 100-liter polymerization kettle (K / SY166-2007 type), vacuumize and fill nitrogen 3 times, and replace the inside of the kettle The temperature of the air and oil bath gradually rises to 270-275°C. When the pressure in the kettle rises to 1.5MPa, slowly open the vent valve on the kettle to keep the pressure at 1.5MPa. When the temperature in the kettle reaches 230°C, slowly open the valve. Vent the valve to reduce the pressure in the kettle from 1.5MPa to normal pressure evenly within 2 hours. After maintaining the normal pressure for 1 hour, evacuate to -0.05MPa (gauge pressure), keep the vacuum for 2min, and fill the polymerization kettle with Nitrogen gas to a p...

Embodiment 3

[0048] Polymerization: Add 2.7kg of adipic acid, 2.4kg of sebacic acid, 3.0kg of tetradecanedibasic acid, 2.5kg of dimer acid, 0.3kg of propionic acid, 2.2kg of pentamethylenediamine, 1.9kg of octyldiamine, and decanediamine Put 2.2kg, caprolactam 3.9kg, laurolactam 4.2kg, phosphorous acid 80g, water 0.4kg and polyethylene wax 60g into a 100-liter polymerization kettle (K / SY166-2007 type), vacuumize and nitrogen gas 3 times, Replace the air in the kettle, and gradually increase the temperature of the oil bath to 260-265°C. When the pressure in the kettle rises to 1.7MPa, slowly open the vent valve on the kettle to keep the pressure at 1.7MPa. Slowly open the large vent valve to reduce the pressure in the kettle from 1.7MPa to normal pressure uniformly within 2 hours. Fill the interior with nitrogen to a pressure of 0.5 MPa, start melting and discharging, and use a pelletizer (electromagnetic speed-adjustable motor 300 type cantilever type) to granulate, dry at 80°C and vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com