Temperature sensor

A temperature sensor and electronic device technology, applied to thermometers, thermometer parts, instruments, etc., can solve the problems of high cost, deviation, and difficulty in accurately measuring junction temperature of temperature detection circuits, and achieve electrical insulation and accurate operation control , the effect of accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

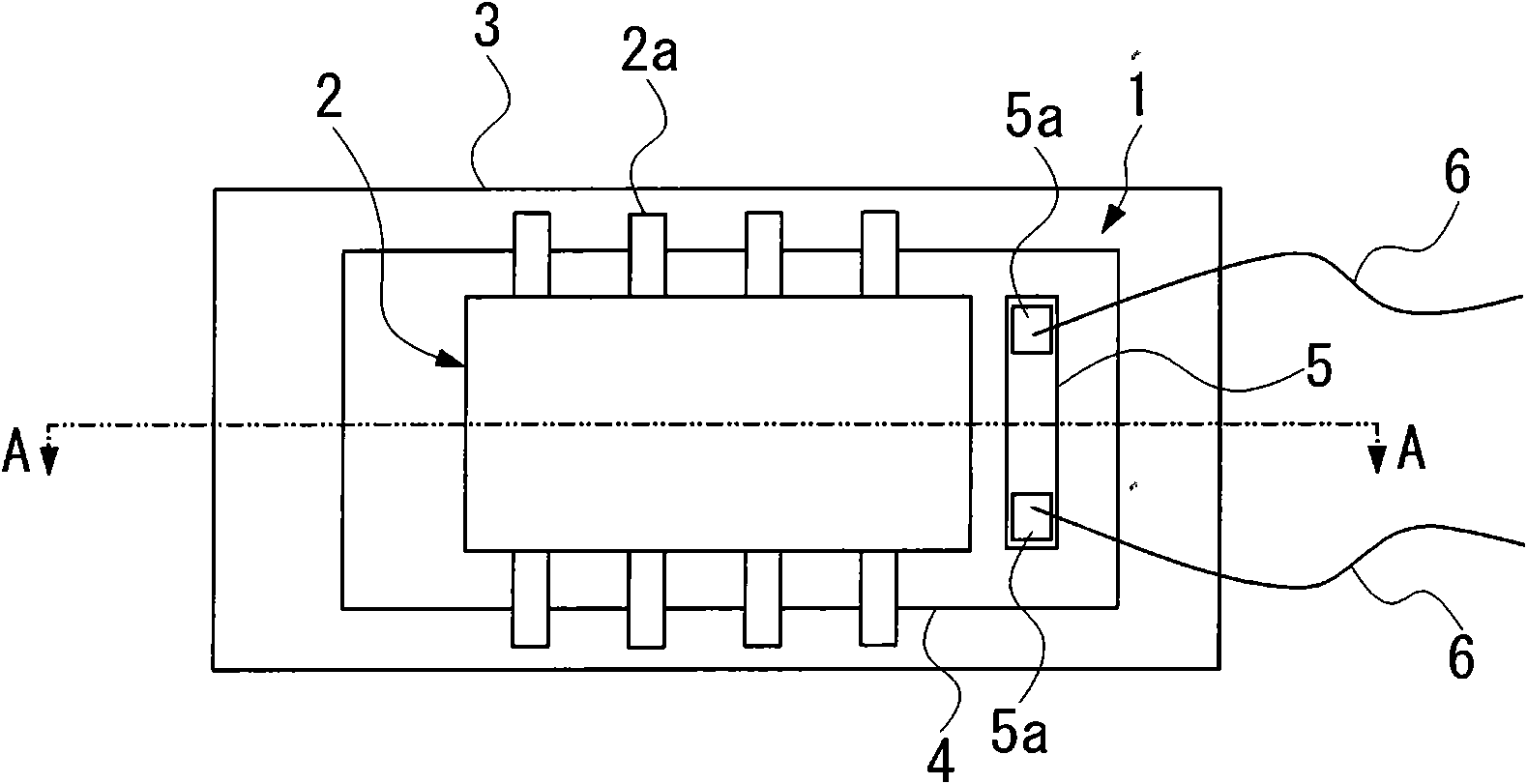

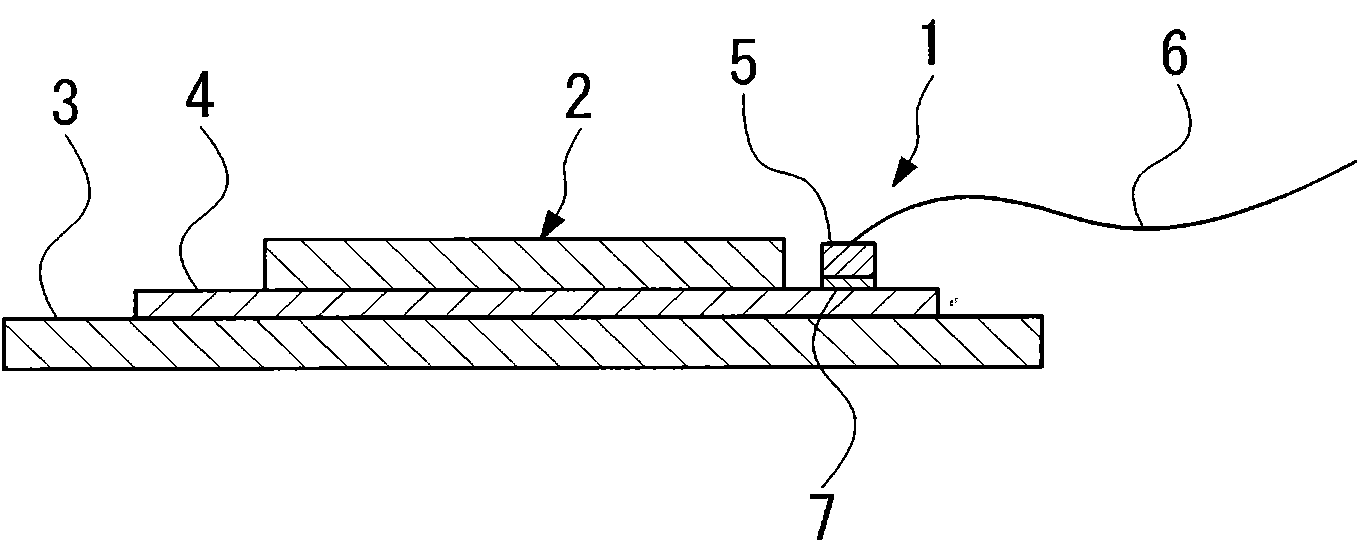

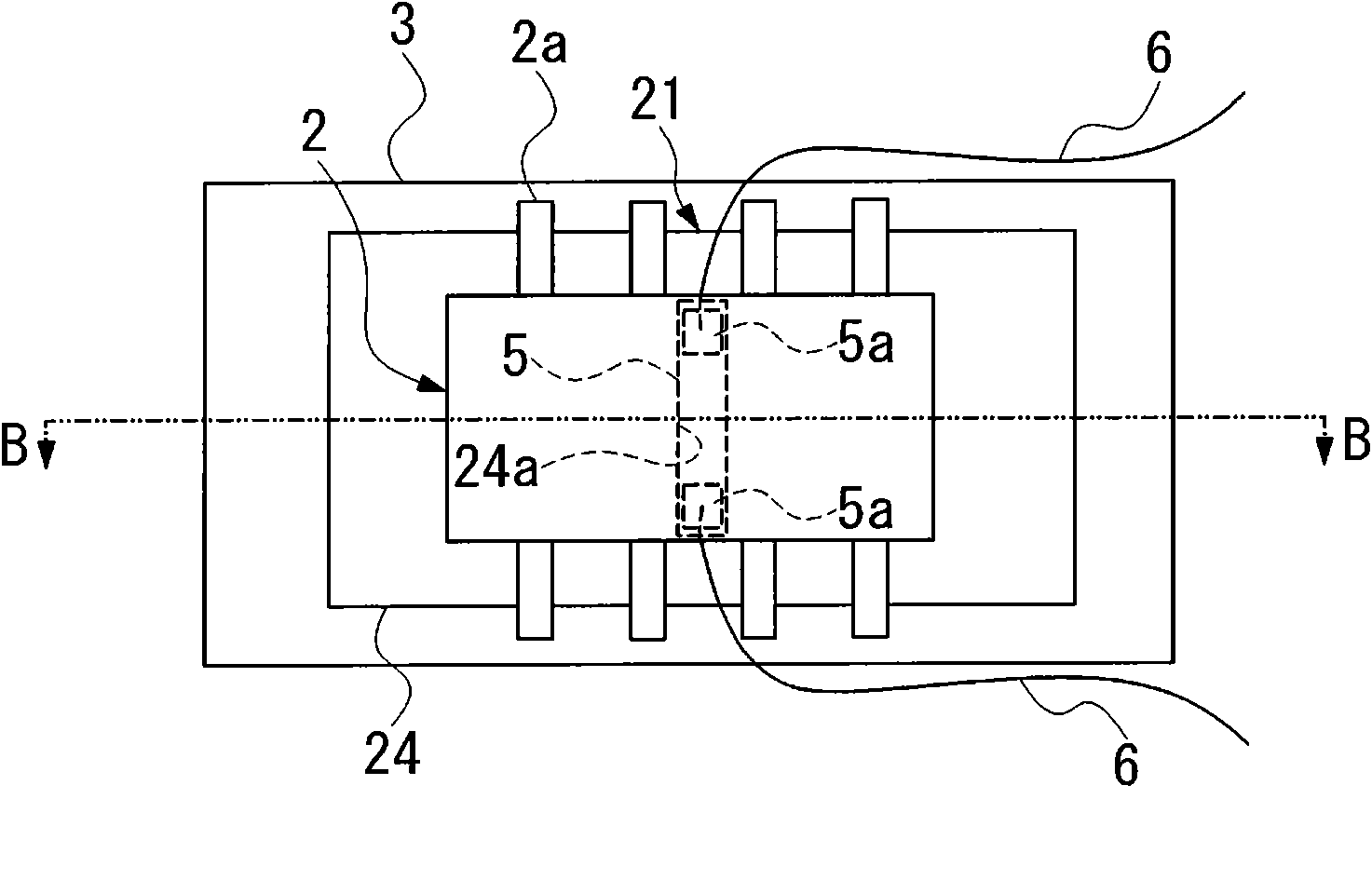

[0023] Below, refer to figure 1 and figure 2 A first embodiment of the temperature sensor of the present invention will be described. In addition, in each drawing used for the following description, in order to make each member recognizable or easily recognizable, the scale is changed suitably.

[0024] like figure 1 and figure 2 As shown, the temperature sensor 1 of this embodiment is used, for example, to measure the temperature of an electronic device 2 that generates heat during operation. between the substrates 3 , and conduct the heat of the electronic device 2 to the substrate 3 ;

[0025] The above-mentioned electronic device 2 is, for example, a transistor such as a power transistor or a power FET. That is, when the electronic device 2 is a transistor, the temperature sensor 1 of this embodiment measures the junction temperature for driving control of the transistor.

[0026] The above-mentioned substrate 3 is, for example, a printed substrate formed with patt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com