Preparation method of two-aqueous-phase micro liquid droplets with uniform and controllable sizes

A two-phase, micro-droplet technology, applied in the field of droplet microfluidics and microcapsules, can solve problems such as difficult mass industrial production, removal of solid particle templates, complex processes, etc., to achieve precise operation control, Controllable capsule size and uniform capsule size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] The PDMS chip microfluidic device described in Comparative Example 1 was used to prepare two-phase aqueous microdroplets.

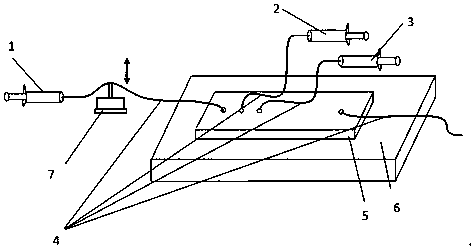

[0048] The attached drawings are the same figure 1 , and the labels are as follows: 1, inner phase syringe, 2, middle phase syringe, 3, outer phase syringe, 4, silica gel connecting tube, 5, upper part of PDMS chip, 6, slide glass, 7, mechanical wave vibration generator.

[0049] With 15% dextran aqueous solution as the inner phase, 17% polyethylene glycol aqueous solution as the middle phase and the outer phase, draw the above aqueous solution with a syringe, connect it to the corresponding feed port with a silicone tube, and use the pump to set the liquid flow rate of each phase , the flow rate of the outer phase is 120 μL / h, the flow rate of the middle phase is 120 μL / h, and the flow rate of the inner phase is 30 μL / h. The silicone tube of the inner phase is fixed on a mechanical wave vibration generator, so that the silicone tube follows the me...

Embodiment 2

[0051] use as Image 6 , Figure 7 with Figure 8 The glass capillary microfluidic device shown prepares aqueous two-phase microdroplets. The inner phase flows out from the tip of the round glass capillary at the left end, the middle phase flows out from the gap between the round glass capillary tube at the left end and the square glass capillary tube, the outer phase flows out from the gap between the round glass capillary tube at the right end and the square glass capillary tube, and finally undrawn from the right end together Outflow from a round glass capillary. The circular glass capillary at the left end of the square capillary was inserted into a tapered end drawn to a diameter of 30 μm, and the circular glass capillary at the right end of the square capillary was not drawn. The distance between two circular glass capillaries is about 1000 μm.

[0052] Reference numerals: 1, inner phase syringe, 2, middle phase syringe, 3, outer phase syringe, 4, silica gel connecti...

Embodiment 3

[0055] The glass capillary microfluidic device described in Example 2 was used to prepare two-phase aqueous microdroplets.

[0056] With 15% dextran aqueous solution as the inner phase, 17% polyethylene glycol aqueous solution as the middle phase and the outer phase, draw the above aqueous solution with a syringe, connect it to the corresponding feed port with a silicone tube, and use the pump to set the liquid flow rate of each phase , the flow rate of the outer phase is 1000 μL / h, the flow rate of the middle phase is 1000 μL / h, and the flow rate of the inner phase is 30 μL / h. The silicone tube of the inner phase is fixed on a mechanical wave vibration generator, so that the silicone tube follows the mechanical wave vibration generator Vibrate at a certain frequency, the vibration frequency is 25Hz, to obtain monodisperse two-phase micro-droplets with a diameter of 88 μm, see Figure 10 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com